SiC Ceramic Tray ya Wafer Carrier yokhala ndi High-Temperature Resistance

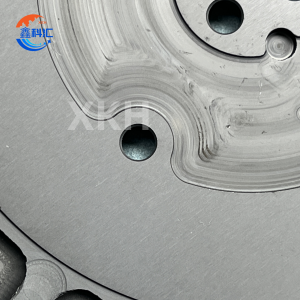

Silicon Carbide Ceramic Tray (SiC Tray).

Chigawo cha ceramic chogwira ntchito kwambiri chozikidwa pa silicon carbide (SiC), chopangidwira ntchito zapamwamba zamafakitale monga kupanga semiconductor ndi kupanga LED. Ntchito zake zazikuluzikulu zikuphatikiza kugwira ntchito ngati chonyamulira chophatikizika, pulatifomu ya etching, kapena chithandizo cha kutentha kwapamwamba, kugwiritsa ntchito matenthedwe apadera, kukana kutentha kwambiri, komanso kukhazikika kwamankhwala kuti zitsimikizire kufanana kwazinthu komanso zokolola.

Zofunika Kwambiri

1. Thermal Performance

- High Thermal Conductivity: 140–300 W/m·K, kupitirira kwambiri ma graphite akale (85 W/m·K), zomwe zimathandiza kuti kutentha kuzitha msanga komanso kuchepetsa kupsinjika kwa kutentha.

- Low Thermal Expansion Coefficient: 4.0 × 10⁻⁶/℃ (25–1000℃), yofananira kwambiri ndi silicon (2.6 × 10⁻⁶/℃), kuchepetsa kuopsa kwa kutentha kwa thupi.

2. Mechanical Properties

- Mphamvu Yapamwamba : Flexural mphamvu ≥320 MPa (20 ℃), kugonjetsedwa ndi kupsinjika ndi kukhudzidwa.

- Kuuma Kwakukulu: Kuuma kwa Mohs 9.5, yachiwiri kwa diamondi, kumapereka kukana kwamphamvu kwambiri.

3. Chemical Kukhazikika

- Kulimbana ndi Corrosion Resistance: Kusagwirizana ndi ma acid amphamvu (mwachitsanzo, HF, H₂SO₄), oyenera malo opangira ma etching.

- Non-Magnetic: Intrinsic magnetic susceptibility <1×10⁻⁶ emu/g, kupewa kusokonezedwa ndi zida zolondola.

4. Kulekerera Kwachilengedwe Kwambiri

- Kukhalitsa Kwambiri Kutentha: Kutentha kwanthawi yayitali mpaka 1600-1900 ℃; kukana kwakanthawi kochepa mpaka 2200 ℃ (malo opanda okosijeni).

- Thermal Shock Resistance: Imalimbana ndi kusintha kwadzidzidzi kutentha (ΔT> 1000 ℃) popanda kusweka.

Mapulogalamu

| Munda wa Ntchito | Specific Scenarios | Mtengo waukadaulo |

| Semiconductor Manufacturing | Wafer etching (ICP), thin-film deposition (MOCVD), CMP polishing | High matenthedwe madutsidwe amaonetsetsa yunifolomu minda kutentha; kutsika kwamafuta pang'ono kumachepetsa masamba ophikira. |

| Kupanga kwa LED | Kukula kwa Epitaxial (mwachitsanzo, GaN), kuyika madontho, kuyika | Imapondereza zolakwika zamitundu yambiri, kupititsa patsogolo kuwala kwa LED komanso moyo wautali. |

| Chithunzi cha Photovoltaic | Silicon wafer sintering ng'anjo, zida za PECVD zimathandizira | Kutentha kwambiri komanso kukana kugwedezeka kwamafuta kumawonjezera moyo wa zida. |

| Laser & Optics | Magawo oziziritsa amphamvu kwambiri a laser, makina owoneka bwino amathandizira | High matenthedwe madutsidwe kumathandiza mofulumira kutentha dispation, stabilizing zigawo kuwala. |

| Zida za Analytical | TGA/DSC okhala ndi zitsanzo | Kutentha kochepa komanso kuyankhidwa kwamafuta othamanga kumapangitsa kuti muyezo ukhale wolondola. |

Ubwino Wopanga

- Magwiridwe Okwanira: Kutentha kwamafuta, mphamvu, ndi kukana kwa dzimbiri kumaposa zoumba za alumina ndi silicon nitride, zomwe zimakwaniritsa zofunikira pakugwirira ntchito.

