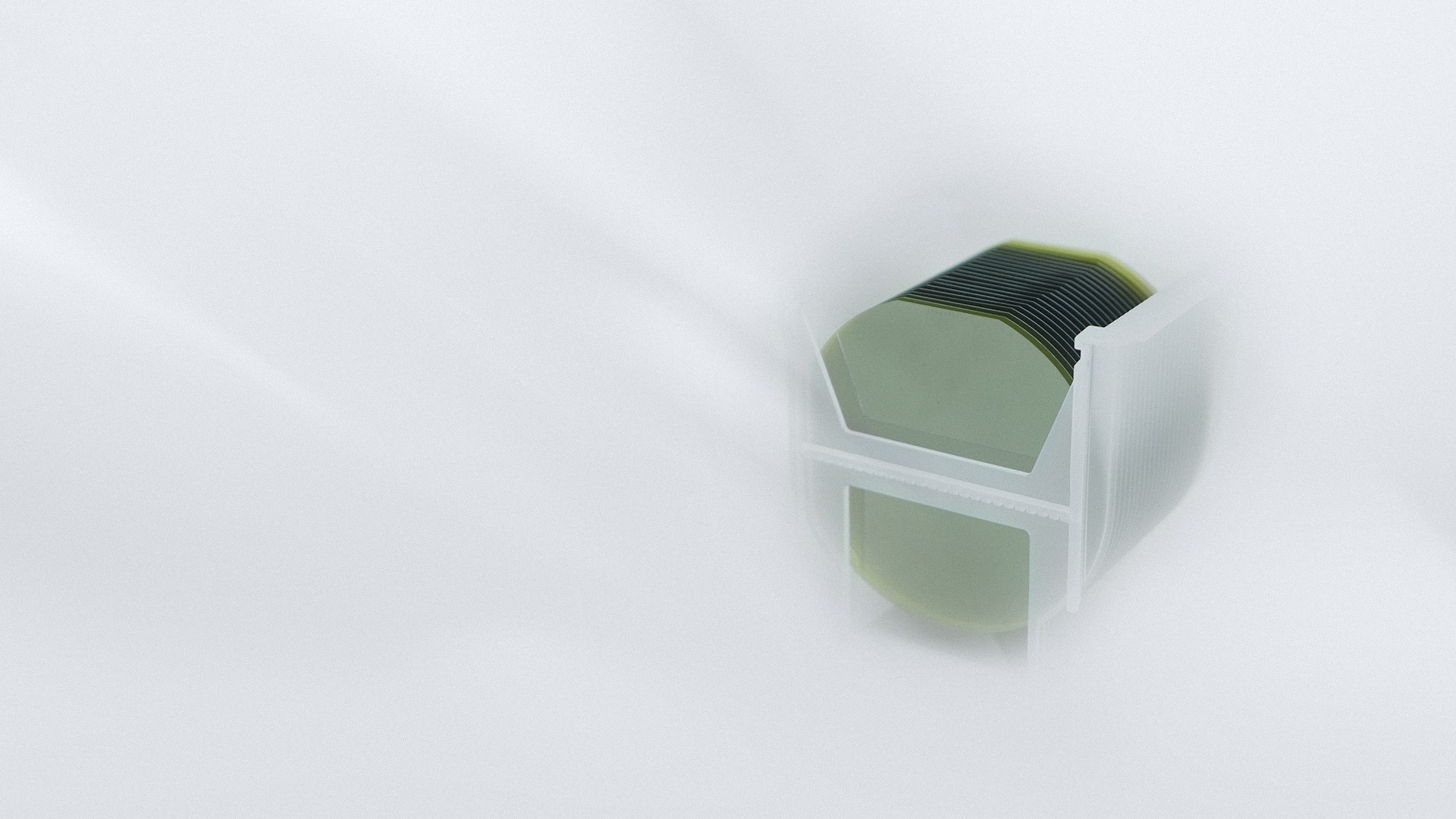

4H-N HPSI SiC wafer 6H-N 6H-P 3C-N SiC Epitaxial wafer ya MOS kapena SBD

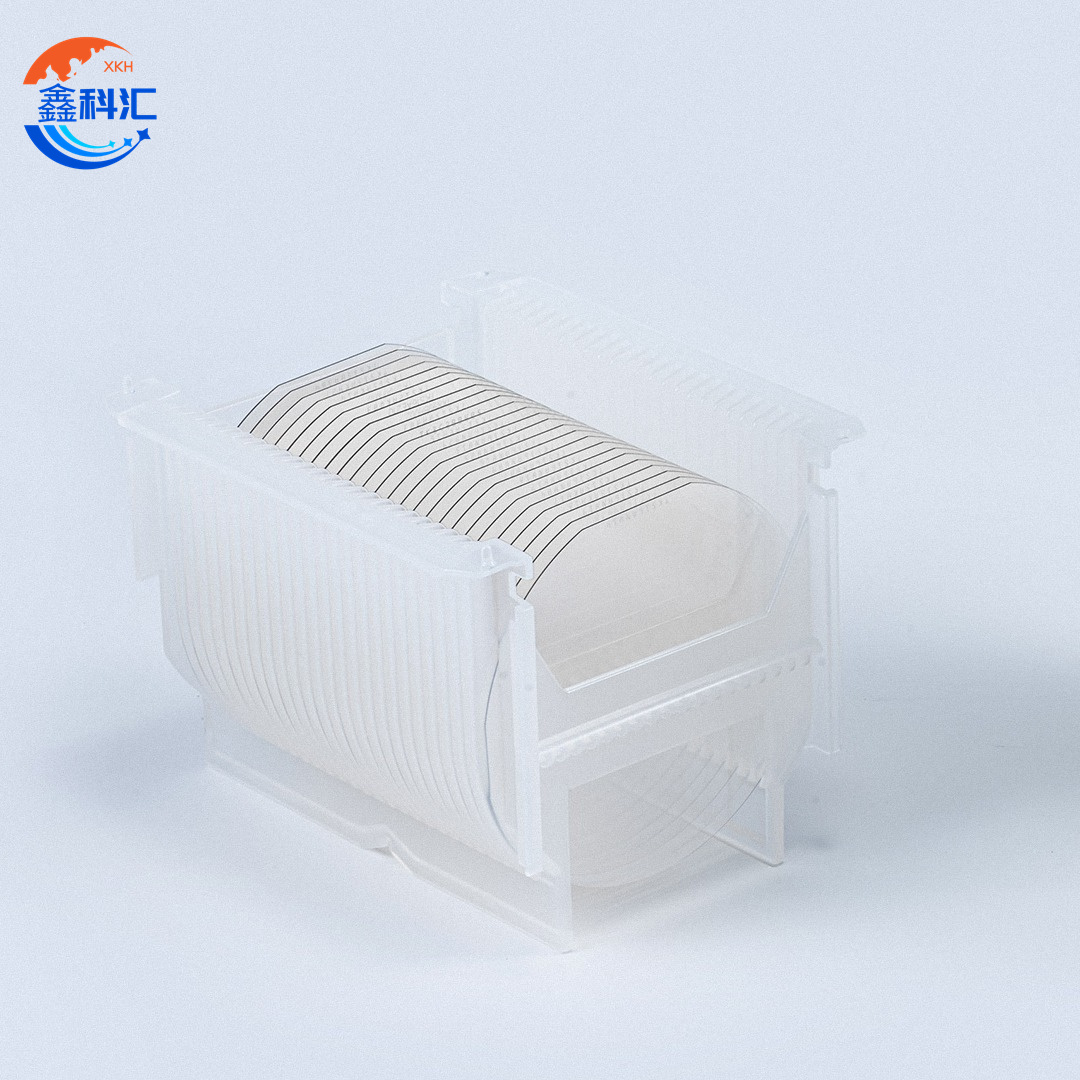

SiC Substrate SiC Epi-wafer Mwachidule

Timapereka gawo lonse la magawo apamwamba a SiC ndi ma sic wafers mumitundu ingapo ndi mbiri ya doping-kuphatikiza 4H-N (n-type conductive), 4H-P (p-type conductive), 4H-HPSI (high-purity semi-insulating), ndi 6H-P (p-type conductive) - 6" ″ 6 ″, 6 ″ ″, 6 ″, 4 mpaka 12 ″. Kupitilira malo opanda kanthu, ntchito zathu zokulitsa ma epi wafer zamtengo wapatali zimabweretsa zowotcha za epitaxial (epi) zolimba zolimba (1-20 µm), kuchuluka kwa ma doping, komanso kusalimba.

Sic wafer iliyonse ndi epi wafer imawunikiridwa mosamalitsa (kuchulukira kwa ma micropipe <0.1 cm⁻², kuuma pamwamba pa Ra <0.2 nm) ndi mawonekedwe amagetsi athunthu (CV, ma mapu a resistivity) kuti zitsimikizire kufanana kwa kristalo ndi magwiridwe antchito. Kaya amagwiritsidwa ntchito ngati ma module amagetsi amagetsi, ma amplifiers apamwamba kwambiri a RF, kapena zida za optoelectronic (ma LED, ma photodetectors), gawo lathu la SiC substrate ndi mizere ya epi wafer imapereka kudalirika, kukhazikika kwamafuta, ndi mphamvu zosweka zomwe zimafunikira ndikugwiritsa ntchito masiku ano ovuta kwambiri.

Mitundu ya SiC Substrate 4H-N ndi kugwiritsa ntchito kwake

