Monga gawo lachitatu la semiconductor gawo lapansi,silicon carbide (SiC)Single crystal ili ndi chiyembekezo chogwiritsa ntchito kwambiri popanga zida zamagetsi zothamanga kwambiri komanso zamphamvu kwambiri. Ukadaulo waukadaulo wa SiC umagwira ntchito yofunika kwambiri popanga zida zapamwamba zapansi panthaka. Nkhaniyi ikuwonetsa momwe kafukufukuyu akuyendera paukadaulo wa SiC ku China komanso kumayiko ena, kusanthula ndikuyerekeza njira zodulira, kupera, ndi kupukuta, komanso momwe zimakhalira pakupendekeka kwamphete komanso kuuma kwa pamwamba. Ikuwonetsanso zovuta zomwe zilipo mu SiC wafer processing ndikukambirana zachitukuko chamtsogolo.

Silicon carbide (SiC)zowotcherera ndi zida zofunika zoyambira pazida za m'badwo wachitatu za semiconductor ndipo zimakhala zofunikira kwambiri komanso kuthekera kwa msika m'magawo monga ma microelectronics, magetsi amagetsi, ndi kuyatsa kwa semiconductor. Chifukwa cha kuuma kwambiri ndi kukhazikika kwa mankhwalaSiC single makhiristo, njira zachikhalidwe zopangira semiconductor sizoyenera kwathunthu makina awo. Ngakhale makampani ambiri apadziko lonse lapansi achita kafukufuku wambiri paukadaulo wofunikira wa makina a SiC single crystals, matekinoloje oyenera amasungidwa mwachinsinsi.

M'zaka zaposachedwa, China yawonjezera kuyesetsa pakupanga zida ndi zida za SiC single crystal. Komabe, kupita patsogolo kwaukadaulo wa zida za SiC mdziko muno pano kuli koletsedwa ndi ukadaulo wowongolera komanso mtundu wawafer. Chifukwa chake, ndikofunikira kuti China ipititse patsogolo luso la SiC kuti lipititse patsogolo mtundu wa magawo amtundu wa SiC single crystal ndikukwaniritsa ntchito zawo zothandiza komanso kupanga misa.

Njira zazikuluzikulu zogwirira ntchito zikuphatikizapo: kudula → kugaya kowawa → kupukuta bwino → kupukuta movutikira (kupukuta makina) → kupukuta bwino (kupukuta kumakina, CMP) → kuyendera.

| Khwerero | SiC Wafer Processing | Traditional Semiconductor Single-Crystal Material Processing |

| Kudula | Amagwiritsa ntchito ukadaulo wocheka mawaya angapo kuti adule ma ingots a SiC kukhala zowonda zazing'ono | Nthawi zambiri amagwiritsa ntchito njira zodulira masamba amkati-m'mimba mwake kapena kunja kwa m'mimba mwake |

| Kupera | Agawanika coarse ndi chabwino akupera kuchotsa macheka zizindikiro ndi kuwonongeka zigawo chifukwa kudula | Njira zogaya zingasiyane, koma cholinga chake n’chofanana |

| Kupukutira | Kuphatikizirapo kupukuta kwaukali komanso kopitilira muyeso kwambiri pogwiritsa ntchito makina opukutira ndi mankhwala (CMP) | Nthawi zambiri zimaphatikizapo kupukuta kwamankhwala (CMP), ngakhale masitepe enieni amatha kusiyana |

Kudula kwa SiC Single Crystals

Mu processing waSiC single makhiristo, kudula ndi sitepe yoyamba komanso yovuta kwambiri. Uta, wopingasa, ndi kusiyanasiyana kwa makulidwe (TTV) obwera chifukwa cha kudula kumatsimikizira ubwino ndi mphamvu za ntchito zotsatizana ndi kupera ndi kupukuta.

Zida zodulira zitha kugawidwa molingana ndi mawonekedwe kukhala macheka a diamondi amkati (ID), macheka akunja (OD), macheka amagulu, ndi mawaya. Mawaya, nawonso, amatha kugawidwa ndi mtundu wawo woyenda kukhala mawaya obwerezabwereza komanso a loop (osatha). Kutengera kudula limagwirira a abrasive, mawaya macheka slicing njira akhoza kugawidwa mu mitundu iwiri: ufulu abrasive waya macheka ndi anakonza abrasive diamondi waya macheka.

1.1 Njira Zachikhalidwe Zodula

Kuzama kwa macheka a m'mimba mwake (OD) kumachepetsedwa ndi kukula kwa tsamba. Panthawi yodula, tsambalo limakonda kugwedezeka ndi kupatuka, zomwe zimapangitsa kuti pakhale phokoso lalikulu komanso kusakhazikika bwino. Macheka amkati amkati (ID) amagwiritsa ntchito ma abrasives a diamondi mkatikati mwa tsamba ngati m'mphepete mwake. Masamba awa amatha kukhala owonda ngati 0.2 mm. Pakudula, tsamba la ID limazungulira mwachangu pomwe zinthu zomwe ziyenera kudulidwa zimayenda mozungulira mozungulira pakatikati pa tsambalo, ndikumadula ndikusuntha uku.

Macheka a diamondi amafunikira kuyimitsidwa pafupipafupi ndikusintha, ndipo liwiro lodulira ndilotsika kwambiri - nthawi zambiri silidutsa 2 m / s. Amavutikanso ndi kuvala kwakukulu kwamakina komanso mtengo wokonza. Chifukwa cha kukula kwa tsamba la macheka, utali wodulira sungakhale wocheperako, ndipo kudula magawo ambiri sikutheka. Zida zocheka zachikhalidwe izi zimachepetsedwa ndi kulimba kwa maziko ndipo sizingadutse mokhotakhota kapena kutsekereza ma radiyo. Amatha kudula mowongoka, kupanga ma kerfs ambiri, kukhala ndi zokolola zochepa, motero ndi osayenera kudula.SiC makristasi.

