Chiyambi cha silicon carbide

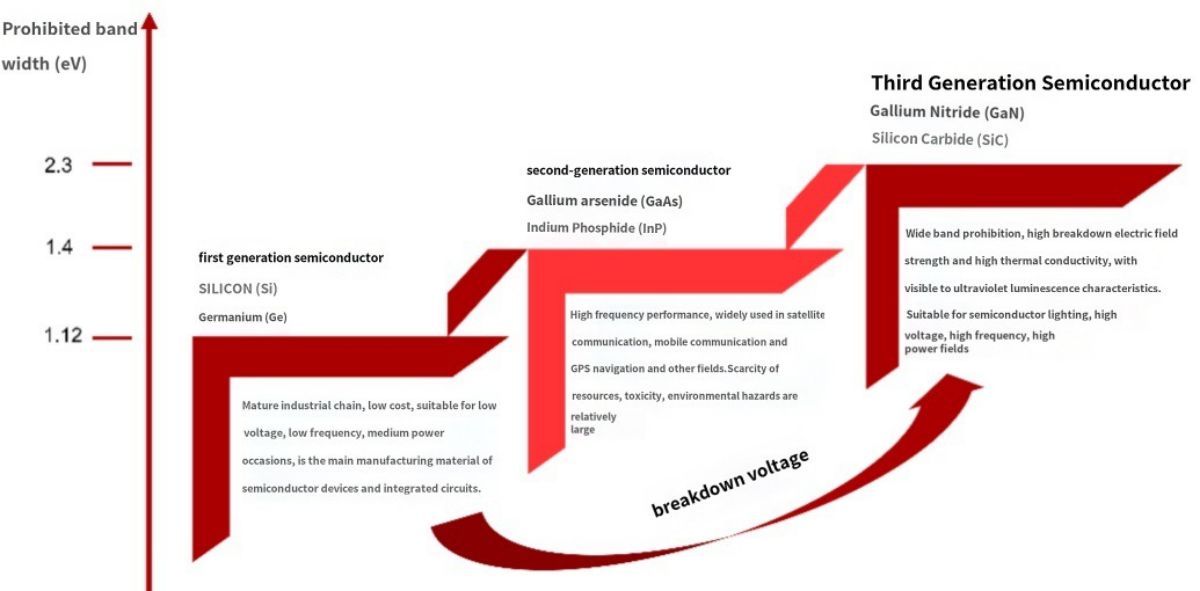

Silicon carbide (SiC) ndi zida zopangira semiconductor zopangidwa ndi kaboni ndi silicon, zomwe ndi zida zabwino kwambiri zopangira kutentha kwambiri, ma frequency apamwamba, zida zamphamvu kwambiri komanso zida zapamwamba kwambiri.Poyerekeza ndi zinthu zachikhalidwe za silicon (Si), kusiyana kwa gulu la silicon carbide ndi kuwirikiza katatu kuposa silicon.The matenthedwe madutsidwe ndi 4-5 nthawi silicon;Mphamvu yowonongeka ndi 8-10 nthawi ya silicon;Kuthamanga kwamagetsi pamagetsi ndi 2-3 nthawi ya silicon, yomwe imakwaniritsa zosowa zamakampani amakono amphamvu kwambiri, magetsi okwera komanso ma frequency apamwamba.Amagwiritsidwa ntchito makamaka popanga zida zamagetsi zothamanga kwambiri, zothamanga kwambiri, zamphamvu komanso zotulutsa kuwala.Magawo ogwiritsira ntchito kumunsi akuphatikizapo gridi yanzeru, magalimoto oyendetsa magetsi atsopano, mphamvu ya mphepo ya photovoltaic, kulankhulana kwa 5G, etc. Silicon carbide diode ndi MOSFETs akhala akugwiritsidwa ntchito pamalonda.

Kukana kutentha kwakukulu.The gulu kusiyana m'lifupi la pakachitsulo carbide ndi 2-3 nthawi silicon, ma elekitironi n'zovuta kusintha pa kutentha, ndipo akhoza kupirira kutentha ntchito apamwamba, ndi matenthedwe madutsidwe wa pakachitsulo carbide ndi 4-5 nthawi pakachitsulo, kupanga kutentha kwa chipangizocho kukhala kosavuta komanso kuchepetsa kutentha kwa ntchito.Kukana kwa kutentha kwapamwamba kumatha kukulitsa mphamvu zamagetsi ndikuchepetsa zofunikira pazida zoziziritsa, kupangitsa kuti terminal ikhale yopepuka komanso yaying'ono.

