Silicon Carbide Ceramic Fork Arm/Hand

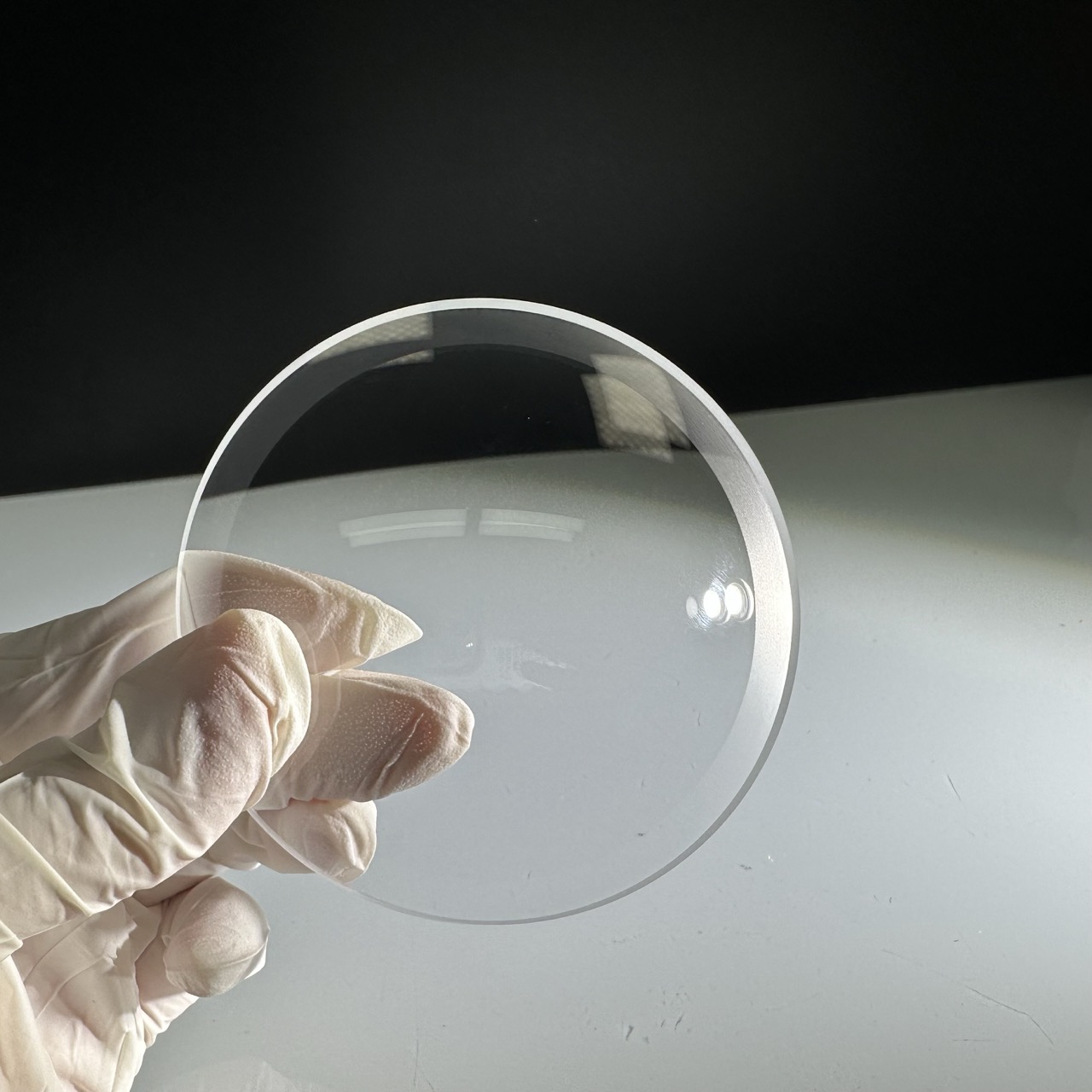

Chithunzi chatsatanetsatane

Kuyambitsa Silicon Carbide Ceramic Fork Arm/Hand

TheSilicon Carbide Ceramic Fork Arm/Handndi gawo lotsogola lopangira makina opangira makina olondola kwambiri, makamaka m'mafakitale a semiconductor ndi optical. Chigawochi chimakhala ndi mawonekedwe apadera a U-mawonekedwe okongoletsedwa kuti azigwira zopindika, kuwonetsetsa mphamvu zamakina komanso kulondola kwapang'onopang'ono pansi pazachilengedwe. Wopangidwa kuchokera ku high-purity silicon carbide ceramic, themkono / dzanjaimapereka kulimba kwapadera, kukhazikika kwamafuta, komanso kukana kwamankhwala.

