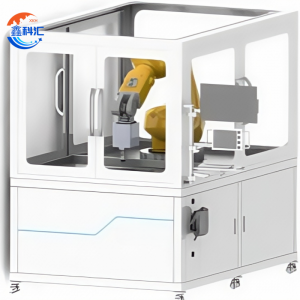

Makina Opukutira a Robotic - High-Precision Automated Surface Finishing

Chithunzi chatsatanetsatane

Chidule cha Makina Opukutira a Robotic

Makina Opukutira a Robotic ndi makina apamwamba kwambiri, opangidwa ndi makina opangidwa kuti akwaniritse zofunikira kwambiri popanga molondola. Zimaphatikiza ukadaulo wa robotic wa ma axis asanu ndi limodzi, ukadaulo wopukutira mokakamiza, komanso masinthidwe amutu wapawiri kuti agwiritse ntchito zida zambiri ndi ma geometries ovuta kulondola kwapadera komanso kusasinthika.

Kaya ndi magalasi owoneka bwino, zida zam'mlengalenga, zida zaukadaulo zolondola, kapena zida zogwiritsira ntchito semiconductor, makinawa amapereka mawonekedwe okhazikika, obwerezabwereza, komanso apamwamba kwambiri, ngakhale pamlingo wa nanometer.

Kugwirizana Kwathunthu kwa Makina Opukutira a Robotic

Dongosolo limathandizira kukonza:

-

Malo athyathyathyakwa galasi, ceramics, ndi zitsulo mbale

-

Mawonekedwe a cylindrical ndi conicalmonga ma rollers, shafts, ndi machubu

-

Zozungulira ndi aspherical zigawokwa optical systems

-

Mawonekedwe a Freeform ndi opanda-axisndi zokhotakhota zovuta ndi kusintha

Kusinthasintha kwake kumapangitsa kuti ikhale yoyenerakupanga zambiri komanso kupanga mwazolondola kwambiri.

Zofunika Kwambiri & Ubwino wa Makina Opukutira a Robotic

1. Dual polishing Head Technology

-

Okonzeka ndikusinthasintha kamodzindikudzizungulirakupukuta mitu kuti athe kusinthasintha.

-

Kusintha kwachangu kwa chida kumathandizira mitundu ingapo yosinthira popanda nthawi yayitali.

-

Ndibwino kuti musinthe pakati pa magawo ovuta komanso opukutira bwino.

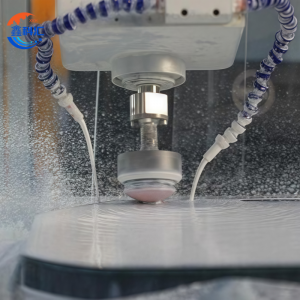

2. Precision Force-Control System

-

Kuwunika nthawi yeniyeni yakuthamanga, kutentha, ndi kupukuta kutuluka kwamadzimadzi.

-

Kugwiritsiridwa ntchito kwa mphamvu kosasinthasintha kumatsimikizira kutha kwapamwamba pamtunda wonsewo.

-

Wokhoza kusintha kuti agwirizane ndi zolakwika zokha.

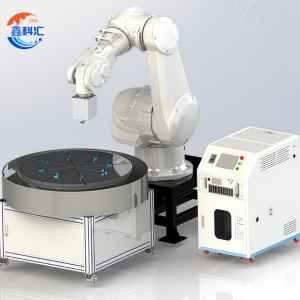

3. Six-Axis Robotic Control

-

Ufulu wathunthu woyenda kuti ugwire ma geometri ovuta.

-

Njira zoyenda zosalala, zolondola zowerengedwera pogwiritsa ntchito ma algorithms apamwamba.

-

Kubwereza kobwerezabwereza kwapamwamba kuchokera ku ± 0.04 mm kufika ku ± 0.1 mm kutengera chitsanzo.

4. Smart Automation & Measurement

-

Zida zosinthira zokha kuti mukhazikitse bwino ndikuyanjanitsa.

-

Dongosolo la kuyeza kolinganiza kuti muyike bwino.

-

Zosankhakuwunika makulidwe a pa intanetikwa nthawi yeniyeni kulamulira khalidwe.

5. Industrial-Grade Build Quality

-

Mapangidwe apawiri a servo-motor amawonjezera kupukuta bwino komanso kukhazikika.

-

Makina okhwima amachepetsa kugwedezeka ndikuwonetsetsa kukhazikika kwanthawi yayitali.

