Makina Opukutira a Ion Beam a safiro SiC Si

Chithunzi chatsatanetsatane

Chidule cha Makina Opukutira a Ion Beam

Makina a Ion Beam Figuring and Polishing Machine amachokera pa mfundo ya ion sputtering. Mkati mwa chipinda chokhala ndi vacuum yapamwamba, gwero la ion limapanga plasma, yomwe imafulumizitsa kukhala mtengo wa ion wopatsa mphamvu kwambiri. Dongosololi limagunda pamwamba pa gawo la kuwala, ndikuchotsa zinthu pamlingo wa atomiki kuti zitheke kuwongolera bwino kwambiri ndikumaliza.

Monga njira yosalumikizana, kupukuta kwa ion mtengo kumachotsa kupsinjika kwamakina ndikupewa kuwonongeka kwapansi panthaka, ndikupangitsa kuti ikhale yabwino kupanga ma optics olondola kwambiri omwe amagwiritsidwa ntchito mu zakuthambo, zakuthambo, semiconductors, ndi ntchito zofufuzira zapamwamba.

Mfundo Yogwira Ntchito ya Ion Beam Polishing Machine

Mtundu wa ion

Mpweya wosagwira ntchito (mwachitsanzo, argon) umalowetsedwa mu chipinda cha vacuum ndi ionized kupyolera muzitsulo zamagetsi kuti apange plasma.

Kuthamanga & Kupanga Beam

Ma ion amathamangitsidwa mpaka mazana angapo kapena masauzande a ma electron volts (eV) ndipo amapangidwa kukhala malo okhazikika, olunjika.

Kuchotsa Zinthu Zofunika

Mtengo wa ion umatulutsa maatomu kuchokera pamwamba popanda kuyambitsa kusintha kwamankhwala.

Kuzindikira Zolakwa & Kukonza Njira

Kupatuka kwazithunzi kumayesedwa ndi interferometry. Ntchito zochotsa zimagwiritsidwa ntchito kudziwa nthawi yokhalamo ndikupanga njira zowonjezera zida.

Kuwongolera Kotsekedwa-Loop

Kachitidwe kobwerezabwereza ndi kuyeza kumapitilira mpaka zolinga zolondola za RMS/PV zitakwaniritsidwa.

Zofunika Kwambiri za Ion Beam Polishing Machine

Kugwirizana kwa Universal Surface- Amakonza malo osalala, ozungulira, owoneka bwino komanso omasuka

Mlingo Wochotsa Wokhazikika Wokhazikika- Imathandizira kuwongolera kwazithunzi za sub-nanometer

Kukonza Kopanda Zowonongeka- Palibe zolakwika zapansi panthaka kapena kusintha kwamapangidwe

Magwiridwe Osasinthika- Imagwira ntchito mofanana bwino pazinthu za kuuma kosiyanasiyana

Kuwongolera pafupipafupi kwapakati/pakatikati- Imachotsa zolakwika popanda kupanga zapakatikati / zapamwamba kwambiri

Zofunikira Zosamalira Zochepa- Opaleshoni yopitilira nthawi yayitali yokhala ndi nthawi yochepa

Mfundo Zazikulu Zaukadaulo za Ion Beam Polishing Machine

| Kanthu | Kufotokozera |

| Processing Njira | Ion sputtering mu malo apamwamba vacuum |

| Mtundu Wokonza | Kuyerekeza ndi kupukuta kwapamwamba kosalumikizana |

| Max Workpiece Kukula | Φ4000 mm |

| Zoyenda Nkhwangwa | 3-axis / 5-axis |

| Kuchotsa Kukhazikika | ≥95% |

| Kulondola Pamwamba | PV <10 nm; RMS ≤ 0.5 nm (mtundu wa RMS <1 nm; PV <15 nm) |

| Kuwongolera pafupipafupi | Imachotsa zolakwika zapakati-pakatikati popanda kuyambitsa zolakwika zapakati/zapamwamba |

| Ntchito Yopitiriza | 3-5 milungu popanda vacuum kukonza |

| Mtengo Wokonza | Zochepa |

Kukonzekera Kwamakina a Ion Beam Polishing Machine

Mitundu Yapamwamba Yothandizira

Zosavuta: Zosalala, zozungulira, zamtengo wapatali

Complex: Symmetric/asymmetric asphere, off-axis asphere, cylindrical

Zapadera: Ultra-thin Optics, slat Optics, hemispherical Optics, Conformal Optics, mbale zagawo, mawonekedwe aulere

Zida Zothandizira

galasi kuwala: Quartz, microcrystalline, K9, etc.

Zida za infuraredi: Silicon, germanium, etc.

Zitsulo: Aluminiyamu, chitsulo chosapanga dzimbiri, titaniyamu aloyi, etc.