Pamene zida za semiconductor zikusintha kupita ku ma geometri abwino kwambiri komanso kulolerana kolimba, kufunikira kwa zida zopanda kuipitsidwa komanso zokhazikika zamafuta kumakhala kovuta. TheSilicon Carbide Ceramic Fork Arm/Handamakumana ndi vutoli popereka kutsika kwa tinthu tating'onoting'ono, malo osalala kwambiri, komanso mawonekedwe olimba. Kaya mumayendedwe ophatikizika, malo apansi panthaka, kapena mitu ya zida za robotic, gawoli limapangidwa kuti likhale lodalirika komanso kuti likhale ndi moyo wautali.

Zifukwa zazikulu kusankha iziSilicon Carbide Ceramic Fork Arm/Handzikuphatikizapo:

-

Kuwonjezako pang'ono kwa kutentha kuti muwoneke bwino

-

Kuuma kwakukulu kwa moyo wautali wautumiki

-

Kukaniza ma acid, alkalis, ndi mpweya wotuluka

-

Kugwirizana ndi malo oyeretsa a ISO Class 1

Mfundo Yopanga Silicon Carbide Ceramic Fork Arm/Hand

TheSilicon Carbide Ceramic Fork Arm/Handimapangidwa kudzera mumayendedwe oyendetsedwa bwino a ceramic opangidwa kuti awonetsetse kuti zinthu zakuthupi ndi zapamwamba komanso kusasinthasintha.

1. Kukonzekera Ufa

Njirayi imayamba ndikusankha ufa wa silicon carbide ufa. Ufawu umasakanizidwa ndi zomangira ndi zothandizira kuti zithandizire kukhazikika komanso kulimba. Za ichimkono / dzanja, β-SiC kapena α-SiC ufa amagwiritsidwa ntchito pofuna kutsimikizira kuuma komanso kulimba.

2. Kujambula ndi Preforming

Malinga ndi zovuta zamkono / dzanjakapangidwe, gawolo limapangidwa pogwiritsa ntchito kukanikiza kwa isostatic, kuumba jekeseni, kapena kuponyera. Izi zimalola ma geometries ovuta komanso zomangira zokhala ndi khoma, zomwe ndizofunikira kuti pakhale mawonekedwe opepuka aSilicon Carbide Ceramic Fork Arm/Hand.

3. High-Kutentha Sintering

Sintering imachitika pa kutentha pamwamba pa 2000 ° C mu vacuum kapena argon atmospheres. Gawo ili limasintha thupi lobiriwira kukhala chigawo chokhazikika cha ceramic. The sinteredmkono / dzanjaamakwaniritsa kachulukidwe wapafupi ndi theoretical, ndikupereka mawonekedwe apamwamba amakina ndi matenthedwe.

4. Precision Machining

Post-sintering, ndiSilicon Carbide Ceramic Fork Arm/Handamadutsa diamondi akupera ndi CNC Machining. Izi zimatsimikizira kusalala mkati mwa ± 0.01 mm ndipo zimalola kuphatikizika kwa mabowo okwera ndikupeza zinthu zofunika kwambiri pakuyika kwake mumakina ochita kupanga.

5. Kumaliza Pamwamba

Kupukuta kumachepetsa roughness pamwamba (Ra <0.02 μm), kofunika kuti muchepetse m'badwo wa tinthu tating'onoting'ono. Zovala zosankhidwa za CVD zitha kugwiritsidwa ntchito kuti zithandizire kukana kwa plasma kapena kuwonjezera magwiridwe antchito monga anti-static behavior.

Munthawi yonseyi, ma protocol oyang'anira bwino amagwiritsidwa ntchito kutsimikiziraSilicon Carbide Ceramic Fork Arm/Handimagwira ntchito modalirika pamapulogalamu ovuta kwambiri.

Magawo a Silicon Carbide Ceramic Fork Arm/Hand

| Zofunika Kwambiri za CVD-SIC Coating | ||

| SiC-CVD Properties | ||

| Kapangidwe ka Crystal | FCC β gawo | |

| Kuchulukana | g/cm³ | 3.21 |

| Kuuma | Vickers kuuma | 2500 |

| Ukulu wa Mbewu | μm | 2-10 |

| Chemical Purity | % | 99.99995 |

| Kutentha Mphamvu | J·kg-1 ·K-1 | 640 |

| Kutentha kwa Sublimation | ℃ | 2700 |

| Felexural Mphamvu | MPa (RT 4-point) | 415 |

| Young's Modulus | Gpa (4pt bend, 1300 ℃) | 430 |

| Kukula kwa Thermal (CTE) | 10-6K-1 | 4.5 |

| Thermal conductivity | (W/mK) | 300 |

Kugwiritsa ntchito Silicon Carbide Ceramic Fork Arm/Hand

TheSilicon Carbide Ceramic Fork Arm/Handamagwiritsidwa ntchito kwambiri m'mafakitale omwe chiyero chapamwamba, kukhazikika, ndi makina olondola ndizofunikira. Izi zikuphatikizapo:

