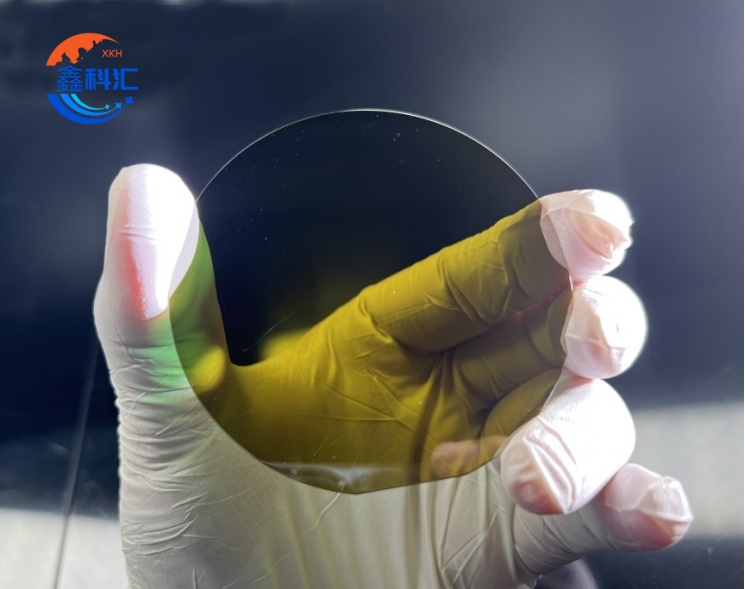

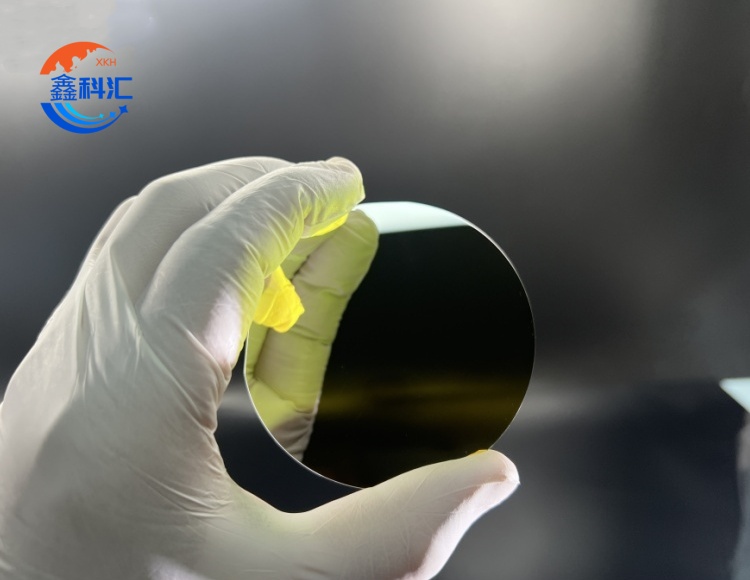

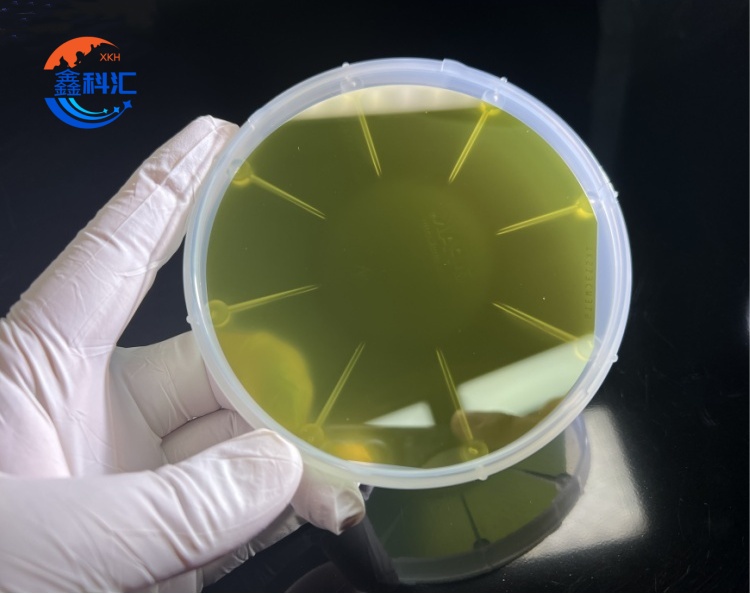

Sic Substrate Silicon Carbide Wafer 4H-N Type High Hardness Corrosion Resistance Prime Grade Polishing

