Semiconductor Laser Lift-Off Equipment Revolutionize Ingot Kupatulira

Chithunzi chatsatanetsatane

Kuyambitsa Kwazinthu za Semiconductor Laser Lift-Off Equipment

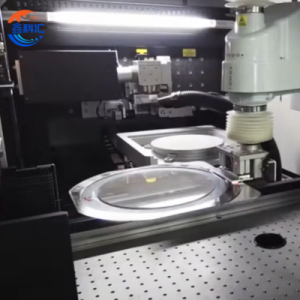

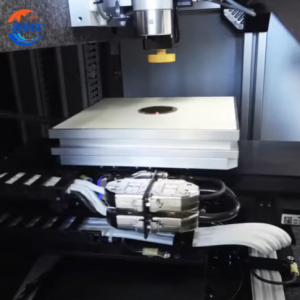

Semiconductor Laser Lift-Off Equipment ndi njira yapadera kwambiri yamafakitale yomwe idapangidwa kuti ichepetse molondola komanso mosalumikizana ndi ma semiconductor ingots kudzera munjira zonyamulira zopangidwa ndi laser. Dongosolo lotsogolali limakhala ndi gawo lofunikira kwambiri pakuwotcha kwamakono kwa semiconductor, makamaka popanga zowonda kwambiri zamagetsi zamagetsi zamagetsi, ma LED, ndi zida za RF. Pakupangitsa kulekanitsidwa kwa zigawo zoonda kuchokera ku ma ingots ambiri kapena magawo opereka, Semiconductor Laser Lift-Off Equipment imasintha kupatulira kwa ingot pochotsa masitepe ocheka ndi makina, kugaya, ndi machedwe a mankhwala.

Kupatulira kwachikale kwa semiconductor ingots, monga gallium nitride (GaN), silicon carbide (SiC), ndi safiro, nthawi zambiri kumakhala kovutirapo, kuwononga, komanso kumakonda kuwonongeka kwapang'onopang'ono. Mosiyana ndi izi, Semiconductor Laser Lift-Off Equipment imapereka njira yosawononga, yolondola yomwe imachepetsa kutayika kwa zinthu ndi kupsinjika kwa pamwamba pomwe ikukulitsa zokolola. Zimathandizira mitundu yosiyanasiyana ya crystalline ndi zida zophatikizika ndipo zimatha kuphatikizidwa mosagwirizana ndi mizere yakutsogolo kapena yapakatikati yopangira semiconductor.

Ndi ma laser wavelengths osinthika, makina osinthira, ndi ma chucks ophatikizika ndi vacuum, zida izi ndizoyenera kwambiri kudula kwa ingot, kupanga lamella, komanso kutsekereza filimu yowonda kwambiri pamapangidwe azipangizo zoyima kapena kusamutsa kwa heteroepitaxial.