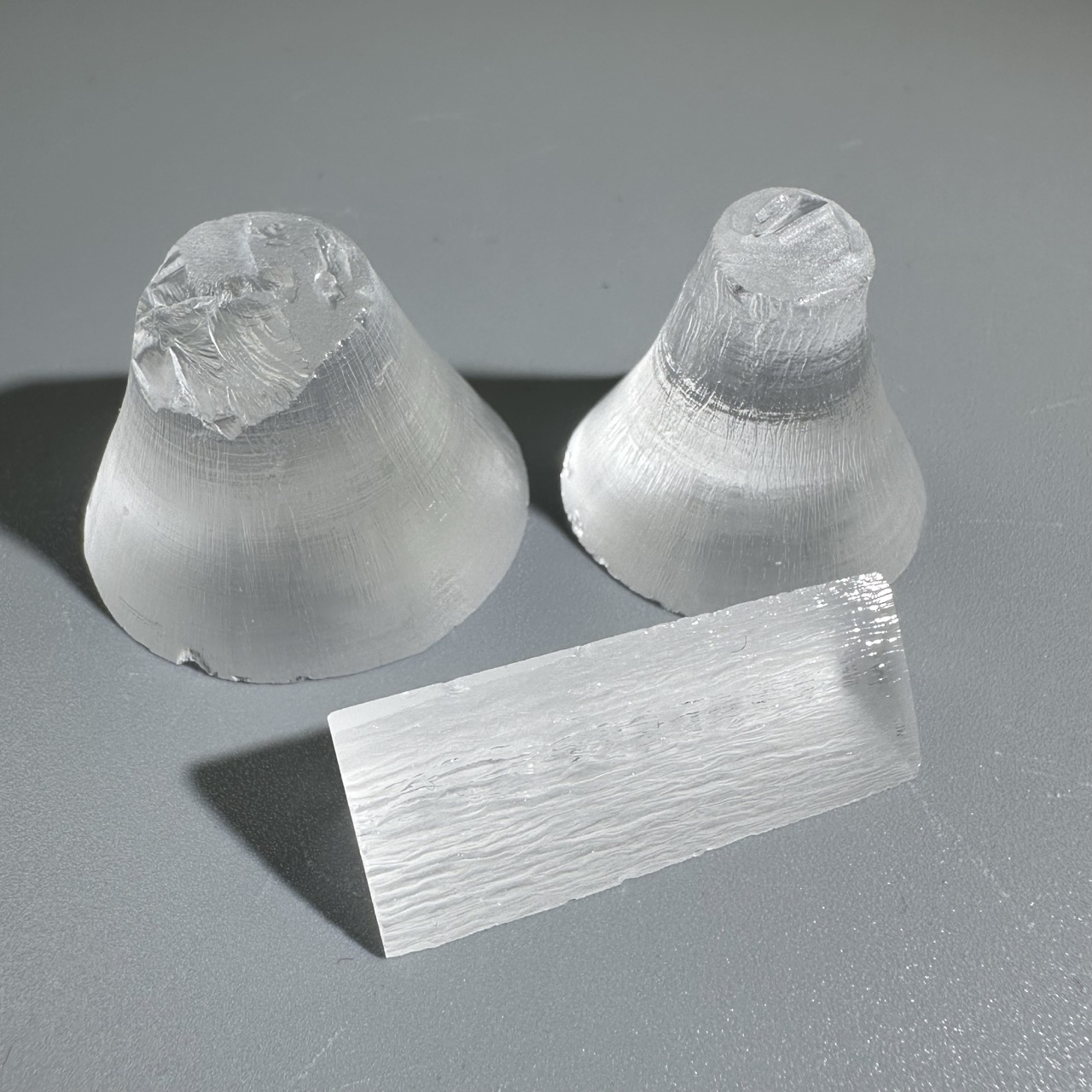

Makhiristo: YAG, single-crystal silicon carbide, etc.

Zida zolimba / zowonongeka: Silicon carbide, etc.