1.2 Waya wa Abrasive Waulere Wawona Kudula Mawaya Ambiri

Njira yodula mawaya yaulere imagwiritsa ntchito kuthamanga kwa waya kunyamula matope mu kerf, ndikupangitsa kuchotsa zinthu. Imagwiritsa ntchito mawonekedwe obwereza ndipo pakadali pano ndi njira yokhwima komanso yogwiritsidwa ntchito kwambiri pakudulira koyenera kwa silicon imodzi ya kristalo. Komabe, kugwiritsa ntchito kwake mu kudula kwa SiC sikunaphunziridwe mozama.

Mawaya aulere abrasive amatha kupanga mawafa okhala ndi makulidwe osakwana 300 μm. Amapereka kutayika kwa kerf pang'ono, nthawi zambiri kumapangitsa kutsika, ndipo kumapangitsa kuti pakhale mawonekedwe abwino. Komabe, chifukwa cha njira yochotsera zinthu - kutengera kugudubuza ndi kulowetsa kwa ma abrasives - pamwamba pake pamakhala kupsinjika kotsalira, ma microcracks, ndi zigawo zozama kwambiri. Izi zimatsogolera ku warping, zimapangitsa kuti zikhale zovuta kuwongolera kulondola kwambiri, ndikuwonjezera katundu pamasitepe otsatirawa.

Ntchito yodula imakhudzidwa kwambiri ndi slurry; m'pofunika kusunga sharpness wa abrasives ndi ndende ya slurry. Kuchiza matope ndi kubwezeretsanso zinthu zina ndi zodula. Mukadula ma ingot akulu akulu, ma abrasives amavutika kulowa m'mizere yakuya komanso yayitali. Pansi pa njere zonyezimira zomwezo, kutayika kwa kerf ndikokulirapo kuposa macheka awaya okhazikika.

1.3 Fixed Abrasive Diamond Waya Anawona Multi-Waya Kudula

Mawaya a diamondi osasunthika amapangidwa ndikuyika tinthu tating'ono ta diamondi pagawo lachitsulo chachitsulo kudzera pa electroplating, sintering, kapena njira zomangira utomoni. Mawaya a diamondi opangidwa ndi electroplated amapereka zabwino monga ma kerfs ocheperako, mtundu wabwino wa magawo, kuchita bwino kwambiri, kuipitsidwa kochepa, komanso kutha kudula zida zolimba kwambiri.

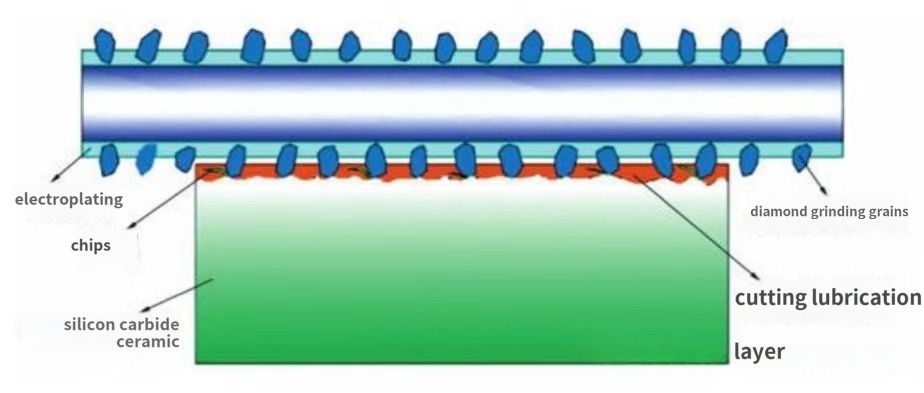

The reciprocating electroplated diamondi waya macheka pakali pano ambiri ambiri njira kudula SiC. Chithunzi 1 (chosasonyezedwa apa) chikuwonetsa kusalala kwa pamwamba kwa zowotcha za SiC zodulidwa pogwiritsa ntchito njirayi. Pamene kudula kukupitirira, masamba ofiira amawonjezeka. Izi ndichifukwa choti malo olumikizana pakati pa waya ndi zinthu zimawonjezeka pamene waya akupita pansi, kuwonjezereka kukana ndi kugwedezeka kwa waya. Wayayo akafika m'mimba mwake, kugwedezeka kumakhala pachimake, zomwe zimapangitsa kuti pakhale nkhondo.

M'magawo omaliza a kudula, chifukwa cha kuthamanga kwa waya, kuyenda kwa liwiro lokhazikika, kutsika, kuyimitsa, ndi kubwereranso, komanso zovuta kuchotsa zinyalala ndi choziziritsa kukhosi, mawonekedwe a pamwamba a chophatikizira amawonongeka. Kusintha kwa mawaya ndi kusinthasintha kwa liwiro, komanso tinthu tating'ono ta diamondi pawaya, ndizomwe zimayambitsa kukwapula pamwamba.

1.4 Ukadaulo Wopatukana Wozizira

Kulekanitsa kozizira kwa makhiristo amodzi a SiC ndi njira yatsopano yopangira zinthu zamtundu wachitatu wa semiconductor. M'zaka zaposachedwa, yakopa chidwi kwambiri chifukwa cha zabwino zake pakuwongolera zokolola komanso kuchepetsa kutayika kwa zinthu. Ukadaulowu utha kuwunikidwa kuchokera kuzinthu zitatu: mfundo yogwirira ntchito, kuyenda kwa njira, ndi zabwino zazikulu.

