Njira Yodulira Laser Yotsogozedwa ndi Madzi ya Microjet ya Zida Zapamwamba

Ubwino Wapamwamba

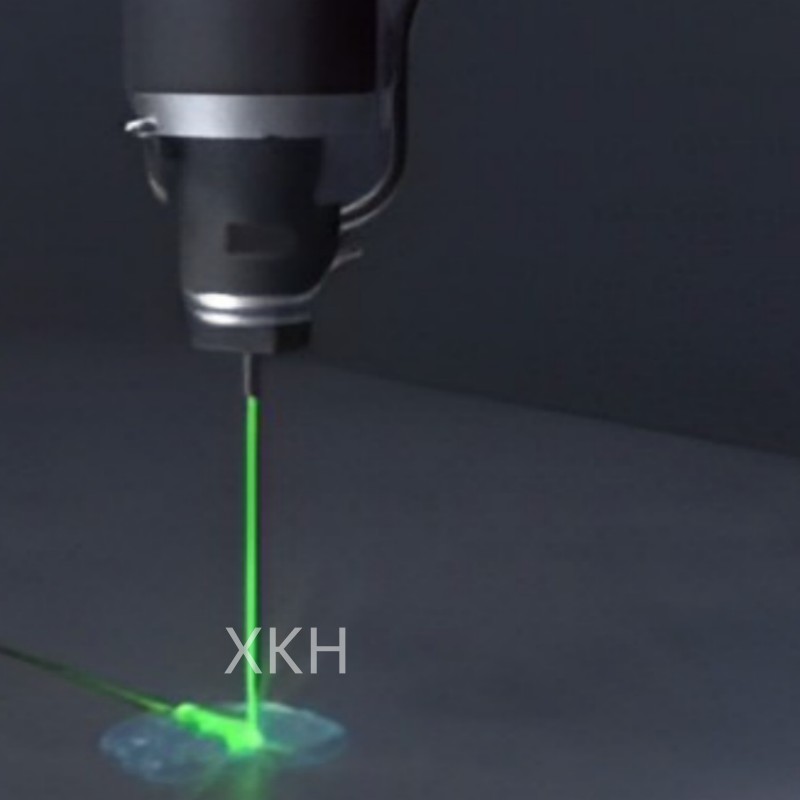

1. Mphamvu Zosayerekezeka Zoyang'ana Kudzera mu Upangiri Wamadzi

Pogwiritsa ntchito jet yamadzi yopukutidwa bwino ngati mafunde a laser, dongosololi limachotsa kusokoneza kwa mpweya ndikuwonetsetsa kuti laser imayang'ana kwathunthu. Zotsatira zake zimakhala m'lifupi mwake-zopapatiza kwambiri - zazing'ono ngati 20μm - zokhala ndi mbali zakuthwa, zoyera.

2. Ochepa Matenthedwe Phazi

Dongosolo lenileni la nthawi yotentha limatsimikizira kuti malo omwe amakhudzidwa ndi kutentha samapitilira 5μm, ndikofunikira kuti musunge magwiridwe antchito ndikupewa ma microcracks.

3. Wide Material Kugwirizana

Kutulutsa kwapawiri-wavelength (532nm/1064nm) kumathandizira kuyamwa bwino, kupangitsa makinawo kuti azitha kusintha magawo osiyanasiyana, kuyambira makhiristo owoneka bwino mpaka zoumba zowoneka bwino.

4. High-Speed, High-Precision Motion Control

Ndi zosankha zamakina opangira ma liniya ndi olunjika, makinawa amathandizira zosowa zapamwamba popanda kusokoneza kulondola. Kusuntha kwa ma axis asanu kumathandiziranso kupanga mapangidwe ovuta komanso mabala osiyanasiyana.

5. Modular ndi Scalable Design

Ogwiritsa ntchito amatha kusintha masinthidwe adongosolo kutengera zomwe akufuna - kuchokera ku ma labotale otengera ma labotale kupita ku magawo opanga - kupangitsa kuti ikhale yoyenera kudutsa R&D ndi madera aku mafakitale.