Kupirira kuthamanga kwambiri.Mphamvu yamagetsi ya silicon carbide yowononga mphamvu ya silicon carbide ndi nthawi 10 kuposa ya silicon, yomwe imatha kupirira ma voltages apamwamba ndipo ndiyoyenera kwambiri pazida zamphamvu kwambiri.

Mkulu pafupipafupi kukana.Silicon carbide imakhala ndi kuchuluka kwa ma elekitironi othamangitsidwa kuwirikiza kawiri kuposa silicon, zomwe zimapangitsa kuti pakhale kusakhalapo kwa mchira wapano panthawi yotseka, zomwe zimatha kusintha ma frequency a chipangizocho ndikuzindikira kuchepera kwa chipangizocho.

Kutaya mphamvu zochepa.Poyerekeza ndi zinthu za silicon, silicon carbide imakhala yotsika kwambiri komanso yotsika kwambiri.Nthawi yomweyo, kuchuluka kwa band-gap m'lifupi mwa silicon carbide kumachepetsa kwambiri kutayikira kwapano komanso kutaya mphamvu.Kuonjezera apo, chipangizo cha silicon carbide sichikhala ndi zochitika zamakono panthawi yotseka, ndipo kutayika kosinthika kumakhala kochepa.

Silicon carbide industry unyolo

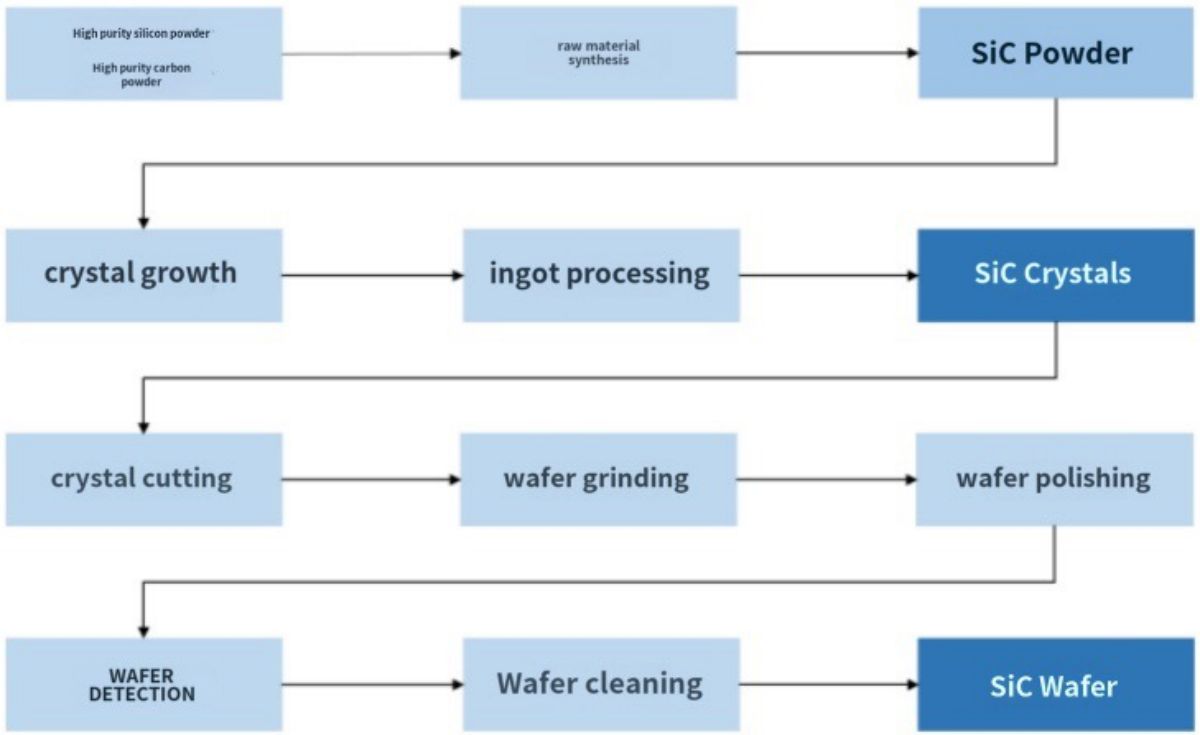

Zimaphatikizapo gawo lapansi, epitaxy, mapangidwe a chipangizo, kupanga, kusindikiza ndi zina zotero.Silicon carbide kuchokera kuzinthu kupita ku chipangizo chamagetsi cha semiconductor idzakhala ndi kukula kwa kristalo imodzi, kudulidwa kwa ingot, kukula kwa epitaxial, kapangidwe kake, kupanga, kuyika ndi njira zina.Pambuyo pa kaphatikizidwe ka silicon carbide powder, silicon carbide ingot imapangidwa poyamba, ndiyeno gawo lapansi la silicon carbide limapezeka mwa kudula, kugaya ndi kupukuta, ndipo pepala la epitaxial limapezeka ndi kukula kwa epitaxial.Epitaxial wafer amapangidwa ndi silicon carbide kudzera mu lithography, etching, ion implantation, chitsulo passivation ndi njira zina, chowotchacho chimadulidwa kufa, chipangizocho chimapakidwa, ndipo chipangizocho chimaphatikizidwa mu chipolopolo chapadera ndikusonkhanitsidwa kukhala gawo.

