Q: Kodi matekinoloje akuluakulu omwe amagwiritsidwa ntchito podula ndi kukonza makina a SiC ndi ati?

A:Silicon carbide (SiC) ili ndi kuuma kwachiwiri kwa diamondi ndipo imatengedwa kuti ndi chinthu cholimba kwambiri komanso chophwanyika. Ntchito yodula, yomwe imaphatikizapo kudula makhiristo okulirapo kukhala zowonda zowonda, zimatenga nthawi komanso sachedwa kudulidwa. Monga sitepe yoyambaSiCsingle crystal processing, khalidwe la slicing zimakhudza kwambiri pambuyo akupera, kupukuta, ndi kupatulira. Kudula nthawi zambiri kumayambitsa ming'alu ya pamwamba ndi pansi, kuonjezera mitengo yosweka komanso mtengo wopangira. Chifukwa chake, kuwongolera kuwonongeka kwa ming'alu pakudula ndikofunikira kuti mupititse patsogolo kupanga zida za SiC.

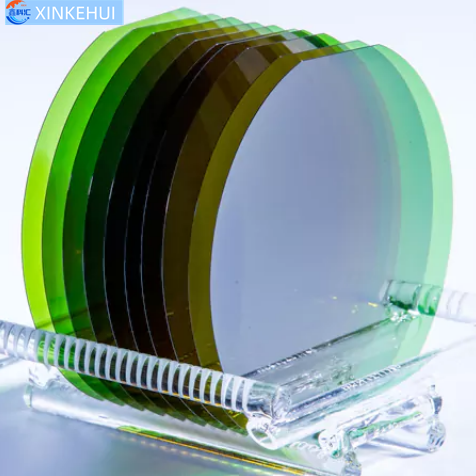

Pakali pano, njira za SiC slicing zomwe zanenedwapo zikuphatikizapo kutsekemera kosasunthika, kutsekemera kwaufulu, kudula laser, kusanjikiza kosanjikiza (kulekanitsa kozizira), ndi kudula kwamagetsi. Mwa izi, kubwereza mawaya angapo okhala ndi ma abrasives okhazikika a diamondi ndiyo njira yomwe imagwiritsidwa ntchito kwambiri pokonza makhiristo a SiC amodzi. Komabe, makulidwe a ingot akafika mainchesi 8 kupita kupitilira apo, macheka achikhalidwe amawaya sakhala othandiza chifukwa cha kuchuluka kwa zida, mtengo wake, komanso kutsika kwachangu. Pakufunika mwachangu njira zamaukadaulo zotsika mtengo, zotsika, zotsika kwambiri.

Q: Ubwino wa laser slicing ndi chiyani kuposa kudula mawaya ambiri?

A: Traditional waya macheka amadulaSiC ndalamamotsatira njira yeniyeni mu magawo mazana angapo a microns wandiweyani. Magawowo amasiyidwa pogwiritsa ntchito miyala ya diamondi kuti achotse macheka ndi kuwonongeka kwapansi panthaka, kutsatiridwa ndi kupukuta kwamankhwala (CMP) kuti akwaniritse planarization yapadziko lonse lapansi, ndipo pomaliza amatsukidwa kuti apeze zowotcha za SiC.

Komabe, chifukwa cha kuuma kwambiri kwa SiC ndi kuphulika kwake, masitepewa amatha kuyambitsa kugwedezeka, kusweka, kuwonjezereka kwa kusweka, kutsika mtengo kwa kupanga, ndipo kumapangitsa kuti pakhale kuuma komanso kuipitsidwa kwapamwamba (fumbi, madzi oipa, ndi zina zotero). Kuphatikiza apo, macheka amawaya amachedwa ndipo amakhala ndi zokolola zochepa. Ziwerengero zikuwonetsa kuti kudula kwamawaya ambiri kumangogwiritsa ntchito pafupifupi 50%, ndipo mpaka 75% yazinthuzo zimatayika pambuyo popukuta ndikupera. Zopangira zakale zakunja zidawonetsa kuti zitha kutenga masiku pafupifupi 273 kuti apange ma ola 24 mosalekeza kuti apange ma wafer 10,000 - otenga nthawi kwambiri.

Kunyumba, makampani ambiri okulitsa makristalo a SiC amayang'ana kwambiri kuchuluka kwa ng'anjo. Komabe, m'malo mongokulitsa zotuluka, ndikofunikira kuganizira momwe mungachepetse zotayika - makamaka pamene zokolola za crystal sizili bwino.

