Njira yopangira pamwamba ya titaniyamu-doped safiro crystal rods laser

Chiyambi cha Ti:safire/ruby

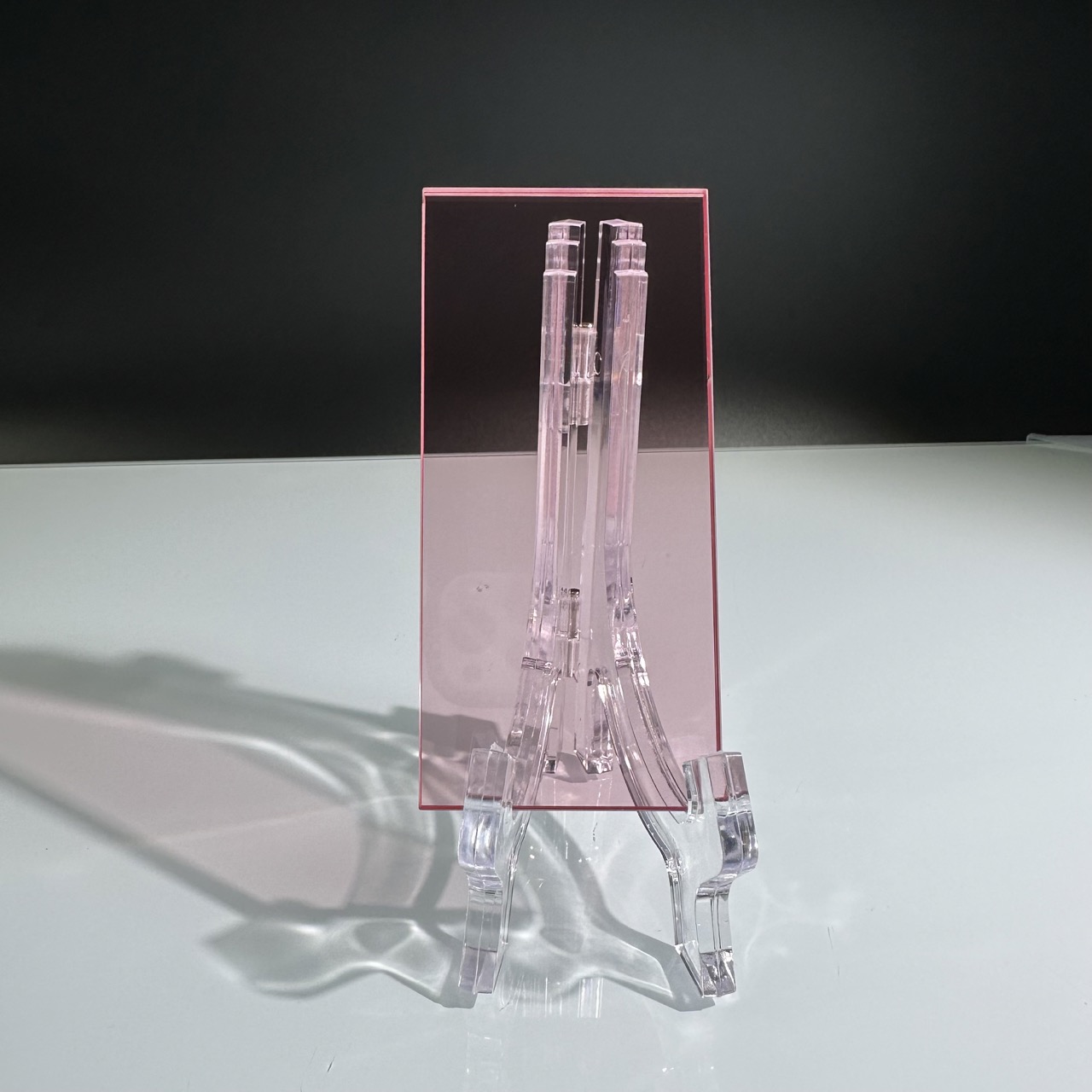

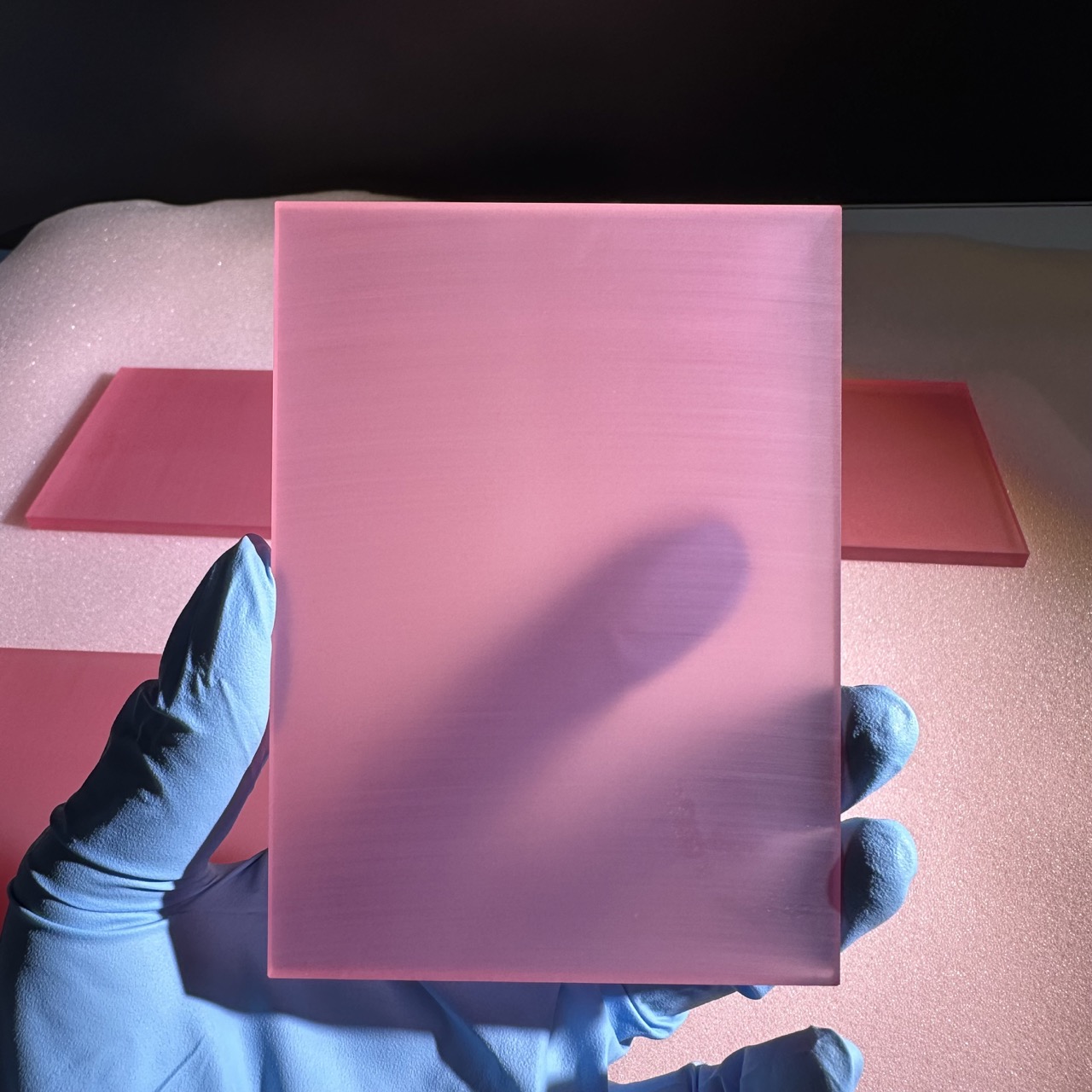

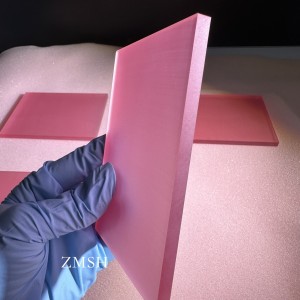

Titaniyamu miyala yamtengo wapatali makhiristo Ti:Al2O3 (doping ndende 0.35 wt% Ti2O3), zosoweka krustalo amene ali molingana ndi ndondomeko otaya chithunzi cha pamwamba processing njira ya titaniyamu mwala wamtengo wapatali kristalo laser rod wa kutulukira panopa akuwonetsedwa mkuyu. Masitepe enieni okonzekera njira yopangira pamwamba pa titaniyamu mwala wamtengo wapatali wa kristalo laser ndodo ya zomwe zidapangidwa pano ndi izi:

<1> Kudula koyang'ana: miyala yamtengo wapatali ya titaniyamu imayendetsedwa koyamba, kenako imadulidwa muzambiri zooneka ngati zoboola pakati posiya chololeza cha 0,4 mpaka 0.6 mm molingana ndi kukula kwa ndodo yomalizidwa ya laser.

<2> Mzere waukali ndi wopera bwino: Mzere wosalembedwawo umasinthidwa kukhala gawo la tetragonal kapena cylindrical ndi 120 ~ 180# silicon carbide kapena boron carbide abrasives pamakina opukutira, okhala ndi vuto la taper komanso lozungulira. ± 0.01mm.

<3> Mapeto processing nkhope: titaniyamu mwala wamtengo wapatali laser bar awiri mapeto nkhope processing motsatizana ndi W40, W20, W10 boron carbide akupera nkhope mapeto pa chimbale zitsulo.Pogaya, chidwi chiyenera kulipidwa pakuyezera kuima kwa nkhope yomaliza.