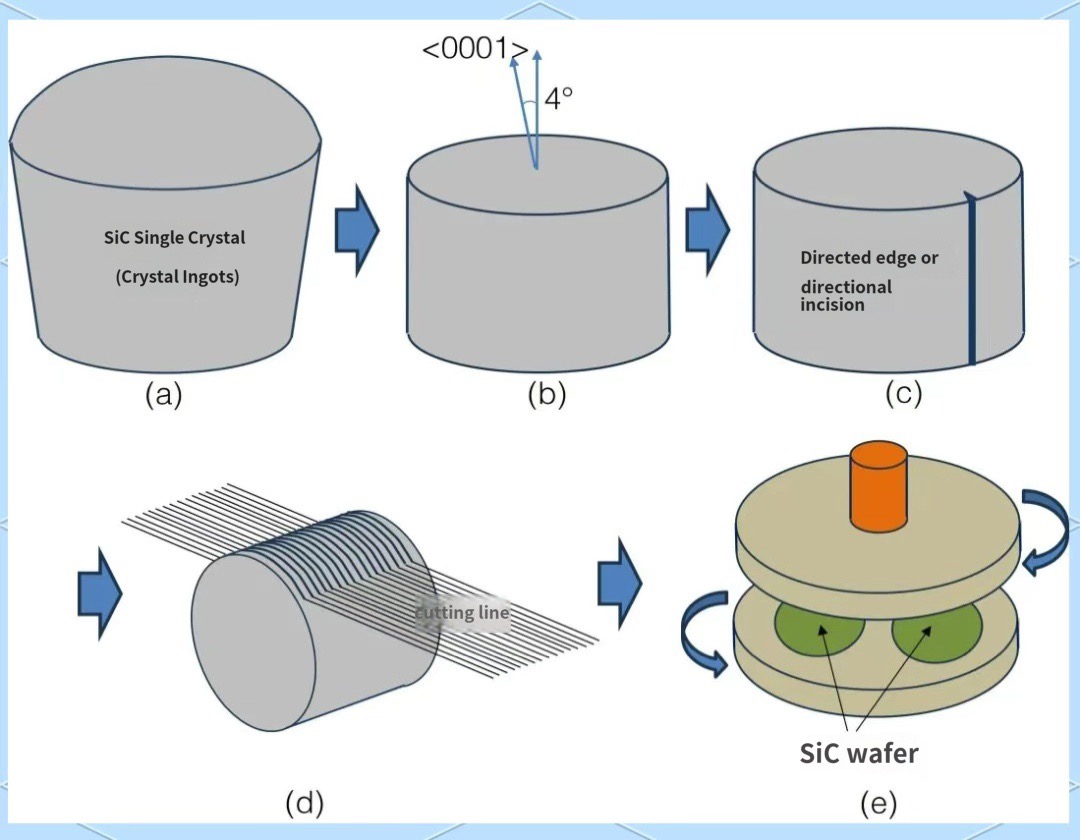

Crystal Orientation Determination ndi Outer Diameter Akupera: Asanayambe kukonza, mawonekedwe a kristalo a SiC ingot ayenera kutsimikiziridwa. Ingot imapangidwa kukhala cylindrical (yomwe nthawi zambiri imatchedwa SiC puck) kudzera m'mimba mwake yakunja. Sitepe iyi imayala maziko a kudula ndi kudula kotsatira.

Kudula Mawaya Angapo: Njira iyi imagwiritsa ntchito tinthu totupa tophatikizika ndi mawaya odulira kuti tidutse chitsulo cha cylindrical. Komabe, imakhala ndi kutayika kwakukulu kwa kerf komanso zovuta zapamtunda.

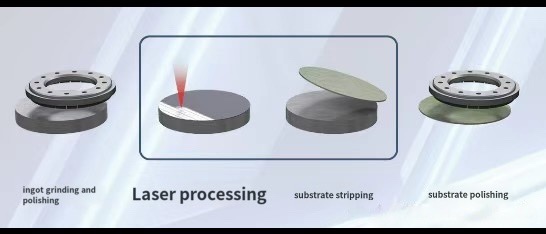

Laser Cutting Technology: Laser imagwiritsidwa ntchito kupanga wosanjikiza wosinthidwa mkati mwa kristalo, pomwe magawo owonda amatha kuchotsedwa. Njirayi imachepetsa kutayika kwa zinthu komanso imathandizira kukonza bwino, ndikupangitsa kuti ikhale njira yatsopano yopangira SiC wafer kudula.

Kudula Njira Kukhathamiritsa

Fixed Abrasive Multi-Wire Cutting: Uwu ndiye ukadaulo wodziwika bwino, woyenererana ndi kuuma kwakukulu kwa SiC.

Electrical Discharge Machining (EDM) ndi Cold Separation Technology: Njirazi zimapereka mayankho osiyanasiyana ogwirizana ndi zofunikira zenizeni.

Njira Yopulitsira: Ndikofunikira kulinganiza kuchuluka kwa kuchotsera zinthu komanso kuwonongeka kwapamtunda. Chemical Mechanical Polishing (CMP) imagwiritsidwa ntchito kuti ikhale yofanana.

Kuwunika Munthawi Yeniyeni: Matekinoloje owunikira pa intaneti amayambitsidwa kuti azitha kuyang'anira kuuma kwapanthawi yeniyeni.

Laser Slicing: Njira iyi imachepetsa kutayika kwa kerf ndikufupikitsa kachipangizo kameneka, ngakhale malo okhudzidwa ndi kutentha amakhalabe ovuta.

Ukadaulo Wopangira Ma Hybrid: Kuphatikiza njira zamakina ndi mankhwala kumathandizira kukonza bwino.

Ukadaulo uwu wakwaniritsa kale ntchito zamafakitale. Infineon, mwachitsanzo, adapeza SILTECTRA ndipo tsopano ali ndi ziphaso zoyambira zomwe zimathandizira kupanga zowotcha ma inchi 8. Ku China, makampani ngati Delong Laser akwanitsa kutulutsa zopyapyala 30 pa ingot iliyonse pokonza ma 6-inch wafer, kuyimira kusintha kwa 40% kuposa njira zachikhalidwe.

Pamene kupanga zida zapakhomo kukuchulukirachulukira, ukadaulo uwu ukuyembekezeka kukhala yankho lalikulu pakukonza gawo la SiC. Ndi kukula kwa zida za semiconductor, njira zodulira zachikhalidwe zatha. Pakati pa zosankha zamakono, ukadaulo wa diamondi wobwereza ukuwonetsa chiyembekezo chogwiritsa ntchito kwambiri. Kudula kwa laser, monga njira yomwe ikuwonekera, kumapereka zabwino zambiri ndipo akuyembekezeredwa kukhala njira yoyamba yodulira mtsogolo.