Kumtunda kwa unyolo wamakampani 1: gawo lapansi - kukula kwa kristalo ndiye ulalo woyambira

Silicon carbide gawo lapansi nkhani pafupifupi 47% ya mtengo wa zida pakachitsulo carbide, apamwamba kupanga zotchinga luso, mtengo waukulu, ndiye pachimake cha tsogolo lalikulu mafakitale SiC.

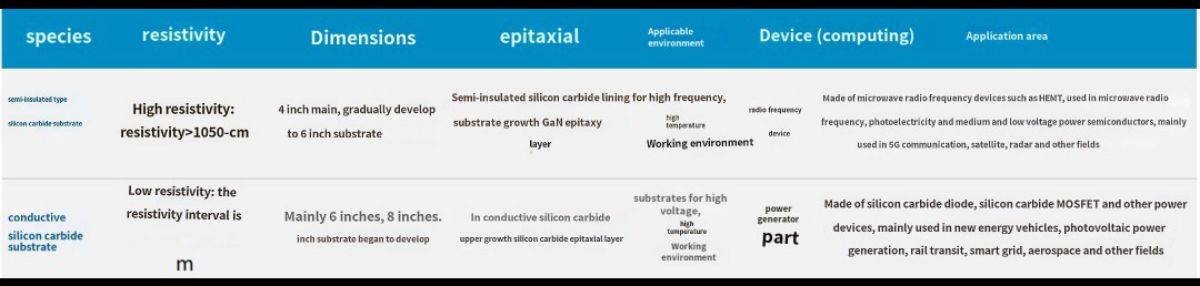

Malinga ndi kusiyana kwa electrochemical katundu, silicon carbide gawo lapansi akhoza kugawidwa magawo conductive (resistivity dera 15 ~ 30mΩ·cm) ndi theka insulated magawo (resistivity apamwamba kuposa 105Ω · cm).Magawo awiriwa amagwiritsidwa ntchito popanga zida zamphamvu monga zida zamagetsi ndi zida zamawayilesi motsatana pambuyo pakukula kwa epitaxial.Pakati pawo, theka-insulated silicon carbide gawo lapansi makamaka ntchito kupanga gallium nitride RF zipangizo, zipangizo photoelectric ndi zina zotero.Pakukula gan epitaxial layer pa semi-insulated SIC substrate, sic epitaxial mbale imakonzedwa, yomwe imatha kukonzedwanso kukhala zida za HEMT gan iso-nitride RF.Conductive silicon carbide gawo lapansi limagwiritsidwa ntchito makamaka popanga zida zamagetsi.Mosiyana ndi chikhalidwe silicon mphamvu chipangizo kupanga ndondomeko, silicon carbide mphamvu chipangizo sangathe mwachindunji pa silicon carbide gawo lapansi, ndi pakachitsulo carbide epitaxial wosanjikiza ayenera kukhala wamkulu pa conductive gawo lapansi kupeza silicon carbide epitaxial pepala, ndi epitaxial. wosanjikiza amapangidwa pa Schottky diode, MOSFET, IGBT ndi zida zina zamagetsi.

