Pakalipano, kampani yathu ikhoza kupitiriza kupereka mtanda waing'ono wa 8inchN mtundu wa SiC wafers, ngati muli ndi zosowa zachitsanzo, chonde omasuka kulankhula nane.Tili ndi zowola zachitsanzo zokonzeka kutumiza.

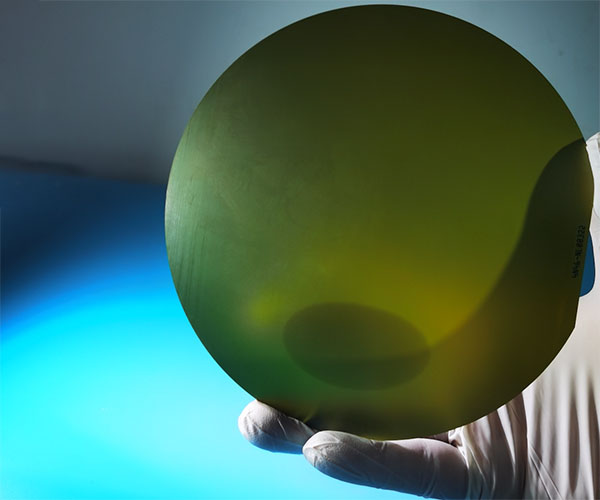

Pankhani ya zida za semiconductor, kampaniyo yachita bwino kwambiri pakufufuza ndi kupanga makhiristo akuluakulu a SiC.Pogwiritsa ntchito makhiristo ake ambewu pambuyo pakukulitsa kambirimbiri, kampaniyo idakula bwino makhiristo amtundu wa 8-inch N-mtundu wa SiC, omwe amathetsa mavuto monga kutentha kosiyanasiyana, kusweka kwa kristalo ndi kugawa gasi zopangira pakukula. 8-inch SIC makhiristo, ndipo imathandizira kukula kwa makhiristo akuluakulu a SIC ndi ukadaulo wodziyimira pawokha komanso wowongolera.Kupititsa patsogolo mpikisano waukulu wamakampani pamakampani a SiC single crystal substrate.Pa nthawi yomweyo, kampani mwakhama amalimbikitsa kudzikundikira luso ndi ndondomeko ya kukula kwakukulu pakachitsulo carbide gawo lapansi kukonzekera experimental mzere, kumalimbitsa kuwombola luso ndi mgwirizano mafakitale kumtunda ndi kumtunda minda, ndipo amagwirizana ndi makasitomala nthawi zonse iterate mankhwala ntchito, ndi olowa. imalimbikitsa kuthamanga kwa mafakitale azinthu za silicon carbide.

| 8inch N-mtundu wa SiC DSP Zolemba | |||||

| Nambala | Kanthu | Chigawo | Kupanga | Kafukufuku | Dummy |

| 1. Zigawo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | kuyang'ana pamwamba | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Parameter yamagetsi | |||||

| 2.1 | dopant | -- | n-mtundu wa Nayitrogeni | n-mtundu wa Nayitrogeni | n-mtundu wa Nayitrogeni |

| 2.2 | resistivity | uwu ·cm | 0.015 ~ 0.025 | 0.01~0.03 | NA |

| 3. Mawotchi parameter | |||||

| 3.1 | awiri | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | makulidwe | μm | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Notch orientation | ° | [1- 100] ± 5 | [1- 100] ± 5 | [1- 100] ± 5 |

| 3.4 | Kuzama kwa Notch | mm | 1-1.5 | 1-1.5 | 1-1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Kugwada | μm | -25-25 | -45-45 | - 65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Kapangidwe | |||||

| 4.1 | kachulukidwe ka micropipe | ndi cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | zitsulo | ma atomu/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ndi cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ndi cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ndi cm2 | ≤7000 | ≤10000 | NA |

| 5. Khalidwe labwino | |||||

| 5.1 | kutsogolo | -- | Si | Si | Si |

| 5.2 | kumaliza pamwamba | -- | Si-nkhope CMP | Si-nkhope CMP | Si-nkhope CMP |

| 5.3 | chidutswa | mkate / mkate | ≤100(kukula≥0.3μm) | NA | NA |

| 5.4 | zikande | mkate / mkate | ≤5, Total Utali≤200mm | NA | NA |

| 5.5 | M'mphepete tchipisi/ma indents/ming'alu/madontho/kuipitsidwa | -- | Palibe | Palibe | NA |

| 5.6 | Zigawo za polytype | -- | Palibe | Chigawo ≤10% | Chigawo ≤30% |

| 5.7 | chizindikiro chakutsogolo | -- | Palibe | Palibe | Palibe |

| 6. Back khalidwe | |||||

| 6.1 | kumaliza kumbuyo | -- | C-nkhope MP | C-nkhope MP | C-nkhope MP |

| 6.2 | zikande | mm | NA | NA | NA |

| 6.3 | Kumbuyo zolakwika m'mphepete chips / indents | -- | Palibe | Palibe | NA |

| 6.4 | Msana roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kulemba kumbuyo | -- | Notch | Notch | Notch |

| 7. Mphepete | |||||

| 7.1 | m'mphepete | -- | Chamfer | Chamfer | Chamfer |

| 8. Phukusi | |||||

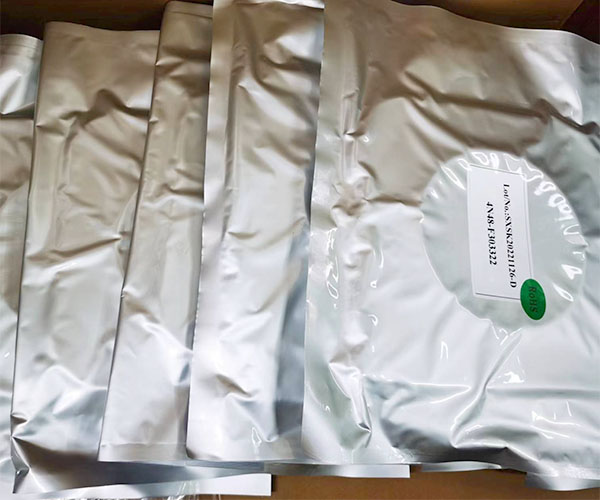

| 8.1 | kuyika | -- | Epi-okonzeka ndi vacuum kuyika | Epi-okonzeka ndi vacuum kuyika | Epi-okonzeka ndi vacuum kuyika |

| 8.2 | kuyika | -- | Zophika zambiri kupaka makaseti | Zophika zambiri kupaka makaseti | Zophika zambiri kupaka makaseti |

Nthawi yotumiza: Apr-18-2023