Microjet laser teknoloji zida zopyapyala kudula SiC processing zinthu

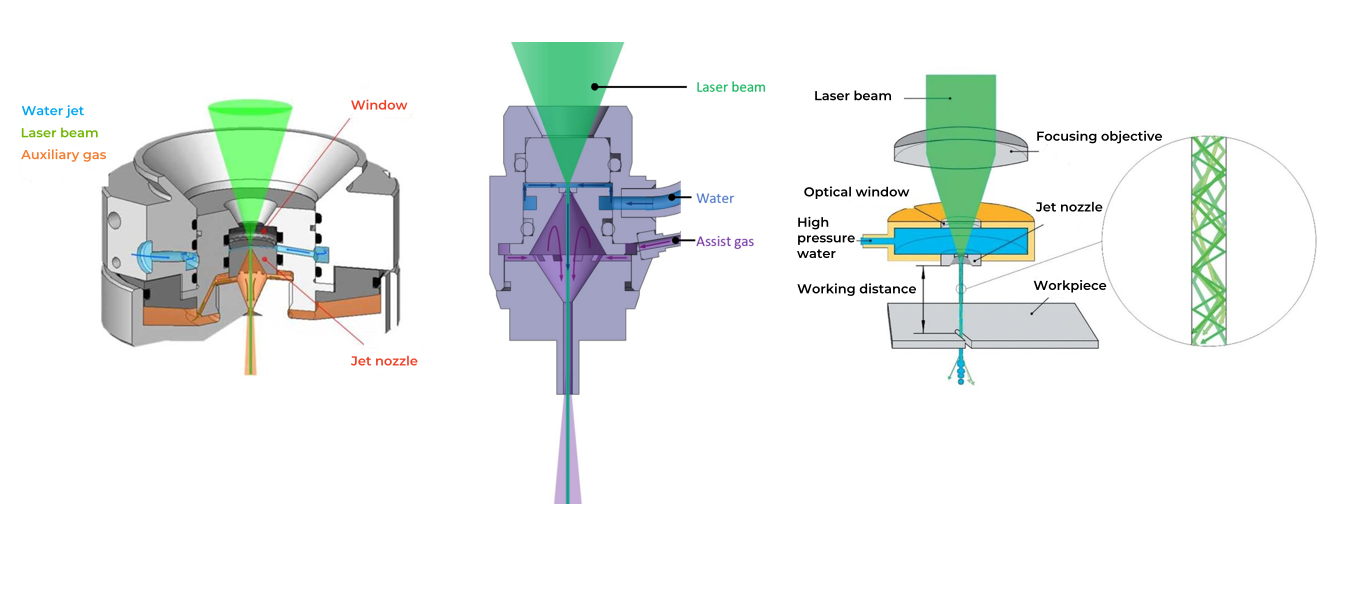

Ntchito mfundo:

1. Kulumikizana kwa laser: pulsed laser (UV / green / infuraredi) imayang'ana mkati mwa jet yamadzimadzi kuti ipange njira yokhazikika yotumizira mphamvu.

2. Chitsogozo chamadzimadzi: jet yothamanga kwambiri (kuthamanga kwa 50-200m / s) kuziziritsa malo opangirako ndikuchotsa zinyalala kuti zisawonongeke kutentha ndi kuipitsa.

3. Kuchotsa zinthu: Mphamvu ya laser imayambitsa cavitation mumadzi kuti ikwaniritse kuzizira kwazinthu (kutentha komwe kumakhudzidwa <1μm).

4. Kuwongolera kwamphamvu: kusintha kwa nthawi yeniyeni ya magawo a laser (mphamvu, mafupipafupi) ndi kuthamanga kwa jet kuti akwaniritse zosowa za zipangizo ndi mapangidwe osiyanasiyana.