2,SiC Single Crystal Akupera

Monga woimira semiconductors a m'badwo wachitatu, silicon carbide (SiC) imapereka zabwino zambiri chifukwa cha kuchuluka kwake, malo amagetsi osweka kwambiri, kuthamanga kwambiri kwa ma elekitironi oyendetsa, komanso matenthedwe abwino kwambiri. Izi zimapangitsa SiC kukhala yopindulitsa kwambiri pamakina apamwamba kwambiri (mwachitsanzo, malo a 1200V). Ukadaulo wopangira magawo a SiC ndi gawo lofunikira pakupangira zida. Ubwino wa pamwamba ndi kulondola kwa gawo lapansi zimakhudza mwachindunji ubwino wa epitaxial wosanjikiza ndi ntchito ya chipangizo chomaliza.

Cholinga chachikulu cha ntchito yopera ndikuchotsa macheka a pamwamba ndi zigawo zowonongeka zomwe zimayambitsidwa panthawi yocheka, ndi kukonza mapindikidwe opangidwa ndi kudula. Popeza SiC ndi yolimba kwambiri, kugaya kumafuna kugwiritsa ntchito zomatira zolimba monga boron carbide kapena diamondi. Kugaya kozolowereka kumagawika kukhala mphesa komanso kugaya bwino.

2.1 Kusanja kosalala komanso kosalala

Akupera akhoza m'gulu kutengera abrasive tinthu kukula:

Coarse Akupera: Amagwiritsa ntchito zomatira zokulirapo makamaka kuchotsa macheke ndi zigawo zowonongeka zomwe zimachitika podula, kuwongolera kukonza bwino.

Kugaya Bwino: Kumagwiritsa ntchito zomatira zonyezimira bwino kuchotsa zosanjikiza zomwe zatsala chifukwa chogaya, kuchepetsa kuuma kwa pamwamba, ndikuwonjezera kukongola kwa pamwamba.

Ambiri opanga magawo apanyumba a SiC amagwiritsa ntchito njira zazikulu zopangira. Njira yodziwika bwino imaphatikizapo kugaya mbali ziwiri pogwiritsa ntchito mbale yachitsulo chonyezimira ndi slurry ya diamondi ya monocrystalline. Izi zimachotsa bwino chiwonongeko chomwe chimasiyidwa ndi macheka a waya, kukonza mawonekedwe opindika, ndikuchepetsa TTV (Total Thickness Variation), Bow, ndi Warp. Mlingo wochotsa zinthu ndi wokhazikika, nthawi zambiri umafika 0.8-1.2 μm/min. Komabe, mawonekedwe opindikawa amakhala owuma kwambiri - nthawi zambiri pafupifupi 50 nm - zomwe zimapangitsa kuti pakhale zofunikira kwambiri pamasitepe opukutira.

2.2 Kupera Mbali Limodzi

Njira yopera ya mbali imodzi yokha ya mkate wophwanyika panthawi imodzi. Panthawi imeneyi, kapezi kameneka kamayikidwa sera pa mbale yachitsulo. Pansi pa kukakamizidwa kogwiritsidwa ntchito, gawo lapansi limadutsa pang'onopang'ono, ndipo pamwamba pake amaphwanyidwa. Pambuyo popera, m'munsi pamwamba ndi angafanane. Kuponderezedwako kukachotsedwa, kumtunda kumakonda kubwerera ku mawonekedwe ake oyambirira, zomwe zimakhudzanso malo omwe ali pansi kale-kuchititsa kuti mbali zonse ziwiri zipirire ndi kutsika pansi.

Kuphatikiza apo, mbale yoperayo imatha kukhala yopindika pakanthawi kochepa, zomwe zimapangitsa kuti mkatewo ukhale wowoneka bwino. Kuti mbale ikhale yosalala, kuvala pafupipafupi kumafunika. Chifukwa cha kuchepa kwachangu komanso kusayenda bwino kwa kanyumba kakang'ono, kugaya mbali imodzi sikoyenera kupanga misa.

Nthawi zambiri, #8000 mawilo akupera amagwiritsidwa ntchito popera bwino. Ku Japan, njirayi ndi yokhwima ndipo imagwiritsa ntchito #30000 mawilo opukuta. Izi zimathandiza kuti pamwamba pa roughness ya zowotcha kukonzedwa kufika pansi 2 nm, kupanga yopyapyala kukonzekera CMP yomaliza (Chemical Mechanical Polishing) popanda processing zina.

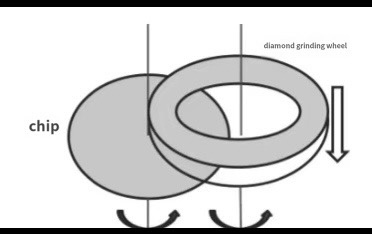

2.3 Ukadaulo Wopatulira Mbali Imodzi

Diamondi Single Sided Thinning Technology ndi njira yatsopano yopera mbali imodzi. Monga momwe chithunzi 5 (chosasonyezedwa apa), ndondomekoyi imagwiritsa ntchito mbale yopera ya diamondi. Chophikacho chimakhazikika kudzera pa vacuum adsorption, pomwe chowotcha ndi gudumu lopera la diamondi zimazungulira nthawi imodzi. Gudumu lopera limasunthira pansi pang'onopang'ono kuti likhale lopyapyala kuti likhale lokhuthala. Mbali imodzi ikamalizidwa, chophikacho chimatembenuzidwira kuti chigwire mbali inayo.

Pambuyo kupatulira, 100 mm wafer akhoza kukwaniritsa:

Kuwerama <5 μm

TTV <2 μm

Kukula kwapamwamba <1 nm

Njira yopangira kaphatikizidwe kamodzi kameneka imapereka kukhazikika kwakukulu, kusasinthika kwabwino kwambiri, komanso kuchotsera kwazinthu zambiri. Poyerekeza ndi mphero wamba wambali ziwiri, njira iyi imathandizira kuti akupera bwino ndi 50%.

2.4 Kupera M'mbali Ziwiri

Kupera kwa mbali ziwiri kumagwiritsa ntchito mbale ya pamwamba ndi yotsika kuti ipere mbali zonse ziwiri za gawo lapansi, kuwonetsetsa kuti pamwamba ndi pamwamba pabwino mbali zonse ziwiri.