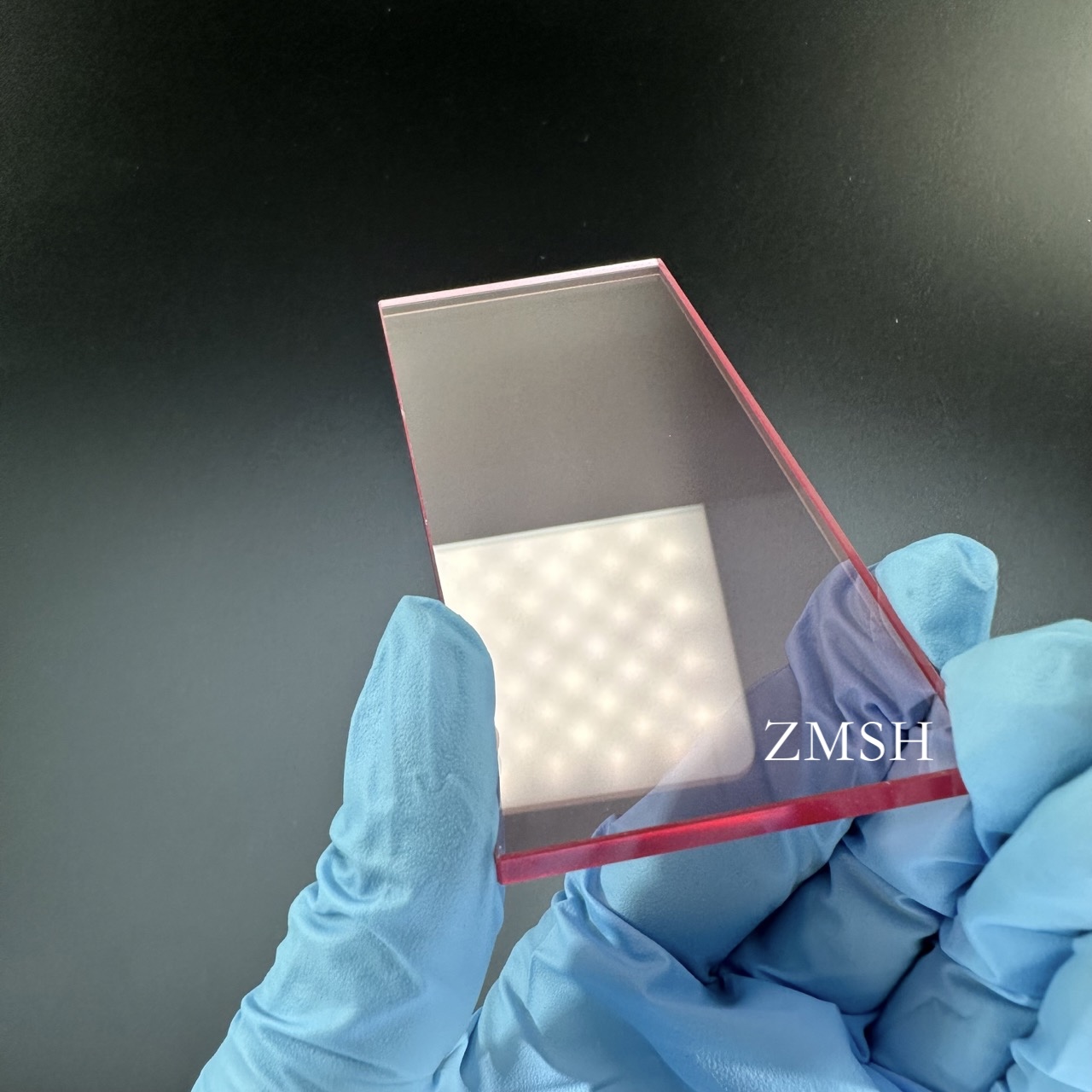

<4> Chemical-mechanical polishing: chemical-mechanical polishing is the process of polishing crystals on polishing pad with madontho a pre-formulated chemical etching solution.Chopukutira chopukutira ndi chopukutira choyenda pang'onopang'ono ndi kukangana, pomwe mukupanga kafukufuku wokhala ndi ma etching agent (otchedwa kupukuta madzi) kuti amalize kupukuta mothandizidwa ndi.

<5> Acid etching: Ndodo za titaniyamu zamtengo wapatali zitatha kupukuta monga momwe tafotokozera pamwambapa zimayikidwa mu chisakanizo cha H2SO4: H3PO4 = 3: 1 (v / v), pa kutentha kwa 100-400 ° C, ndi acid-yokhazikika kwa 5 -30 mphindi.Cholinga ndi kuchotsa ndondomeko kupukuta pamwamba pa bala laser opangidwa