Malo Ofunsira

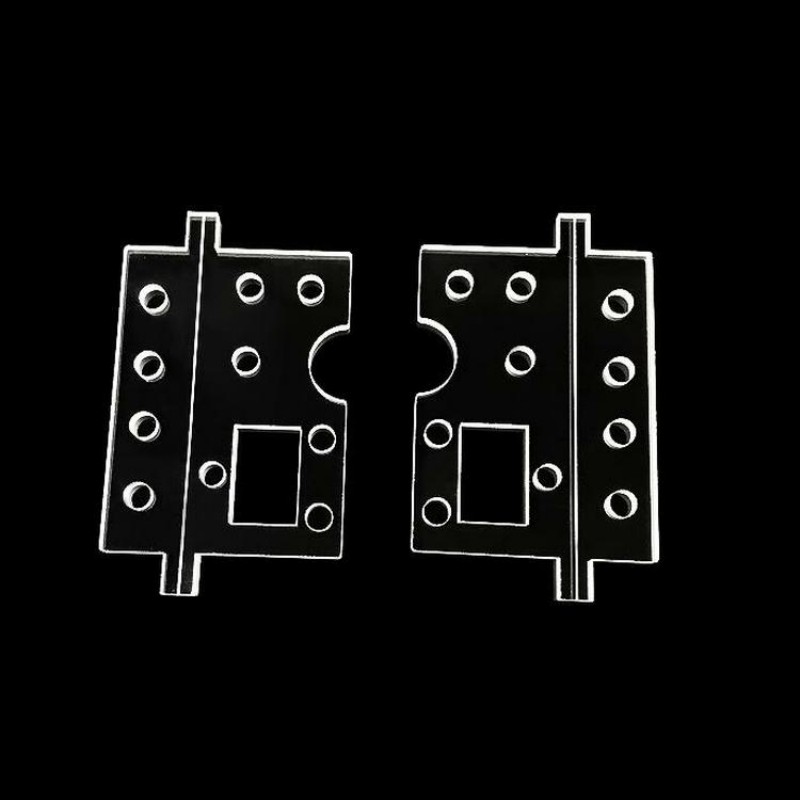

Ma Semiconductors a M'badwo Wachitatu:

Zokwanira pa zowotcha za SiC ndi GaN, makinawa amachita kudulira, kudula, ndi kudula mopanda malire.

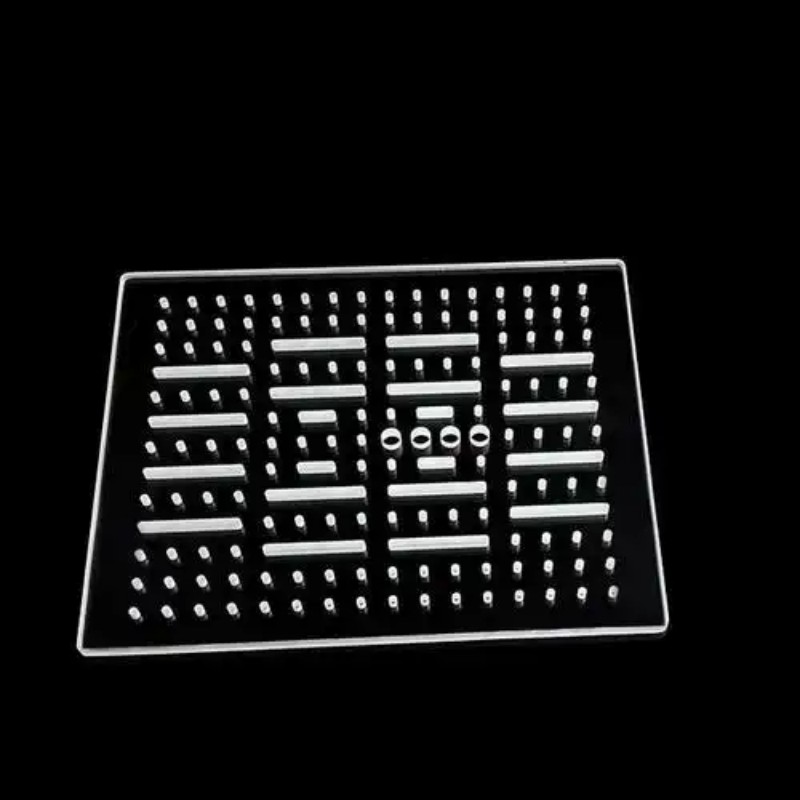

Diamondi ndi Oxide Semiconductor Machining:

Amagwiritsidwa ntchito podula ndi kubowola zinthu zolimba kwambiri monga diamondi imodzi ya kristalo ndi Ga₂O₃, popanda carbonization kapena kutentha kwa kutentha.

Zida Zapamwamba Zamlengalenga:

Imathandizira mawonekedwe amitundu yolimba kwambiri ya ceramic ndi ma superalloys a injini ya jet ndi zida za satellite.

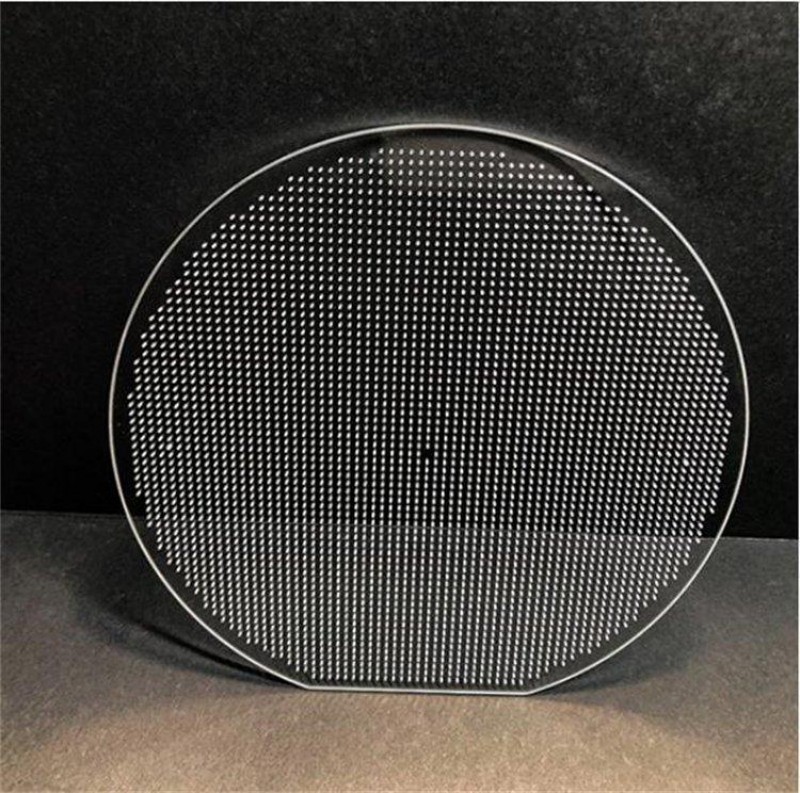

Magawo a Photovoltaic ndi Ceramic:

Imathandiza kudula opanda burr kwa zowonda zopyapyala ndi magawo a LTCC, kuphatikiza mabowo ndi mphero zolumikizirana.

Scintillators ndi Optical Components:

Imasunga kusalala komanso kufalikira kwa zinthu zosalimba zowoneka ngati Ce: YAG, LSO, ndi zina.

Kufotokozera

| Mbali | Kufotokozera |

| Gwero la Laser | DPSS Nd:YAG |

| Zosankha za Wavelength | 532nm / 1064nm |

| Miyezo ya Mphamvu | 50/100/200 Watts |

| Kulondola | ± 5μm |

| Dulani M'lifupi | Zopapatiza ngati 20μm |

| Malo Okhudzidwa ndi Kutentha | ≤5μm |

| Mtundu Woyenda | Linear / Direct Drive |

| Zida Zothandizira | SiC, GaN, Diamondi, Ga₂O₃, etc. |

Chifukwa Chiyani Sankhani Dongosololi?