Panthawiyi, mbale zopera zimayamba kukakamiza pamwamba pa chogwirira ntchito, zomwe zimapangitsa kuti pakhale kusintha komanso kuchotsa zinthu pang'onopang'ono pamalowo. Pamene mawanga okwera akuwongolera, kukakamiza kwa gawo lapansi pang'onopang'ono kumakhala kofanana, zomwe zimapangitsa kuti pakhale kusintha kosasinthasintha pamtunda wonse. Izi zimathandiza kuti pamwamba ndi pansi pakhale pansi mofanana. Kugaya kukatha ndipo kukakamizidwa kumasulidwa, gawo lililonse la gawo lapansi limachira mofanana chifukwa cha kupanikizika kofanana komwe kunachitika. Izi zimabweretsa kugundana kochepa komanso kukhazikika bwino.

Kukhwimira kwa pamwamba kwa mtandawo ukapera kumadalira kukula kwa tinthu ting'onoting'ono tomwe timapanga timapanga tosalala. Mukamagwiritsa ntchito ma abrasives a 5 μm pogaya mbali ziwiri, kusalala kwa mkate ndi kusiyanasiyana kwa makulidwe kumatha kuwongoleredwa mkati mwa 5 μm. Miyezo ya Atomic Force Microscopy (AFM) imawonetsa kuuma kwapamtunda (Rq) pafupifupi 100 nm, yokhala ndi maenje opera mpaka 380 nm kuya ndi zizindikiro zowoneka bwino zobwera chifukwa cha abrasive.

Njira yotsogola kwambiri imaphatikizapo kugaya mbali ziwiri pogwiritsa ntchito mapepala a thovu a polyurethane ophatikizidwa ndi polycrystalline diamondi slurry. Njirayi imapanga zowotcha zokhala ndi roughness yotsika kwambiri, kukwaniritsa Ra <3 nm, zomwe zimapindulitsa kwambiri pakupukuta kwa magawo a SiC.

Komabe, kukanda pamwamba kumakhalabe nkhani yosathetsedwa. Kuonjezera apo, diamondi ya polycrystalline yomwe imagwiritsidwa ntchito popanga izi imapangidwa kudzera muzitsulo zophulika, zomwe zimakhala zovuta mwaukadaulo, zimapereka zotsika mtengo, komanso ndizokwera mtengo kwambiri.

Kupukuta kwa SiC Single Crystals

Kuti tikwaniritse malo apamwamba opukutidwa pazitsulo za silicon carbide (SiC), kupukuta kuyenera kuchotseratu maenje okupera ndi ma nanometer-scale padziko undulations. Cholinga chake ndi kupanga malo osalala, opanda chilema popanda kuipitsidwa kapena kuwonongeka, palibe kuwonongeka kwapansi, komanso kupanikizika kotsalira pamwamba.

3.1 Mechanical polishing ndi CMP ya SiC Wafers

Pambuyo pa kukula kwa SiC single crystal ingot, zolakwika zapamtunda zimalepheretsa kuti isagwiritsidwe ntchito mwachindunji kukula kwa epitaxial. Choncho, processing ina chofunika. Ingot imapangidwa koyamba kukhala mawonekedwe a cylindrical pozungulira, kenaka amadulidwa muzowotcha pogwiritsa ntchito waya, ndikutsatiridwa ndi kutsimikizira kwa crystallographic. Kupukutira ndi gawo lofunikira pakuwongolera mtundu wawafer, kuthana ndi kuwonongeka komwe kungachitike chifukwa cha kuwonongeka kwa kristalo ndi njira zopangira kale.

Pali njira zinayi zazikulu zochotsera zigawo zowonongeka pa SiC:

Kupukuta pamakina: Kusavuta koma kumasiya zokopa; oyenera kupukuta koyamba.

Chemical Mechanical Polishing (CMP): Imachotsa zokopa pogwiritsa ntchito etching yamankhwala; oyenera kupukuta mwatsatanetsatane.

Hydrogen etching: Imafunikira zida zovuta, zomwe zimagwiritsidwa ntchito kwambiri munjira za HTCVD.

Kupukuta mothandizidwa ndi plasma: Zovuta komanso zosagwiritsidwa ntchito kawirikawiri.

Kupukuta pamakina kokha kumayambitsa zokala, pomwe kupukuta kokha ndi mankhwala kumatha kupangitsa kuti pakhale zosalala. CMP imaphatikiza zabwino zonse ziwiri ndikupereka njira yabwino, yotsika mtengo.

CMP Ntchito Mfundo

CMP imagwira ntchito pozungulira chophatikizira pansi pa kanikizidwe kokhazikitsidwa ndi pad yopukutira yozungulira. Kuyenda kwachibale kumeneku, kuphatikiza ndi ma abrasion amawotchi kuchokera ku nano-kakulidwe abrasives mu slurry ndi zochita za mankhwala a reactive agents, amakwaniritsa pamwamba planarization.

Zida zazikulu zomwe zimagwiritsidwa ntchito:

Polishing slurry: Muli ndi abrasives ndi reagents mankhwala.

Pad yopukutira: Imachepa mukamagwiritsa ntchito, imachepetsa kukula kwa pore komanso kutulutsa bwino. Kuvala nthawi zonse, makamaka pogwiritsa ntchito chovala cha diamondi, kumafunika kubwezeretsa nkhanza.

Njira yodziwika bwino ya CMP

Abrasive: 0.5 μm diamondi slurry

Kukula kwapatsogolo: ~ 0.7 nm

Chemical Mechanical polishing:

Zida zopukutira: AP-810 chopukutira cha mbali imodzi

Kuthamanga: 200 g / cm²

Liwiro la mbale: 50 rpm

Kuthamanga kwa Ceramic: 38 rpm

Kupangidwa kwa Slurry:

SiO₂ (30 wt%, pH = 10.15)

0–70 wt% H₂O₂ (30 wt%, giredi ya reagent)

Sinthani pH kukhala 8.5 pogwiritsa ntchito 5 wt% KOH ndi 1 wt% HNO₃

Kuthamanga kwa slurry: 3 L / min, kubwerezedwa

Izi zimawongolera bwino SiC wafer komanso zimakwaniritsa zofunikira pamayendedwe akumunsi.

