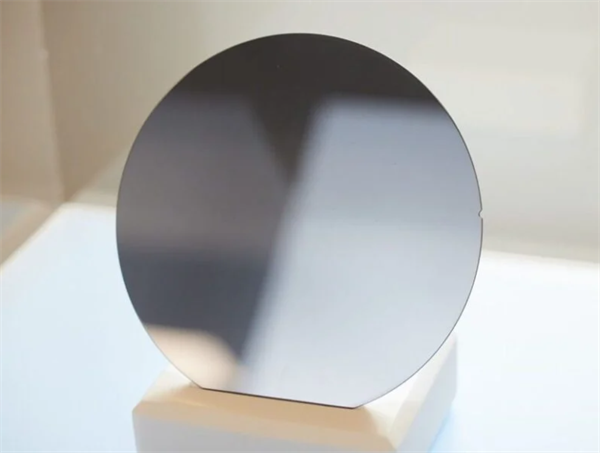

P-mtundu wa SiC 4H/6H-P 3C-N 6inch makulidwe 350 μm okhala ndi Primary Flat Oriental

Specification4H/6H-P Mtundu wa SiC Composite Substrates Common parameter table

6 mainchesi awiri a Silicon Carbide (SiC) gawo lapansi Kufotokozera

| Gulu | Zero MPD ProductionGulu (Z Gulu) | Standard ProductionGawo (P Gulu) | Dummy Grade (D Gulu) | ||

| Diameter | 145.5 mm ~ 150.0 mm | ||||

| Makulidwe | 350 μm ± 25 μm | ||||

| Wafer Orientation | -Offolamulira: 2.0 ° -4.0 ° molunjika [1120] ± 0.5 ° kwa 4H/6H-P, Pa olamulira:〈111〉± 0.5° kwa 3C-N | ||||

| Kuchuluka kwa Micropipe | 0cm-2 | ||||

| Kukaniza | p-mtundu 4H/6H-P | ≤0.1 Ωꞏcm | ≤0.3 Ωꞏcm | ||

| n-mtundu 3C-N | ≤0.8 mΩꞏcm | ≤1 m Ωꞏcm | |||

| Chiyambi cha Flat Orientation | 4H/6H-P | -{1010} ± 5.0° | |||

| 3C-N | -{110} ± 5.0° | ||||

| Utali Woyambira Wathyathyathya | 32.5 mm ± 2.0 mm | ||||

| Kutalika kwa Sekondale | 18.0 mm ± 2.0 mm | ||||

| Sekondale Flat Orientation | Silicon nkhope m'mwamba: 90 ° CW. kuchokera ku Prime flat ± 5.0 ° | ||||

| Kupatula M'mphepete | 3 mm | 6 mm | |||

| LTV/TTV/Bow/Warp | ≤2.5 μm/≤5 μm/≤15 μm/≤30 μm | ≤10 μm/≤15 μm/≤25 μm/≤40 μm | |||

| Ukali | Chipolishi Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Palibe | Utali wophatikiza ≤ 10 mm, utali umodzi≤2 mm | |||

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤0.05% | Malo owonjezera ≤0.1% | |||

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Palibe | Malo owonjezera≤3% | |||

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤0.05% | Malo owonjezera ≤3% | |||

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Palibe | Kutalikirana ≤1 × awiri wafer | |||

| Mphepete Chips Mmwamba Mwamphamvu Kuwala | Palibe chololedwa ≥0.2mm m'lifupi ndi kuya | 5 zololedwa, ≤1 mm iliyonse | |||

| Silicon Surface Kuipitsidwa Ndi High Intensity | Palibe | ||||

| Kupaka | Makaseti amitundu yopyapyala kapena Chidebe Chowotcha Chimodzi | ||||

Ndemanga:

※ Malire opumira amagwira ntchito pamtunda wonse kupatula malo opatulapo. # Zikandazo ziyenera kuyang'aniridwa pa Si face o

Chophika cha P-mtundu wa SiC, 4H/6H-P 3C-N, chokhala ndi kukula kwake kwa mainchesi 6 ndi makulidwe a 350 μm, chimagwira ntchito yofunika kwambiri popanga zida zamagetsi zamagetsi zogwira ntchito kwambiri m'mafakitale. Kutentha kwake kwabwino kwambiri komanso kuphulika kwakukulu kwamagetsi kumapangitsa kuti ikhale yabwino popanga zinthu monga zosinthira magetsi, ma diode, ndi ma transistors omwe amagwiritsidwa ntchito m'malo otentha kwambiri monga magalimoto amagetsi, ma gridi amagetsi, ndi magetsi ongowonjezwdwa. Kuthekera kwa wafer kuti azigwira ntchito bwino m'malo ovuta kumatsimikizira kugwira ntchito modalirika pamafakitale omwe amafunikira kuchuluka kwamphamvu kwamagetsi komanso kuwongolera mphamvu. Kuphatikiza apo, kuwongolera kwake koyambira kumathandizira kuwongolera bwino panthawi yopanga zida, kumathandizira kupanga bwino komanso kusasinthika kwazinthu.

Ubwino wa magawo ophatikizika a N-mtundu wa SiC umaphatikizapo

- High Thermal Conductivity: P-mtundu SiC wafers efficiently kutaya kutentha, kuwapanga kukhala abwino kwa ntchito kwambiri kutentha.

- High Breakdown Voltage: Kutha kupirira ma voltages apamwamba, kuwonetsetsa kudalirika kwamagetsi amagetsi ndi zida zamphamvu kwambiri.

- Kukaniza Malo Ovuta: Kukhalitsa kwabwino kwambiri m'malo ovuta kwambiri, monga kutentha kwambiri komanso malo owononga.

- Kutembenuka Kwamphamvu Kwambiri: Doping yamtundu wa P imathandizira kugwiritsa ntchito mphamvu moyenera, kupangitsa kuti chophatikiziracho chizikhala choyenera makina osinthira mphamvu.

- Chiyambi cha Flat Orientation: Imawonetsetsa kulumikizidwa bwino panthawi yopanga, kuwongolera kulondola kwa chipangizocho komanso kusasinthika.

- Kapangidwe Kakang'ono (350 μm): Kukula kokwanira kwa chophatikizira kumathandizira kuphatikizika ndi zida zamagetsi zapamwamba, zokhala ndi malo.

Ponseponse, chowotcha cha P-mtundu wa SiC, 4H/6H-P 3C-N, chimapereka zabwino zingapo zomwe zimapangitsa kuti zikhale zoyenera kwambiri pamafakitale ndi zamagetsi. Kutentha kwake kwapamwamba komanso kuphulika kwa magetsi kumapangitsa kuti ntchito yodalirika ikhale yodalirika m'madera otentha kwambiri komanso otentha kwambiri, pamene kukana kwake ku zovuta kumatsimikizira kukhazikika. Doping yamtundu wa P imalola kutembenuka kwamphamvu kwamphamvu, ndikupangitsa kuti ikhale yabwino pamagetsi amagetsi ndi mphamvu zamagetsi. Kuphatikiza apo, mawonekedwe apamwamba a wafer amawonetsetsa kulumikizidwa bwino panthawi yopanga, kukulitsa kusasinthika kwa kupanga. Ndi makulidwe a 350 μm, ndi oyenera kuphatikiza pazida zapamwamba, zophatikizika.

Chithunzi chatsatanetsatane