Silicon carbide ufa adapangidwa kuchokera ku chiyero chapamwamba cha kaboni ufa ndi chiyero chachikulu cha silicon ufa, ndipo makulidwe osiyanasiyana a silicon carbide ingot adakulitsidwa pansi pa gawo la kutentha kwapadera, kenako gawo lapansi la silicon carbide lidapangidwa kudzera munjira zingapo.core process ikuphatikizapo:

Kaphatikizidwe kazinthu zopangira: Kuyeretsedwa kwakukulu kwa silicon ufa + tona kumasakanizidwa molingana ndi chilinganizo, ndipo zomwe zimachitika mu chipinda chochitiramo pansi pa kutentha kwambiri kuposa 2000 ° C kupanga tinthu tating'ono ta silicon carbide ndi mtundu wina wa kristalo ndi tinthu. kukula.Ndiye mwa kuphwanya, kuwunika, kuyeretsa ndi njira zina, kuti akwaniritse zofunikira za chiyero cha silicon carbide ufa zopangira.

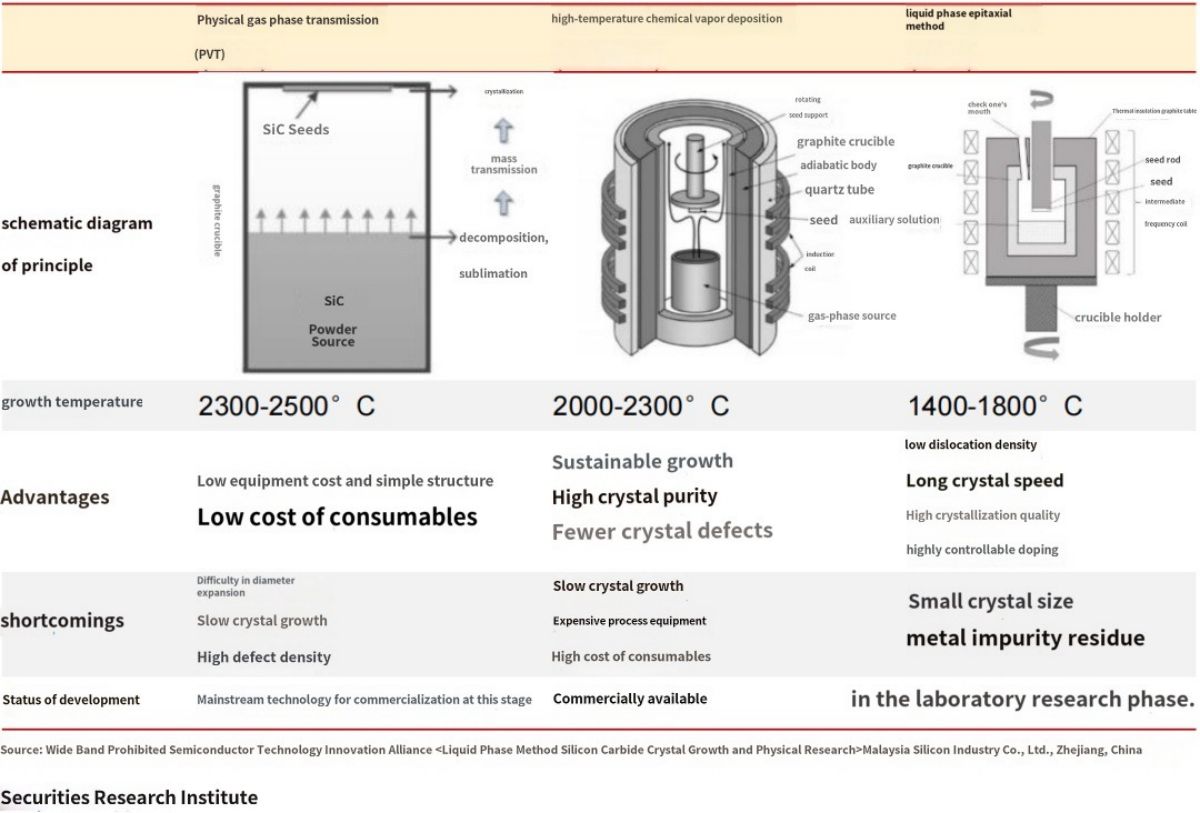

Kukula kwa Crystal ndiye njira yayikulu yopangira silicon carbide substrate, yomwe imatsimikizira mphamvu yamagetsi ya silicon carbide gawo lapansi.Pakali pano, njira zazikulu za kukula kwa kristalo ndi kutengerapo kwa nthunzi (PVT), kutentha kwa mankhwala opangira mpweya (HT-CVD) ndi epitaxy yamadzimadzi (LPE).Pakati pawo, njira ya PVT ndiyo njira yodziwika bwino yakukula kwa malonda a gawo lapansi la SiC pakadali pano, yokhala ndi luso lapamwamba kwambiri komanso lomwe limagwiritsidwa ntchito kwambiri muukadaulo.

Kukonzekera kwa gawo lapansi la SiC ndizovuta, zomwe zimapangitsa kuti pakhale mtengo wake wapamwamba

Kuwotcha kumunda kumakhala kovuta: Si crystal ndodo kukula kumangofunika 1500 ℃, pamene SiC crystal ndodo imayenera kukulira pa kutentha kwakukulu kuposa 2000 ℃, ndipo pali ma isomers oposa 250 SiC, koma 4H-SiC imodzi yokha ya kristalo kupanga zida zamagetsi, ngati sikuli kuwongolera