Zovuta Zaukadaulo Pakupukuta Kwamakina

SiC, monga semiconductor ya bandgap, imagwira ntchito yofunika kwambiri pamakampani opanga zamagetsi. Ndi zinthu zabwino kwambiri zakuthupi ndi zamankhwala, makhiristo a SiC amodzi ndi oyenerera malo owopsa, monga kutentha kwambiri, ma frequency apamwamba, mphamvu yayikulu, komanso kukana ma radiation. Komabe, mawonekedwe ake olimba komanso opepuka amapereka zovuta zazikulu pakugaya ndi kupukuta.

Monga opanga otsogola padziko lonse lapansi akusintha kuchoka pa 6-inchi kupita ku 8-inchi zowotcha, zovuta monga kung'amba ndi kuwonongeka kwa zopindika panthawi yokonza zakhala zikudziwika kwambiri, zomwe zimakhudza kwambiri zokolola. Kuthana ndi zovuta zaukadaulo zamagawo a 8-inch SiC tsopano ndiye chizindikiro chachikulu chakupita patsogolo kwamakampani.

Munthawi ya 8-inch, SiC wafer processing ikukumana ndi zovuta zambiri:

Kuchulukitsa kwawafer ndikofunikira kuti muwonjezere kutulutsa kwa chip pa batch iliyonse, kuchepetsa kutayika kwa m'mphepete, komanso kutsitsa mtengo wopangira - makamaka chifukwa cha kukwera kwa kuchuluka kwa magalimoto amagetsi.

Ngakhale kukula kwa makhiristo amodzi a 8-inch SiC kwakula, njira zobwerera kumbuyo monga kugaya ndi kupukuta zimakumanabe ndi zovuta, zomwe zimapangitsa kuti pakhale zokolola zochepa (40-50% yokha).

Zophika zazikuluzikulu zimakumana ndi kugawa kovutirapo kowonjezereka, kumawonjezera kuvutikira kwa kuwongolera kupsinjika kwa kupukuta ndi kusasinthika kwa zokolola.

Ngakhale makulidwe a 8-inch wafers akuyandikira a 6-inch wafers, amatha kuwonongeka pakagwira ntchito chifukwa cha kupsinjika ndi kumenyana.

Kuchepetsa kupsinjika kokhudzana ndi kudula, tsamba lankhondo, ndi kusweka, kudula kwa laser kumagwiritsidwa ntchito kwambiri. Komabe:

Ma lasers autali-wavelength amachititsa kuwonongeka kwa kutentha.

Ma lasers amfupi-wavelength amapanga zinyalala zolemetsa ndikukulitsa zosanjikiza zowonongeka, ndikuwonjezera kukhathamiritsa.

Mechanical polishing Workflow ya SiC

General process flow ikuphatikizapo:

Kudula koyang'ana

Coarse akupera

Akupera bwino

Kupukuta kwamakina

Chemical Mechanical polishing (CMP) ngati sitepe yomaliza

Kusankha njira ya CMP, kapangidwe ka njira, ndi kukhathamiritsa kwa magawo ndikofunikira. Popanga ma semiconductor, CMP ndiye gawo lodziwikiratu popanga zowotcha za SiC zokhala ndi zosalala, zopanda chilema, komanso zosawonongeka, zomwe ndizofunikira pakukula kwapamwamba kwa epitaxial.

(a) Chotsani ingot ya SiC ku crucible;

(b) Pangani mawonekedwe oyambira pogwiritsa ntchito kupera awiri akunja;

(c) Dziwani mawonekedwe a kristalo pogwiritsa ntchito ma flats kapena notches;

(d) Dulani ingot kukhala zopyapyala zopyapyala pogwiritsa ntchito macheke a mawaya ambiri;

(e) Kukwaniritsa kusalala kwa pamwamba ngati galasi pogaya ndi kupukuta masitepe.

Mukamaliza masitepe angapo okonzekera, m'mphepete mwakunja kwa chowotcha cha SiC nthawi zambiri chimakhala chakuthwa, zomwe zimawonjezera chiwopsezo chopukutira mukamagwira kapena kugwiritsa ntchito. Pofuna kupewa fragility yotere, kugaya m'mphepete ndikofunikira.