-

4H-N SiC gawo lapansi Polytype (Hexagonal) Kapangidwe

Wide bandgap ya ~ 3.26 eV imatsimikizira kukhazikika kwamagetsi ndi kulimba kwa kutentha pansi pa kutentha kwambiri komanso kumunda wamagetsi.

-

Gawo la SiCN-Type Doping

Doping ya nayitrogeni yoyendetsedwa bwino imabweretsa zonyamula kuchokera pa 1×10¹⁶ kufika pa 1×10¹⁹ cm⁻³ ndi ma elekitironi otenthetsera m'chipinda mpaka ~900 cm²/V·s, kumachepetsa kutayika kwa ma conduction.

-

Gawo la SiCWide Resistivity & Uniformity

Zomwe zilipo zotha kupirira za 0.01–10 Ω·cm ndi makulidwe opingasa a 350–650 µm okhala ndi ±5% kulolerana ndi doping ndi makulidwe—oyenera kupanga zida zamphamvu kwambiri.

-

Gawo la SiCUltra-Low Defect Density

Kachulukidwe ka ma micropipe <0.1 cm⁻² ndi kusasunthika kwa ndege yoyambira 500 cm⁻², kutulutsa > 99% kutulutsa kwazida ndi kusasunthika kopambana kwa kristalo.

- Gawo la SiCExceptional Thermal Conductivity

Kutentha kwa kutentha kufika ~ 370 W/m·K kumathandizira kuchotsa kutentha koyenera, kulimbikitsa kudalirika kwa chipangizo ndi kusachulukira kwamagetsi.

-

Gawo la SiCZolinga Zofunsira

Ma SiC MOSFET, ma Schottky diode, ma module amagetsi ndi zida za RF zamagalimoto amagetsi, ma inverter a solar, ma drive amafakitale, ma traction system, ndi misika ina yofunika kwambiri yamagetsi.