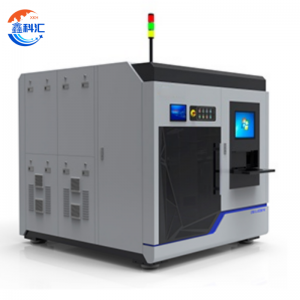

Parameter ya Semiconductor Laser Lift-Off Equipment

| Wavelength | IR/SHG/THG/FHG |

|---|---|

| Pulse Width | Nanosecond, Picosecond, Femtosecond |

| Optical System | Makina owoneka bwino kapena Galvano-optical system |

| Gawo la XY | 500 mm × 500 mm |

| Processing Range | 160 mm |

| Kuthamanga Kwambiri | Kusapitirira 1,000 mm/mphindi |

| Kubwerezabwereza | ± 1 μm kapena kuchepera |

| Kulondola Mtheradi: | ± 5 μm kapena kuchepera |

| Wafer Size | 2-6 mainchesi kapena makonda |

| Kulamulira | Windows 10, 11 ndi PLC |

| Mphamvu yamagetsi yamagetsi | AC 200 V ± 20 V, gawo limodzi, 50/60 kHz |

| Miyeso Yakunja | 2400 mm (W) × 1700 mm (D) × 2000 mm (H) |

| Kulemera | 1,000 kg |

Mfundo Yogwira Ntchito ya Semiconductor Laser Lift-Off Equipment

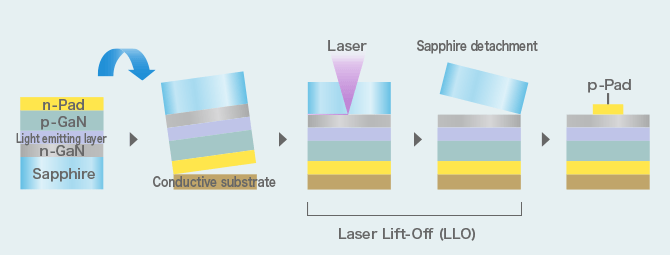

Makina oyambira a Semiconductor Laser Lift-Off Equipment amadalira kusankha kwa Photothermal kuwonongeka kapena ablation pa mawonekedwe pakati pa ingot yopereka ndi epitaxial kapena chandamale. Laser ya UV yamphamvu kwambiri (yomwe nthawi zambiri imakhala KrF pa 248 nm kapena ma lasers olimba a UV mozungulira 355 nm) imayang'aniridwa kudzera muzinthu zowonekera kapena zowoneka bwino, pomwe mphamvuyo imadziwikiratu pakuzama komwe kudakonzedweratu.

Mayamwidwe am'derali amapangitsa kuti pakhale mpweya wothamanga kwambiri kapena wosanjikiza wowonjezera kutentha pamawonekedwe, zomwe zimayambitsa kuyeretsa koyera kwa chophatikizira chapamwamba kapena wosanjikiza wa chipangizo kuchokera pamunsi pa ingot. Njirayi imawunikidwa bwino posintha magawo monga kugunda kwa mtima, kuthamanga kwa laser, kuthamanga kwa sikani, ndi kuya kwa z-axis. Zotsatira zake zimakhala zowonda kwambiri—nthawi zambiri mumtunda wa 10 mpaka 50 µm—zopatulidwa bwino ndi ingot ya kholo popanda kuvulala.

Njira iyi yonyamulira laser pakupatulira ingot imapewa kutayika kwa kerf ndi kuwonongeka kwa pamwamba komwe kumayenderana ndi macheke a waya wa diamondi kapena kuwotcha kwa makina. Imatetezanso kukhulupirika kwa kristalo ndikuchepetsa zofunikira zopukutira pansi, kupanga Semiconductor Laser Lift-Off Equipment kukhala chida chosinthira masewera chopangira chowotcha cham'badwo wotsatira.

Kugwiritsa Ntchito Semiconductor Laser Lift-Off Equipment

Semiconductor Laser Lift-Off Equipment imapeza kugwiritsa ntchito kwambiri pakupatulira kwa ingot pazida zosiyanasiyana zapamwamba ndi mitundu yazida, kuphatikiza:

-

GaN ndi GaAs Ingot Thinning for Power Devices

Imathandiza kupanga zowonda zowonda kuti zizigwira ntchito bwino kwambiri, ma transistors amphamvu otsika komanso ma diode.

-

SiC Substrate Reclamation ndi Lamella Kupatukana

Imalola kunyamulidwa kwa tinthu tating'onoting'ono kuchokera ku magawo ambiri a SiC pazida zoyima ndikugwiritsanso ntchito zopingasa.

-

Kuwongolera kwa LED

Imathandizira kukwezedwa kwa zigawo za GaN kuchokera ku ma ingots a safiro kuti apange magawo owonda kwambiri a LED.

-

RF ndi Microwave Chipangizo Kupanga

Imathandizira ma ultra-thin high-electron-mobility transistor (HEMT) omwe amafunikira mu 5G ndi makina a radar.

-

Epitaxial Layer Transfer

Imachotsa ndendende zigawo za epitaxial kuchokera ku ma crystalline ingots kuti zigwiritsidwenso ntchito kapena kuziphatikiza mu heterostructures.

-

Maselo a Solar a Thin-Film ndi Photovoltaics

Amagwiritsidwa ntchito kulekanitsa zigawo zoonda zama cell a solar osinthika kapena apamwamba kwambiri.

M'madera onsewa, Semiconductor Laser Lift-Off Equipment imapereka ulamuliro wosayerekezeka pa kufanana kwa makulidwe, khalidwe lapamwamba, ndi kukhulupirika kosanjikiza.

Ubwino wa Laser-based Ingot Thinning

-

Kutayika kwa Zero-Kerf Material

Poyerekeza ndi njira zachikhalidwe zocheka zowomba, njira ya laser imabweretsa pafupifupi 100% kugwiritsa ntchito zinthu.

-

Kupanikizika Kochepa ndi Kulimbana

Kukweza kopanda kulumikizana kumachotsa kugwedezeka kwamakina, kumachepetsa uta wa wafer ndi mapangidwe a microcrack.

-

Kusunga Ubwino Wapamwamba

Palibe kupukuta pambuyo pakupukuta kapena kupukuta kofunikira nthawi zambiri, chifukwa kukweza kwa laser kumateteza kukhulupirika kwapamwamba.

