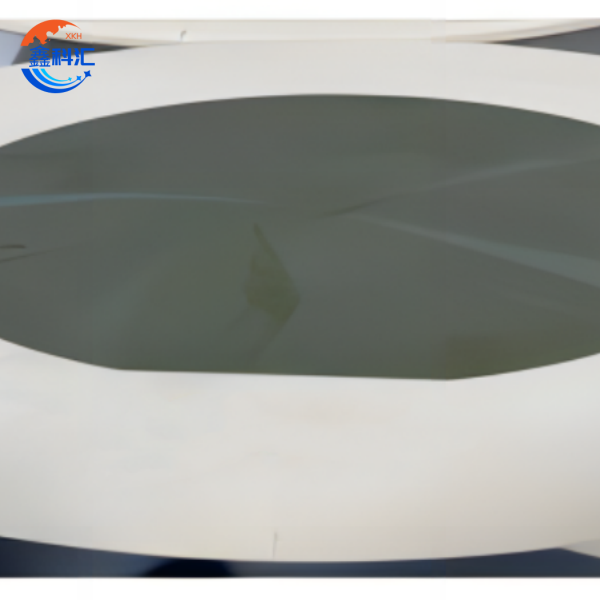

Chida Chowotcha Chopindika cha 4 Inchi-12 Inchi Sapphire/SiC/Si Wafers Processing

Mfundo Yogwirira Ntchito

Njira yochepetsera zowonda imayenda m'njira zitatu:

Kupera Movuta: Gudumu la diamondi (grit size 200–500 μm) limachotsa 50–150 μm ya zinthu pa 3000–5000 rpm kuti muchepetse makulidwe mwachangu.

Kupera Kwabwino: Gudumu labwino kwambiri (kukula kwa grit 1-50 μm) kumachepetsa makulidwe mpaka 20-50 μm pa <1 μm/s kuti achepetse kuwonongeka kwa pansi.

Kupukuta (CMP): slurry yamankhwala imachotsa zowonongeka zotsalira, kukwaniritsa Ra <0.1 nm.

Zogwirizana

Silikoni (Si): Muyezo wamawotchi a CMOS, owonda mpaka 25 μm pakusunga 3D.

Silicon Carbide (SiC): Imafunika mawilo apadera a diamondi (80% diamondi concentration) kuti matenthedwe azikhala okhazikika.

Sapphire (Al₂O₃): Wopendekeka kufika pa 50 μm pakugwiritsa ntchito ma LED a UV.

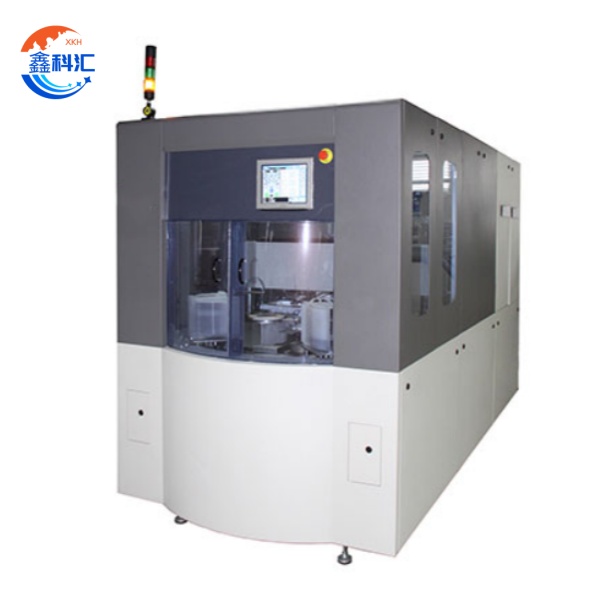

Core System Components

1. Grinding System

Dual-Axis Grinder: Zimaphatikiza kugaya kosalala / kosalala papulatifomu imodzi, kuchepetsa nthawi yozungulira ndi 40%.

Aerostatic Spindle: 0-6000 rpm liwiro losiyana ndi <0.5 μm radial runout.

2. Wafer Handling System

Vacuum Chuck: > 50 N yogwira mphamvu yokhala ndi ± 0.1 μm kulondola kwa malo.

Robotic Arm: Amanyamula zowotcha 4-12-inch pa 100 mm/s.

3. Control System

Laser Interferometry: Kuyang'anira makulidwe a nthawi yeniyeni (kutsimikiza 0.01 μm).