ndi mawotchi wapansi pamwamba kuwonongeka, ndi kuchotsa madontho osiyanasiyana, kuti atomiki mlingo yosalala ndi lathyathyathya, latisi umphumphu wa pamwamba woyera. .

<6> KUCHITA KWA NTCHITO KWA NTCHITO: Pofuna kuthetsa kupsinjika kwa pamwamba ndi zokopa zomwe zimapangidwa chifukwa cha ndondomeko yapitayi ndikupeza malo ophwanyika pamtunda wa atomiki, ndodo yamtengo wapatali ya titaniyamu pambuyo pa kutsekemera kwa asidi inatsukidwa ndi madzi osungunuka kwa mphindi 5, ndipo ndodo yamtengo wapatali ya titaniyamu inayikidwa m'malo a 1360 ± 20 ° C. pa kutentha kosalekeza kwa 1 kwa maola a 3 mumlengalenga wa haidrojeni, ndikugonjetsedwa ndi kutentha kwapamwamba.

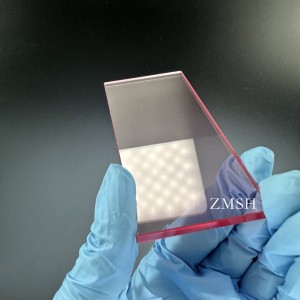

Chithunzi chatsatanetsatane