SiCOI wafer 4inch 6inch HPSI SiC SiO2 Si subatrate kapangidwe

Mapangidwe a SiCOI wafer

HPB (High-Performance Bonding) BIC (Bonded Integrated Circuit) ndi SOD (Silicon-on-Diamond kapena Silicon-on-Insulator-like technology). Zimaphatikizapo:

Magwiridwe Antchito:

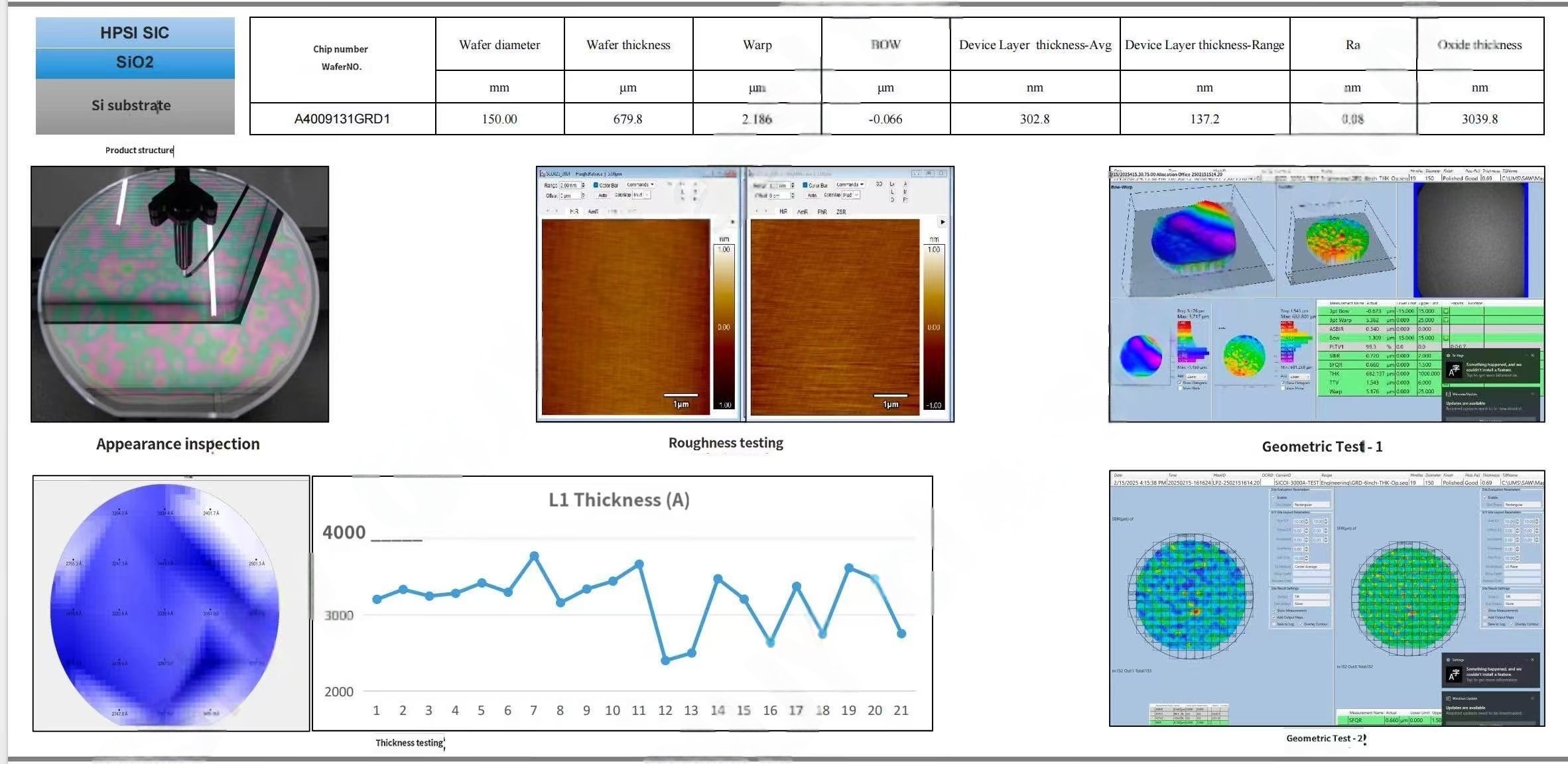

Imatchula zinthu monga kulondola, mitundu yolakwika (mwachitsanzo, "Palibe cholakwika," "Kutalikirana kwamtengo"), ndi miyeso ya makulidwe (mwachitsanzo, "Direct-Layer thickness/kg").