Feedforward Yoyendetsedwa ndi AI: Imaneneratu kuvala kwa magudumu ndikusintha magawo okha.

4. Kuzizira & Kuyeretsa

Kuyeretsa kwa Ultrasonic: Kumachotsa tinthu > 0.5 μm ndi 99.9% bwino.

Madzi Osungunulidwa: Amazizira pansi kufika pa 5 ° C pamwamba pa malo ozungulira.

Ubwino Wachikulu

1. Kulondola Kwambiri Kwambiri: TTV (Kusiyanasiyana Kwamakulidwe Kwathunthu) <0.5 μm, WTW (Kusiyanasiyana kwa Makulidwe a Mkati mwa Wafer) <1 μm.

2. Kuphatikiza kwa Multi-Process: Zimaphatikiza kugaya, CMP, ndi plasma etching mu makina amodzi.

3. Kugwirizana kwazinthu:

Silicon: Kuchepetsa makulidwe kuchokera ku 775 μm mpaka 25 μm.

SiC: Imakwaniritsa <2 μm TTV pamapulogalamu a RF.

Zophika Zophika: Zophika za Phosphorus-doped InP zokhala ndi <5% resistivity drift.

4. Smart Automation: Kuphatikiza kwa MES kumachepetsa zolakwika za anthu ndi 70%.

5. Mphamvu Zamagetsi: 30% kutsika kwamphamvu kwamagetsi kudzera pabraking regenerative.

Mapulogalamu Ofunika Kwambiri

1. Advanced Packaging

• 3D ICs: Wafer kupatulira kumathandizira kuyika molunjika kwa logic/memory chips (monga ma HBM stacks), kukwaniritsa 10× apamwamba bandwidth ndi 50% kuchepetsa kugwiritsa ntchito mphamvu poyerekeza ndi mayankho a 2.5D. Zidazi zimathandizira hybrid bonding ndi TSV (Kupyolera-Silicon Via) kuphatikiza, kofunikira kwa mapurosesa a AI/ML omwe amafunikira <10 μm interconnect pitch. Mwachitsanzo, zowotcha 12-inchi zoonda mpaka 25 μm zimalola kuyika zigawo 8+ ndikusunga <1.5% tsamba lankhondo, lofunikira pamakina amagalimoto a LiDAR.

• Kupaka kwa Fan-Out: Pochepetsa makulidwe a wafer mpaka 30 μm, kutalika kwa kulumikizana kumafupikitsidwa ndi 50%, kuchepetsa kuchedwa kwa ma siginecha (<0.2 ps/mm) ndikupangitsa 0.4 mm ultra-thin chipset yama SoCs am'manja. Njirayi imathandizira ma aligorivimu opumira omwe amalipidwa ndi kupsinjika kuti ateteze tsamba lankhondo (> 50 μm TTV control), kuwonetsetsa kudalirika pakugwiritsa ntchito pafupipafupi kwa RF.

2. Zamagetsi Zamagetsi

• IGBT Modules: Kupatulira ku 50 μm kumachepetsa kukana kwa kutentha kwa <0.5 ° C/W, kumapangitsa 1200V SiC MOSFETs kugwira ntchito pa kutentha kwa 200 ° C. Zida zathu zimagwiritsa ntchito masitepe ambiri akupera (coarse: 46 μm grit → chabwino: 4 μm grit) kuti athetse kuwonongeka kwapansi panthaka, kukwaniritsa> 10,000 mizungulire yodalirika yoyendetsa njinga. Izi ndizofunikira kwambiri kwa ma inverters a EV, pomwe ma 10 μm-wokhuthala a SiC amakulitsa liwiro losinthira ndi 30%.

• Zida Zamagetsi za GaN-on-SiC: Kupatulira kwa Wafer mpaka 80 μm kumawonjezera kuyenda kwa ma elekitironi (μ > 2000 cm²/V·s) kwa 650V GaN HEMTs, kumachepetsa kutayika kwa conduction ndi 18%. Njirayi imagwiritsa ntchito dicing yothandizidwa ndi laser, kuteteza kusweka pakuwonda, kukwaniritsa <5 μm m'mphepete mwa ma amplifiers a RF.