Zofunikira zazikulu:

1. Mphamvu ya laser: 10-500W (yosinthika)

2. Jeti awiri: 50-300μm

3.Machining kulondola: ± 0.5μm (kudula), kuya ndi m'lifupi chiŵerengero 10:1 (kubowola)

Ubwino waukadaulo:

(1) Kuwononga pafupifupi zero kutentha

- Kuziziritsa kwa ndege yamadzimadzi kumawongolera malo omwe akhudzidwa ndi kutentha (HAZ) kupita ku **<1μm**, kupewa ming'alu yaying'ono yomwe imayambitsidwa ndi kukonza kwa laser wamba (HAZ nthawi zambiri imakhala> 10μm).

(2) Makina olondola kwambiri

- Kudula / kubowola molondola mpaka ** ± 0.5μm **, roughness m'mphepete Ra<0.2μm, kuchepetsa kufunika kwa kupukuta kotsatira.

- Imathandizira kukonza kamangidwe ka 3D (monga mabowo owoneka bwino, mipata yowoneka bwino).

(3) Kugwirizana kwazinthu zambiri

- Zipangizo zolimba komanso zonyeka: SiC, safiro, galasi, zoumba (njira zachikhalidwe ndizosavuta kusweka).

- Zida zokhudzidwa ndi kutentha: ma polima, minyewa yachilengedwe (palibe chiwopsezo cha kutsika kwamafuta).

(4) Kuteteza chilengedwe ndi kuchita bwino

- Palibe kuipitsidwa kwa fumbi, madzi amatha kubwezeretsedwanso ndikusefedwa.

- 30% -50% kuwonjezeka pa liwiro processing (vs. Machining).

(5) Kulamulira mwanzeru

- Mawonekedwe ophatikizika ndi kukhathamiritsa kwa magawo a AI, makulidwe azinthu zosinthika ndi zolakwika.

Mafotokozedwe aukadaulo:

| Voliyumu ya countertop | 300*300*150 | 400*400*200 |

| Linear axis XY | Linear mota. Linear mota | Linear mota. Linear mota |

| Linear axis Z | 150 | 200 |

| Kuyika kulondola μm | +/-5 | +/-5 |

| Kulondola kobwerezabwereza μm | +/-2 | +/-2 |

| Kuthamanga kwa G | 1 | 0.29 |

| Kuwongolera manambala | 3 olamulira / 3 + 1 olamulira / 3 + 2 olamulira | 3 olamulira / 3 + 1 olamulira / 3 + 2 olamulira |

| Mtundu wowongolera manambala | DPSS Nd:YAG | DPSS Nd:YAG |

| Wavelength nm | 532/1064 | 532/1064 |

| Adavoteledwa ndi W | 50/100/200 | 50/100/200 |

| Ndege yamadzi | 40-100 | 40-100 |

| Nozzle pressure bar | 50-100 | 50-600 |

| Makulidwe (chida cha makina) (m'lifupi * kutalika * kutalika) mm | 1445*1944*2260 | 1700*1500*2120 |

| Kukula (control cabinet) (W * L * H) | 700*2500*1600 | 700*2500*1600 |

| Kulemera (zida) T | 2.5 | 3 |

| Kulemera (control cabinet) KG | 800 | 800 |

| Processing luso | Pamwamba pa roughness Ra≤1.6um Liwiro lotsegula ≥1.25mm/s Kudula mozungulira ≥6mm/s Liniya kudula liwiro ≥50mm/s | Pamwamba pa roughness Ra≤1.2um Liwiro lotsegula ≥1.25mm/s Kudula mozungulira ≥6mm/s Liniya kudula liwiro ≥50mm/s |

