Zida Zodulira Laser za Infrared Picosecond Dual-Platform Laser za Optical Glass/Quartz/Sapphire Processing

Main parameter

| Mtundu wa Laser | Infrared Picosecond |

| Kukula kwa nsanja | 700 × 1200 (mm) |

| 900 × 1400 (mm) | |

| Kudula Makulidwe | 0.03-80 (mm) |

| Kudula Liwiro | 0-1000 (mm/s) |

| Kudula M'mphepete Kusweka | <0.01 (mm) |

| Chidziwitso: Kukula kwa nsanja kumatha kusinthidwa makonda. | |

Zofunika Kwambiri

1.Ultrafast Laser Technology:

· Picosecond-level short pulse (10⁻¹²s) kuphatikizidwa ndi ukadaulo wa MOPA tuning amapeza mphamvu zochulukirapo >10¹² W/cm².

Mawonekedwe a infrared (1064nm) amalowa muzinthu zowonekera kudzera pamayamwidwe osagwirizana, kuteteza kutulutsa pamwamba.

· Proprietary Multi-focus Optical system imapanga malo anayi odziyimira pawokha panthawi imodzi.

2.Dual-Station Synchronization System:

· Magawo amagetsi amtundu wa granite-base awiri (kulondola kwa malo: ± 1μm).

· Nthawi yosinthira masiteshoni <0.8s, ndikupangitsa magwiridwe antchito a "processing-loading/unloading".

Kuwongolera kutentha kodziyimira pawokha (23 ± 0.5 ° C) pa station iliyonse kumatsimikizira kukhazikika kwa makina kwanthawi yayitali.

3.Intelligent Process Control:

* Nawonso yazinthu zophatikizika (magalasi 200+) zofananira ndi magawo.

Kuwunika kwenikweni kwa plasma kumasintha mphamvu ya laser (kusintha kosintha: 0.1mJ).

Kutetezedwa kwa makatani a mpweya kumachepetsa ming'alu yaying'ono (<3μm).

M'machitidwe wamba wophatikizira 0.5mm-thick sapphire dicing, makinawa amakwaniritsa liwiro lodulira la 300mm/s ndi miyeso yopukutira <10μm, kuyimira kuwongolera bwino kwa 5x kuposa njira zachikhalidwe.

Processing Ubwino

1.Integrated dual-station cutting and splitting system for flexible operation;

2.High-liwiro Machining a geometries zovuta timapitiriza ndondomeko kutembenuka dzuwa;

3.Mphepete mwazopanda taper ndi kudula kochepa (<50μm) ndi kugwiritsira ntchito motetezeka;

Kusintha kwa 4.Seamless pakati pa zinthu zomwe zimagwiritsidwa ntchito mwachilengedwe;

5.Ndalama zotsika mtengo, zokolola zambiri, zopanda pake komanso zopanda kuipitsa;

6.Zero m'badwo wa slag, zotayira zamadzimadzi kapena madzi onyansa okhala ndi kukhulupirika kotsimikizika pamwamba;

Chiwonetsero chachitsanzo

Mapulogalamu Okhazikika

1.Consumer Electronics Manufacturing:

· Kudula kolondola kwa magalasi ophimba a smartphone 3D (kulondola kwa R-angle: ± 0.01mm).

Kubowola zazing'ono m'magalasi a wotchi ya safiro (malo ochepera: Ø0.3mm).

· Kumaliza kwa magalasi owoneka bwino a makamera osawonetsedwa.

2.Optical Component Production:

· Makina opanga ma Microstructure a AR/VR ma lens array (kukula kwa mawonekedwe ≥20μm).

Kudula kwa angled kwa ma prisms a quartz kwa ma collimators a laser (kulekerera kwa angular: ± 15").

· Mawonekedwe a mbiri ya zosefera za infrared (kudula taper <0.5 °).

3. Semiconductor Packaging:

· Galasi kudzera munjira (TGV) pokonza pamlingo wophatikizika (chiwerengero cha 1:10).

· Kuyika kwa Microchannel pagawo lagalasi la tchipisi ta microfluidic (Ra <0.1μm).

· Kudula pafupipafupi kwa ma resonator a MEMS quartz.