6inch 4H-N mtundu wa SiC wafer's specifications | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Gulu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 350µm ± 15µm | 350µm ± 25µm |

| Wafer Orientation | Kuchokera kumtunda: 4.0 ° kulowera <1120> ± 0.5 ° | Kuchokera kumtunda: 4.0 ° kulowera <1120> ± 0.5 ° |

| Kuchuluka kwa Micropipe | ≤ 0.2cm² | ≤ 15 cm² |

| Kukaniza | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Chiyambi cha Flat Orientation | [10-10] ± 50° | [10-10] ± 50° |

| Utali Woyambira Wathyathyathya | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ukali | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 3% |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 5% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Kutalika kwake ≤ 1 wafer awiri | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥ 0.2 mm m'lifupi ndi kuya | 7 zololedwa, ≤ 1 mm iliyonse |

| Kusintha kwa Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ||

| Kupaka | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi |

8inch 4H-N mtundu wa SiC wafer's specifications | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Gulu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 500µm ± 25µm | 500µm ± 25µm |

| Wafer Orientation | 4.0 ° kulowera <110> ± 0.5° | 4.0 ° kulowera <110> ± 0.5° |

| Kuchuluka kwa Micropipe | ≤ 0.2cm² | ≤ 5 cm² |

| Kukaniza | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ukali | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 3% |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 5% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Kutalika kwake ≤ 1 wafer awiri | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥ 0.2 mm m'lifupi ndi kuya | 7 zololedwa, ≤ 1 mm iliyonse |

| Kusintha kwa Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ||

| Kupaka | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi |

4H-SiC ndi zinthu zapamwamba zomwe zimagwiritsidwa ntchito pamagetsi amagetsi, zida za RF, ndi ntchito zotentha kwambiri. "4H" imatanthawuza mawonekedwe a kristalo, omwe ali ndi hexagonal, ndipo "N" akuwonetsa mtundu wa doping womwe umagwiritsidwa ntchito kukhathamiritsa ntchito ya zinthuzo.

The4H-SiCtype imagwiritsidwa ntchito kwambiri:

Zamagetsi Zamagetsi:Amagwiritsidwa ntchito pazida monga ma diode, ma MOSFET, ndi ma IGBT pamagalimoto amagetsi amagetsi, makina am'mafakitale, ndi makina ongowonjezera mphamvu.

5G Technology:Ndi kufunidwa kwa 5G kwa zigawo zothamanga kwambiri komanso zogwira mtima kwambiri, kuthekera kwa SiC kuthana ndi ma voltages apamwamba ndikugwira ntchito pa kutentha kwakukulu kumapangitsa kukhala koyenera kwa ma base station amplifiers ndi zida za RF.

Ma Solar Energy Systems:Mphamvu zabwino kwambiri za SiC ndizoyenera ma inverters ndi ma photovoltaic (mphamvu yadzuwa).

Magalimoto Amagetsi (EVs):SiC imagwiritsidwa ntchito kwambiri mu ma EV powertrains kuti azitha kutembenuza mphamvu moyenera, kutulutsa kutentha kochepa, komanso kachulukidwe kamphamvu kwambiri.

SiC Substrate 4H Semi-Insulating mtundu wa katundu ndi ntchito

Katundu:

-

Njira zowongolera kachulukidwe ka micropipe: Imawonetsetsa kusakhalapo kwa ma micropipe, kuwongolera gawo lapansi.

-

Njira zowongolera za Monocrystalline: Imatsimikizira kapangidwe ka kristalo kamodzi kazinthu zowonjezera.

-

Inclusions control njira: Imachepetsa kupezeka kwa zonyansa kapena zophatikizika, kuonetsetsa gawo lapansi loyera.

-

Resistivity control njira: Imalola kuwongolera bwino kwa mphamvu yamagetsi yamagetsi, yomwe ndiyofunikira kuti chipangizocho chizigwira ntchito.

-

Kuwongolera zonyansa ndi njira zowongolera: Imawongolera ndikuletsa kuyambitsidwa kwa zonyansa kuti zisunge umphumphu wa gawo lapansi.

-

Njira zowongolera magawo a substrate: Amapereka chiwongolero cholondola pakukula kwa masitepe, kuonetsetsa kusasinthika kudutsa gawo lapansi

6Ichi 4H-semi SiC gawo lapansi | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Pa axis: ± 0.0001 ° | Pa axis: ± 0.05 ° |

| Kuchuluka kwa Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kukaniza (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Chiyambi cha Flat Orientation | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Utali Woyambira Wathyathyathya | Notch | Notch |

| Kupatula M'mphepete (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / mbale / Warp | ≤3 µm | ≤3 µm |

| Ukali | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Mphepete Chips Mwa High Intensity Kuwala | ≤20µm | ≤60µm |

| Kutentha Mbale Mwa Kuwala Kwakukulu Kwambiri | Zowonjezera ≤ 0.05% | Zowonjezera ≤ 3% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Kuphatikizika kwa Carbon ≤ 0.05% | Zowonjezera ≤ 3% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | ≤ 0.05% | Zowonjezera ≤ 4% |

| Edge Chips Mwa Kuwala Kwambiri Kwambiri (Kukula) | Silololedwa> 02 mm M'lifupi ndi Kuzama | Silololedwa> 02 mm M'lifupi ndi Kuzama |

| The Aid Screw Dilation | ≤500µm | ≤500µm |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Kupaka | Makaseti amitundu yopyapyala kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala kapena Chidebe Chowotcha Chimodzi |

4-Inch 4H-Semi Insulating SiC Substrate Kufotokozera

| Parameter | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

|---|---|---|

| Zakuthupi | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Pa axis: <600h> 0.5° | Pa axis: <000h> 0.5° |

| Zida Zamagetsi | ||

| Kuchulukana kwa Micropipe (MPD) | ≤1cm⁻² | ≤15cm⁻² |

| Kukaniza | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Kulekerera kwa Geometric | ||

| Chiyambi cha Flat Orientation | (0x10) ± 5.0° | (0x10) ± 5.0° |

| Utali Woyambira Wathyathyathya | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Kutalika kwa Sekondale | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Sekondale Flat Orientation | 90 ° CW kuchokera ku Prime flat ± 5.0 ° (Si nkhope mmwamba) | 90 ° CW kuchokera ku Prime flat ± 5.0 ° (Si nkhope mmwamba) |