kolondola, kudzapeza zida zina zamakristali.Komanso, kutentha gradient mu crucible amatsimikiza mlingo wa SiC sublimation kutengerapo ndi makonzedwe ndi kukula mode wa maatomu mpweya pa kristalo mawonekedwe, amene amakhudza kristalo kukula mlingo ndi kristalo khalidwe, choncho m'pofunika kupanga mwadongosolo kutentha kumunda. ukadaulo wowongolera.Poyerekeza ndi zipangizo za Si, kusiyana kwa kupanga kwa SiC kumakhalanso mu kutentha kwapamwamba monga kutentha kwa ion implantation, kutentha kwa okosijeni, kutentha kwa kutentha, ndi ndondomeko ya chigoba cholimba chomwe chimafunidwa ndi kutentha kwakukulu kumeneku.

Kukula pang'onopang'ono kwa kristalo: kukula kwa ndodo ya Si crystal kumatha kufika 30 ~ 150mm / h, ndipo kupanga 1-3m silicon crystal ndodo kumangotenga tsiku limodzi;SiC krustalo ndodo ndi njira PVT monga chitsanzo, mlingo kukula ndi za 0.2-0.4mm/h, masiku 7 kukula zosakwana 3-6cm, mlingo kukula ndi zosakwana 1% ya zinthu pakachitsulo, mphamvu kupanga kwambiri. zochepa.

Magawo apamwamba a mankhwala ndi zokolola zochepa: magawo apakati a gawo lapansi la SiC akuphatikizapo kachulukidwe ka microtubule, kachulukidwe ka dislocation, resistivity, warpage, roughness pamwamba, ndi zina zotero. poyang'anira ma index index.

Zomwe zili ndi kuuma kwakukulu, kuphulika kwakukulu, nthawi yayitali yodula komanso kuvala kwambiri: SiC Mohs kuuma kwa 9.25 ndi yachiwiri kwa diamondi, zomwe zimabweretsa kuwonjezeka kwakukulu kwa zovuta kudula, kugaya ndi kupukuta, ndipo zimatenga pafupifupi maola 120 kudula 35-40 zidutswa za 3cm wandiweyani ingot.Kuonjezera apo, chifukwa cha kuwonongeka kwakukulu kwa SiC, kuvala kwachitsulo chophatikizira kumakhala kochulukirapo, ndipo chiŵerengero chotuluka chimakhala pafupifupi 60%.