1. Kupanga Semiconductor

Mu kupanga semiconductor, theSilicon Carbide Ceramic Fork Arm/Handamagwiritsidwa ntchito kunyamula zowotcha za silicon mkati mwa zida zogwirira ntchito monga zipinda zotsekera, makina oyikapo, ndi zida zowunikira. Kukana kwake kwamafuta ndi kulondola kwake kumapangitsa kuti ikhale yabwino pochepetsa kusalumikizana bwino komanso kuipitsidwa.

2. Onetsani Panel Production

Pakupanga mawonekedwe a OLED ndi LCD, amkono / dzanjaimagwiritsidwa ntchito m'makina osankha ndi malo, pomwe imagwira magalasi osalimba. Kutsika kwake kochepa komanso kuuma kwakukulu kumathandizira kuyenda mwachangu komanso kokhazikika popanda kugwedezeka kapena kupotoza.

3. Optical ndi Photonic Systems

Kuyika ndi kuyika kwa magalasi, magalasi, kapena ma photonic chips, ndiSilicon Carbide Ceramic Fork Arm/Handimapereka chithandizo chopanda kugwedezeka, chofunikira kwambiri pakukonza kwa laser ndi kugwiritsa ntchito molondola kwa metrology.

4. Azamlengalenga & Vacuum Systems

M'makina owoneka bwino amlengalenga ndi zida za vacuum, gawo ili lopanda maginito, losagwirizana ndi dzimbiri limatsimikizira kukhazikika kwanthawi yayitali. Themkono / dzanjaimathanso kugwira ntchito mu ultra-high vacuum (UHV) popanda kutulutsa mpweya.

M'magawo onse awa, aSilicon Carbide Ceramic Fork Arm/Handimaposa njira zachikhalidwe zachitsulo kapena polima podalirika, ukhondo, ndi moyo wautumiki.

FAQ ya Silicon Carbide Ceramic Fork Arm/Hand

Q1: Ndi miyeso yanji yophika yomwe imathandizidwa ndi Silicon Carbide Ceramic Fork Arm/Hand?

Themkono / dzanjaakhoza makonda kuthandizira 150 mm, 200 mm, ndi 300 mm wafers. Kutalika kwa foloko, m'lifupi mwa mkono, ndi mabowo amatha kupangidwa kuti agwirizane ndi nsanja yanu yodzichitira nokha.

Q2: Kodi Silicon Carbide Ceramic Fork Arm / Hand imagwirizana ndi makina otsekemera?

Inde. Themkono / dzanjandi oyenera onse otsika vacuum ndi ultra-high vacuum machitidwe. Ili ndi mitengo yotsika yotulutsa mpweya ndipo siyitulutsa tinthu, kupangitsa kuti ikhale yabwino pazipinda zoyeretsera komanso malo opanda vacuum.

Q3: Kodi ndingawonjezere zokutira kapena kusinthidwa pamwamba pa mkono/dzanja la foloko?

Ndithudi. TheSilicon Carbide Ceramic Fork Arm/Handakhoza yokutidwa ndi CVD-SiC, mpweya, kapena okusayidi zigawo kuonjezera plasma kukana, odana ndi malo amodzi katundu, kapena pamwamba kuuma.

Q4: Kodi mtundu wa foloko / dzanja umatsimikiziridwa bwanji?

AliyenseSilicon Carbide Ceramic Fork Arm/Handimayesedwa mozama pogwiritsa ntchito CMM ndi zida za laser metrology. Ubwino wapamtunda umawunikidwa kudzera pa SEM ndi profilometry yosalumikizana kuti ikwaniritse miyezo ya ISO ndi SEMI.

Q5: Ndi nthawi yanji yotsogola ya maoda a foloko / manja?

Nthawi yotsogolera imakhala kuyambira masabata atatu mpaka 5 kutengera zovuta komanso kuchuluka kwake. Rapid prototyping ikupezeka pazofunsira mwachangu.

Mafunsowa amafuna kuthandiza mainjiniya ndi magulu ogula zinthu kuti amvetsetse kuthekera ndi zosankha zomwe zilipo posankha aSilicon Carbide Ceramic Fork Arm/Hand.

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.