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ubwino Wapamwamba | ||

| Kukalipa Pamwamba (Polish Ra) | ≤1 nm | ≤1 nm |

| Kuvuta Kwambiri (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (Kuwala Kwambiri) | Zosaloledwa | Kutalika kwa ≥10 mm, mng'alu umodzi ≤2 mm |

| Zowonongeka za Hexagonal Plate | ≤0.05% malo ophatikizika | ≤0.1% malo ophatikizika |

| Madera a Polytype Inclusion | Zosaloledwa | ≤1% malo ophatikizika |

| Mawonekedwe a Carbon Inclusions | ≤0.05% malo ophatikizika | ≤1% malo ophatikizika |

| Zojambula za Silicon Surface | Zosaloledwa | ≤1 wafer awiri kutalika kokwanira |

| Chips za Edge | Palibe chololedwa (≥0.2 mm m'lifupi/kuya) | ≤5 tchipisi (iliyonse ≤1 mm) |

| Kuwonongeka kwa Silicon Surface | Zomwe sizinafotokozedwe | Zomwe sizinafotokozedwe |

| Kupaka | ||

| Kupaka | Multi-wafer cassette kapena single-wafer container | Multi-wafer kaseti kapena |

Ntchito:

TheSiC 4H Semi-Insulating substratesamagwiritsidwa ntchito makamaka pazida zamagetsi zamphamvu kwambiri komanso zothamanga kwambiri, makamaka muRF munda. Ma substrates awa ndi ofunikira pamapulogalamu osiyanasiyana kuphatikizamakina olumikizirana ma microwave, magawo osiyanasiyana radar,ndizida zamagetsi zopanda zingwe. Kutentha kwawo kwakukulu komanso mawonekedwe abwino kwambiri amagetsi amawapangitsa kukhala oyenera kugwiritsa ntchito zida zamagetsi zamagetsi ndi njira zoyankhulirana.

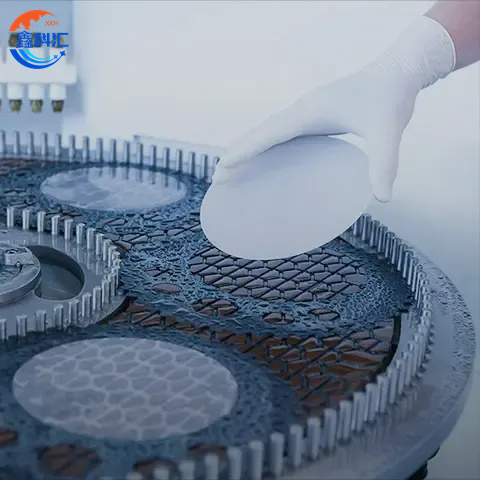

SiC epi wafer 4H-N mtundu wa katundu ndi ntchito

SiC 4H-N Mtundu wa Epi Wafer Properties ndi Mapulogalamu

Katundu wa SiC 4H-N Mtundu wa Epi Wafer:

Zofunika:

SiC (Silicon Carbide): Imadziwika chifukwa cha kuuma kwake kwapadera, kukhathamiritsa kwamafuta kwambiri, komanso mphamvu zabwino kwambiri zamagetsi, SiC ndiyabwino pazida zamagetsi zogwira ntchito kwambiri.

4H-SiC Polytype: 4H-SiC polytype imadziwika chifukwa chapamwamba komanso kukhazikika pamagetsi.

N-mtundu wa Doping: Doping yamtundu wa N (yopangidwa ndi nayitrogeni) imapereka kuyenda bwino kwa ma elekitironi, kupangitsa SiC kukhala yoyenera kugwiritsa ntchito pafupipafupi komanso mphamvu zambiri.

High Thermal Conductivity:

Zophika za SiC zimakhala ndi matenthedwe apamwamba kwambiri, makamaka kuyambira120–200 W/m·K, kuwalola kuti aziyendetsa bwino kutentha pazida zamphamvu kwambiri monga ma transistors ndi ma diode.

Wide Bandgap:

Ndi bandgap ya3.26 eV, 4H-SiC ikhoza kugwira ntchito pamagetsi apamwamba, mafupipafupi, ndi kutentha poyerekeza ndi zipangizo zamakono zomwe zimagwiritsidwa ntchito ndi silicon, zomwe zimapangitsa kuti zikhale zabwino kwambiri, zogwiritsira ntchito kwambiri.

Zamagetsi:

Kuyenda kwa ma elekitironi kwa SiC komanso kusinthasintha kumapangitsa kuti ikhale yabwinozamagetsi zamagetsi, yopereka liwiro losinthira mwachangu komanso mphamvu yamagetsi yamagetsi, zomwe zimapangitsa kuti pakhale njira zowongolera mphamvu zamagetsi.

Mechanical and Chemical Resistance:

SiC ndi imodzi mwazinthu zolimba kwambiri, yachiwiri kwa diamondi, ndipo imalimbana kwambiri ndi okosijeni ndi dzimbiri, zomwe zimapangitsa kuti ikhale yolimba m'malo ovuta.

Kugwiritsa ntchito SiC 4H-N Mtundu wa Epi Wafer:

Zamagetsi Zamagetsi:

SiC 4H-N mtundu wa epi wafers amagwiritsidwa ntchito kwambirimphamvu MOSFETs, Zithunzi za IGBT,ndidiodeszakutembenuka kwa mphamvumu machitidwe mongama inverters a dzuwa, magalimoto amagetsi,ndimachitidwe osungira mphamvu, yopereka magwiridwe antchito owonjezereka komanso kugwiritsa ntchito mphamvu.

Magalimoto Amagetsi (EVs):

In magetsi galimoto powertrains, owongolera magalimoto,ndimalo opangira, zowotcha za SiC zimathandizira kuti batire igwire bwino ntchito, kuyitanitsa mwachangu, komanso kuwongolera mphamvu zonse chifukwa chotha kunyamula mphamvu ndi kutentha kwambiri.