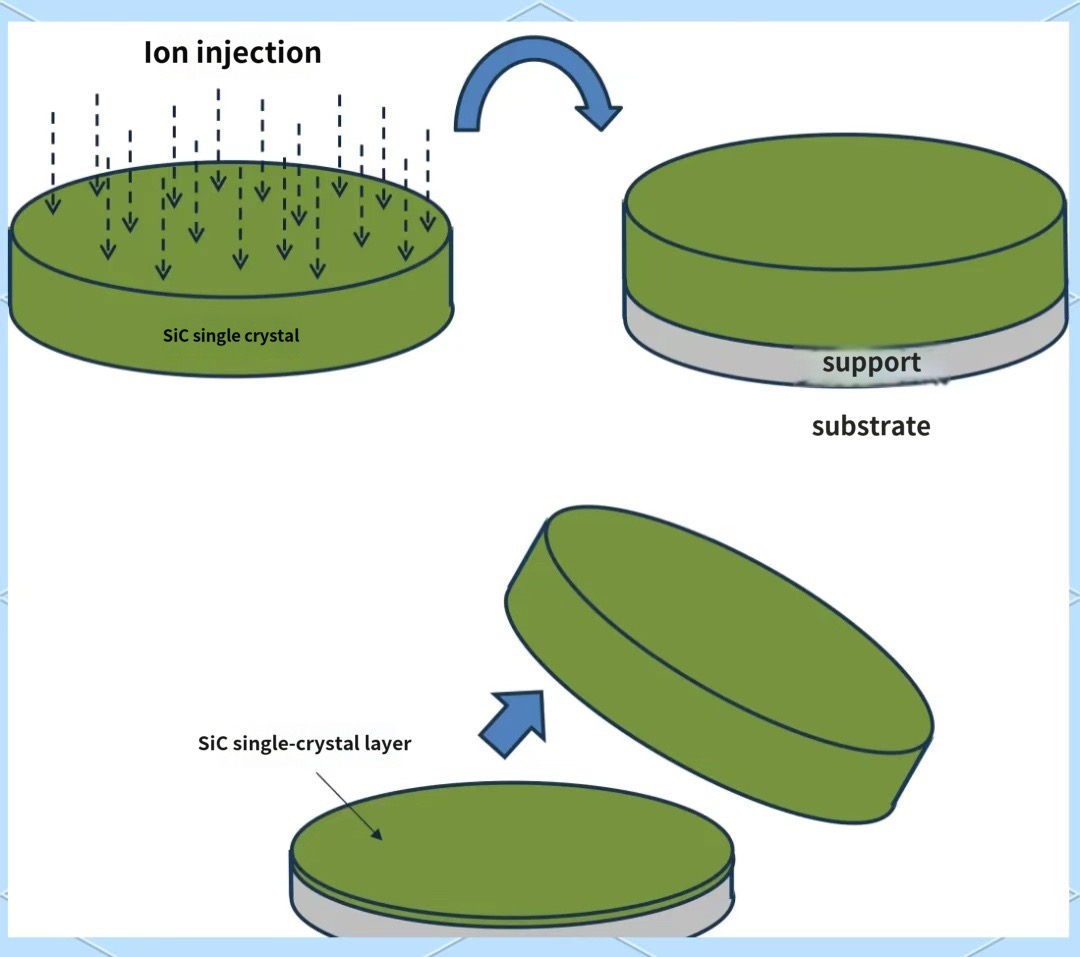

Kuphatikiza pa njira zachikhalidwe zodula, njira yatsopano yokonzekera zowotcha za SiC zimaphatikizapo ukadaulo wolumikizana. Njirayi imathandizira kupanga chophatikizika mwa kumangiriza wosanjikiza wocheperako wa SiC single-crystal ku gawo laling'ono (lothandizira gawo lapansi).

Chithunzi 3 chikuwonetsa njira yoyendetsera:

Choyamba, delamination wosanjikiza amapangidwa pa kuya kwapadera pamwamba pa SiC single crystal kudzera hydrogen ion implantation kapena njira zofanana. SiC single crystal yomwe idakonzedwa imamangirizidwa ku gawo lapansi lothandizira lathyathyathya ndikuyika kupsinjika ndi kutentha. Izi zimalola kusamutsa bwino ndikulekanitsa kwa SiC single-crystal layer pagawo lothandizira.

Wopatukana wa SiC wosanjikiza amalandila chithandizo chapamwamba kuti akwaniritse kupendekera kofunikira ndipo atha kugwiritsidwanso ntchito munjira zomangirira. Poyerekeza ndi kudula kwachikhalidwe kwa makristalo a SiC, njirayi imachepetsa kufunikira kwa zida zodula. Ngakhale zovuta zaukadaulo zikadalipo, kafukufuku ndi chitukuko zikupita patsogolo kuti athe kupanga zowotcha zotsika mtengo.

Chifukwa cha kuuma kwakukulu ndi kukhazikika kwa mankhwala a SiC-omwe amapangitsa kuti asagwirizane ndi kutentha kwa chipinda-kupukuta kwa makina kumafunika kuchotsa maenje abwino akupera, kuchepetsa kuwonongeka kwa pamwamba, kuthetsa zipsera, kupukuta, ndi kuwonongeka kwa peel lalanje, kutsika kwapamwamba kwapamwamba, kuwongolera kusalala, ndi kupititsa patsogolo khalidwe lapamwamba.

Kuti mukwaniritse malo opukutidwa apamwamba, ndikofunikira:

Sinthani mitundu ya abrasive,

Chepetsani kukula kwa tinthu,

Konzani magawo a process,

Sankhani zipangizo zopukutira ndi mapepala okhala ndi kuuma kokwanira.

Chithunzi 7 chikuwonetsa kuti kupukuta kwa mbali ziwiri ndi ma abrasives a 1 μm kumatha kuwongolera kutsika komanso kusiyanasiyana kwa makulidwe mkati mwa 10 μm, ndikuchepetsa kuuma kwa pamwamba mpaka pafupifupi 0.25 nm.

3.2 Chemical Mechanical polishing (CMP)

Chemical Mechanical Polishing (CMP) imaphatikiza ultrafine particle abrasion ndi chemical etching kuti ikhale yosalala, yolinganiza pamwamba pa zinthu zomwe zikukonzedwa. Mfundo yofunikira ndi:

A mankhwala zimachitika pakati pa kupukuta slurry ndi yopyapyala pamwamba, kupanga wosanjikiza zofewa.

Mkangano pakati pa abrasive particles ndi wosanjikiza wofewa amachotsa zinthuzo.

Ubwino wa CMP:

Amagonjetsa zovuta za kupukuta kwamakina kapena mankhwala,

Imakwaniritsa mapulani apadziko lonse lapansi komanso amderalo,

Amapanga malo okhala ndi flatness kwambiri komanso otsika roughness,

Sichisiya kuwonongeka pamwamba kapena pansi.

Mwatsatanetsatane:

Chophikacho chimayenda molingana ndi pad yopukutira mopanikizika.

Nanometer-scale abrasives (mwachitsanzo, SiO₂) mu slurry amatenga nawo mbali pakumeta, kufooketsa zomangira za Si-C komanso kupititsa patsogolo kuchotsa zinthu.

Mitundu ya Njira za CMP:

Kupukuta Kwaulere Kwaulere: Ma Abrasives (mwachitsanzo, SiO₂) amayimitsidwa pamatope. Kuchotsa zinthu kumachitika kudzera m'matupi atatu (wafer-pad-abrasive). Kukula kwa abrasive (kawirikawiri 60-200 nm), pH, ndi kutentha ziyenera kuyendetsedwa bwino kuti zikhale zofanana.

Fixed Abrasive polishing: Ma abrasives amayikidwa mu pad yopukutira kuti ateteze kuphatikizika - koyenera kukonzedwa bwino kwambiri.

