SiC ceramic mbale/thireyi ya 4inch 6inch wafer chofukizira cha ICP

SiC ceramic mbale Abstract

SiC ceramic mbale ndi gawo lapamwamba kwambiri lopangidwa kuchokera ku Silicon Carbide yoyera kwambiri, yopangidwira kuti igwiritsidwe ntchito m'malo otentha kwambiri, mankhwala, komanso makina. SiC yodziwika bwino chifukwa cha kuuma kwake kwapadera, kukhathamiritsa kwamafuta, komanso kukana dzimbiri, imagwiritsidwa ntchito kwambiri ngati chonyamulira chophatikizira, chowongolera, kapena gawo lazopangapanga m'mafakitale a semiconductor, LED, photovoltaic, ndi zakuthambo.

Ndi kukhazikika kwamafuta mpaka 1600 ° C komanso kukana bwino kwa mpweya wokhazikika komanso malo a plasma, mbale ya SiC imawonetsetsa kuti imagwira ntchito nthawi zonse pakutentha kwambiri, kuyika, ndi kufalikira. Mipangidwe yake yolimba, yopanda porous imachepetsa kupangika kwa tinthu, ndikupangitsa kuti ikhale yabwino kugwiritsa ntchito zoyera kwambiri mu vacuum kapena zoyeretsa.

SiC ceramic mbale Kugwiritsa Ntchito

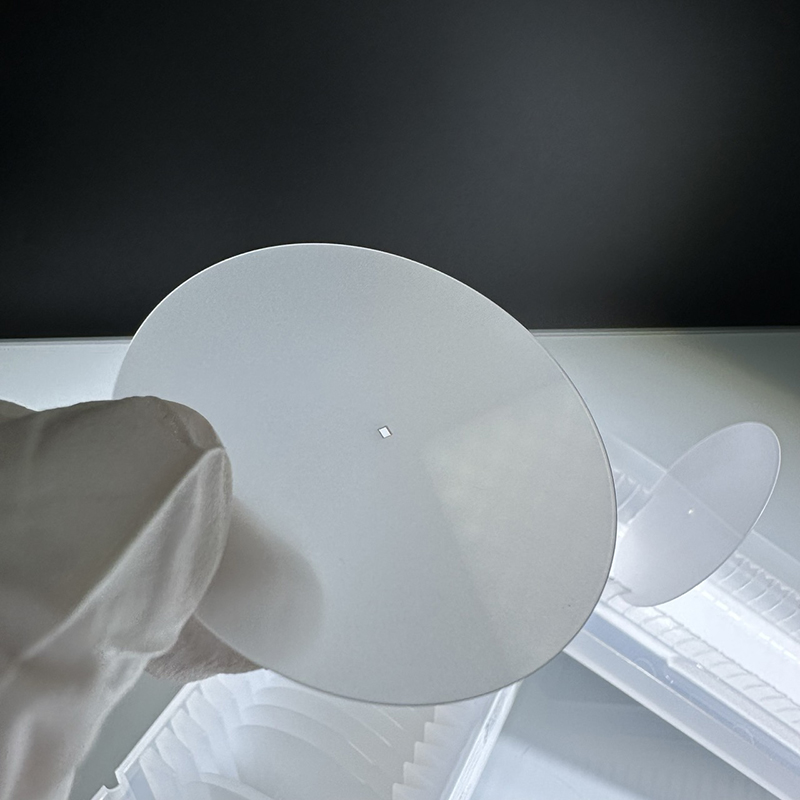

1. Kupanga Semiconductor

Ma mbale a ceramic a SiC nthawi zambiri amagwiritsidwa ntchito ngati zonyamulira zopyapyala, zowongolera, ndi mbale zoyambira pazida zopangira semiconductor monga CVD (Chemical Vapor Deposition), PVD (Physical Vapor Deposition), ndi makina ojambulira. Kutentha kwawo kwabwino kwambiri komanso kutsika kwamafuta ochepa kumawalola kuti azisunga kutentha kofanana, zomwe ndizofunikira kwambiri pakukonza bwino kwambiri. Kukana kwa SiC ku mipweya yowononga ndi plasma kumatsimikizira kulimba m'malo ovuta, kuthandiza kuchepetsa kuipitsidwa kwa tinthu ndi kukonza zida.