● Kumathetsa nkhani mmene laser Machining monga matenthedwe akulimbana ndi m'mphepete chipping

● Imakulitsa zokolola ndi kusasinthasintha kwa zipangizo zotsika mtengo

● Itha kugwiritsidwa ntchito poyendetsa ndege komanso m'mafakitale

● Pulatifomu yotsimikizira zamtsogolo yasayansi yosintha zinthu

Q&A

Q1: Ndi zipangizo ziti zomwe dongosololi lingathe kuchita?

A: Dongosololi limapangidwa mwapadera kuti likhale ndi zida zolimba komanso zosalimba zamtengo wapatali. Imatha kukonza bwino silicon carbide (SiC), gallium nitride (GaN), diamondi, gallium oxide (Ga₂O₃), magawo a LTCC, ma composite amlengalenga, zowotcha za photovoltaic, ndi makristalo a scintillator monga Ce:YAG kapena LSO.

Q2: Kodi ukadaulo wa laser wotsogozedwa ndi madzi umagwira ntchito bwanji?

A: Imagwiritsa ntchito kapu yamadzi yothamanga kwambiri kuwongolera mtengo wa laser kudzera pakuwunikira kwathunthu kwamkati, ndikuwongolera mphamvu ya laser ndikumwaza kochepa. Izi zimatsimikizira kuyang'ana kwabwino kwambiri, kutsika kwamafuta ochepa, komanso kudula kolondola ndi m'lifupi mwake mpaka 20μm.

Q3: Kodi ma kasinthidwe amphamvu a laser omwe alipo?

A: Makasitomala amatha kusankha kuchokera ku 50W, 100W, ndi 200W zosankha zamphamvu za laser malinga ndi liwiro lawo lokonzekera ndi zosowa zawo. Zosankha zonse zimakhalabe zokhazikika komanso zobwerezabwereza.

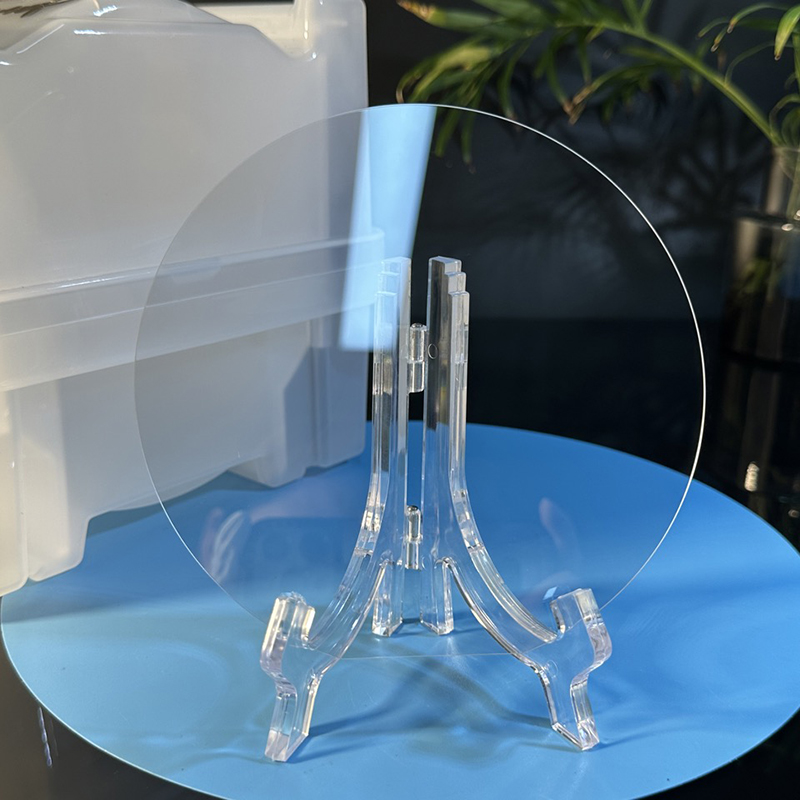

Chithunzi chatsatanetsatane