Zida zopangira laser zimatha kuchepetsa kutayika kwa zinthu ndikuwonjezera zokolola. Mwachitsanzo, kugwiritsa ntchito limodzi 20 mmSiC ndalama:Kucheka kwawaya kumatha kutulutsa mozungulira 30 zopyapyala za makulidwe a 350 μm. Kucheka kwa laser kumatha kutulutsa zowotcha zopitilira 50. Ngati makulidwe opatulira achepetsedwa mpaka 200 μm, zowotcha zopitilira 80 zitha kupangidwa kuchokera ku ingot yomweyo. Masiku 10-15 ndi njira zachikhalidwe, zomwe zimafuna zida zapamwamba komanso zotsika mtengo komanso zotsika mtengo. Pansi pazimenezi, zabwino za laser slicing zimawonekera, ndikupangitsa kuti ikhale ukadaulo wamtsogolo wamakina 8-inch.

Ndi laser kudula, slicing nthawi yopyapyala 8-inchi akhoza kukhala pansi mphindi 20, ndi kutaya chuma pa yopyapyala pansi 60 μm.

Mwachidule, poyerekeza ndi kudula mawaya angapo, kudula kwa laser kumapereka liwiro lalikulu, zokolola zabwino, kutayika kwa zinthu zochepa, komanso kukonza koyeretsa.

Q: Ndi zovuta ziti zaukadaulo pakudula kwa laser ya SiC?

A: Njira yodula laser imaphatikizapo njira ziwiri zazikulu: kusintha kwa laser ndi kupatukana kwa wafer.

Pachimake pakusintha kwa laser ndikusintha kwamitengo ndi kukhathamiritsa kwa parameter. Ma parameters monga mphamvu ya laser, m'mimba mwake, ndi liwiro la scan zonse zimakhudza mtundu wa ablation wa zinthu komanso kupambana kwa kupatukana kwa mkate wotsatira. Ma geometry a zone yosinthidwa amatsimikizira kuuma kwapamtunda ndi zovuta zolekanitsa. Kuvuta kwapamwamba kumapangitsa kuti kugaya kukhale kovuta komanso kumawonjezera kutaya kwa zinthu.

Pambuyo pa kusinthidwa, kupatukana kwa wafer kumatheka kudzera mu mphamvu zometa ubweya, monga kusweka kozizira kapena kupsinjika kwamakina. Zina zapakhomo zimagwiritsa ntchito ma transducers akupanga kuti apangitse kugwedezeka kwa kupatukana, koma izi zingayambitse kupukutira ndi kupunduka m'mphepete, kutsitsa zokolola zomaliza.

Ngakhale kuti masitepe awiriwa sali ovuta mwachibadwa, kusagwirizana kwa khalidwe la kristalo-chifukwa cha kukula kosiyana, miyeso ya doping, ndi kugawanika kwapakati pa nkhawa-zimakhudza kwambiri slicing zovuta, zokolola, ndi kutaya kwakuthupi. Kungozindikira madera omwe ali ndi vuto ndikusintha madera ojambulira laser sikungawongolere zotsatira.

Chinsinsi cha kutengera kufalikira kwagona pakupanga njira zatsopano ndi zida zomwe zimatha kutengera mikhalidwe yambiri ya kristalo kuchokera kwa opanga osiyanasiyana, kukhathamiritsa magawo azinthu, ndikumanga makina opangira ma laser ndikugwiritsa ntchito konsekonse.

Q: Kodi luso la laser slicing lingagwiritsidwe ntchito pazinthu zina za semiconductor pambali pa SiC?

A: Ukadaulo wodulira laser wakhala ukugwiritsidwa ntchito pazinthu zosiyanasiyana. M'ma semiconductors, poyamba ankagwiritsidwa ntchito popanga dicing wafer ndipo kuyambira pamenepo adakula mpaka kudula makhiristo ambiri ochuluka.

Kupitilira SiC, kudula kwa laser kumatha kugwiritsidwanso ntchito pazinthu zina zolimba kapena zowonongeka monga diamondi, gallium nitride (GaN), ndi gallium oxide (Ga₂O₃). Maphunziro oyambilira pazidazi awonetsa kuthekera ndi ubwino wa kudula kwa laser pakugwiritsa ntchito semiconductor.

Q: Kodi pakali pano pali zida zopangira zida za laser zokhwima? Kodi kafukufuku wanu ali pati?

A: Large-diameter SiC laser slicing zida chimagwiritsidwa ntchito pachimake zida za tsogolo la 8-inchi SiC kupanga yopyapyala. Pakalipano, Japan yekha ndi amene angapereke machitidwe oterowo, ndipo ndi okwera mtengo ndipo amaloledwa kugulitsa kunja.

Kufunika kwapakhomo kwa makina ocheka / kupatulira kwa laser akuti kuli pafupifupi mayunitsi 1,000, kutengera mapulani opangira SiC komanso kuchuluka kwa mawaya omwe alipo. Makampani akuluakulu apakhomo adayika ndalama zambiri pazachitukuko, koma palibe zida zapakhomo zokhwima, zopezeka pamalonda zomwe zidafikabe potumiza mafakitale.