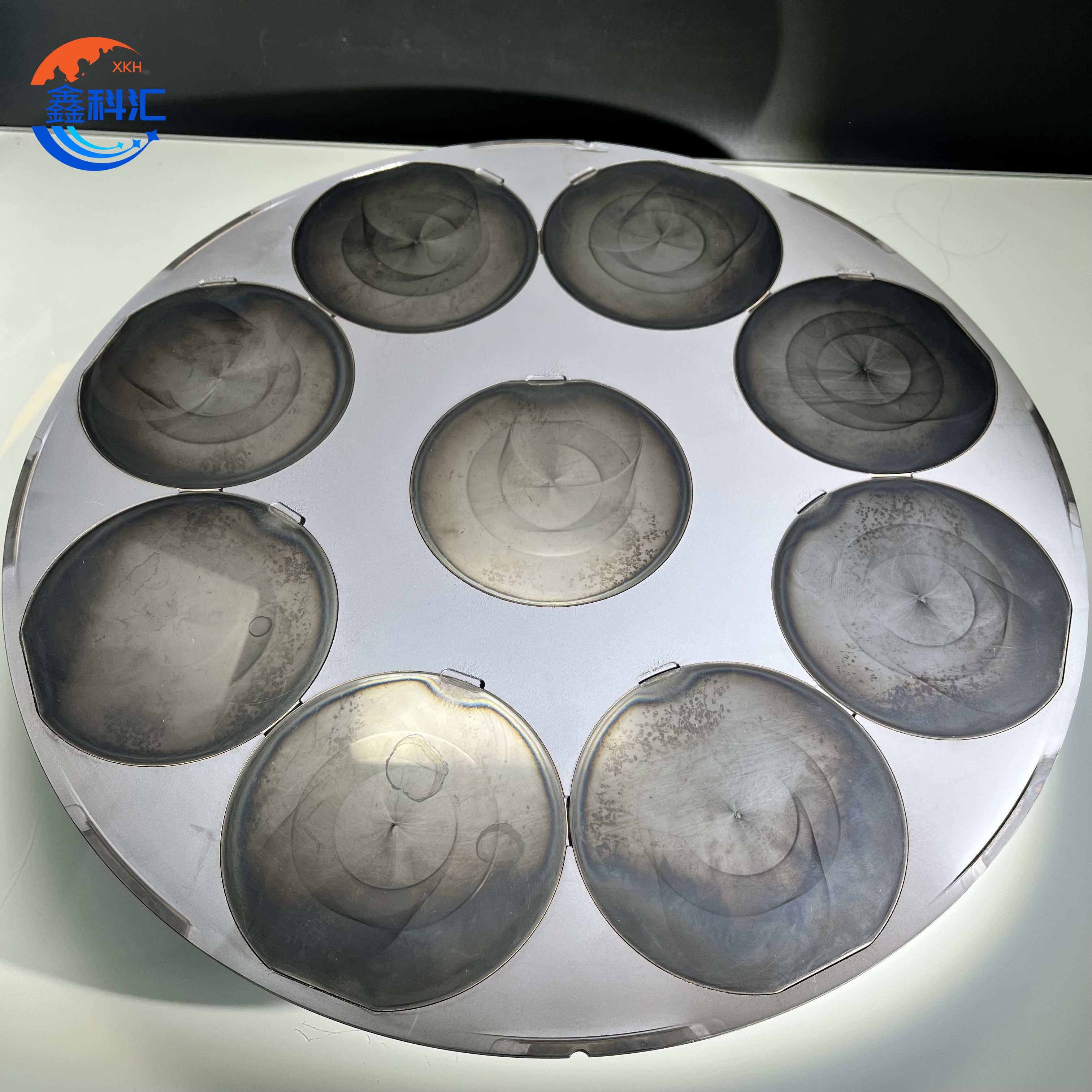

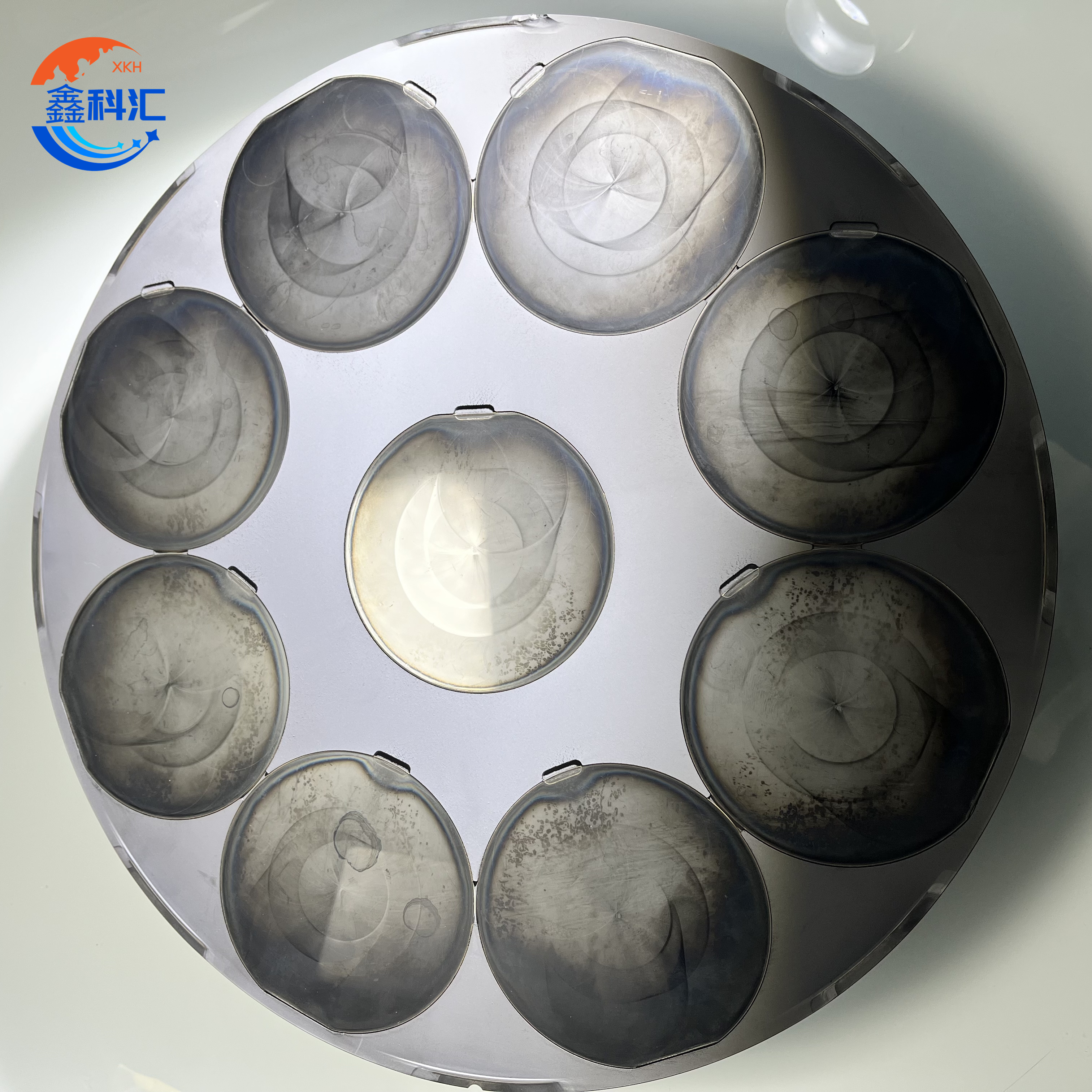

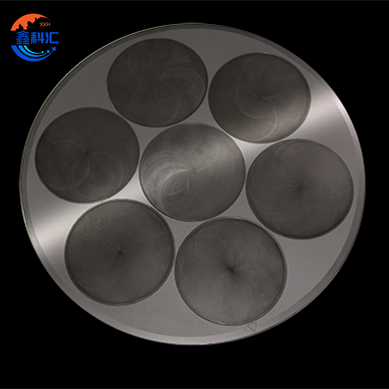

2. Makampani a LED - ICP Etching

M'gawo lopanga ma LED, mbale za SiC ndizomwe zili mu ICP (Inductively Coupled Plasma) etching systems. Kugwira ntchito ngati zophatikizika, zimapereka nsanja yokhazikika komanso yolimba kuti ithandizire zowotcha za safiro kapena GaN pakukonza plasma. Kukana kwawo kwa plasma kwabwino kwambiri, kutsika kwapansi, komanso kukhazikika kwa mawonekedwe kumathandiza kuwonetsetsa kulondola kwapamwamba komanso kufananiza, zomwe zimapangitsa kuti pakhale zokolola zambiri komanso magwiridwe antchito a chipangizo mu tchipisi ta LED.