Renewable Energy Systems:

Ma Solar Inverters: Zophika za SiC zimagwiritsidwa ntchitomachitidwe a dzuwaposintha mphamvu ya DC kuchokera ku solar panel kupita ku AC, kukulitsa magwiridwe antchito ndi magwiridwe antchito.

Ma turbines a Mphepo: Ukadaulo wa SiC umagwiritsidwa ntchitomakina owongolera makina opangira mphepo, kukhathamiritsa kupanga mphamvu ndi kutembenuka kwachangu.

Zamlengalenga ndi Chitetezo:

Zophika za SiC ndizoyenera kugwiritsidwa ntchitozamagetsi zammlengalengandintchito zankhondo, kuphatikizapomachitidwe a radarndisatellite zamagetsi, kumene kukana kwambiri kwa ma radiation ndi kukhazikika kwa kutentha ndikofunikira.

Kutentha Kwambiri ndi Kugwiritsa Ntchito pafupipafupi:

SiC wafers amapambana muzamagetsi zotentha kwambiri, yogwiritsidwa ntchitoinjini za ndege, chombo,ndimafakitale Kutentha machitidwe, pamene amasunga ntchito mu kutentha kwakukulu. Kuphatikiza apo, bandgap yawo yayikulu imalola kugwiritsidwa ntchito mkatihigh-frequency applicationsmongaZida za RFndimicrowave kulumikizana.

| 6-inch N-mtundu wa epit axial specifications | |||

| Parameter | unit | Z-MOS | |

| Mtundu | Condutivity / Dopant | - | N-mtundu / Nayitrogeni |

| Buffer Layer | Buffer Layer Makulidwe | um | 1 |

| Kulekerera kwa Makulidwe a Buffer Layer | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Kulekerera kwa Buffer Layer Concentration | % | ±20% | |

| 1st Epi Layer | Epi Layer Makulidwe | um | 11.5 |

| Epi Layer Makulidwe Uniformity | % | ±4% | |

| Epi Layers Thickness Tolerance ((Spec- Max , Mphindi)/Spec) | % | ± 5% | |

| Epi Layer Concentration | cm-3 | 1Ndi 15–1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /anthu) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Kugwada | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤10 | |

| LTV | um | ≤2 | |

| General Makhalidwe | Kutalika kwa zikwapu | mm | ≤30 mm |

| Chips za Edge | - | PALIBE | |

| Tanthauzo la zolakwika | ≥97% (Kuyezedwa ndi 2*2, Zowonongeka zakupha zikuphatikizapo: Zowonongeka zimaphatikizapo Micropipe/Maenje Aakulu, Kaloti, Triangular | ||

| Kuwonongeka kwachitsulo | ma atomu/cm² | df ndi ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Phukusi | Mafotokozedwe ake | pcs/bokosi | makaseti amitundu yopyapyala kapena chidebe chopyapyala chimodzi |

| 8-inch N-mtundu wa epitaxial specifications | |||

| Parameter | unit | Z-MOS | |

| Mtundu | Condutivity / Dopant | - | N-mtundu / Nayitrogeni |

| Buffer wosanjikiza | Buffer Layer Makulidwe | um | 1 |

| Kulekerera kwa Makulidwe a Buffer Layer | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Kulekerera kwa Buffer Layer Concentration | % | ±20% | |

| 1st Epi Layer | Epi Layers Makulidwe Avereji | um | 8-12 |

| Epi Layers Thickness Uniformity (σ/kutanthauza) | % | ≤2.0 | |

| Epi Layers Thickness Tolerance ((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/kutanthauza) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi)/S) Warp | um | ≤50.0 |

| Kugwada | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| General Makhalidwe | Zikanda | - | Kutalika kokwanira≤ 1/2 Wafer awiri |

| Chips za Edge | - | ≤2 tchipisi, utali uliwonse≤1.5mm | |

| Surface Metals Kuipitsidwa | ma atomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Kuyendera Chilema | % | ≥ 96.0 (Zowonongeka za 2X2 zimaphatikizapo Micropipe / maenje Aakulu, Karoti, zolakwika za katatu, kugwa, Linear/IGSF-s, BPD) | |

| Surface Metals Kuipitsidwa | ma atomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Phukusi | Mafotokozedwe ake | - | makaseti amitundu yopyapyala kapena chidebe chopyapyala chimodzi |

Q&A ya SiC wafer

Q1: Kodi maubwino otani ogwiritsira ntchito zopyapyala za SiC pazowotcha zachikhalidwe za silicon mumagetsi amagetsi?

A1:

Zowotcha za SiC zimapereka maubwino angapo ofunikira kuposa zowotcha zachikhalidwe za silicon (Si) mumagetsi amagetsi, kuphatikiza:

Kuchita Mwapamwamba: SiC ili ndi bandgap yotakata (3.26 eV) poyerekeza ndi silicon (1.1 eV), kulola zida kuti zizigwira ntchito pamagetsi apamwamba, ma frequency, ndi kutentha. Izi zimabweretsa kutsika kwamphamvu kwamphamvu komanso kuchita bwino kwambiri pamakina osinthira mphamvu.

High Thermal Conductivity: SiC's thermal conductivity ndi yapamwamba kwambiri kuposa ya silicon, yomwe imapangitsa kuti kutentha kwabwino kumagwiritsidwe ntchito pamagetsi apamwamba, zomwe zimapangitsa kudalirika ndi moyo wautali wa zipangizo zamagetsi.

Mphamvu Yamagetsi Yapamwamba ndi Kugwira Kwatsopano: Zipangizo za SiC zimatha kunyamula ma voltage okwera komanso omwe ali pano, kuwapangitsa kukhala oyenera kugwiritsa ntchito mphamvu zambiri monga magalimoto amagetsi, makina opangira mphamvu zongowonjezwdwa, ndi ma drive motor motor.

Kuthamanga Kwambiri Kwambiri: Zipangizo za SiC zili ndi mphamvu zosinthira mofulumira, zomwe zimathandizira kuchepetsa kutayika kwa mphamvu ndi kukula kwa dongosolo, kuzipanga kukhala zabwino kwa mapulogalamu apamwamba kwambiri.