Pakupanga mazenera agalimoto a LiDAR, makinawa amathandizira kudula magalasi a quartz 2mm-thick perpendicularity ya 89.5 ± 0.3 °, kukwaniritsa zofunikira zoyesa kugwedezeka kwamagalimoto.

Sinthani Mapulogalamu

Amapangidwa makamaka kuti azidula mwatsatanetsatane zida zosalimba / zolimba kuphatikiza:

1.Magalasi okhazikika & magalasi a kuwala (BK7, silika wosakanikirana);

2. Makhiristo a quartz & safiro gawo;

3. Magalasi otenthedwa & zosefera zowonera

4. Mirror substrates

Kutha kudula mizere ndikubowola m'mabowo amkati (ochepera Ø0.3mm)

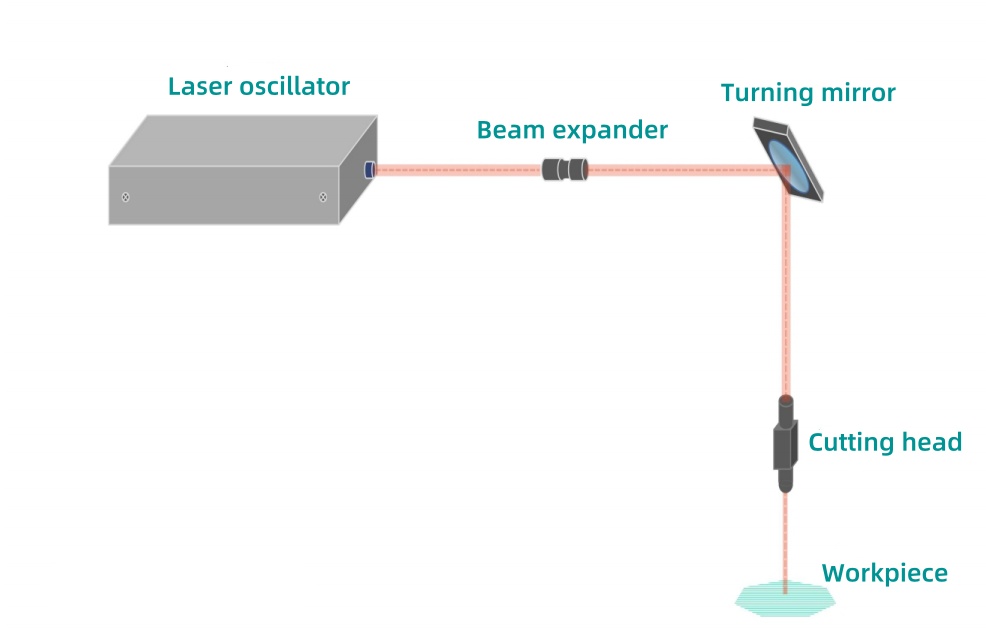

Laser Cutting Mfundo

Laser imapanga ma ultrashort pulses okhala ndi mphamvu zambiri zomwe zimalumikizana ndi chogwirira ntchito mkati mwa femtosecond-to-picosecond timescales. Pakufalitsa kudzera muzinthuzo, mtengowo umasokoneza kapangidwe kake kakupanikizika kuti apange mabowo a micron-scale filamentation. Kutalikirana bwino kwa dzenje kumapanga ming'alu yaying'ono yoyendetsedwa, yomwe imaphatikizana ndi ukadaulo wong'ambika kuti mupatule bwino.

Ubwino Wodula Laser

1.Kuphatikizika kwapamwamba kwambiri (kuphatikiza kudula / kudula ntchito) ndi kugwiritsa ntchito mphamvu zochepa komanso ntchito yosavuta;

Kukonzekera kwa 2.Non-contact kumapangitsa kuti luso lapadera lisakwaniritsidwe kudzera mu njira wamba;

3.Consumable-free ntchito amachepetsa kuthamanga ndalama ndi kumawonjezera chilengedwe zisathe;

4.Superior mwatsatanetsatane ndi zero taper angle ndi kuchotsa yachiwiri workpiece kuwonongeka;

XKH imapereka ntchito zambiri zosinthira makina athu odulira laser, kuphatikiza masanjidwe a nsanja, njira yapadera yopangira magawo, ndi mayankho okhudzana ndi kugwiritsa ntchito kuti akwaniritse zofunikira zapadera zopanga m'mafakitale osiyanasiyana.