TGV Glass imayika 12inch wafer Kuboola kwagalasi

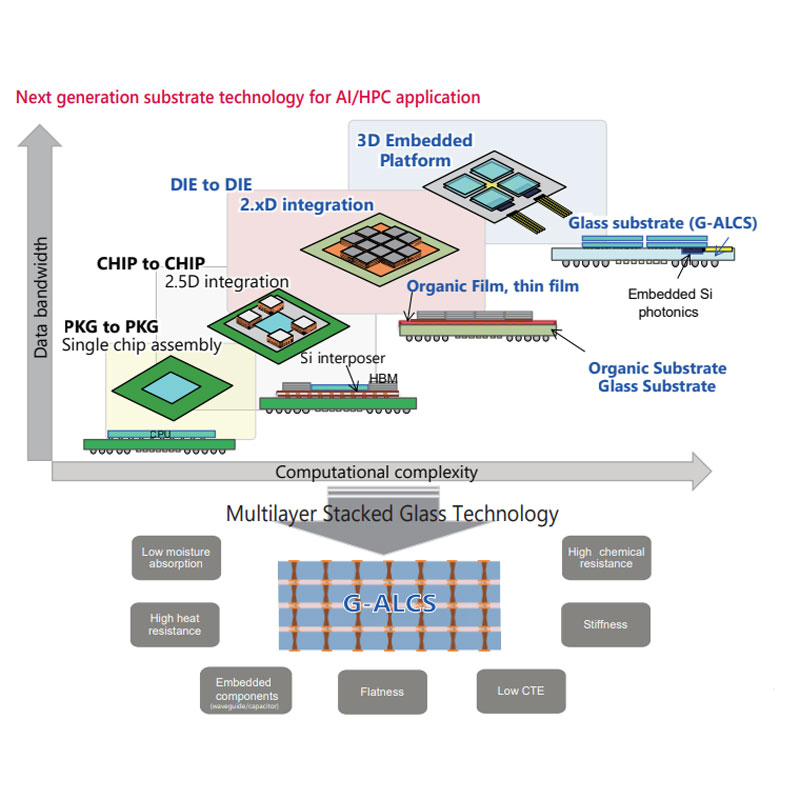

Magalasi a galasi amachita bwino kwambiri potengera kutentha, kukhazikika kwa thupi, komanso kutentha kwambiri komanso kusagwirizana ndi zovuta zowonongeka kapena zowonongeka chifukwa cha kutentha kwakukulu;

Kuphatikiza apo, mawonekedwe apadera amagetsi apakati pagalasi amalola kutayika kochepa kwa dielectric, kulola chizindikiro chomveka bwino komanso kufalitsa mphamvu. Zotsatira zake, kutayika kwa mphamvu panthawi yotumizira ma siginecha kumachepetsedwa ndipo mphamvu yonse ya chip imakulitsidwa mwachilengedwe. Makulidwe a gawo lapansi lapakati pagalasi amatha kuchepetsedwa ndi theka poyerekeza ndi pulasitiki ya ABF, ndipo kupatulira kumathandizira kuthamanga kwa ma siginecha komanso mphamvu zamagetsi.

Tekinoloje yopanga mabowo ya TGV:

Njira yokhotakhota ya laser imagwiritsidwa ntchito kukopa mayendedwe osalekeza kudzera pa laser pulsed, kenako galasi lopaka laser limayikidwa mu hydrofluoric acid yankho kuti liziwombera. Kuchuluka kwa magalasi a denaturation zone mu hydrofluoric acid kumathamanga kuposa magalasi osapangidwa ndi magalasi kuti apange mabowo.

TGV lembani:

Choyamba, mabowo akhungu a TGV amapangidwa. Kachiwiri, wosanjikiza wa mbewu adayikidwa mkati mwa dzenje lakhungu la TGV ndi vapor deposition (PVD). Chachitatu, electroplating yapansi-mmwamba imakwaniritsa kudzazidwa kosasunthika kwa TGV; Potsirizira pake, kupyolera mu kugwirizana kwakanthawi, kugaya msana, kuwonekera kwa mkuwa kwa chemical mechanical polishing (CMP), kusagwirizana, kupanga TGV zitsulo zodzaza mbale.

Chithunzi chatsatanetsatane