CVD njira kubala mkulu chiyero SiC zipangizo mu silicon carbide synthesis ng'anjo pa 1600 ℃

Ntchito mfundo:

1. Precursor supply. Gwero la silicon (mwachitsanzo SiH₄) ndi gwero la kaboni (mwachitsanzo C₃H₈) mpweya amasakanizidwa molingana ndikudyetsedwa m'chipinda chochitiramo.

2. Kutentha kwakukulu kwa kutentha: Pa kutentha kwakukulu kwa 1500 ~ 2300 ℃, kuwonongeka kwa mpweya kumapanga maatomu ogwira ntchito a Si ndi C.

3. Maonekedwe a pamwamba: Ma atomu a Si ndi C amaikidwa pagawo laling'ono kuti apange kristalo wa SiC.

4. Kukula kwa kristalo: Kupyolera mu kuwongolera kutentha kwa kutentha, kutuluka kwa mpweya ndi kupanikizika, kuti mukwaniritse kukula kolunjika pamodzi ndi c axis kapena axis.

Zofunikira zazikulu:

Kutentha: 1600 ~ 2200 ℃ (> 2000 ℃ kwa 4H-SiC)

Kupanikizika: 50 ~ 200mbar (kutsika kochepa kuti muchepetse mpweya wa mpweya)

· Chiŵerengero cha mpweya: Si/C≈1.0~1.2 (kupewa Si kapena C zolemeretsa zolakwika)

Zofunikira zazikulu:

(1) Ubwino wa kristalo

Kachulukidwe kakang'ono kachilema: kachulukidwe ka microtubule <0.5cm ⁻², kusasunthika kwapang'onopang'ono <10⁴cm⁻².

Kuwongolera kwamtundu wa Polycrystalline: kumatha kukula 4H-SiC (mainstream), 6H-SiC, 3C-SiC ndi mitundu ina ya kristalo.

(2) Kugwiritsa ntchito zida

Kukhazikika kwa kutentha kwakukulu: Kutentha kwa graphite kapena kukana kutentha, kutentha> 2300 ℃.

Kuwongolera kofanana: kusinthasintha kwa kutentha ± 5 ℃, kukula kwa 10 ~ 50μm/h.

Gasi dongosolo: High mwatsatanetsatane misa flowmeter (MFC), mpweya chiyero ≥99.999%.

(3) Ubwino waukadaulo

Kuyera kwambiri: Kukhazikika kwachidebe chakumbuyo <10¹⁶cm⁻³ (N, B, etc.).

Kukula Kwakukulu: Kuthandizira 6 "/8" SiC gawo lapansi kukula.

(4) Kugwiritsa ntchito mphamvu ndi mtengo

Kugwiritsa ntchito mphamvu zambiri (200 ~ 500kW · h pa ng'anjo), kuwerengera 30% ~ 50% ya mtengo wopangira gawo lapansi la SiC.

Ntchito zazikulu:

1. Mphamvu ya semiconductor substrate: SiC MOSFETs popanga magalimoto amagetsi ndi ma photovoltaic inverters.

2. Rf chipangizo: 5G base station GaN-on-SiC epitaxial substrate.

3.Zida za chilengedwe kwambiri: masensa apamwamba a kutentha kwamlengalenga ndi magetsi a nyukiliya.

Mafotokozedwe aukadaulo:

| Kufotokozera | Tsatanetsatane |

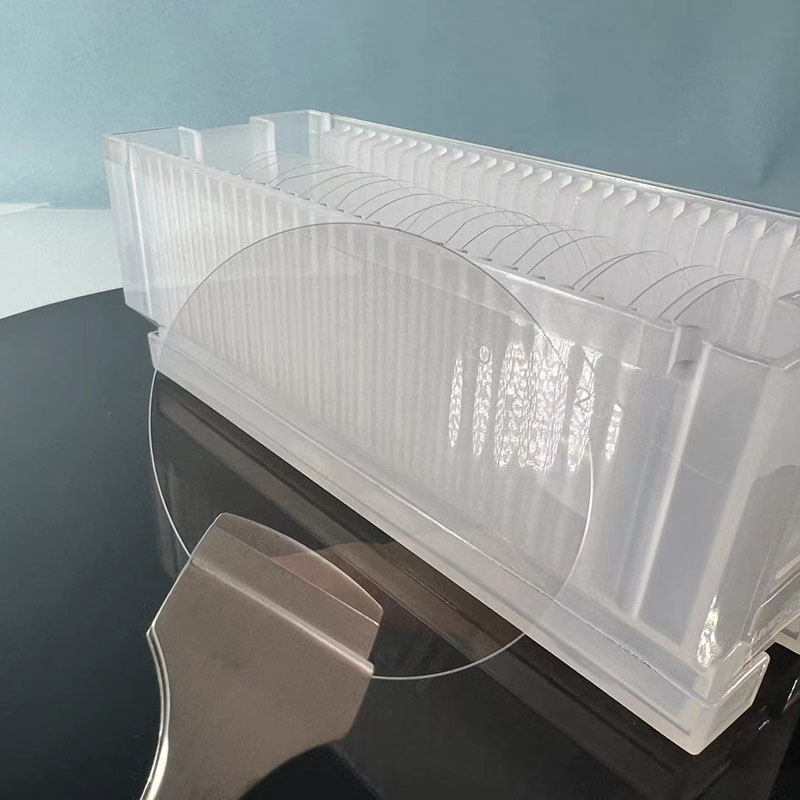

| Makulidwe (L × W × H) | 4000 x 3400 x 4300 mm kapena makonda |

| Chipinda cha ng'anjo chambiri | 1100 mm |

| Kukweza mphamvu | 50kg pa |

| Digiri ya vacuum malire | 10-2Pa(2h pambuyo poyambira ma cell) |

| Chamber pressure kukwera | ≤10Pa/h (pambuyo calcination) |

| M'munsi ng'anjo chivundikiro chokweza sitiroko | 1500 mm |

| Njira yowotchera | Kutentha kwa induction |

| Kutentha kwakukulu mu ng'anjo | 2400 ° C |

| Kutentha kwamagetsi | 2x40kW |

| Kuyeza kutentha | Kuyeza kwa kutentha kwamitundu iwiri |

| Kutentha kosiyanasiyana | 900 ~ 3000 ℃ |

| Kuwongolera kutentha | ±1°C |

| Control pressure range | 1-700 pa |

| Kulondola kwa Pressure Control | 1 ~ 5mbar ± 0.1mbar; 5 ~ 100mbar ± 0.2mbar; 100 ~ 700mbar ± 0.5mbar |

| Njira yotsegula | Kutsitsa kwapansi; |

| Kusintha kosankha | Pawiri kutentha malo kuyeza, kutsitsa forklift. |

Ntchito za XKH:

XKH amapereka ntchito zonse mkombero kwa pakachitsulo carbide ng'anjo CVD, kuphatikizapo makonda zida (kutentha zone kamangidwe, mpweya dongosolo kasinthidwe), ndondomeko chitukuko (crystal kulamulira, chilema kukhathamiritsa), maphunziro luso (ntchito ndi kukonza) ndi pambuyo-malonda thandizo (zigawo zosungirako zigawo zikuluzikulu, matenda akutali) kuthandiza makasitomala kukwaniritsa apamwamba SiC gawo lapansi kupanga misa. Ndipo perekani ntchito zopititsa patsogolo ntchito kuti mupititse patsogolo zokolola za kristalo ndikukula bwino.