Zotsatirazi ndi mawonekedwe a silicon carbide wafer

1. Kutentha kwapamwamba kwambiri: Kutentha kwazitsulo za SIC ndizokwera kwambiri kuposa za silicon, zomwe zikutanthauza kuti zitsulo za SIC zimatha kutaya kutentha bwino ndipo zimakhala zoyenera kugwira ntchito m'madera otentha kwambiri.

2. Kuyenda kwa ma elekitironi apamwamba: Zophika za SIC zimakhala ndi ma electron apamwamba kuposa silicon, zomwe zimathandiza kuti zipangizo za SIC zizigwira ntchito mofulumira kwambiri.

3. Magetsi apamwamba kwambiri: SIC wafer material imakhala ndi magetsi owononga kwambiri, zomwe zimapangitsa kuti zikhale zoyenera kupanga zipangizo zamakono zopangira ma semiconductor.

4. Kukhazikika kwamankhwala apamwamba: Zophika za SIC zimakhala ndi kukana kwamphamvu kwa mankhwala, zomwe zimathandiza kuti chipangizocho chikhale chodalirika komanso cholimba.

5. Wider band gap: SIC wafers ali ndi kusiyana kwakukulu kwa gulu kuposa silicon, kupanga zipangizo za SIC bwino komanso zokhazikika pa kutentha kwakukulu.

Silicon carbide wafer ili ndi ntchito zingapo

1.Mechanical field: zida zodula ndi zipangizo zopera; Zigawo zosagwirizana ndi kuvala ndi tchire; Ma valve a mafakitale ndi zisindikizo; Mipira ndi ma bearings

2.Munda wamagetsi amagetsi: zida za semiconductor zamagetsi; High frequency mayikirowevu element; High voteji ndi mkulu kutentha mphamvu zamagetsi; Zida zoyendetsera kutentha

3.Chemical makampani: riyakitala mankhwala ndi zipangizo; Mapaipi osamva dzimbiri ndi akasinja osungira; Chithandizo chothandizira mankhwala

Gawo la 4.Energy: turbine ya gasi ndi zigawo za turbocharger; nyukiliya mphamvu pachimake ndi structural zigawo zikuluzikulu kutentha mafuta maselo zigawo

5.Aerospace: machitidwe otetezera kutentha kwa mizinga ndi magalimoto apamlengalenga; masamba a injini ya jet; Kuphatikiza kowonjezera

6.Madera ena: Sensa yapamwamba ya kutentha ndi thermopiles; Imfa ndi zida zopangira sintering; Kupera ndi kupukuta ndi kudula minda

ZMKJ imatha kupereka chofufumitsa chamtundu wapamwamba wa SiC (Silicon Carbide) kumakampani amagetsi ndi optoelectronic. SiC wafer ndi m'badwo wotsatira wa semiconductor zakuthupi , zomwe zimakhala ndi magetsi apadera komanso matenthedwe abwino kwambiri, poyerekeza ndi silicon wafer ndi GaAs wafer, SiC wafer ndiyoyenera kutentha kwambiri komanso kugwiritsa ntchito zida zamphamvu kwambiri. SiC yopyapyala akhoza kuperekedwa m'mimba mwake 2-6 inchi, onse 4H ndi 6H SiC, N-mtundu, nayitrogeni doped, ndi theka-amateteza mtundu zilipo. Chonde titumizireni kuti mudziwe zambiri zamalonda.

Fakitale yathu ili ndi zida zopangira zapamwamba komanso gulu laukadaulo, lomwe lingasinthire makonda osiyanasiyana, makulidwe ndi mawonekedwe a SiC wafer malinga ndi zomwe makasitomala amafuna.

Chithunzi chatsatanetsatane