Gome lokhala ndi manambala (mwina zoyeserera kapena zoyeserera) pansi pamitu ngati "ADDR/SYGBDT," "10/0," ndi zina zotero.

Deta ya Makulidwe Osanjikiza:

Zolemba zambiri zobwerezabwereza zolembedwa "L1 Makulidwe (A)" ku "L270 Makulidwe (A)" (mwina Ångströms, 1 Å = 0.1 nm).

Imawonetsa mawonekedwe amitundu yambiri okhala ndi zowongolera zonenedweratu pagawo lililonse, zomwe zimafanana ndi zowotcha zapakatikati za semiconductor.

SiCOI Wafer Structure

SiCOI (Silicon Carbide pa Insulator) ndi mawonekedwe apadera ophatikizika ophatikizira silicon carbide (SiC) yokhala ndi chosanjikiza, chofanana ndi SOI (Silicon-on-Insulator) koma yokonzedwa kuti ikhale yamphamvu kwambiri / kutentha kwambiri. Zofunikira zazikulu:

Masanjidwe:

Gulu Lapamwamba: Single-crystal Silicon Carbide (SiC) yokhala ndi ma elekitironi apamwamba komanso kukhazikika kwamafuta.

Wokwiriridwa Insulator: Nthawi zambiri SiO₂ (oxide) kapena diamondi (mu SOD) kuti achepetse mphamvu ya parasitic ndikuwongolera kudzipatula.

Base Substrate: Silicon kapena polycrystalline SiC yothandizira makina

Makhalidwe a SiCOI wafer

Zida Zamagetsi Wide Bandgap (3.2 eV ya 4H-SiC): Imathandiza kuti magetsi awonongeke kwambiri (> 10 × apamwamba kuposa silicon) . Amachepetsa mafunde amadzimadzi, amawongolera bwino pazida zamagetsi.

High Electron Mobility:~900 cm²/V·s (4H-SiC) vs. ~1,400 cm²/V·s (Si), koma magwiridwe antchito apamwamba kwambiri.

Kukanika Kwambiri:Ma transistors a SiCOI (mwachitsanzo, ma MOSFET) amawonetsa kutayika kocheperako.

Ubwino wa Insulation:Oxidi wokwiriridwa (SiO₂) kapena wosanjikiza wa diamondi amachepetsa mphamvu ya parasitic ndi crosstalk.

- Thermal PropertiesHigh Thermal Conductivity: SiC (~ 490 W/m·K ya 4H-SiC) vs. Si (~ 150 W/m·K) .Diamond (ngati ikugwiritsidwa ntchito ngati insulator) ikhoza kupitirira 2,000 W/m·K, kupititsa patsogolo kutentha kwapakati.

Thermal Kukhazikika:Imagwira ntchito modalirika pa> 300 ° C (vs. ~ 150 ° C ya silicon). Imachepetsa zofunikira zoziziritsa mumagetsi amagetsi.

3. Mechanical & Chemical PropertiesKuuma Kwambiri (~ 9.5 Mohs): Imakana kuvala, kupangitsa SiCOI kukhala yolimba pamalo ovuta.

Chemical Inertness:Imalimbana ndi oxidation ndi dzimbiri, ngakhale mumikhalidwe ya acidic/alkaline.

Kuwotcha Kutsika Kwambiri:Imagwirizana bwino ndi zida zina zotentha kwambiri (mwachitsanzo, GaN).

4. Ubwino Wamapangidwe (vs. Bulk SiC kapena SOI)

Kutayika Kwagawo Lapansi:Insulating layer imalepheretsa kutayikira kwapano mu gawo lapansi.

Kuchita bwino kwa RF:Kutsika kwa parasitic capacitance kumathandizira kusintha mwachangu (kothandiza pazida za 5G/mmWave).

Mapangidwe Osinthika:Thin SiC pamwamba wosanjikiza amalola kukhathamiritsa kwa chipangizo (mwachitsanzo, mayendedwe owonda kwambiri mu transistors).

