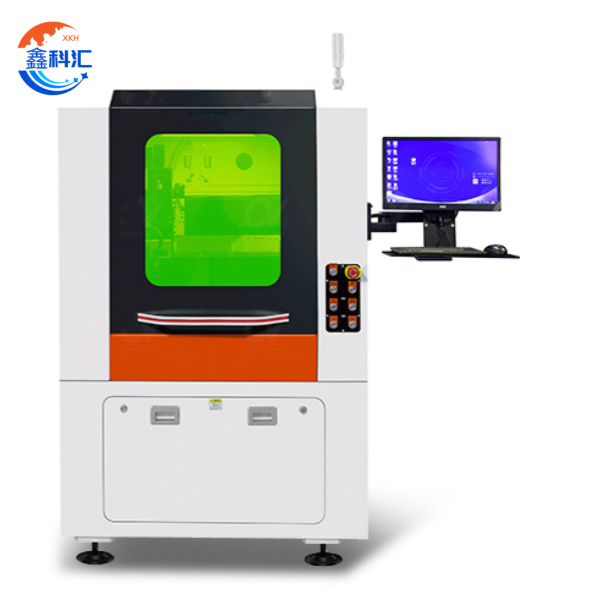

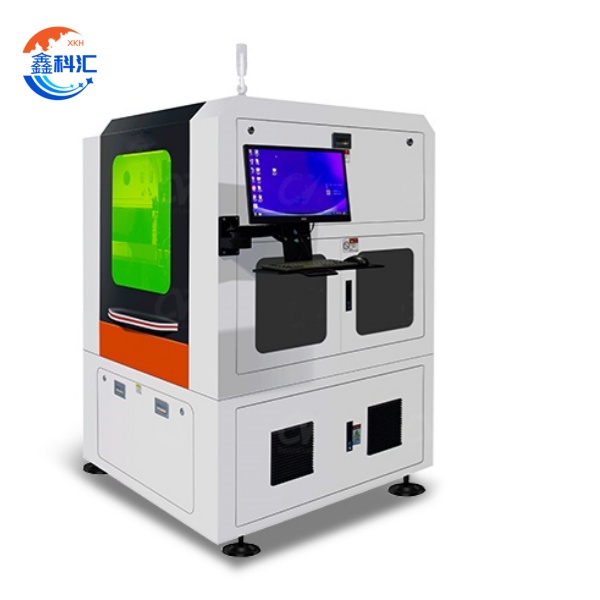

Small tebulo laser kukhomerera makina 1000W-6000W osachepera kabowo 0.1MM angagwiritsidwe ntchito zitsulo galasi ceramic zipangizo

Zogwiritsidwa ntchito

1. Zida zachitsulo: monga aluminium, mkuwa, titaniyamu aloyi, zitsulo zosapanga dzimbiri, etc.

2. Zida zopanda zitsulo: monga pulasitiki (kuphatikizapo polyethylene PE, polypropylene PP, polyester PET ndi mafilimu ena apulasitiki), galasi (kuphatikizapo galasi wamba, galasi lapadera monga galasi loyera kwambiri, galasi la K9, galasi la borosilicate, galasi la quartz, etc. pa.

3. Zophatikizika: zopangidwa ndi zida ziwiri kapena zingapo zokhala ndi zinthu zosiyanasiyana kudzera munjira zakuthupi kapena zamankhwala, zokhala ndi zinthu zambiri.

4.Zida Zapadera: M'madera enieni, makina a laser punching angagwiritsidwenso ntchito pokonza zipangizo zina zapadera.

Specification parameters

| Dzina | Deta |

| Mphamvu ya laser: | 1000W-6000W |

| Kudula molondola: | ± 0.03MM |

| Kabowo kakang'ono kwambiri: | 0.1MM |

| Utali wodula: | 650MM×800MM |

| Kulondola kwamalo: | ≤± 0.008MM |

| Kubwerezabwereza: | 0.008MM |

| Kudula gasi: | Mpweya |

| Mtundu wokhazikika: | Pneumatic m'mphepete clamping, fixture thandizo |

| Dongosolo Loyendetsa: | Maginito kuyimitsidwa linear motor |

| Kudula makulidwe | 0.01MM-3MM |

Ubwino waukadaulo

1.Kubowola mogwira mtima: Kugwiritsa ntchito mtengo wa laser high-energy for non-contact processing, mofulumira, 1 sekondi kuti amalize kukonza mabowo ang'onoang'ono.

2.Kusamalitsa kwakukulu: Mwa kulamulira bwino mphamvu, kuthamanga kwafupipafupi ndi malo owonetsetsa a laser, ntchito yobowola ndi micron molondola ikhoza kutheka.

3. Zogwiritsidwa ntchito kwambiri: zimatha kukonza zinthu zosiyanasiyana zowonongeka, zovuta kuzikonza ndi zipangizo zapadera, monga pulasitiki, mphira, zitsulo (zitsulo zosapanga dzimbiri, aluminiyamu, mkuwa, titaniyamu alloy, etc.), galasi, ceramics ndi zina zotero.

4. Kugwira ntchito mwanzeru: Makina a laser punching ali ndi zida zapamwamba zowongolera manambala, zomwe zimakhala zanzeru kwambiri komanso zosavuta kuphatikizira ndi mapangidwe othandizidwa ndi makompyuta ndi makina opanga makina opangidwa ndi makompyuta kuti azindikire mapulogalamu ofulumira komanso kukhathamiritsa kwa chiphaso chovuta komanso njira yopangira.

Mikhalidwe yogwirira ntchito

1.Diversity: akhoza kuchita zosiyanasiyana zovuta mawonekedwe dzenje processing, monga mabowo ozungulira, mabowo lalikulu, mabowo makona atatu ndi zina mwapadera zooneka ngati mabowo.