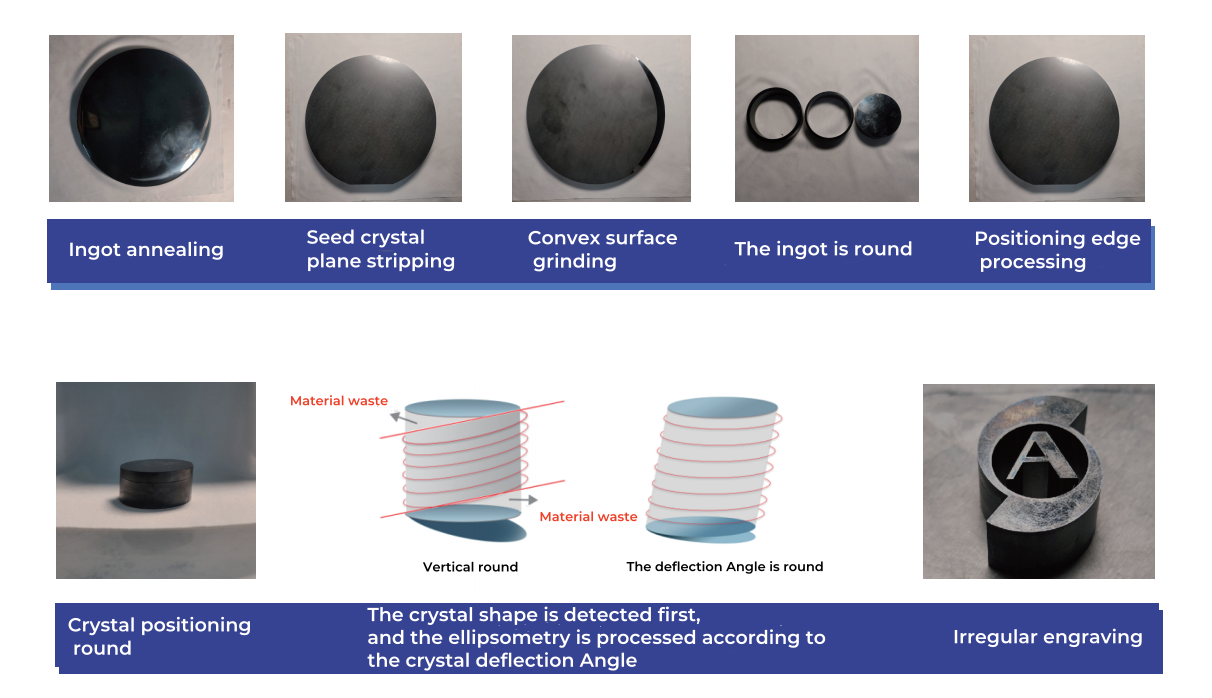

| Kwa gallium nitride crystal, ultra-wide band gap semiconductor materials (diamond/Gallium oxide), zipangizo zapadera zakuthambo, LTCC carbon ceramic substrate, photovoltaic, scintillator crystal ndi kukonza zipangizo zina. Zindikirani: Kuchuluka kwa ntchito kumasiyana malinga ndi mawonekedwe a zinthu

| ||

Processing case:

Ntchito za XKH:

XKH amapereka uthunthu wonse wa moyo mkombero utumiki thandizo kwa microjet laser zipangizo luso, kuyambira oyambirira ndondomeko chitukuko ndi kusankha zipangizo kufunsira, kwa m'ma makonda makonda dongosolo kaphatikizidwe (kuphatikiza mafananidwe wapadera wa laser gwero, dongosolo ndege ndi zochita zokha gawo), kuti pambuyo ntchito ndi maphunziro yokonza ndi mosalekeza ndondomeko kukhathamiritsa, ndondomeko lonse ali okonzeka ndi akatswiri luso gulu thandizo; Kutengera zaka 20 za luso lopanga makina olondola, titha kupereka mayankho okhazikika kuphatikiza kutsimikizira zida, kuyambitsa kupanga kwakukulu komanso kuyankha mwachangu (maola 24 athandizo laukadaulo + zosungirako zofunikira) pamafakitale osiyanasiyana monga semiconductor ndi zamankhwala, ndikulonjeza chitsimikizo cha miyezi 12 ndikusamalira moyo wonse ndikukweza ntchito. Onetsetsani kuti zida zamakasitomala nthawi zonse zimasunga magwiridwe antchito otsogola m'makampani komanso kukhazikika.

Chithunzi chatsatanetsatane