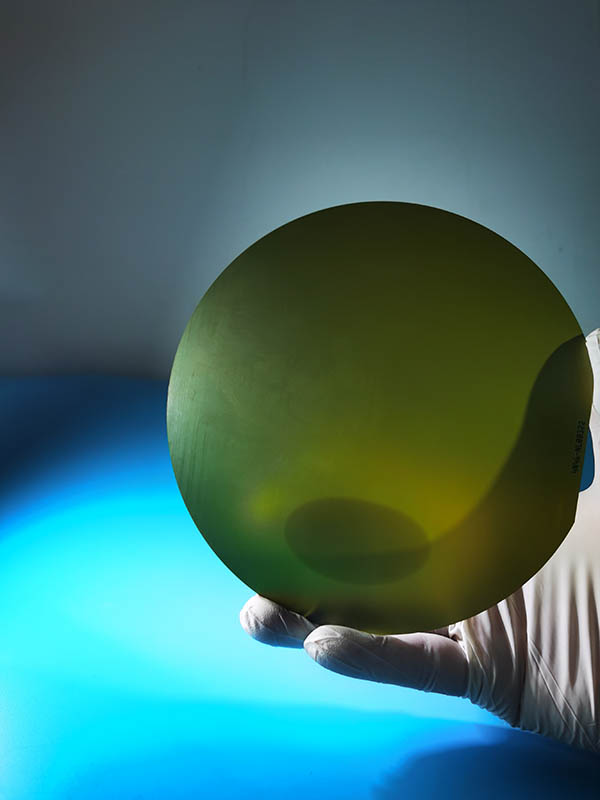

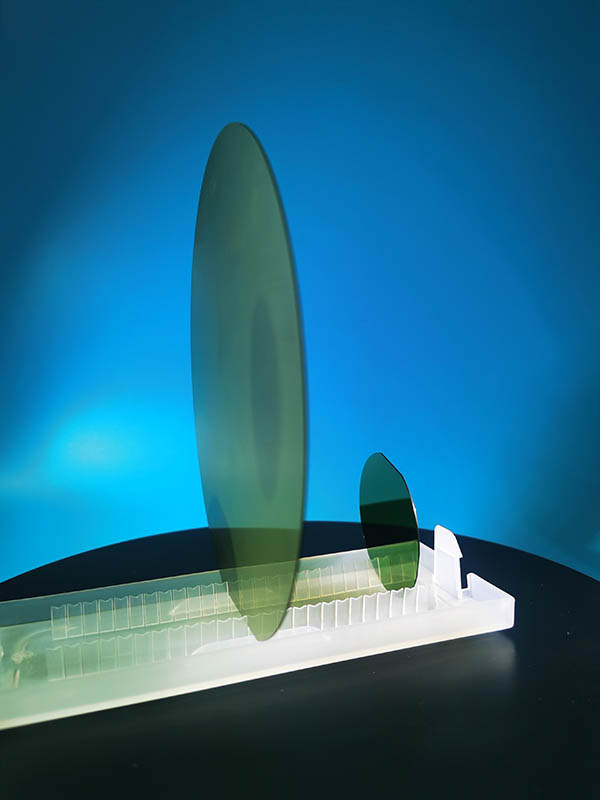

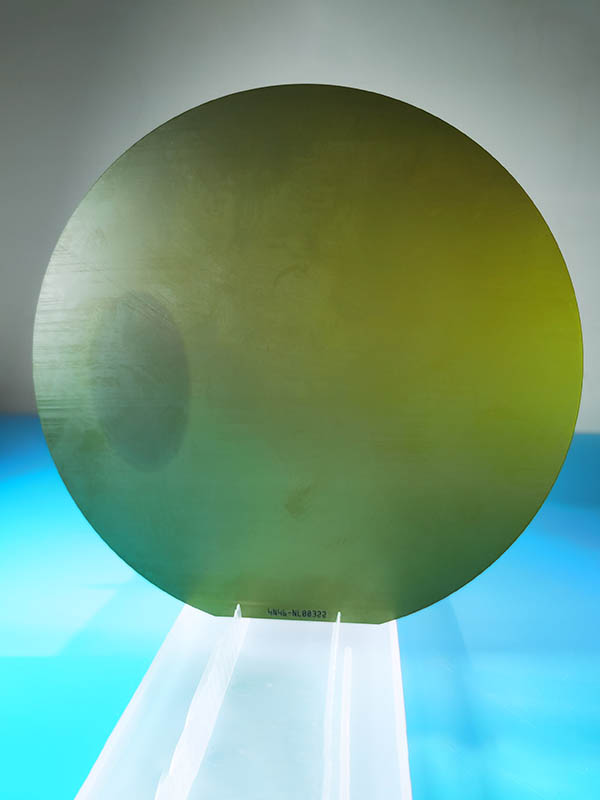

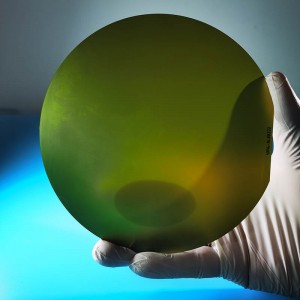

8Inch 200mm 4H-N SiC Wafer Conductive dummy kafukufuku kalasi

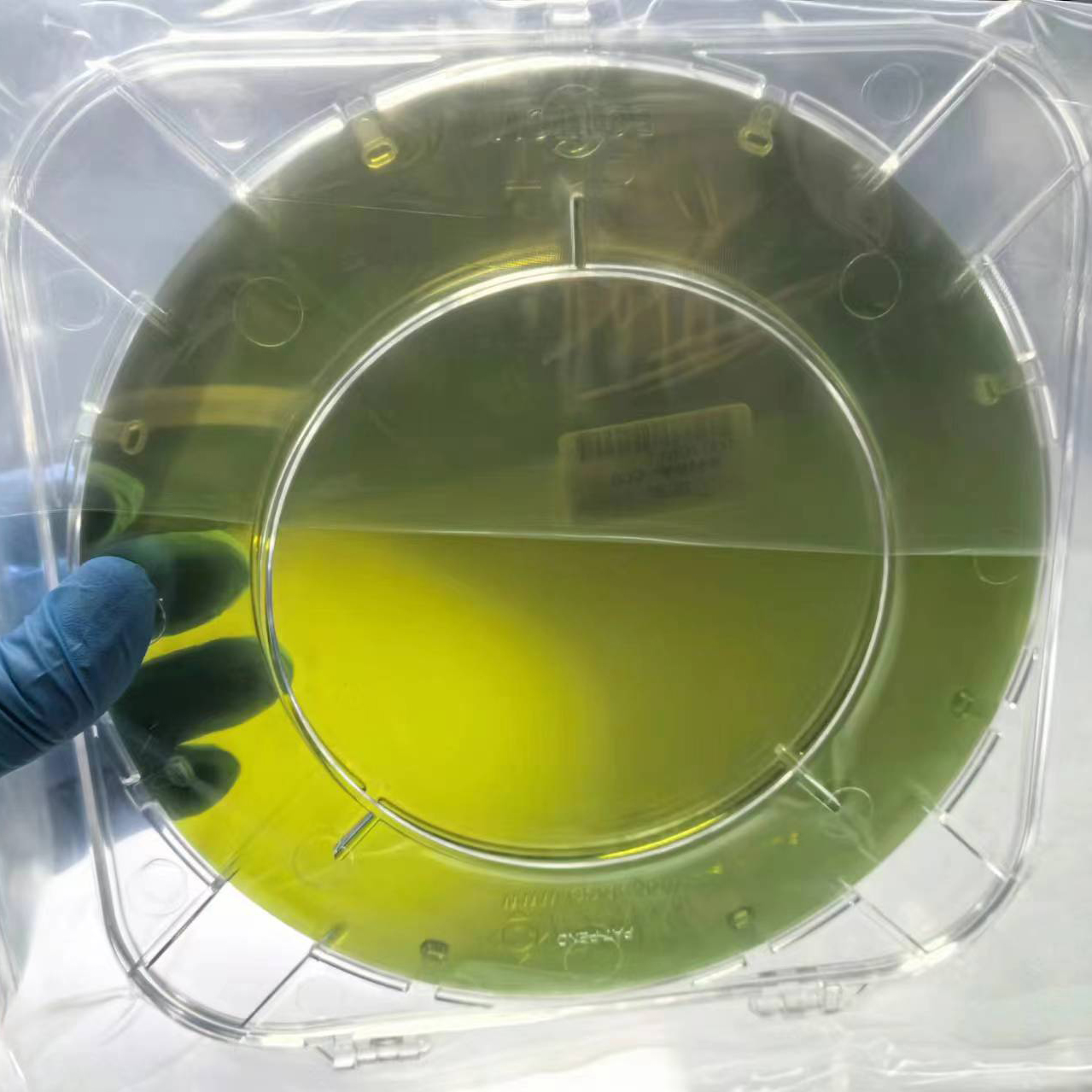

Chifukwa cha mawonekedwe ake apadera akuthupi ndi amagetsi, 200mm SiC wafer semiconductor material amagwiritsidwa ntchito popanga zida zowoneka bwino, zotentha kwambiri, zosagwira ma radiation, komanso zida zamagetsi zothamanga kwambiri. Mtengo wa gawo la 8inch SiC ukuchepa pang'onopang'ono pomwe ukadaulo ukupita patsogolo komanso kufunikira kumakula. Zomwe zachitika posachedwa zaukadaulo zimabweretsa kupanga masikelo opangira ma 200mm SiC wafers. Ubwino waukulu wa zida za SiC wafer semiconductor poyerekeza ndi zowotcha za Si ndi GaAs: Mphamvu yamagetsi ya 4H-SiC panthawi ya kuwonongeka kwa chigumukire ndi yoposa kuyitanitsa kwaukulu kuposa milingo yofananira ya Si ndi GaAs. Izi zimabweretsa kuchepa kwakukulu pachitetezo cha boma Ron. Low on-state resistivity, kuphatikizapo mkulu kachulukidwe panopa ndi matenthedwe conductivity, amalola kugwiritsa ntchito yaing'ono kufa kwa zipangizo mphamvu. Kutentha kwapamwamba kwa SiC kumachepetsa kukana kwa kutentha kwa chip. Zida zamagetsi zamagetsi zozikidwa pa zowotcha za SiC zimakhala zokhazikika pakapita nthawi komanso pa kutentha kokhazikika, zomwe zimatsimikizira kudalirika kwazinthu. Silicon carbide imalimbana kwambiri ndi cheza cholimba, chomwe sichimanyoza zida zamagetsi za chip. Kutentha kocheperako kwambiri kwa kristalo (kupitilira 6000C) kumakupatsani mwayi wopanga zida zodalirika zogwirira ntchito movutikira komanso ntchito zapadera. Pakadali pano, titha kupereka zowotcha zazing'ono za 200mmSiC mosalekeza komanso mosalekeza ndikukhala ndi katundu m'nyumba yosungiramo zinthu.