3. Photovoltaics (PV) ndi Solar Energy

Ma mbale a ceramic a SiC amagwiritsidwanso ntchito popanga ma cell a solar, makamaka panthawi yotentha kwambiri ya sintering ndi ma annealing. Kusakhazikika kwawo pamatenthedwe okwera komanso kuthekera kokana kuthamangitsidwa kumatsimikizira kusasinthika kwamafuta a silicon. Kuphatikiza apo, chiwopsezo chawo chochepa cha kuipitsidwa ndi chofunikira pakusunga mphamvu zama cell a photovoltaic.

SiC ceramic mbale Properties

1. Mphamvu Zapadera Zamakina ndi Kuuma

Ma mbale a ceramic a SiC amawonetsa mphamvu zamakina apamwamba kwambiri, okhala ndi mphamvu yosinthira yopitilira 400 MPa ndi kuuma kwa Vickers kufika> 2000 HV. Izi zimawapangitsa kukhala osagwirizana kwambiri ndi kuvala kwamakina, ma abrasion, ndi mapindikidwe, kuwonetsetsa moyo wautali wautumiki ngakhale atalemedwa kwambiri kapena kupalasa njinga mobwerezabwereza.

2. High Thermal Conductivity

SiC ili ndi matenthedwe abwino kwambiri (nthawi zambiri 120–200 W/m·K), kuwalola kugawira kutentha mofanana pamwamba pake. Katunduyu ndi wofunikira kwambiri pamachitidwe monga kuwotcha, kuyika, kapena sintering, pomwe kufanana kwa kutentha kumakhudza kwambiri zokolola ndi mtundu wake.

3. Kukhazikika Kwambiri Kutentha Kwambiri

Pokhala ndi malo osungunuka kwambiri (2700 ° C) ndi kutsika kwa mphamvu yowonjezera kutentha (4.0 × 10⁻⁶/K), mbale za ceramic za SiC zimasunga kulondola kwa mawonekedwe ndi kukhulupirika kwapangidwe pansi pa kutentha kofulumira ndi kuzizira. Izi zimawapangitsa kukhala abwino kuti azigwiritsidwa ntchito m'ng'anjo zotentha kwambiri, zipinda za vacuum, ndi malo a plasma.

| Katundu Waumisiri | ||||

| Mlozera | Chigawo | Mtengo | ||

| Dzina lazinthu | Reaction Sintered Silicon Carbide | Pressureless Sintered Silicon Carbide | Recrystallized Silicon Carbide | |

| Kupanga | Mtengo wa RBSiC | SSiC | R-SiC | |

| Kuchulukana Kwambiri | g/cm3 | 3 | 3.15 ± 0.03 | 2.60-2.70 |

| Flexural Mphamvu | MPa (kpsi) | 338 (49) | 380 (55) | 80-90 (20°C) 90-100(1400°C) |

| Compressive Mphamvu | MPa (kpsi) | 1120 (158) | 3970 (560) | > 600 |

| Kuuma | Knoop | 2700 | 2800 | / |

| Kuphwanya Kukhazikika | MPa m1/2 | 4.5 | 4 | / |

| Thermal Conductivity | W/mk | 95 | 120 | 23 |

| Coefficient of Thermal Expansion | 10-6.1/°C | 5 | 4 | 4.7 |

| Kutentha Kwapadera | Uwu/g 0k | 0.8 | 0.67 | / |

| Kutentha kwakukulu mumlengalenga | ℃ | 1200 | 1500 | 1600 |

| Elastic Modulus | Gpa | 360 | 410 | 240 |

SiC ceramic mbale Q&A

Q: Kodi silicon carbide mbale ndi chiyani?

A: Ma mbale a Silicon carbide (SiC) amadziwika chifukwa champhamvu zawo, kulimba, komanso kukhazikika kwamafuta. Amapereka ma conductivity abwino kwambiri amafuta komanso kufalikira kwamafuta ochepa, kuonetsetsa kuti magwiridwe antchito odalirika akuyenda kwambiri. SiC imakhalanso ndi mankhwala osakanikirana, osagonjetsedwa ndi ma acid, alkalis, ndi malo a plasma, zomwe zimapangitsa kuti zikhale zabwino kwa semiconductor ndi LED processing. Malo ake owundana, osalala amachepetsa kupanga tinthu tating'ono, ndikusunga zipinda zoyera. Ma mbale a SiC amagwiritsidwa ntchito kwambiri ngati zonyamulira zowotcha, zowombelera, ndi zida zothandizira pakutentha kwambiri komanso malo owononga kudera lonse la semiconductor, photovoltaic, ndi aerospace.