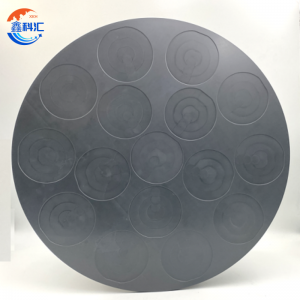

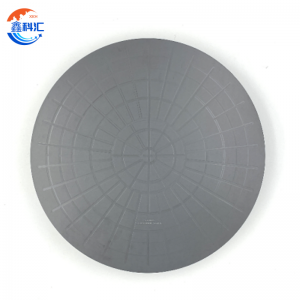

Silicon Carbide Ceramic Tray - Ma tray Olimba, Ogwira Ntchito Kwambiri Opangira Ma Thermal ndi Chemical

Chithunzi chatsatanetsatane

Chiyambi cha Zamalonda

Silicon carbide (SiC) matayala a ceramic ndi zigawo zogwira ntchito kwambiri zomwe zimagwiritsidwa ntchito kwambiri m'malo otentha kwambiri, olemetsa kwambiri, komanso m'mafakitale ovuta kwambiri. Opangidwa kuchokera ku zida zapamwamba za silicon carbide ceramic, matayalawa adapangidwa kuti apereke mphamvu zapadera zamakina, matenthedwe apamwamba kwambiri, komanso kukana kwambiri kugwedezeka kwamafuta, okosijeni, ndi dzimbiri. Makhalidwe awo olimba amawapangitsa kukhala oyenerera ntchito zosiyanasiyana zamafakitale kuphatikiza kupanga semiconductor, kukonza kwa photovoltaic, sintering of powder metallurgy parts, ndi zina.

Ma tray a silicon carbide amagwira ntchito ngati zonyamulira zofunikira kapena zothandizira panthawi yamankhwala otenthetsera pomwe kulondola kwazithunzi, kukhulupirika kwamapangidwe, komanso kukana kwamankhwala ndikofunikira. Poyerekeza ndi zida zakale za ceramic monga alumina kapena mullite, ma tray a SiC amapereka magwiridwe antchito apamwamba kwambiri, makamaka m'mikhalidwe yomwe imaphatikizapo kupalasa njinga mobwerezabwereza komanso mlengalenga mwaukali.

Njira Yopangira & Kapangidwe kazinthu

Kupanga ma tray a ceramic a SiC kumaphatikizapo uinjiniya wolondola komanso matekinoloje apamwamba a sintering kuti awonetsetse kuti kachulukidwe kwambiri, mawonekedwe ofananirako, komanso magwiridwe antchito osasinthika. Masitepe ambiri ndi awa:

-

Kusankha Kwazinthu Zopangira

High-purity silicon carbide powder (≥99%) imasankhidwa, nthawi zambiri ndi kuwongolera kukula kwa tinthu ndi zonyansa zochepa kuti zitsimikizire mawotchi apamwamba komanso matenthedwe. -

Kupanga Njira

Kutengera mawonekedwe a tray, njira zosiyanasiyana zopangira zimagwiritsidwa ntchito:-

Cold Isostatic Pressing (CIP) ya kachulukidwe kwambiri, ma compact compact

-

Extrusion kapena slip casting kwa mawonekedwe ovuta

-

Jakisoni wopangira ma geometries olondola, atsatanetsatane

-

-

Sintering Techniques

Thupi lobiriwira limatenthedwa ndi kutentha kwambiri, nthawi zambiri pafupifupi 2000 ° C, pansi pa mlengalenga wa inert kapena vacuum. Njira zodziwika bwino za sintering ndi izi:-

Reaction Bonded SiC (RB-SiC)

-

Pressureless Sintered SiC (SSiC)

-

Recrystallized SiC (RBSiC)

Njira iliyonse imabweretsa zinthu zosiyana pang'ono, monga porosity, mphamvu, ndi matenthedwe matenthedwe.

-

-

Precision Machining

Pambuyo pa sintering, ma tray amapangidwa kuti azitha kupirira molimba, kumaliza kosalala komanso kusalala. Zochizira zapamwamba monga kupukutira, kupera, ndi kupukuta zitha kugwiritsidwa ntchito potengera zosowa za makasitomala.