Q2: Kodi ntchito zazikulu za SiC wafers mu makampani magalimoto?

A2:

M'makampani amagalimoto, zowotcha za SiC zimagwiritsidwa ntchito makamaka mu:

Galimoto Yamagetsi (EV) Powertrains: SiC ofotokoza zigawo ngatima invertersndimphamvu MOSFETskuwongolera magwiridwe antchito ndi magwiridwe antchito amagetsi amagetsi amagetsi pothandizira kuthamanga kwakusintha mwachangu komanso kuchuluka kwamphamvu kwamagetsi. Izi zimabweretsa moyo wautali wa batri komanso kuyendetsa bwino kwagalimoto yonse.

Ma Charger Pa board: Zipangizo za SiC zimathandizira kukonza magwiridwe antchito a makina ochapira omwe ali pa bolodi popangitsa kuti pakhale nthawi yolipirira mwachangu komanso kuwongolera bwino kwamafuta, zomwe ndizofunikira kuti ma EV azithandizira malo opangira magetsi amphamvu kwambiri.

Kasamalidwe ka Battery (BMS): Ukadaulo wa SiC umawongolera magwiridwe antchito amachitidwe oyendetsera batri, kulola kuwongolera bwino kwamagetsi, kugwiritsa ntchito mphamvu zambiri, komanso moyo wautali wa batri.

Zosintha za DC-DC: Zophika za SiC zimagwiritsidwa ntchitoZosintha za DC-DCkutembenuza mphamvu yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yotsika kwambiri ya DC mogwira mtima kwambiri, zomwe ndi zofunika kwambiri m'magalimoto amagetsi kuti muzitha kuyendetsa mphamvu kuchokera ku batire kupita kuzinthu zosiyanasiyana zagalimoto.

Kuchita bwino kwambiri kwa SiC pamagetsi okwera kwambiri, kutentha kwambiri, komanso kugwiritsa ntchito bwino kwambiri kumapangitsa kuti pakhale kufunikira kwakusintha kwamakampani amagalimoto kupita kumayendedwe amagetsi.

6inch 4H-N mtundu wa SiC wafer's specifications | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Gulu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter | 149.5 mm - 150.0 mm | 149.5 mm - 150.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 350µm ± 15µm | 350µm ± 25µm |

| Wafer Orientation | Kuchokera kumtunda: 4.0 ° kulowera <1120> ± 0.5 ° | Kuchokera kumtunda: 4.0 ° kulowera <1120> ± 0.5 ° |

| Kuchuluka kwa Micropipe | ≤ 0.2cm² | ≤ 15 cm² |

| Kukaniza | 0.015 - 0.024 Ω·cm | 0.015 - 0.028 Ω·cm |

| Chiyambi cha Flat Orientation | [10-10] ± 50° | [10-10] ± 50° |

| Utali Woyambira Wathyathyathya | 475 mm ± 2.0 mm | 475 mm ± 2.0 mm |

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 2.5 µm / ≤ 6 µm / ≤ 25 µm / ≤ 35 µm | ≤ 5 µm / ≤ 15 µm / ≤ 40 µm / ≤ 60 µm |

| Ukali | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 3% |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 5% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Kutalika kwake ≤ 1 wafer awiri | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥ 0.2 mm m'lifupi ndi kuya | 7 zololedwa, ≤ 1 mm iliyonse |

| Kusintha kwa Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ||

| Kupaka | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi |

8inch 4H-N mtundu wa SiC wafer's specifications | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Gulu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter | 199.5 mm - 200.0 mm | 199.5 mm - 200.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 500µm ± 25µm | 500µm ± 25µm |

| Wafer Orientation | 4.0 ° kulowera <110> ± 0.5° | 4.0 ° kulowera <110> ± 0.5° |

| Kuchuluka kwa Micropipe | ≤ 0.2cm² | ≤ 5 cm² |

| Kukaniza | 0.015 - 0.025 Ω·cm | 0.015 - 0.028 Ω·cm |

| Noble Orientation | ||

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TIV / Bow / Warp | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 70 µm | ≤ 5 µm / ≤ 15 µm / ≤ 35 µm / 100 µm |

| Ukali | Polish Ra ≤ 1 nm | Polish Ra ≤ 1 nm |

| CMP Ra | ≤ 0.2 nm | ≤ 0.5 nm |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm | Kutalikirana kutalika ≤ 20 mm utali umodzi ≤ 2 mm |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 3% |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 5% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Kutalika kwake ≤ 1 wafer awiri | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥ 0.2 mm m'lifupi ndi kuya | 7 zololedwa, ≤ 1 mm iliyonse |

| Kusintha kwa Screw Dislocation | <500cm³ | <500cm³ |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ||

| Kupaka | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi |

6Ichi 4H-semi SiC gawo lapansi | ||

| Katundu | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

| Diameter (mm) | 145 mm - 150 mm | 145 mm - 150 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe (um) | 500 ± 15 | 500 ± 25 |

| Wafer Orientation | Pa axis: ± 0.0001 ° | Pa axis: ± 0.05 ° |

| Kuchuluka kwa Micropipe | ≤ 15 cm-2 | ≤ 15 cm-2 |

| Kukaniza (Ωcm) | ≥ 10E3 | ≥ 10E3 |

| Chiyambi cha Flat Orientation | (0-10)° ± 5.0° | (10-10)° ± 5.0° |

| Utali Woyambira Wathyathyathya | Notch | Notch |

| Kupatula M'mphepete (mm) | ≤ 2.5 µm / ≤ 15 µm | ≤ 5.5 µm / ≤ 35 µm |

| LTV / mbale / Warp | ≤3 µm | ≤3 µm |

| Ukali | Polish Ra ≤ 1.5 µm | Polish Ra ≤ 1.5 µm |

| Mphepete Chips Mwa High Intensity Kuwala | ≤20µm | ≤60µm |

| Kutentha Mbale Mwa Kuwala Kwakukulu Kwambiri | Zowonjezera ≤ 0.05% | Zowonjezera ≤ 3% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Kuphatikizika kwa Carbon ≤ 0.05% | Zowonjezera ≤ 3% |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | ≤ 0.05% | Zowonjezera ≤ 4% |

| Edge Chips Mwa Kuwala Kwambiri Kwambiri (Kukula) | Silololedwa> 02 mm M'lifupi ndi Kuzama | Silololedwa> 02 mm M'lifupi ndi Kuzama |

| The Aid Screw Dilation | ≤500µm | ≤500µm |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | ≤ 1 x 10^5 | ≤ 1 x 10^5 |

| Kupaka | Makaseti amitundu yopyapyala kapena Chidebe Chowotcha Chimodzi | Makaseti amitundu yopyapyala kapena Chidebe Chowotcha Chimodzi |