3. Optoelectronics

• Ma LED a GaN-on-SiC: Magawo a safiro a 50 μm amapangitsa kuti kuwala kukhale bwino (LEE) mpaka 85% (vs. 65% kwa 150 μm wafers) mwa kuchepetsa kujambula kwa photon. Zida zathu zowongolera kwambiri za TTV (<0.3 μm) zimatsimikizira kutulutsa kwa LED kofananira pamawotchi 12-inchi, ofunikira paziwonetsero za Micro-LED zomwe zimafunikira <100nm kutalika kwa mawonekedwe.

• Silicon Photonics: 25μm-thick silicon wafers amathandiza 3 dB / masentimita kuchepa kwa kufalikira kwa ma waveguides, ofunikira kwa 1.6 Tbps optical transceivers. Njirayi imaphatikizapo kusalaza kwa CMP kuti muchepetse roughness pamwamba pa Ra <0.1 nm, kupititsa patsogolo kugwirizanitsa bwino ndi 40%.

4. Masensa a MEMS

• Accelerometers: 25 μm silicon wafers amakwaniritsa SNR> 85 dB (vs. 75 dB kwa 50 μm wafers) powonjezera umboni-misala kusamuka tilinazo. Dongosolo lathu logaya la ma axis awiri limalipiritsa ma gradients opsinjika, kuwonetsetsa kuti <0.5% kumva kusuntha kupitilira -40°C mpaka 125°C. Mapulogalamuwa akuphatikiza kuzindikira kuwonongeka kwa magalimoto komanso kutsatira mayendedwe a AR/VR.

• Makanema a Pressure: Kupatulira mpaka 40 μm kumathandizira 0–300 mipiringidzo yoyezera mipiringidzo ndi <0.1% FS hysteresis. Pogwiritsa ntchito kulumikizana kwakanthawi (zonyamulira magalasi), njirayi imapewa kuthyoka kwa ng'anjo panthawi yokhotakhota kumbuyo, kukwaniritsa <1 μm kulekerera kwamphamvu kwa masensa a IoT a mafakitale.

• Technical Synergy: Zida zathu zopatulira zopyapyala zimagwirizanitsa mawotchi akupera, CMP, ndi plasma etching kuti athetse mavuto osiyanasiyana (Si, SiC, Sapphire). Mwachitsanzo, GaN-on-SiC imafuna kugaya kosakanizidwa (mawilo a diamondi + plasma) kuti azitha kulimba komanso kukulitsa kutentha, pomwe masensa a MEMS amafuna kuuma kwapansi kwa 5 nm kudzera pakupukuta kwa CMP.

• Impact Impact: Pothandizira zowonda zowonda, zowonda kwambiri, ukadaulo uwu umayendetsa zatsopano mu tchipisi ta AI, ma module a 5G mmWave, ndi zamagetsi zosinthika, zokhala ndi TTV tolerances <0.1 μm zowonetsera zopindika ndi <0.5 μm za masensa agalimoto a LiDAR.

Ntchito za XKH

1. Customized Solutions

Zosintha Zowonongeka: Mapangidwe a zipinda za 4-12-inchi ndi kutsitsa / kutsitsa.

Thandizo la Doping: Maphikidwe achizolowezi a makhiristo a Er/Yb-doped ndi zowotcha za InP/GaAs.

2. Thandizo Lomaliza ndi Lomaliza

Kupititsa patsogolo Ntchito: Kuyesa kwaulere kumayenda ndikukhathamiritsa.

Maphunziro a Padziko Lonse: Maphunziro aukadaulo pachaka pazokonza ndi kuthetsa mavuto.

3. Multi-Material Processing

SiC: Wafer kupatulira mpaka 100 μm ndi Ra <0.1 nm.

safiro: 50μm makulidwe a UV laser mazenera (transmittance> 92%@200 nm).

4. Value-Added Services

Zinthu Zogwiritsidwa Ntchito: Mawilo a diamondi (2000+ wafer / moyo) ndi CMP slurries.

Mapeto

Chida chopatulira ichi chimapereka mwatsatanetsatane m'mafakitale, kusinthasintha kwazinthu zambiri, komanso makina anzeru, zomwe zimapangitsa kuti zikhale zofunika kwambiri kuphatikiza 3D ndi zamagetsi zamagetsi. Ntchito zonse za XKH-kuyambira pakusintha makonda mpaka kukonzanso-kuwonetsetsa kuti makasitomala amapeza ndalama zogulira komanso kuchita bwino pakupanga ma semiconductor.