Ubwino Wapamwamba / Kulondola

PV <10 nm

RMS ≤ 0.5 nm

Kukonza Maphunziro a Ion Beam Polishing Machine

Mlandu 1 - Standard Flat Mirror

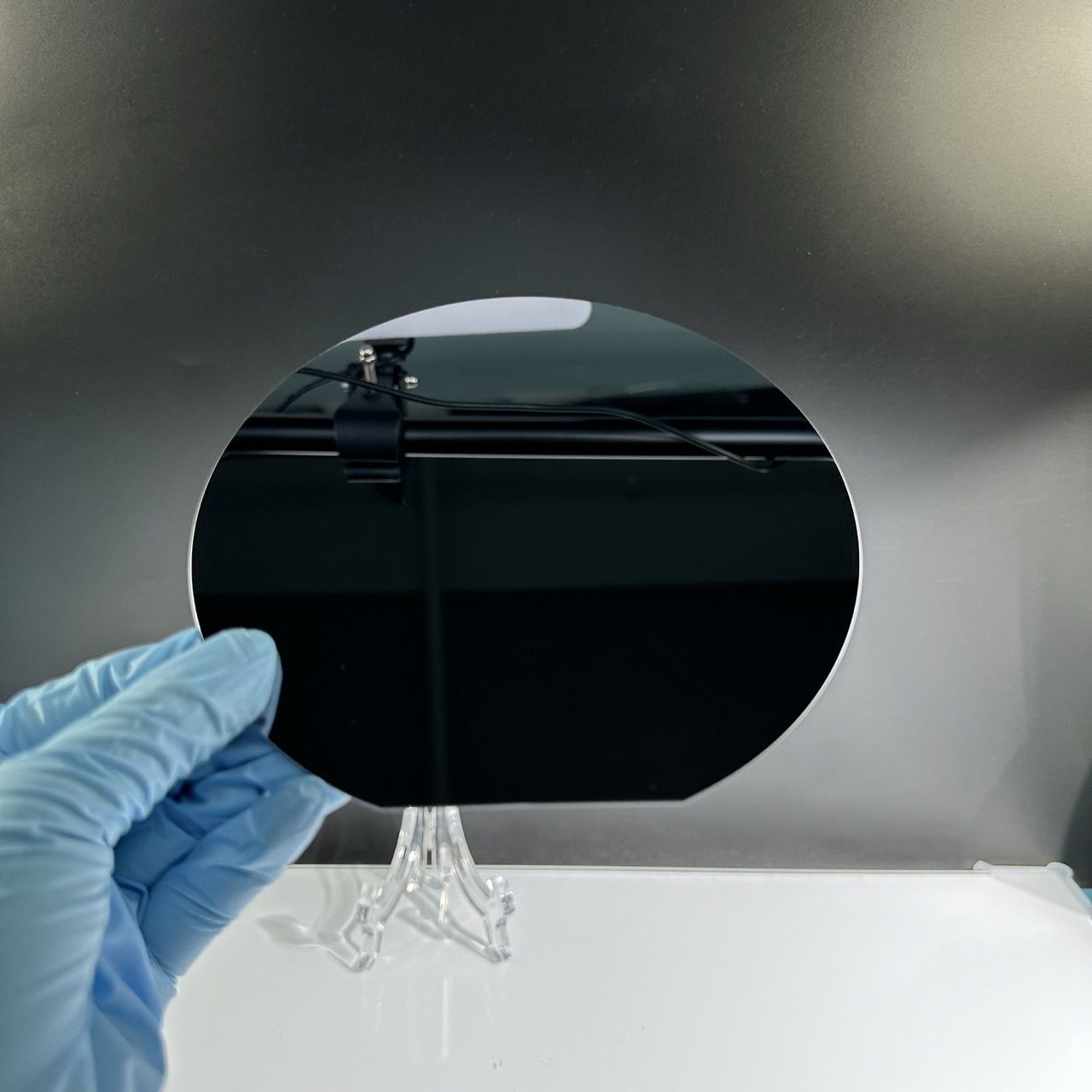

Chogwirira ntchito: D630 mm quartz flat

Zotsatira: PV 46.4 nm; RMS 4.63 nm

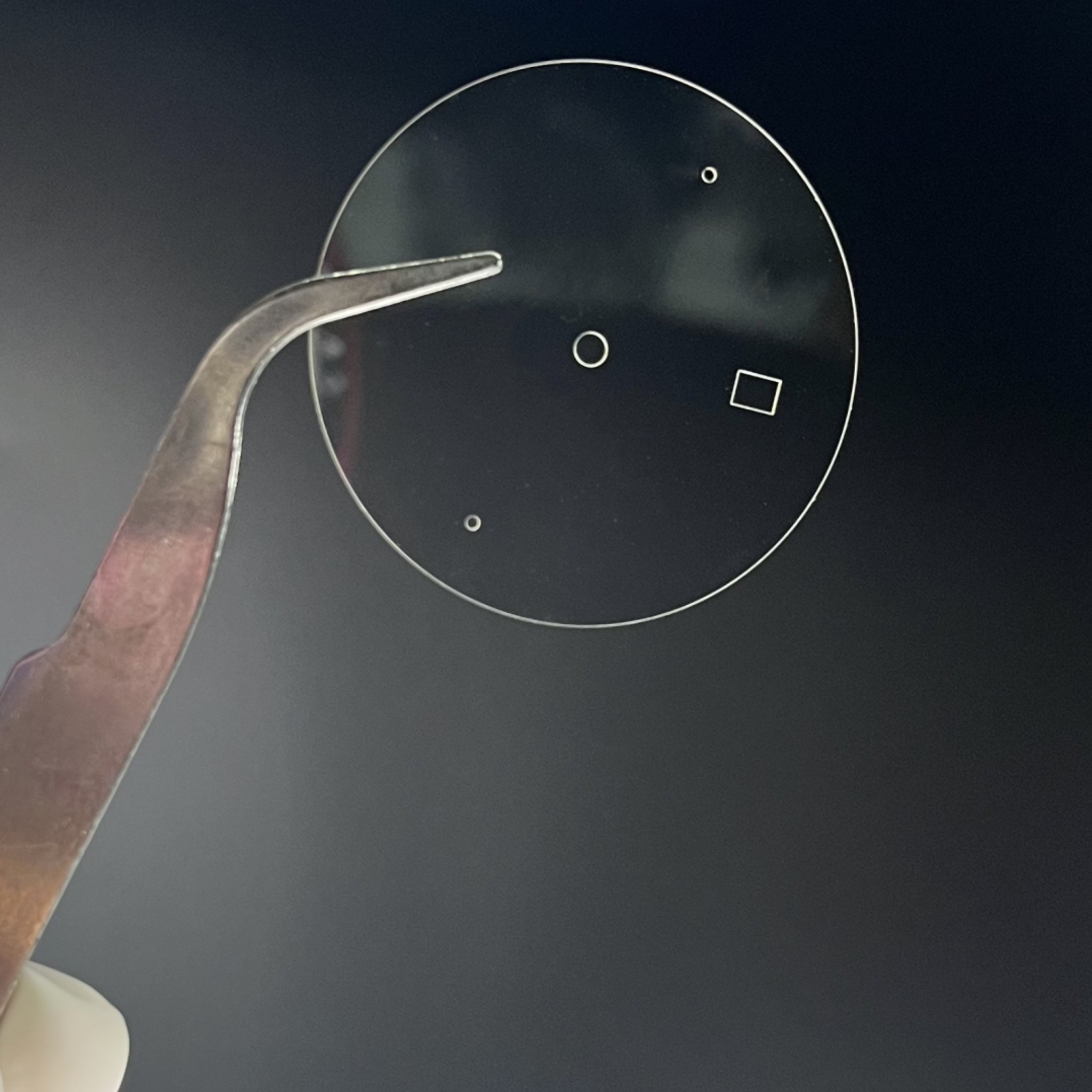

Mlandu 2 - Kalilore Wowonetsera X-ray

Ntchito: 150 × 30 mm silicon flat

Zotsatira: PV 8.3 nm; RMS 0.379 nm; Kutsika 0.13 µrad

Mlandu 3 - Mirror ya Off-Axis

Chogwirira ntchito: D326 mm pagalasi lapansi la axis

Zotsatira: PV 35.9 nm; RMS 3.9 nm

FAQ ya Magalasi a Quartz

FAQ - Makina Opukutira a Ion Beam

Q1: Kodi kupukuta kwa ion mtengo ndi chiyani?

A1:Kupukuta kwa ion ndi njira yosalumikizana yomwe imagwiritsa ntchito mtengo wolunjika wa ma ion (monga ma argon ion) kuti achotse zinthu pamalo ogwirira ntchito. Ma ion amafulumizitsidwa ndikulunjika pamwamba, zomwe zimapangitsa kuchotsa zinthu za mulingo wa atomiki, zomwe zimapangitsa kuti pakhale zosalala kwambiri. Njirayi imachotsa kupsinjika kwamakina ndi kuwonongeka kwapansi panthaka, ndikupangitsa kuti ikhale yabwino kwa zigawo zowoneka bwino.

Q2: Ndi mawonekedwe amtundu wanji omwe angapangidwe ndi Ion Beam Polishing Machine?

A2:TheMakina Opukutira a Ion Beamimatha kukonza mawonekedwe osiyanasiyana, kuphatikiza zida zosavuta zowoneka ngatiflats, mabwalo, ndi ma prisms, komanso ma geometries ovuta mongama aspheres, off-axis aspheres,ndimawonekedwe aulere. Ndiwothandiza makamaka pazinthu monga magalasi owoneka, ma infrared optics, zitsulo, ndi zida zolimba/zowonongeka.

Q3: Ndi zida ziti zomwe Ion Beam Polishing Machine ingagwire ntchito?

A3:TheMakina Opukutira a Ion Beamimatha kupukuta zida zambiri, kuphatikiza:

-

Galasi la kuwala: Quartz, microcrystalline, K9, etc.

-

Zida za infuraredi: Silicon, germanium, etc.

-

Zitsulo: Aluminiyamu, chitsulo chosapanga dzimbiri, titaniyamu aloyi, etc.

-

Zida za kristalo: YAG, single-crystal silicon carbide, etc.

-

Zida zina zolimba/zowonongeka: Silicon carbide, etc.

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.