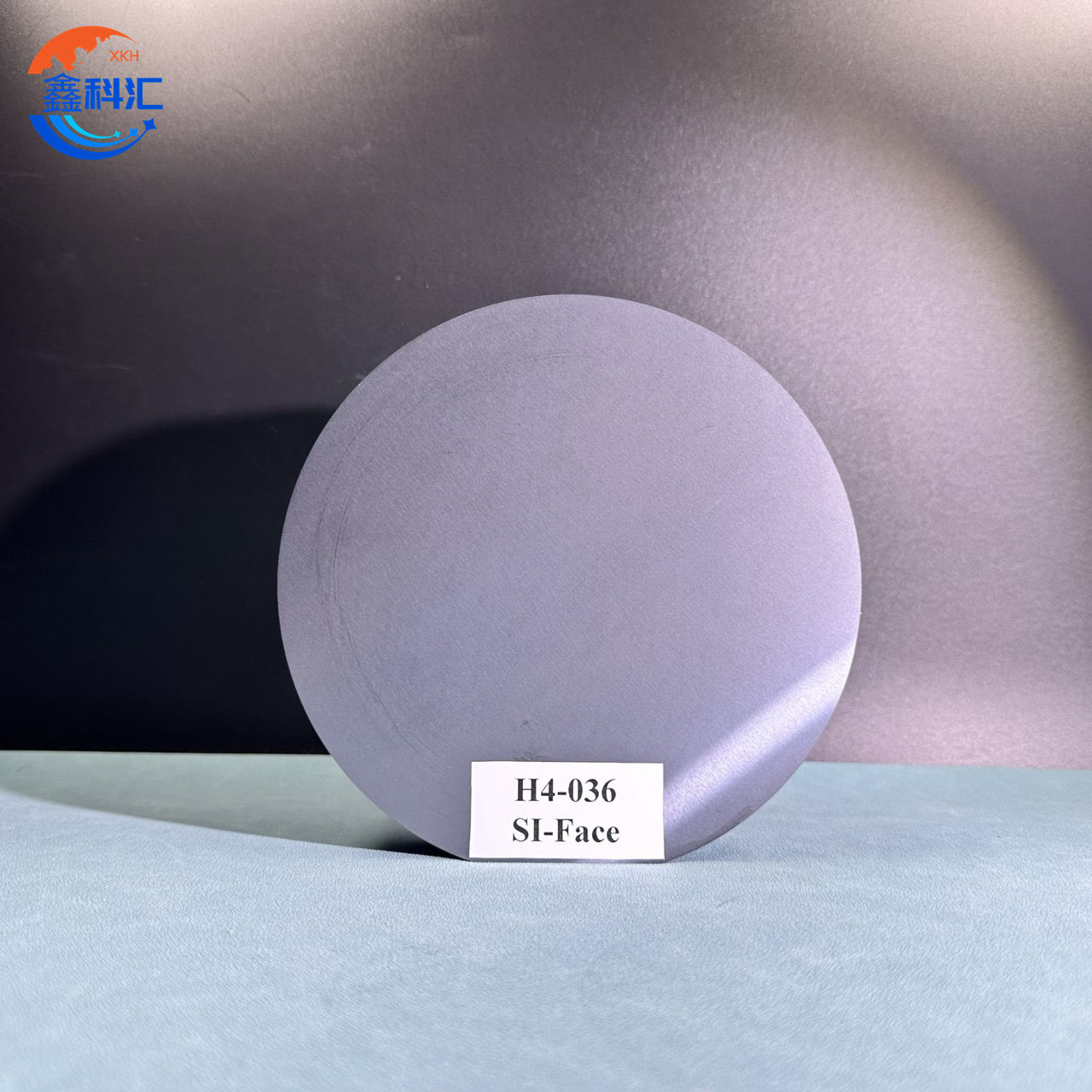

Magulu ofufuza akhala akupanga ukadaulo wonyamula laser kuyambira 2001 ndipo tsopano akulitsa izi mpaka kudula ndi kupatulira kwa laser ya SiC. Apanga njira yopangira ma prototype ndi ma slicing omwe amatha: Kudula ndi kupatulira 4-6 inch semi-insulating SiC wafersSlicing 6-8 inch conductive SiC ingotsPerformance benchmarks: 6-8 inch semi-insulating SiC: slicing nthawi 10-15 mphindi / wafer; kutaya kwakuthupi <30 μm6-8 inch conductive SiC: slicing nthawi 14-20 mphindi / mkate; kutaya kwakuthupi <60 μm

Chiyerekezo cha zokolola zophika mkate chawonjezeka ndi 50%

Pambuyo podulidwa, zowonda zimakwaniritsa miyezo yadziko lonse ya geometry pambuyo popera ndi kupukuta. Kafukufuku akuwonetsanso kuti matenthedwe opangidwa ndi laser samakhudza kwambiri kupsinjika kapena geometry muzowotcha.

Zida zomwezi zagwiritsidwanso ntchito kutsimikizira kuthekera kodula diamondi, GaN, ndi Ga₂O₃ makhiristo amodzi.

Nthawi yotumiza: May-23-2025