Chitukuko: Kuwonjezeka kwa kukula + kutsika kwamitengo

Msika wapadziko lonse wa SiC mzere wopanga voliyumu 6 ukukula, ndipo makampani otsogola alowa mumsika wa mainchesi 8.Ntchito zachitukuko zapakhomo nthawi zambiri zimakhala mainchesi 6.Pakali pano, ngakhale makampani ambiri zoweta akadali zochokera mizere 4-inchi kupanga, koma makampani pang'onopang'ono kukula kwa 6 inchi, ndi kukhwima kwa 6-inchi kuthandiza zipangizo luso, zoweta SiC gawo lapansi luso komanso pang'onopang'ono kusintha chuma cha. kukula kwa mizere yopangira zazikuluzikulu kudzawonetsedwa, ndipo kusiyana kwanthawi yopangira 6-inch kwacheperako mpaka zaka 7.Kukula kokulirapo kumatha kubweretsa kuchuluka kwa tchipisi tating'ono, kuwongolera zokolola, ndikuchepetsa kuchuluka kwa tchipisi tating'ono, ndipo mtengo wa kafukufuku ndi chitukuko ndi kutayika kwa zokolola zidzasungidwa pafupifupi 7%, potero kuwongolera tchipisi tating'onoting'ono. kugwiritsa ntchito.

Pali zovuta zambiri pakupanga zida

Kutsatsa kwa SiC diode kumakulitsidwa pang'onopang'ono, pakalipano, opanga angapo apakhomo apanga zinthu za SiC SBD, zopangira za SiC SBD zapakati komanso zapamwamba zimakhala ndi kukhazikika bwino, m'galimoto ya OBC, kugwiritsa ntchito SiC SBD +SI IGBT kuti mukwaniritse zokhazikika. kachulukidwe panopa.Pakalipano, palibe zopinga pakupanga kwapatent kwa zinthu za SiC SBD ku China, ndipo kusiyana ndi mayiko akunja ndi kochepa.

SiC MOS idakali ndi zovuta zambiri, pakadali kusiyana pakati pa SiC MOS ndi opanga kunja kwa nyanja, ndipo nsanja yoyenera yopangira ikumangidwabe.Pakadali pano, ST, Infineon, Rohm ndi ena 600-1700V SiC MOS akwanitsa kupanga zambiri ndikusaina ndikutumizidwa ndi mafakitale ambiri opanga, pomwe mapangidwe apanyumba a SiC MOS amalizidwa, ambiri opanga mapangidwe akugwira ntchito ndi nsalu pa. siteji yowotcherera, ndipo pambuyo pake kutsimikizika kwamakasitomala kumafunikabe nthawi, kotero pakadali nthawi yayitali kuchokera kumalonda akuluakulu.

Pakalipano, mapangidwe a planar ndiye chisankho chachikulu, ndipo mtundu wa ngalande umagwiritsidwa ntchito kwambiri m'munda wothamanga kwambiri m'tsogolomu.Planar kapangidwe SiC MOS opanga ambiri, dongosolo planar si zophweka kutulutsa mavuto kusweka m'deralo poyerekeza ndi poyambira, zimakhudza bata la ntchito, mu msika pansipa 1200V ali osiyanasiyana ntchito mtengo, ndi dongosolo planar ndi zosavuta pakupanga mapeto, kukumana manufacturability ndi mtengo kulamulira mbali ziwiri.Chipangizo cha groove chili ndi zabwino zake zotsika kwambiri za parasitic inductance, liwiro losinthira mwachangu, kutayika kochepa komanso magwiridwe antchito apamwamba.

2--SiC wafer nkhani

Kupanga kwa msika wa Silicon carbide ndi kukula kwa malonda, samalani ndi kusalinganika kwadongosolo pakati pa kupezeka ndi kufunikira

Ndi kukula kwachangu kwa msika wamagetsi amagetsi othamanga kwambiri komanso amphamvu kwambiri, malire amagetsi a zida za semiconductor opangidwa ndi silicon ayamba kuonekera pang'onopang'ono, ndipo zida za m'badwo wachitatu za semiconductor zoyimiridwa ndi silicon carbide (SiC) zayamba pang'onopang'ono. kukhala otukuka.Kuchokera pamawonedwe azinthu zakuthupi, silicon carbide ili ndi nthawi 3 kuposa kuchuluka kwa zida za silicon, nthawi 10 kuwononga mphamvu yamagetsi yamagetsi, 3 nthawi matenthedwe matenthedwe, kotero zida zamagetsi za silicon carbide ndizoyenera pafupipafupi, kuthamanga kwambiri, kutentha kwambiri ndi ntchito zina, zimathandizira kukonza magwiridwe antchito ndi kachulukidwe kamagetsi amagetsi amagetsi.

