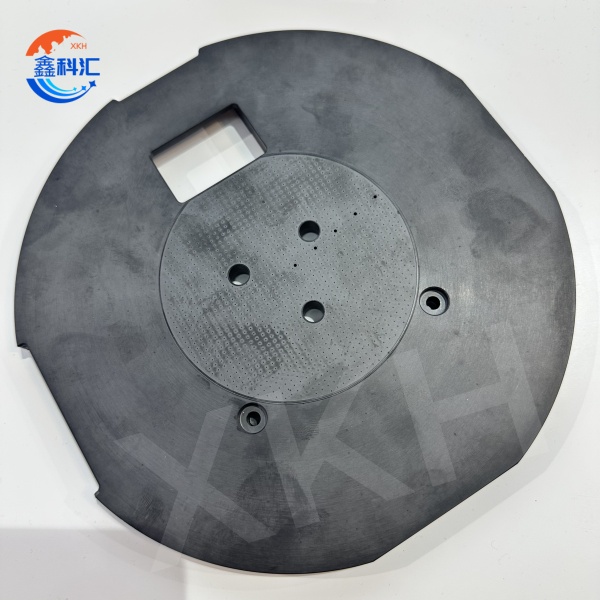

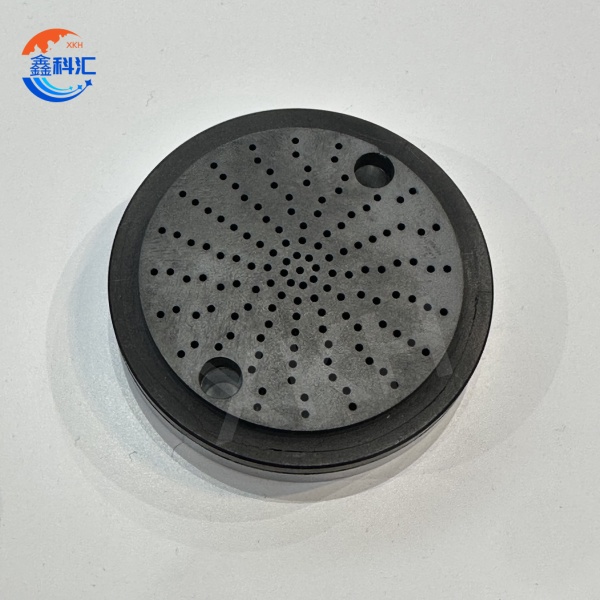

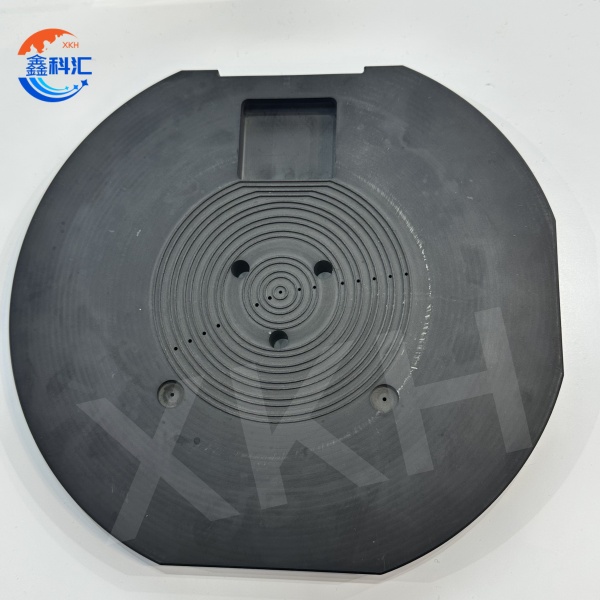

SiC ceramic chuck tray Ceramic suction makapu mwatsatanetsatane machining makonda

Zofunika:

1.Kuuma kwakukulu: kuuma kwa Mohs kwa silicon carbide ndi 9.2-9.5, yachiwiri kwa diamondi, yokhala ndi kukana kolimba.

2. Kutentha kwapamwamba kwambiri: kutentha kwa silicon carbide kumakhala kokwanira 120-200 W / m · K, komwe kungathe kutaya kutentha mofulumira ndipo kuli koyenera kutentha kwapamwamba.

3. Coefficient yowonjezera kutentha kwapansi: silicon carbide yowonjezera kutentha kwapakati ndi yotsika (4.0-4.5 × 10⁻⁶/K), ikhoza kukhalabe yokhazikika pa kutentha kwakukulu.

4. Kukhazikika kwa Chemical: silicon carbide acid ndi alkali corrosion resistance, yoyenera kugwiritsidwa ntchito m'malo owononga mankhwala.

5. Mphamvu zamakina apamwamba: silicon carbide imakhala ndi mphamvu yopindika kwambiri komanso mphamvu yopondereza, ndipo imatha kupirira kupsinjika kwakukulu kwamakina.

Mawonekedwe:

1. M'makampani a semiconductor, zowonda zowonda kwambiri zimafunika kuyikidwa pa kapu ya vacuum suction, vacuum suction imagwiritsidwa ntchito kukonza zopatulira, ndipo njira yopangira phula, kupatulira, kupaka phula, kuyeretsa ndi kudula kumapangidwa pamipando.

2.Silicon carbide sucker ali ndi matenthedwe abwino matenthedwe, akhoza mogwira kufupikitsa phula ndi phula nthawi, patsogolo kupanga dzuwa.

3.Silicon carbide vacuum sucker ilinso ndi asidi wabwino komanso kukana dzimbiri za alkali.