Poyerekeza ndi SOI & Bulk SiC

| Katundu | SiCOI | SOI (Si/SiO₂/Si) | Zambiri SiC |

| Bandgap | 3.2 eV (SiC) | 1.1 eV (Si) | 3.2 eV (SiC) |

| Thermal Conductivity | Wapamwamba (SiC + diamondi) | Otsika (SiO₂ imachepetsa kutentha kwapakati) | Kukwera (SiC kokha) |

| Kuwonongeka kwa Voltage | Wapamwamba kwambiri | Wapakati | Wapamwamba kwambiri |

| Mtengo | Zapamwamba | Pansi | Wapamwamba kwambiri (Pure SiC) |

Mapulogalamu a SiCOI wafer

Zamagetsi Zamagetsi

Zowotcha za SiCOI zimagwiritsidwa ntchito kwambiri pazida zokhala ndi magetsi okwera kwambiri komanso zamphamvu kwambiri monga ma MOSFET, ma Schottky diode, ndi masiwichi amagetsi. Kuchuluka kwa bandgap ndi kutsika kwakukulu kwamagetsi a SiC kumathandizira kutembenuka kwamphamvu kwamphamvu ndikutayika kocheperako komanso kupititsa patsogolo magwiridwe antchito amafuta.

Ma Radio Frequency (RF) Zipangizo

Kuyika kwa insulating mu ma wafers a SiCOI kumachepetsa mphamvu ya parasitic, kuwapangitsa kukhala oyenera ma transistors othamanga kwambiri komanso ma amplifiers omwe amagwiritsidwa ntchito pamatelefoni, radar, ndi ukadaulo wa 5G.

Microelectromechanical Systems (MEMS)

Zophika za SiCOI zimapereka nsanja yolimba yopangira masensa a MEMS ndi ma actuators omwe amagwira ntchito modalirika m'malo ovuta chifukwa cha kusakhazikika kwamankhwala a SiC komanso mphamvu zamakina.

Zida Zamagetsi Zotentha Kwambiri

SiCOI imathandizira zamagetsi zomwe zimasunga magwiridwe antchito komanso kudalirika pakutentha kokwera, kupindula ndi magalimoto, ndege, ndi ntchito zama mafakitale pomwe zida za silicon wamba zimalephera.

Zida za Photonic ndi Optoelectronic

Kuphatikizika kwa mawonekedwe a mawonekedwe a SiC ndi kusanjikiza kotsekera kumathandizira kuphatikizika kwa ma frequency a Photonic ndi kasamalidwe kabwino ka kutentha.

Radiation-Hardened Electronics

Chifukwa cha kulekerera kwachilengedwe kwa SiC, zowotcha za SiCOI ndizoyenera malo ndi zida zanyukiliya zomwe zimafunikira zida zomwe zimapirira malo okhala ndi ma radiation apamwamba.

Q&A ya SiCOI wafer

Q1: Kodi mkate wa SiCOI ndi chiyani?

A: SiCOI imayimira Silicon Carbide-on-Insulator. Ndi mawonekedwe a semiconductor wafer pomwe gawo lopyapyala la silicon carbide (SiC) limalumikizidwa pagawo loteteza (nthawi zambiri silicon dioxide, SiO₂), yomwe imathandizidwa ndi gawo lapansi la silicon. Kapangidwe kameneka kamaphatikiza zinthu zabwino kwambiri za SiC ndi kudzipatula kwamagetsi ku insulator.

Q2: Ubwino waukulu wa zowotcha za SiCOI ndi ziti?

A: Ubwino waukulu ndi monga voteji yosweka kwambiri, bandgap yotakata, matenthedwe abwino kwambiri, kulimba kwamakina, komanso kuchepa kwa mphamvu ya parasitic chifukwa cha kusanjikiza kotsekera. Izi zimapangitsa kuti chipangizocho chizigwira ntchito bwino, chikhale chogwira ntchito bwino, komanso chodalirika.

Q3: Kodi ma wafers a SiCOI ndi ati?

A: Amagwiritsidwa ntchito pamagetsi amagetsi, zida za RF zothamanga kwambiri, masensa a MEMS, zida zamagetsi zotentha kwambiri, zida zamafotoko, ndi zida zamagetsi zowumitsidwa ndi radiation.

Chithunzi chatsatanetsatane