Wafer Orientation System ya Crystal Orientation Measurement

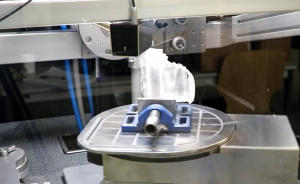

Equipment Introduction

Zida zoyang'anira wafer ndi zida zolondola zomwe zimatengera mfundo za X-ray diffraction (XRD), zomwe zimagwiritsidwa ntchito makamaka popanga semiconductor, zida zowoneka bwino, zoumba, ndi mafakitale ena a crystalline.

Zida izi zimatsimikizira mawonekedwe a crystal lattice ndikuwongolera njira zodulira kapena kupukuta. Zinthu zazikuluzikulu zikuphatikiza:

- Miyezo yolondola kwambiri:Wokhoza kuthetsa ndege za crystallographic zokhala ndi ma angular mpaka 0.001 ° .

- Zitsanzo zazikulu zogwirizana:Imathandizira zowotcha mpaka 450 mm m'mimba mwake ndi zolemera za 30 kg, zoyenera zida ngati silicon carbide (SiC), safiro, ndi silicon (Si).

- Modular Design:Zochita zokulirapo zikuphatikiza kusanthula kwa ma curve curve, mapu a zolakwika za 3D, ndi zida zosungiramo zitsanzo zingapo.

Key Technical Parameters

| Gulu la Parameter | Makhalidwe abwino/Masinthidwe |

| Chithunzi cha X-ray | Cu-Kα (0.4 × 1 mm malo olunjika), 30 kV accelerating voltage, 0–5 mA chubu chosinthika chapano |

| Angular Range | θ: -10 ° mpaka +50 °; 2θ: -10° mpaka +100° |

| Kulondola | Kupendekeka kwa ngodya: 0.001 °, kuzindikira cholakwika chapamtunda: ± 30 arcseconds (kugwedezeka kopindika) |

| Kuthamanga kwa Scan | Omega scan imamaliza kuyang'ana kwathunthu kwa lattice mumasekondi 5; Kujambula kwa Theta kumatenga ~ mphindi imodzi |

| Chitsanzo cha Stage | V-groove, kuyamwa pneumatic, kuzungulira kozungulira, kumagwirizana ndi zowotcha za 2-8-inch |

| Ntchito Zowonjezera | Kusanthula kwa ma curve curve, mapu a 3D, chida chodulira, kuzindikira cholakwika cha kuwala (zokanda, ma GB) |

Ntchito Mfundo

1. X-ray Diffraction Foundation

- Ma X-ray amalumikizana ndi nyukiliya ya atomiki ndi ma elekitironi mu kristalo wa kristalo, kutulutsa mawonekedwe osinthika. Chilamulo cha Bragg (nλ = 2d sinθ) chimayang'anira ubale wapakati pa ngodya zosiyanitsira (θ) ndi malo otsetsereka (d).

Ma detectors amajambula machitidwewa, omwe amawunikidwa kuti amangenso mawonekedwe a crystallographic.

2. Omega Scanning Technology

- Krustalo imazungulira mosalekeza mozungulira mozungulira pomwe ma X-ray amawunikira.

- Zowunikira zimasonkhanitsa ma siginecha osokoneza ndege zingapo zamakristalo, zomwe zimapangitsa kutsimikiza kwathunthu kwa lattice mumasekondi 5.

3. Rocking Curve Analysis

- Makona a kristalo osasunthika okhala ndi ma X-ray osiyanasiyana kuti athe kuyeza m'lifupi mwake (FWHM), kuwunika zolakwika za lattice ndi kupsinjika.

4. Automated Control

- PLC ndi mawonekedwe a touchscreen amathandizira ma angle odulira, mayankho anthawi yeniyeni, ndikuphatikizana ndi makina odulira kuti azitha kuwongolera.

Ubwino ndi Mbali

1. Kulondola ndi Mwachangu

- Kulondola kwapang'onopang'ono ± 0.001 °, kusamvana kwachilema <30 arcseconds.

- Kuthamanga kwa scan ya Omega ndi 200 × mwachangu kuposa masikelo achikhalidwe a Theta.

2. Modularity ndi Scalability

- Zowonjezereka kuti zigwiritsidwe ntchito mwapadera (mwachitsanzo, zowotcha za SiC, masamba a turbine).

- Imaphatikizana ndi machitidwe a MES pakuwunikira nthawi yeniyeni yopanga.

3. Kugwirizana ndi Kukhazikika

- Imakhala ndi zitsanzo zosaoneka bwino (monga ma ingots osweka a safiro).

- Mapangidwe oziziritsa mpweya amachepetsa zosowa zosamalira.

4. Ntchito Yanzeru

- Kudina kumodzi ndikukonza zochita zambiri.

- Kuwongolera mokhazikika ndi makhiristo olozera kuti muchepetse zolakwika zamunthu.

Mapulogalamu

1. Kupanga kwa Semiconductor

- Mawonekedwe a Wafer dicing: Imatsimikizira Si, SiC, GaN wafer orientation kuti muzitha kudula bwino.

- Kujambula kwa zolakwika: Kumazindikiritsa zong'ambika pamwamba kapena zosunthika kuti ziwonjezeke zokolola.

2. Zida Zowonera

- Makhiristo opanda mzere (mwachitsanzo, LBO, BBO) pazida za laser.

- Chizindikiro cha safiro cha safiro cha magawo a LED.

3. Ceramics ndi Composites

- Imawunika momwe mbewu zimayendera mu Si3N4 ndi ZrO2 pazogwiritsa ntchito kutentha kwambiri.

4. Research and Quality Control

- Mayunivesite / ma lab opangira zinthu zatsopano (mwachitsanzo, ma aloyi apamwamba kwambiri).

- Industrial QC kuti mutsimikizire kusasinthika kwa batch.

Ntchito za XKH

XKH imapereka chithandizo chokwanira chaukadaulo pazida zowongoka, kuphatikiza kuyika, kukhathamiritsa kwa magawo, kusanthula kwama curve, ndi mapu a zolakwika za 3D. Mayankho ogwirizana (mwachitsanzo, ukadaulo wa ingot stacking) amaperekedwa kuti apititse patsogolo luso la semiconductor ndi optical material kupanga ndi kupitirira 30%. Gulu lodzipatulira limachita maphunziro apamalo, pomwe thandizo lakutali la 24/7 ndikusintha mwachangu mbali zina zimatsimikizira kudalirika kwa zida.