Kuyeretsa Pambuyo Kupukuta:

Zophika zophika zimaperekedwa:

Kuyeretsa mankhwala (kuphatikiza madzi a DI ndi kuchotsa zotsalira za slurry),

DI kuchapa madzi, ndi

Kutentha kwa nayitrogeni kuyanika

kuchepetsa zowononga pamtunda.

Ubwino Wapamwamba & Magwiridwe

Kuuma kwapamwamba kumatha kuchepetsedwa kukhala Ra <0.3 nm, kukwaniritsa zofunikira za semiconductor epitaxy.

Global Planarization: Kuphatikizika kwa kufewetsa kwa mankhwala ndi kuchotsa makina kumachepetsa zokala ndi zomangira zosagwirizana, kupitilira njira zenizeni zamakina kapena mankhwala.

Kuchita Bwino Kwambiri: Ndikoyenera pazida zolimba komanso zolimba ngati SiC, zochotsa zinthu zopitilira 200 nm/h.

Njira Zina Zomwe Zikudziwikiratu

Kuphatikiza pa CMP, njira zina zaperekedwa, kuphatikiza:

Electrochemical polishing, kupukuta mothandizidwa ndi Catalyst kapena etching, ndi

Kupukuta kwa Tribochemical.

Komabe, njirazi zikadali mu gawo la kafukufuku ndipo zakula pang'onopang'ono chifukwa cha zinthu zovuta za SiC.

Pamapeto pake, kukonza kwa SiC ndi njira yapang'onopang'ono yochepetsera masamba ankhondo ndi roughness kuti apititse patsogolo mawonekedwe, pomwe kuwongolera ndi kuwongolera kumakhala kofunikira pagawo lililonse.

Processing Technology

Pa chophatikizika akupera siteji, diamondi slurry ndi zosiyanasiyana tinthu kukula kwake ntchito pogaya chophatikizika ndi chofunika flatness ndi pamwamba roughness. Izi zimatsatiridwa ndi kupukuta, pogwiritsa ntchito njira zonse zamakina ndi mankhwala opukutira (CMP) kuti apange zowotcha zopanda zowonongeka za silicon carbide (SiC).

Akamaliza kupukuta, zowotcha za SiC zimawunikiridwa mwamphamvu pogwiritsa ntchito zida monga ma microscopes owoneka bwino ndi ma X-ray diffractometers kuti zitsimikizire kuti magawo onse aumisiri akukwaniritsa zofunikira. Pomaliza, zopatulira zopukutidwa zimatsukidwa pogwiritsa ntchito zida zapadera zoyeretsera ndi madzi a ultrapure kuchotsa zoyipitsidwa pamwamba. Kenako amawumitsidwa pogwiritsa ntchito mpweya wa nayitrogeni wa ultra-high purity ndi zowumitsira ma spin, kumaliza ntchito yonse yopanga.

Pambuyo pazaka zoyeserera, kupita patsogolo kwakukulu kwachitika mu SiC single crystal processing mkati mwa China. Pakhomo, 100 mm doped semi-insulating 4H-SiC makhiristo amodzi apangidwa bwino, ndipo n-mtundu wa 4H-SiC ndi 6H-SiC makhiristo amodzi tsopano akhoza kupangidwa m'magulu. Makampani monga TankeBlue ndi TYST apanga kale makhiristo amodzi a 150 mm SiC.

Pankhani yaukadaulo wa SiC wafer processing, mabungwe apakhomo adasanthula kale momwe amagwirira ntchito komanso njira zodulira makristalo, kugaya, ndi kupukuta. Amatha kupanga zitsanzo zomwe zimakwaniritsa zofunikira pakupanga zida. Komabe, poyerekeza ndi miyezo yapadziko lonse lapansi, mawonekedwe opangira zinthu zapakhomo akadali kumbuyo kwambiri. Pali zovuta zingapo:

Malingaliro a International SiC ndi matekinoloje okonza zinthu ndi otetezedwa mwamphamvu komanso osafikirika mosavuta.

Pali kusowa kwa kafukufuku wamalingaliro ndi kuthandizira pakuwongolera ndi kukhathamiritsa.

Mtengo wa kuitanitsa zida zakunja ndi zigawo zake ndizokwera.

Kafukufuku wapakhomo pakupanga zida, kuwongolera bwino, ndi zida zikuwonetsabe mipata yayikulu poyerekeza ndi mayiko apadziko lonse lapansi.

Pakadali pano, zida zambiri zolondola kwambiri zomwe zimagwiritsidwa ntchito ku China zimatumizidwa kunja. Zida zoyesera ndi njira zimafunikiranso kuwongolera kwina.

Ndi kupitirizabe chitukuko cha semiconductors m'badwo wachitatu, awiri a SiC single kristalo gawo lapansi akuchulukirachulukira, pamodzi ndi zofunika apamwamba processing pamwamba khalidwe. Ukadaulo wopangira ma Wafer wakhala chimodzi mwazinthu zovuta kwambiri pambuyo pa SiC single crystal kukula.

Kuti tithane ndi zovuta zomwe zilipo pakukonza, ndikofunikira kupitilira kuphunzira njira zodulira, kugaya, ndi kupukuta, ndikuwunika njira zoyenera ndi njira zopangira SiC wafer. Nthawi yomweyo, ndikofunikira kuphunzira kuchokera kuukadaulo wapamwamba wapadziko lonse lapansi ndikutengera njira zamakono zamakina olondola kwambiri komanso zida kuti apange magawo apamwamba kwambiri.

Pamene kukula kwa kristalo kumawonjezeka, zovuta za kukula kwa kristalo ndi kukonza zimakweranso. Komabe, kupanga bwino kwa zida zapansi panthaka kumakhala bwino kwambiri, ndipo mtengo wagawo umachepetsedwa. Pakali pano, ogulitsa SiC wafer wamkulu padziko lonse lapansi amapereka zinthu kuyambira mainchesi 4 mpaka mainchesi 6 m'mimba mwake. Makampani otsogola monga Cree ndi II-VI ayamba kale kukonzekera kupanga mizere yopangira ma 8-inch SiC.

Nthawi yotumiza: May-23-2025