Kufotokozera

| Nambala | Kanthu | Chigawo | Kupanga | Kafukufuku | Dummy |

| 1. Zigawo | |||||

| 1.1 | polytype | -- | 4H | 4H | 4H |

| 1.2 | kuyang'ana pamwamba | ° | <11-20>4±0.5 | <11-20>4±0.5 | <11-20>4±0.5 |

| 2. Parameter yamagetsi | |||||

| 2.1 | dopant | -- | n-mtundu wa Nayitrogeni | n-mtundu wa Nayitrogeni | n-mtundu wa Nayitrogeni |

| 2.2 | resistivity | uwu ·cm | 0.015 ~ 0.025 | 0.01~0.03 | NA |

| 3. Mawotchi parameter | |||||

| 3.1 | awiri | mm | 200±0.2 | 200±0.2 | 200±0.2 |

| 3.2 | makulidwe | μm | 500 ± 25 | 500 ± 25 | 500 ± 25 |

| 3.3 | Notch orientation | ° | [1- 100] ± 5 | [1- 100] ± 5 | [1- 100] ± 5 |

| 3.4 | Kuzama kwa Notch | mm | 1-1.5 | 1-1.5 | 1-1.5 |

| 3.5 | LTV | μm | ≤5(10mm*10mm) | ≤5(10mm*10mm) | ≤10(10mm*10mm) |

| 3.6 | TTV | μm | ≤10 | ≤10 | ≤15 |

| 3.7 | Kugwada | μm | -25-25 | -45-45 | - 65-65 |

| 3.8 | Warp | μm | ≤30 | ≤50 | ≤70 |

| 3.9 | AFM | nm | Ra≤0.2 | Ra≤0.2 | Ra≤0.2 |

| 4. Kapangidwe | |||||

| 4.1 | kachulukidwe ka micropipe | ndi cm2 | ≤2 | ≤10 | ≤50 |

| 4.2 | zitsulo | ma atomu/cm2 | ≤1E11 | ≤1E11 | NA |

| 4.3 | TSD | ndi cm2 | ≤500 | ≤1000 | NA |

| 4.4 | BPD | ndi cm2 | ≤2000 | ≤5000 | NA |

| 4.5 | TED | ndi cm2 | ≤7000 | ≤10000 | NA |

| 5. Khalidwe labwino | |||||

| 5.1 | kutsogolo | -- | Si | Si | Si |

| 5.2 | kumaliza pamwamba | -- | Si-nkhope CMP | Si-nkhope CMP | Si-nkhope CMP |

| 5.3 | chidutswa | mkate / mkate | ≤100(kukula≥0.3μm) | NA | NA |

| 5.4 | zikande | mkate / mkate | ≤5, Total Utali≤200mm | NA | NA |

| 5.5 | M'mphepete tchipisi/ma indents/ming'alu/madontho/kuipitsidwa | -- | Palibe | Palibe | NA |

| 5.6 | Magawo a polytype | -- | Palibe | Chigawo ≤10% | Chigawo ≤30% |

| 5.7 | chizindikiro chakutsogolo | -- | Palibe | Palibe | Palibe |

| 6. Mmbuyo khalidwe | |||||

| 6.1 | kumaliza kumbuyo | -- | C-nkhope MP | C-nkhope MP | C-nkhope MP |

| 6.2 | zikande | mm | NA | NA | NA |

| 6.3 | Kumbuyo zolakwika m'mphepete chips / indents | -- | Palibe | Palibe | NA |

| 6.4 | Msana roughness | nm | Ra≤5 | Ra≤5 | Ra≤5 |

| 6.5 | Kulemba kumbuyo | -- | Notch | Notch | Notch |

| 7. Mphepete | |||||

| 7.1 | m'mphepete | -- | Chamfer | Chamfer | Chamfer |

| 8. Phukusi | |||||

| 8.1 | kuyika | -- | Epi-okonzeka ndi vacuum kuyika | Epi-okonzeka ndi vacuum kuyika | Epi-okonzeka ndi vacuum kuyika |

| 8.2 | kuyika | -- | Zophika zambiri kupaka makaseti | Zophika zambiri kupaka makaseti | Zophika zambiri kupaka makaseti |

Chithunzi chatsatanetsatane