4.Poyerekeza ndi mbale yachikhalidwe ya corundum chonyamulira, kufupikitsa kutsitsa ndi kutsitsa Kutentha ndi nthawi yozizira, kukonza bwino ntchito; Panthawi imodzimodziyo, imatha kuchepetsa kuvala pakati pa mbale zapamwamba ndi zapansi, kusunga ndege yolondola, ndikuwonjezera moyo wautumiki pafupifupi 40%.

5.Chigawo chakuthupi ndi chaching'ono, cholemera chopepuka. Ndikosavuta kwa ogwira ntchito kunyamula ma pallets, kuchepetsa chiwopsezo cha kuwonongeka komwe kumachitika chifukwa cha zovuta zamayendedwe ndi 20%.

6.Kukula: awiri awiri 640mm; Kutsika: 3um kapena kuchepera

Munda wa ntchito:

1. Kupanga kwa semiconductor

●Wafer processing:

Kukonzekera kwawafa mu photolithography, etching, kuyika filimu yopyapyala ndi njira zina, kuwonetsetsa kulondola kwakukulu komanso kusasinthika kwadongosolo. Kutentha kwake kwapamwamba komanso kukana kwa dzimbiri ndikoyenera kumalo opangira zida za semiconductor.

● Kukula kwa Epitaxial:

Mu SiC kapena GaN epitaxial kukula, monga chonyamulira kutentha ndi kukonza zopyapyala, kuonetsetsa kutentha ndi mtundu wa kristalo pa kutentha kwakukulu, kuwongolera magwiridwe antchito a chipangizocho.

2. Zida zamagetsi

● Kupanga Ma LED:

Ntchito kukonza safiro kapena SiC gawo lapansi, ndi monga chonyamulira Kutentha mu ndondomeko MOCVD, kuonetsetsa yunifolomu kukula epitaxial, kusintha kuwala LED dzuwa ndi khalidwe.

● Laser diode:

Monga mkulu-mwatsatanetsatane fixture, kukonza ndi Kutentha gawo lapansi kuonetsetsa ndondomeko bata, kusintha linanena bungwe mphamvu ndi kudalirika kwa laser diode.

3. Makina olondola

● Optical chigawo processing:

Amagwiritsidwa ntchito pokonza zigawo zolondola monga magalasi owoneka bwino ndi zosefera kuti zitsimikizire kulondola kwambiri komanso kuipitsidwa pang'ono panthawi yokonza, ndipo ndizoyenera kupanga makina apamwamba kwambiri.

● Kukonza Ceramic:

Monga chokhazikika chokhazikika, ndichoyenera kuwongolera mwatsatanetsatane zida za ceramic kuti zitsimikizire kuti makinawa ali olondola komanso osasinthasintha pansi pa kutentha kwambiri komanso malo owononga.

4. Zoyesera za sayansi

●Kuyesa kutentha kwakukulu:

Monga chipangizo chokonzera chitsanzo m'malo otentha kwambiri, chimathandizira kuyesa kutentha kwambiri kuposa 1600 ° C kuti zitsimikizire kufanana kwa kutentha ndi kukhazikika kwachitsanzo.

●Kuyesa kwa vacuum:

Monga chitsanzo kukonza ndi Kutentha chonyamulira mu vakuyumu chilengedwe, kuonetsetsa kulondola ndi repeatability kuyesera, oyenera ❖ kuyanika vakuyumu ndi kutentha mankhwala.

Mfundo zaukadaulo:

| (Katundu) | (Chigawo) | (sizika) | |

| (Zinthu za SiC) |

| (Wt)% | > 99 |

| (Avereji ya kukula kwambewu) |

| micron | 4-10 |

| (Kuchulukana) |

| kg/dm3 | > 3.14 |

| (Kuwoneka kwa porosity) |

| Vo1% | <0.5 |

| (Vickers kuuma) | HV 0.5 | GPA | 28 |

| * (Flexural mphamvu) | 20ºC | MPa | 450 |

| (Compressive mphamvu) | 20ºC | MPa | 3900 pa |

| (Elastic Modulus) | 20ºC | GPA | 420 |

| (Kulimba kwa fracture) |

| MPa/m'% | 3.5 |

| (Thermal conductivity) | 20°C | W/(m*K) | 160 |

| (Kukana) | 20°C | Om.cm | 106-108 |

|

| a(RT**...80ºC) | K-1*10-6 | 4.3 |

|

|

| oºC | 1700 |

Pokhala ndi zaka zambiri zaukadaulo komanso luso lamakampani, XKH imatha kukonza magawo ofunikira monga kukula, njira yotenthetsera ndi kapangidwe ka vacuum adsorption ya chuck malinga ndi zosowa za kasitomala, kuwonetsetsa kuti malondawo asinthidwa bwino ndi kasitomala. SiC silicon carbide ceramic chucks zakhala zofunikira kwambiri pakukonza zophatikizika, kukula kwa epitaxial ndi njira zina zofunika kwambiri chifukwa cha matenthedwe ake abwino kwambiri, kukhazikika kwa kutentha komanso kukhazikika kwamankhwala. Makamaka popanga zida zamtundu wachitatu za semiconductor monga SiC ndi GaN, kufunikira kwa ma silicon carbide ceramic chucks kukupitilira kukula. M'tsogolomu, ndi chitukuko chofulumira cha 5G, magalimoto amagetsi, luntha lochita kupanga ndi matekinoloje ena, chiyembekezo chogwiritsa ntchito silicon carbide ceramic chucks mu makampani opangira semiconductor chidzakhala chokulirapo.

Chithunzi chatsatanetsatane