Pakali pano, SiC diode ndi SiC MOSFETs pang'onopang'ono anasamukira kumsika, ndipo pali zinthu okhwima kwambiri, amene SiC diode ntchito kwambiri m'malo mwa silicon-based diode m'madera ena chifukwa alibe mwayi wobwezera kuchira;SiC MOSFET imagwiritsidwanso ntchito pang'onopang'ono pamagalimoto, kusungirako mphamvu, mulu wolipiritsa, photovoltaic ndi magawo ena;Pankhani yamagalimoto ogwiritsira ntchito magalimoto, machitidwe amodularization akuchulukirachulukira, magwiridwe antchito apamwamba a SiC akuyenera kudalira njira zopangira zotsogola kuti akwaniritse, mwaukadaulo ndi kusindikiza kwachipolopolo kokhwima monga chodziwika bwino, tsogolo kapena chitukuko chosindikiza pulasitiki. , mawonekedwe ake otukuka omwe ali oyenera kwambiri ma module a SiC.

Mtengo wa silicon carbide ukutsika liwiro kapena kupitilira momwe mungaganizire

Kugwiritsa ntchito zida za silicon carbide kumakhala kochepa chifukwa cha kukwera mtengo, mtengo wa SiC MOSFET pansi pamlingo womwewo ndi nthawi 4 kuposa wa IGBT wa Si based, izi ndichifukwa choti njira ya silicon carbide ndizovuta, momwe kukula kwa silicon carbide kumapangidwira. kristalo limodzi ndi epitaxial sizowopsa pa chilengedwe, komanso kukula kwapang'onopang'ono, ndipo kristalo umodzi wokha mu gawo lapansi uyenera kudutsa mu kudula ndi kupukuta.Kutengera ndi mawonekedwe ake akuthupi komanso umisiri waubwana wokonza, zokolola za gawo lapansi zapakhomo ndizochepera 50%, ndipo zinthu zosiyanasiyana zimapangitsa kuti pakhale mitengo yayikulu yagawo ndi epitaxial.

Komabe, mtengo wakupangidwa kwa zida za silicon carbide ndi zida za silicon ndizosiyana kwambiri, mtengo wagawo ndi epitaxial wa akaunti yakutsogolo ya 47% ndi 23% ya chipangizo chonsecho, pafupifupi 70%, kapangidwe ka chipangizocho, kupanga. ndikusindikiza maulalo aakaunti yakumbuyo yakumbuyo kwa 30% yokha, mtengo wopangira zida zokhala ndi silicon umakhazikika kwambiri pakupangira kanjira yakumbuyo pafupifupi 50%, ndipo mtengo wagawo laling'ono umangokwana 7%.Chodabwitsa cha mtengo wamakampani a silicon carbide mozondoka zikutanthauza kuti opanga ma epitaxy omwe ali pamwamba pa mitsinje ali ndi ufulu wolankhula, womwe ndi chinsinsi cha mapangidwe amakampani apakhomo ndi akunja.

Kuchokera pamalingaliro amphamvu pamsika, kuchepetsa mtengo wa silicon carbide, kuwonjezera pakuwongolera silicon carbide yayitali crystal ndi slicing process, ndikukulitsa kukula kwa mtanda, womwenso ndi njira yokhwima ya chitukuko cha semiconductor m'mbuyomu, Deta ya Wolfspeed ikuwonetsa kuti silicon carbide substrate ikukwera kuchokera mainchesi 6 mpaka 8 mainchesi, kupanga chip oyenerera kumatha kuwonjezeka ndi 80% -90%, ndikuthandizira kukonza zokolola.Ikhoza kuchepetsa mtengo wophatikizana ndi 50%.

2023 imadziwika kuti "8-inch SiC chaka choyamba", chaka chino, opanga ma silicon carbide akunyumba ndi akunja akufulumizitsa masanjidwe a 8-inch silicon carbide, monga Wolfspeed wopenga ndalama za 14.55 biliyoni US dollars pakukulitsa kupanga silicon carbide, gawo lofunikira lomwe ndikumanga 8-inch SiC gawo lapansi lopangira gawo lapansi, Kuonetsetsa kuti tsogolo la 200 mm SiC zitsulo zopanda kanthu kumakampani angapo;Domestic Tianyue Advanced ndi Tianke Heda asayinanso mapangano anthawi yayitali ndi Infineon kuti azipereka magawo 8-inch silicon carbide mtsogolomo.