-

Kupititsa patsogolo Kwambiri ndi Zochita Zokonzeka Zokwanira

Kutha kukonza mazana a magawo pang'onopang'ono pakusintha ndi kutsitsa / kutsitsa.

-

Zosintha Pazinthu Zambiri

Imagwirizana ndi GaN, SiC, safiro, GaAs, ndi zida zomwe zikutuluka III-V.

-

Kutetezedwa Kwachilengedwe

Amachepetsa kugwiritsa ntchito ma abrasives ndi mankhwala owopsa omwe amafanana ndi njira zopatulira slurry.

-

Kugwiritsanso ntchito gawo lapansi

Ma Ingots opereka amatha kubwezeretsedwanso kuti azikwera kangapo, ndikuchepetsa kwambiri ndalama zakuthupi.

Mafunso Ofunsidwa Kawirikawiri (FAQ) a Semiconductor Laser Lift-Off Equipment

-

Q1: Ndi makulidwe anji a Semiconductor Laser Lift-Off Equipment angafikire pa magawo opyapyala?

A1:Kuchuluka kwa kagawo kakang'ono kumayambira 10 µm mpaka 100 µm kutengera zinthu ndi masinthidwe.Q2: Kodi zidazi zitha kugwiritsidwa ntchito kupangira zida zoonda zopangidwa ndi zinthu zosawoneka bwino ngati SiC?

A2:Inde. Pakukonza mafunde a laser ndi kukhathamiritsa uinjiniya wa mawonekedwe (mwachitsanzo, zolumikizirana nsembe), ngakhale zida zowoneka bwino zitha kukonzedwa.Q3: Kodi gawo la opereka limalumikizidwa bwanji musananyamule laser?

A3:Dongosololi limagwiritsa ntchito ma sub-micron vision-based alignment modules okhala ndi mayankho kuchokera kumafiducial marks ndi ma scans owoneka bwino.Q4: Kodi nthawi yozungulira yomwe ikuyembekezeredwa kuti igwire ntchito yonyamula laser imodzi ndi iti?

A4:Kutengera ndi kukula kwake komanso makulidwe ake, mikombero yanthawi zonse imatha kuyambira mphindi 2 mpaka 10.Q5: Kodi njirayi imafuna malo oyeretsa?

A5:Ngakhale sikofunikira, kuphatikiza zipinda zoyera kumalimbikitsidwa kuti pakhale ukhondo wa gawo lapansi ndi zokolola za chipangizo panthawi yogwira ntchito bwino kwambiri.

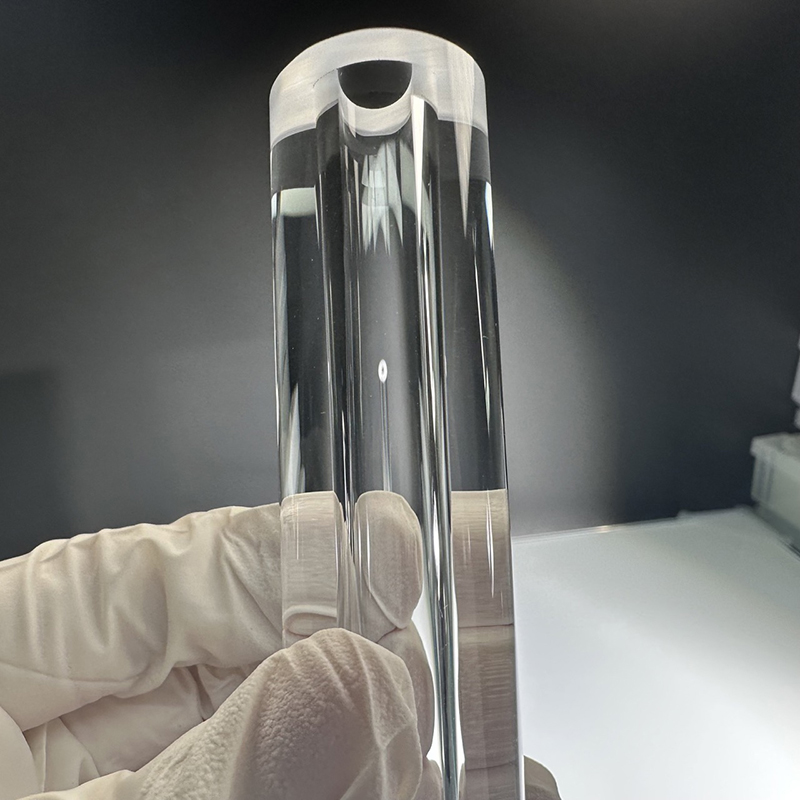

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.