4-Inch 4H-Semi Insulating SiC Substrate Kufotokozera

| Parameter | Zero MPD Kalasi Yopanga (Z Giredi) | Dummy Grade (D Grade) |

|---|---|---|

| Zakuthupi | ||

| Diameter | 99.5 mm - 100.0 mm | 99.5 mm - 100.0 mm |

| Poly-mtundu | 4H | 4H |

| Makulidwe | 500 μm ± 15 μm | 500 μm ± 25 μm |

| Wafer Orientation | Pa axis: <600h> 0.5° | Pa axis: <000h> 0.5° |

| Zida Zamagetsi | ||

| Kuchulukana kwa Micropipe (MPD) | ≤1cm⁻² | ≤15cm⁻² |

| Kukaniza | ≥150 Ω·cm | ≥1.5 Ω·cm |

| Kulekerera kwa Geometric | ||

| Chiyambi cha Flat Orientation | (0×10) ± 5.0° | (0×10) ± 5.0° |

| Utali Woyambira Wathyathyathya | 52.5 mm ± 2.0 mm | 52.5 mm ± 2.0 mm |

| Kutalika kwa Sekondale | 18.0 mm ± 2.0 mm | 18.0 mm ± 2.0 mm |

| Sekondale Flat Orientation | 90 ° CW kuchokera ku Prime flat ± 5.0 ° (Si nkhope mmwamba) | 90 ° CW kuchokera ku Prime flat ± 5.0 ° (Si nkhope mmwamba) |

| Kupatula M'mphepete | 3 mm | 3 mm |

| LTV / TTV / Bow / Warp | ≤2.5 μm / ≤5 μm / ≤15 μm / ≤30 μm | ≤10 μm / ≤15 μm / ≤25 μm / ≤40 μm |

| Ubwino Wapamwamba | ||

| Kukalipa Pamwamba (Polish Ra) | ≤1 nm | ≤1 nm |

| Kuvuta Kwambiri (CMP Ra) | ≤0.2 nm | ≤0.2 nm |

| Edge Cracks (Kuwala Kwambiri) | Zosaloledwa | Kutalika kwa ≥10 mm, mng'alu umodzi ≤2 mm |

| Zowonongeka za Hexagonal Plate | ≤0.05% malo ophatikizika | ≤0.1% malo ophatikizika |

| Madera a Polytype Inclusion | Zosaloledwa | ≤1% malo ophatikizika |

| Mawonekedwe a Carbon Inclusions | ≤0.05% malo ophatikizika | ≤1% malo ophatikizika |

| Zojambula za Silicon Surface | Zosaloledwa | ≤1 wafer awiri kutalika kokwanira |

| Chips za Edge | Palibe chololedwa (≥0.2 mm m'lifupi/kuya) | ≤5 tchipisi (iliyonse ≤1 mm) |

| Kuwonongeka kwa Silicon Surface | Zomwe sizinafotokozedwe | Zomwe sizinafotokozedwe |

| Kupaka | ||

| Kupaka | Multi-wafer cassette kapena single-wafer container | Multi-wafer kaseti kapena |

| 6-inch N-mtundu wa epit axial specifications | |||

| Parameter | unit | Z-MOS | |

| Mtundu | Condutivity / Dopant | - | N-mtundu / Nayitrogeni |

| Buffer Layer | Buffer Layer Makulidwe | um | 1 |

| Kulekerera kwa Makulidwe a Buffer Layer | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Kulekerera kwa Buffer Layer Concentration | % | ±20% | |

| 1st Epi Layer | Epi Layer Makulidwe | um | 11.5 |

| Epi Layer Makulidwe Uniformity | % | ±4% | |

| Epi Layers Thickness Tolerance ((Spec- Max , Mphindi)/Spec) | % | ± 5% | |

| Epi Layer Concentration | cm-3 | 1Ndi 15–1E 18 | |

| Epi Layer Concentration Tolerance | % | 6% | |

| Epi Layer Concentration Uniformity (σ /anthu) | % | ≤5% | |

| Epi Layer Concentration Uniformity <(max-min)/(max+min> | % | ≤ 10% | |

| Epitaixal Wafer Shape | Kugwada | um | ≤±20 |

| WARP | um | ≤30 | |

| TTV | um | ≤10 | |

| LTV | um | ≤2 | |

| General Makhalidwe | Kutalika kwa zikwapu | mm | ≤30 mm |

| Chips za Edge | - | PALIBE | |

| Tanthauzo la zolakwika | ≥97% (Kuyezedwa ndi 2*2, Zowonongeka zakupha zikuphatikizapo: Zowonongeka zimaphatikizapo Micropipe/Maenje Aakulu, Kaloti, Triangular | ||

| Kuwonongeka kwachitsulo | ma atomu/cm² | df ndi ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Phukusi | Mafotokozedwe ake | pcs/bokosi | makaseti amitundu yopyapyala kapena chidebe chopyapyala chimodzi |