Kuyambira chaka chino, silicon carbide ikwera kuchokera mainchesi 6 mpaka 8 mainchesi, Wolfspeed ikuyembekeza kuti pofika 2024, mtengo wa unit chip wa mainchesi 8 poyerekeza ndi mtengo wa unit chip wa mainchesi 6 mu 2022 udzachepetsedwa ndi 60% , ndipo kutsika kwa mtengo kudzatsegulanso msika wofunsira, kafukufuku wa Ji Bond Consulting adawonetsa.Msika womwe ulipo wazinthu za 8-inch ndi wochepera 2%, ndipo msika ukuyembekezeka kukula mpaka 15% pofika 2026.

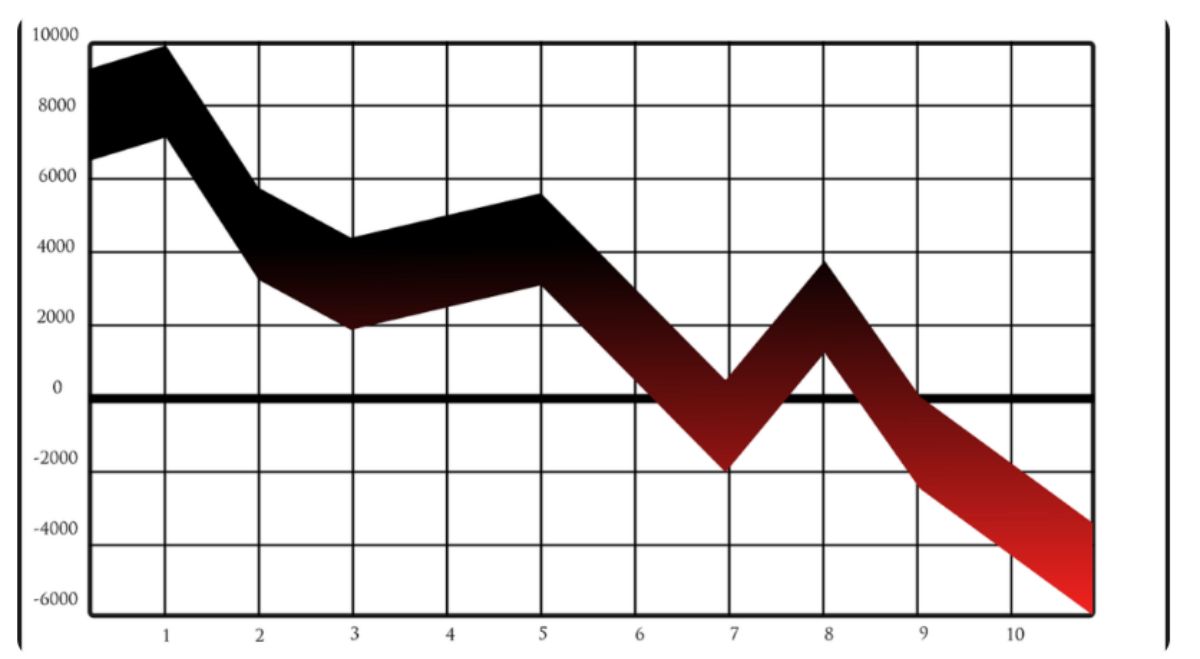

M'malo mwake, kuchuluka kwa mtengo wa silicon carbide gawo lapansi kumatha kupitilira momwe anthu ambiri amaganizira, msika wapano wa 6-inchi gawo lapansi ndi 4000-5000 yuan/chidutswa, poyerekeza ndi chiyambi cha chaka chagwa kwambiri. akuyembekezeka kugwa m'munsimu 4000 yuan chaka chamawa, ndi Dziwani kuti ena opanga kuti apeze msika woyamba, wachepetsa mtengo malonda kwa mtengo mzere m'munsimu, Anatsegula chitsanzo cha mtengo nkhondo, makamaka anaikira mu silicon carbide gawo lapansi. kuperekera kwakhala kokwanira m'munda wamagetsi otsika, opanga zoweta ndi akunja akukulitsa mwamphamvu kupanga, kapena kulola gawo lapansi la silicon carbide substrate oversupply kale kuposa momwe amaganizira.

Nthawi yotumiza: Jan-19-2024