Mapulogalamu Okhazikika

Silicon carbide ceramic trays amagwiritsidwa ntchito m'mafakitale osiyanasiyana chifukwa cha kusinthasintha kwawo komanso kulimba mtima. Ntchito zodziwika bwino ndi izi:

-

Makampani a Semiconductor

Ma tray a SiC amagwiritsidwa ntchito ngati zonyamulira panthawi yophatikizika, kufalikira, makutidwe ndi okosijeni, epitaxy, ndi njira zoyikira. Kukhazikika kwawo kumatsimikizira kugawidwa kwa kutentha kofanana ndi kuipitsidwa kochepa. -

Photovoltaic (PV) Makampani

Pakupanga ma cell a solar, ma tray a SiC amathandizira ma ingots a silicon kapena zowotcha panthawi yotentha kwambiri komanso masitepe akuwotcha. -

Powder Metallurgy ndi Ceramics

Amagwiritsidwa ntchito pothandizira pakupanga zitsulo za ufa, zoumba, ndi zinthu zophatikizika. -

Magalasi ndi Zowonetsera

Amagwiritsidwa ntchito ngati thireyi kapena nsanja zopangira magalasi apadera, magawo a LCD, kapena zida zina zowunikira. -

Chemical Processing ndi Matenthedwe Otentha

Zimagwira ntchito ngati zonyamulira zosagwira dzimbiri m'mayakitala amankhwala kapena ngati matayala othandizira kutentha mung'anjo zopanda mpweya komanso zowongolera mumlengalenga.

Mawonekedwe Ofunikira

-

✅Kukhazikika kwapadera kwa Thermal Stability

Imapirira kugwiritsidwa ntchito mosalekeza kutentha mpaka 1600-2000 ° C popanda kupotoza kapena kuwononga. -

✅Mphamvu Zapamwamba Zamakina

Amapereka mphamvu zosunthika kwambiri (nthawi zambiri> 350 MPa), kuonetsetsa kulimba kwa nthawi yayitali ngakhale pansi pa katundu wambiri. -

✅Thermal Shock Resistance

Kuchita bwino kwambiri m'malo okhala ndi kusinthasintha kwachangu kwa kutentha, kuchepetsa chiopsezo cha kusweka. -

✅Kukaniza kwa Corrosion ndi Oxidation

Kukhazikika kwamankhwala mu ma acid ambiri, ma alkali, ndi oxidizing/kuchepetsa mipweya, yoyenera kupangira mankhwala ovuta. -

✅Kulondola kwa Dimensional ndi Flatness

Amapangidwa mwatsatanetsatane kwambiri, kuwonetsetsa kuti ntchito yofananira ndi yogwirizana ndi makina azida. -

✅Utali Wamoyo & Kugwiritsa Ntchito Ndalama

Mitengo yotsika m'malo ndi kuchepetsedwa kwa ndalama zokonzetsera zimapangitsa kuti ikhale yotsika mtengo pakapita nthawi.

Mfundo Zaukadaulo

| Parameter | Mtengo Wodziwika |

|---|---|

| Zakuthupi | Reaction Bonded SiC / Sintered SiC |

| Max. Kutentha kwa Ntchito | 1600-2000°C |

| Flexural Mphamvu | ≥350 MPa |

| Kuchulukana | ≥3.0 g/cm³ |

| Thermal Conductivity | ~120–180 W/m·K |

| Pamwamba Pamwamba | ≤ 0.1 mm |

| Makulidwe | 5-20 mm (zosintha mwamakonda) |

| Makulidwe | Standard: 200 × 200 mm, 300 × 300 mm, etc. |

| Pamwamba Pamwamba | Opangidwa, opukutidwa (akapempha) |

Mafunso Ofunsidwa Kawirikawiri (FAQ)

Q1: Kodi matayala a silicon carbide angagwiritsidwe ntchito m'ng'anjo za vacuum?

A:Inde, ma tray a SiC ndi abwino kwa malo opanda vacuum chifukwa cha kutsika kwawo, kukhazikika kwamankhwala, komanso kukana kutentha kwambiri.

Q2: Kodi mawonekedwe kapena mipata yomwe ilipo?

A:Mwamtheradi. Timapereka ntchito zosinthira makonda kuphatikiza kukula kwa thireyi, mawonekedwe, mawonekedwe apamwamba (mwachitsanzo, ma grooves, mabowo), ndi kupukuta pamwamba kuti tikwaniritse zofunikira zamakasitomala.

Q3: Kodi SiC ikufananiza bwanji ndi ma tray alumina kapena quartz?

A:SiC ili ndi mphamvu zapamwamba, kuyendetsa bwino kwamafuta, komanso kukana kwambiri kugwedezeka kwamafuta ndi dzimbiri lamankhwala. Ngakhale alumina ndiyotsika mtengo, SiC imachita bwino m'malo ovuta.

Q4: Kodi pali makulidwe okhazikika a trays awa?

A:Kukhuthala kumakhala pakati pa 5-20 mm, koma titha kusintha malinga ndi momwe mumagwiritsira ntchito komanso zonyamula katundu.

Q5: Kodi nthawi yotsogolera ya ma tray osinthidwa a SiC ndi iti?

A:Nthawi zotsogola zimasiyanasiyana kutengera zovuta komanso kuchuluka kwake koma nthawi zambiri zimakhala kuyambira masabata a 2 mpaka 4 potengera zomwe mwakonda.

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.