| 8-inch N-mtundu wa epitaxial specifications | |||

| Parameter | unit | Z-MOS | |

| Mtundu | Condutivity / Dopant | - | N-mtundu / Nayitrogeni |

| Buffer wosanjikiza | Buffer Layer Makulidwe | um | 1 |

| Kulekerera kwa Makulidwe a Buffer Layer | % | ±20% | |

| Buffer Layer Concentration | cm-3 | 1.00E+18 | |

| Kulekerera kwa Buffer Layer Concentration | % | ±20% | |

| 1st Epi Layer | Epi Layers Makulidwe Avereji | um | 8-12 |

| Epi Layers Thickness Uniformity (σ/kutanthauza) | % | ≤2.0 | |

| Epi Layers Thickness Tolerance ((Spec -Max, Min)/Spec) | % | ±6 | |

| Epi Layers Net Average Doping | cm-3 | 8E+15 ~2E+16 | |

| Epi Layers Net Doping Uniformity (σ/kutanthauza) | % | ≤5 | |

| Epi Layers Net DopingTolerance ((Spec -Max, | % | ± 10.0 | |

| Epitaixal Wafer Shape | Mi)/S) Warp | um | ≤50.0 |

| Kugwada | um | ± 30.0 | |

| TTV | um | ≤ 10.0 | |

| LTV | um | ≤4.0 (10mm×10mm) | |

| General Makhalidwe | Zikanda | - | Kutalika kokwanira≤ 1/2 Wafer awiri |

| Chips za Edge | - | ≤2 tchipisi, utali uliwonse≤1.5mm | |

| Surface Metals Kuipitsidwa | ma atomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Kuyendera Chilema | % | ≥ 96.0 (Zowonongeka za 2X2 zimaphatikizapo Micropipe / maenje Aakulu, Karoti, zolakwika za katatu, kugwa, Linear/IGSF-s, BPD) | |

| Surface Metals Kuipitsidwa | ma atomu/cm2 | ≤5E10 maatomu/cm2 (Al, Cr, Fe, Ni, Cu, Zn, Hg,Na,K,Ti,Ca &Mn) | |

| Phukusi | Mafotokozedwe ake | - | makaseti amitundu yopyapyala kapena chidebe chopyapyala chimodzi |

Q1: Kodi maubwino otani ogwiritsira ntchito zopyapyala za SiC pazowotcha zachikhalidwe za silicon mumagetsi amagetsi?

A1:

Zowotcha za SiC zimapereka maubwino angapo ofunikira kuposa zowotcha zachikhalidwe za silicon (Si) mumagetsi amagetsi, kuphatikiza:

Kuchita Mwapamwamba: SiC ili ndi bandgap yotakata (3.26 eV) poyerekeza ndi silicon (1.1 eV), kulola zida kuti zizigwira ntchito pamagetsi apamwamba, ma frequency, ndi kutentha. Izi zimabweretsa kutsika kwamphamvu kwamphamvu komanso kuchita bwino kwambiri pamakina osinthira mphamvu.

High Thermal Conductivity: SiC's thermal conductivity ndi yapamwamba kwambiri kuposa ya silicon, yomwe imapangitsa kuti kutentha kwabwino kumagwiritsidwe ntchito pamagetsi apamwamba, zomwe zimapangitsa kudalirika ndi moyo wautali wa zipangizo zamagetsi.

Mphamvu Yamagetsi Yapamwamba ndi Kugwira Kwatsopano: Zipangizo za SiC zimatha kunyamula ma voltage okwera komanso omwe ali pano, kuwapangitsa kukhala oyenera kugwiritsa ntchito mphamvu zambiri monga magalimoto amagetsi, makina opangira mphamvu zongowonjezwdwa, ndi ma drive motor motor.

Kuthamanga Kwambiri Kwambiri: Zipangizo za SiC zili ndi mphamvu zosinthira mofulumira, zomwe zimathandizira kuchepetsa kutayika kwa mphamvu ndi kukula kwa dongosolo, kuzipanga kukhala zabwino kwa mapulogalamu apamwamba kwambiri.

Q2: Kodi ntchito zazikulu za SiC wafers mu makampani magalimoto?

A2:

M'makampani amagalimoto, zowotcha za SiC zimagwiritsidwa ntchito makamaka mu:

Galimoto Yamagetsi (EV) Powertrains: SiC ofotokoza zigawo ngatima invertersndimphamvu MOSFETskuwongolera magwiridwe antchito ndi magwiridwe antchito amagetsi amagetsi amagetsi pothandizira kuthamanga kwakusintha mwachangu komanso kuchuluka kwamphamvu kwamagetsi. Izi zimabweretsa moyo wautali wa batri komanso kuyendetsa bwino kwagalimoto yonse.

Ma Charger Pa board: Zipangizo za SiC zimathandizira kukonza magwiridwe antchito a makina ochapira omwe ali pa bolodi popangitsa kuti pakhale nthawi yolipirira mwachangu komanso kuwongolera bwino kwamafuta, zomwe ndizofunikira kuti ma EV azithandizira malo opangira magetsi amphamvu kwambiri.

Kasamalidwe ka Battery (BMS): Ukadaulo wa SiC umawongolera magwiridwe antchito amachitidwe oyendetsera batri, kulola kuwongolera bwino kwamagetsi, kugwiritsa ntchito mphamvu zambiri, komanso moyo wautali wa batri.

Zosintha za DC-DC: Zophika za SiC zimagwiritsidwa ntchitoZosintha za DC-DCkutembenuza mphamvu yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yamagetsi yotsika kwambiri ya DC mogwira mtima kwambiri, zomwe ndi zofunika kwambiri m'magalimoto amagetsi kuti muzitha kuyendetsa mphamvu kuchokera ku batire kupita kuzinthu zosiyanasiyana zagalimoto.

Kuchita bwino kwambiri kwa SiC pamagetsi okwera kwambiri, kutentha kwambiri, komanso kugwiritsa ntchito bwino kwambiri kumapangitsa kuti pakhale kufunikira kwakusintha kwamakampani amagalimoto kupita kumayendedwe amagetsi.