Mafotokozedwe Aukadaulo a Makina Opukutira a Robotic

| Zida Model | Thupi la Robot | Bwerezani Kulondola Kwakayimidwe | Processing Diameter Range | Mutu Wowongolerera Umodzi | Multi-Rotation polishing Head | Chida Chaching'ono | Kupukuta kwamtundu wa Wheel Main | Kupukuta Mutu Wozungulira | Malizitsani Kusintha Kwachangu | Auto Calibration Chida | Mutu Woyezera wa Coordinate | Online Makulidwe Monitoring | Numerical Control Platform |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| IRP500S | Chithunzi cha TX2-90L | ± 0.04mm / zonse | Φ50~Φ500mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP600S | Chithunzi cha TX2-140 | ± 0.05mm / zonse | Φ50~Φ600mm | √ | × | √ | √ | √ | × | ○ | ○ | ○ | ○ |

| IRP800S | Chithunzi cha TX2-160 | ± 0.05mm / zonse | Φ80~Φ800mm | √ | √ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000S | Zithunzi za TX200/L | ± 0.06mm / zonse | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP1000A | ABB IRB6700-200/2.6 | ± 0.1mm / zonse | Φ100~Φ1000mm | √ | ○ | √ | √ | √ | ○ | ○ | ○ | ○ | ○ |

| IRP2000A | ABB IRB6700-150/3.2 | ± 0.1mm / zonse | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

| IRP2000AD | ABB IRB6700-150/3.2 | ± 0.1mm / zonse | Φ200~Φ2000mm | √ | ○ | √ | √ | √ | × | × | × | ○ | ○ |

FAQ - Makina Opukutira a Robot

1. Ndi mitundu yanji ya zida zogwirira ntchito zomwe makina opukuta loboti angagwire?

Makina athu opukutira maloboti amathandizira mawonekedwe ndi mawonekedwe osiyanasiyana, kuphatikiza lathyathyathya, lopindika, lozungulira, lopanda mawonekedwe, ndi ma contour ovuta. Ndi yoyenera pazigawo zowoneka bwino, zoumba mwatsatanetsatane, malo achitsulo, ndi ntchito zina zopukutira bwino kwambiri.

2. Kodi pali kusiyana kotani pakati pa Single Rotation ndi Multi-Rotation polishing mitu?

-

Mutu Wowongolerera Umodzi: Chidachi chimazungulira mozungulira nsonga imodzi, yabwino yomaliza yokhazikika komanso yochotsa zinthu mwachangu.

-

Multi-Rotation polishing Head: Chidachi chimaphatikiza kuzungulira ndi kudzizungulira (kuzungulira), kupangitsa kupukuta kofananirako pamalo opindika komanso osakhazikika.

3. Kodi pazipita processing m'mimba mwake?

Kutengera chitsanzo:

-

Mitundu yokhazikika (mwachitsanzo, IRP500S) chogwiriraΦ50–Φ500mm.

-

Mitundu yayikulu (mwachitsanzo, IRP2000AD) imagwira mpakaΦ2000 mm.

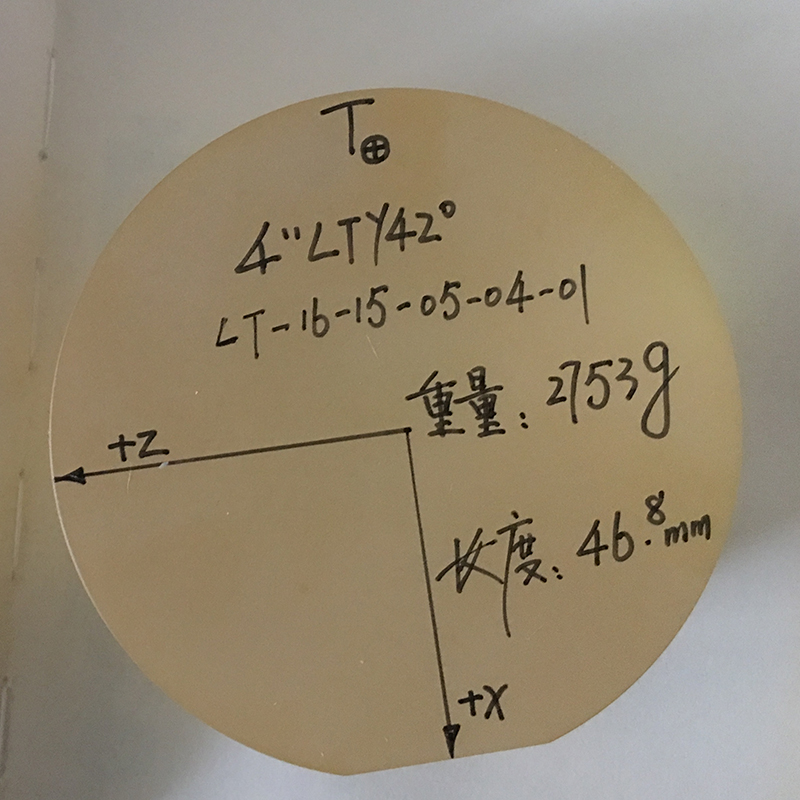

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.