2.Ubwino wapamwamba: Ubwino wa dzenje ndi wapamwamba, m'mphepete mwake ndi wosalala, palibe kumverera kwaukali, ndipo kusinthika kumakhala kochepa.

3.Automation: Ikhoza kumaliza kukonza kabowo kakang'ono ndi kukula kofanana ndi kabowo kakang'ono ndi kugawa yunifolomu nthawi imodzi, ndikuthandizira kukonza dzenje lamagulu popanda kulowererapo pamanja.

Zida mbali

■ Kukula kochepa kwa zida, kuthetsa vuto la malo opapatiza.

■ High mwatsatanetsatane, dzenje pazipita akhoza kufika 0.005mm.

■ Zida ndi zosavuta kugwiritsa ntchito komanso zosavuta kugwiritsa ntchito.

■ Gwero la kuwala likhoza kusinthidwa malinga ndi zipangizo zosiyanasiyana, ndipo kugwirizana kumakhala kolimba.

■ Malo ang'onoang'ono omwe amakhudzidwa ndi kutentha, kuchepa kwa okosijeni kuzungulira mabowo.

Malo ogwiritsira ntchito

1. Makampani opanga zamagetsi

●Printed Circuit Board (PCB) kukhomerera:

Makina a Microhole: Amagwiritsidwa ntchito popanga ma microholes okhala ndi mainchesi osakwana 0.1mm pa PCBS kuti akwaniritse zosowa zama board a high-density interconnect (HDI).

Mabowo akhungu ndi okwiriridwa: Kukonza mabowo akhungu ndi okwiriridwa mu PCBS yamitundu ingapo kuti apititse patsogolo magwiridwe antchito ndi kuphatikiza kwa bolodi.

● Kupaka kwa semiconductor:

Kubowola chimango chotsogolera: Mabowo olondola amapangidwa mu chimango chotsogolera cha semiconductor kuti alumikizitse chip kudera lakunja.

Thandizo la Wafer kudula: Khomeretsani mabowo muwafa kuti muthandizire kudula ndi kulongedza.

2. Makina olondola

●Kukonza magawo ang'onoang'ono:

Kubowola mwatsatanetsatane: Kukonza mabowo olondola kwambiri pamagiya ang'onoang'ono kuti azitha kutengera njira zolondola.

Kubowola kwa gawo la sensa: Kukonza ma microholes pazigawo za sensa kuti muwongolere chidwi komanso liwiro la kuyankha kwa sensa.

●Kupanga Nkhungu:

Bowo lozizirirapo nkhungu: Kukonza dzenje loziziritsa pa nkhungu ya jekeseni kapena nkhungu yoponyera kufa kuti muthe kuwongolera kutentha kwa nkhungu.

Kukonza mpweya: Kukonza timitsempha tating'onoting'ono pa nkhungu kuti tichepetse kuwonongeka.

3. Zipangizo zamankhwala

● Zida Zopangira Opaleshoni Zocheperako:

Kuboola kwa catheter: Ma Microholes amapangidwa m'ma catheter opangira maopaleshoni ochepa kuti apereke mankhwala kapena ngalande zamadzimadzi.

Zigawo za Endoscope: Mabowo olondola amapangidwa mu mandala kapena mutu wa chida cha endoscope kuti chiwongolerocho chizigwira ntchito bwino.

● Dongosolo Lopereka Mankhwala:

Kubowola kwa Microneedle Array: Kuchiza ma microholes pa chigamba cha mankhwala kapena ma microneedle array kuwongolera kuchuluka kwa mankhwala.

Kubowola kwa biochip: Ma Microholes amasinthidwa pa biochips kuti azindikire chikhalidwe cha ma cell.

4. Optical zipangizo

● Cholumikizira cha Fiber Optic:

Kubowola kwa dzenje la Optical fiber: Kupanga ma microholes kumapeto kwa cholumikizira cholumikizira kuti muwongolere magwiridwe antchito amawu.

Kupanga ma fiber array: Kukonza mabowo olondola kwambiri pa mbale ya fiber array kuti athe kulumikizana ndi njira zambiri.

● Zosefera zowonera:

Kubowola zosefera: Kukonza ma microholes pa fyuluta ya kuwala kuti mukwaniritse kusankha kwa mafunde enaake.

Makina opangira ma diffractive element: Machining ma microholes pa zinthu zowoneka bwino za laser kupatukana kapena kupanga.

5. Kupanga magalimoto

●Njira jakisoni wamafuta:

Kuboola kwa jekeseni: Kukonza mabowo ang'onoang'ono pamphuno ya jakisoni kuti muwonjezere mphamvu ya atomiki yamafuta ndikuwonjezera kuyaka bwino.

●Kupanga masensa:

Kubowola kwa sensor ya Pressure: Machining ma microholes pa diaphragm ya pressure sensor kuti mumve zambiri komanso kulondola kwa sensor.

● Batiri lamphamvu:

Kubowola Battery pole Chip: Kusintha ma microholes pa tchipisi ta batire la lithiamu kuti mupititse patsogolo kulowetsa kwa ma electrolyte ndi mayendedwe a ion.

XKH imapereka ntchito zambiri zoyima pazigawo zing'onozing'ono za laser perforators, kuphatikizapo: Kufunsira kwa akatswiri ogulitsa, kupanga makonda apulogalamu, zida zapamwamba kwambiri, kuyika bwino ndi kutumiza, maphunziro atsatanetsatane ogwirira ntchito, kuwonetsetsa kuti makasitomala amapeza ntchito yabwino kwambiri, yolondola komanso yosasamala pomenya nkhondo.

Chithunzi chatsatanetsatane