- Mapangidwe Opepuka: Kachulukidwe wa 3.1–3.2 g/cm³ (40% ya chitsulo), kuchepetsa katundu wa inertial ndi kuwongolera kulondola koyenda.

- Utali Wautali & Kudalirika: Moyo wautumiki umaposa zaka 5 pa 1600 ℃, kuchepetsa nthawi yopumira ndikuchepetsa ndalama zogwirira ntchito ndi 30%.

- Kusintha mwamakonda: Imathandizira ma geometries ovuta (mwachitsanzo, makapu oyamwa a porous, ma tray angapo osanjikiza) okhala ndi cholakwika cha flatness <15 μm kuti agwiritse ntchito molondola.

Mafotokozedwe Aukadaulo

| Gulu la Parameter | Chizindikiro |

| Physical Properties | |

| Kuchulukana | ≥3.10 g/cm³ |

| Flexural Mphamvu (20 ℃) | 320-410 MPa |

| Thermal Conductivity (20 ℃) | 140–300 W/(m·K) |

| Thermal Expansion Coefficient (25–1000 ℃) | 4.0×10⁻⁶/℃ |

| Chemical Properties | |

| Kukaniza Acid (HF/H₂SO₄) | Palibe dzimbiri pambuyo pa kumizidwa kwa maola 24 |

| Machining Precision | |

| Kusalala | ≤15 μm (300×300 mm) |

| Kukalipa Pamwamba (Ra) | ≤0.4 μm |

Ntchito za XKH

XKH imapereka mayankho azamafakitale okhudzana ndi chitukuko cha makonda, makina olondola, komanso kuwongolera kokhazikika. Pachitukuko chamwambo, chimapereka kuyera kwambiri (> 99.999%) ndi mayankho azinthu zaporous (30-50% porosity), ophatikizidwa ndi 3D modelling ndikuyerekeza kukhathamiritsa ma geometri ovuta pakugwiritsa ntchito ngati semiconductors ndi ndege. Makina olondola akutsatira njira yosinthira: kukonza ufa → kukanikiza kwa isostatic/dry → 2200°C sintering → CNC/diamond grinding → kuyendera, kuonetsetsa kupukuta kwa nanometer ndi ± 0.01 mm kulolerana. Kuwongolera kwaubwino kumaphatikizapo kuyezetsa kwathunthu (kupangidwa kwa XRD, mawonekedwe a SEM, kupindika kwa mfundo zitatu) ndi chithandizo chaukadaulo (kukhathamiritsa kwa njira, kuyankhulana kwa 24/7, kuperekera zitsanzo za maola 48), kupereka zodalirika, zogwira ntchito kwambiri pazosowa zapamwamba zamakampani.

Mafunso Ofunsidwa Kawirikawiri (FAQ)

1. Q: Ndi mafakitale ati omwe amagwiritsa ntchito matayala a silicon carbide ceramic?

A: Amagwiritsidwa ntchito kwambiri pakupanga ma semiconductor (kugwiritsitsa kwawafer), mphamvu ya solar (PECVD process), zida zamankhwala (MRI zigawo), ndi ndege (zigawo zotentha kwambiri) chifukwa cha kukana kwawo kutentha kwambiri komanso kukhazikika kwamankhwala.

2. Q: Kodi silicon carbide imaposa bwanji ma tray a quartz/magalasi?

A: Kuchuluka kwa kutentha kwa kutentha (mpaka 1800 ° C vs. quartz's 1100 ° C), zero magnetic interference, ndi moyo wautali (zaka 5+ vs. quartz's 6-12 miyezi).

3. Q: Kodi thireyi za silicon carbide zimatha kukhala ndi acidic?

A: Inde. Kusagonjetsedwa ndi HF, H2SO4, ndi NaOH ndi <0.01mm dzimbiri/chaka, kuwapanga kukhala abwino popangira mankhwala ndi kuyeretsa wafer.

4. Q: Kodi thireyi za silicon carbide zimagwirizana ndi automation?

A: Inde. Zapangidwa kuti zitheke kunyamula vacuum, ndikugwira ntchito ndi robotic, zokhala ndi flatness pansi <0.01mm kuteteza kuipitsidwa ndi tinthu tating'onoting'ono.

5. Q: Kodi mtengo woyerekeza ndi zinthu zakale ndi ziti?

A: Mtengo wapamwamba kwambiri (3-5x quartz) koma TCO yotsika 30-50%, chifukwa cha kutalika kwa moyo, kuchepa kwa nthawi yopuma, komanso kupulumutsa mphamvu kuchokera kumayendedwe apamwamba amafuta.