Zida Zobowola za Nanosecond Laser za Glass Drilling makulidwe≤20mm

Main parameter

| Mtundu wa laser | Infrared nanosecond |

| Kukula kwa nsanja | 800*600(mm) |

|

| 2000*1200(mm) |

| Kubowola makulidwe | ≤20(mm) |

| Liwiro lobowola | 0-5000(mm/s) |

| Kubowola m'mphepete kusweka | <0.5(mm) |

| Chidziwitso: Kukula kwa nsanja kumatha kusinthidwa makonda. | |

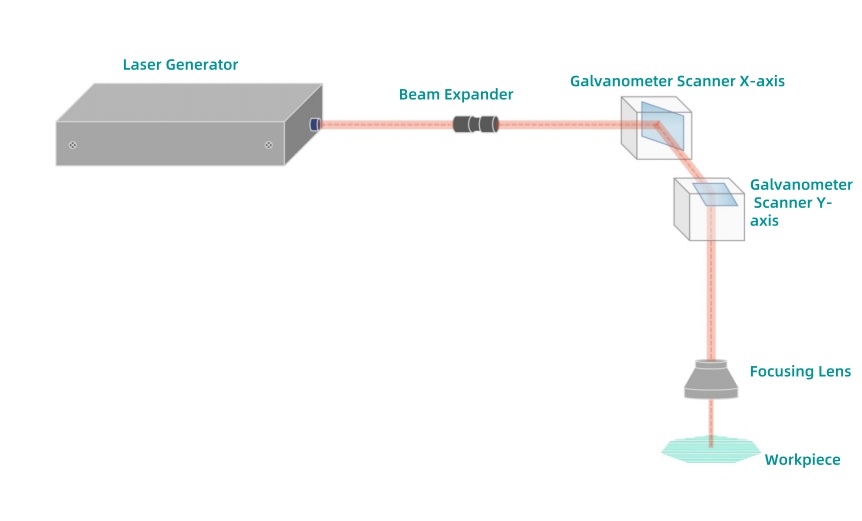

Laser Drilling Principle

Mtsinje wa laser umayang'ana pamalo abwino kwambiri poyerekeza ndi makulidwe a workpiece, kenako amasanthula m'njira zomwe zafotokozedwa mothamanga kwambiri. Kupyolera mu kuyanjana ndi mtengo wamphamvu wa laser, zinthu zomwe chandamale zimachotsedwa mosanjikiza-ndi-wosanjikiza kupanga mayendedwe odulira, kukwaniritsa kuphulika kolondola (zozungulira, masikweya, kapena ma geometri ovuta) ndi kulekanitsa kwazinthu zoyendetsedwa.

Ubwino Wobowola Laser

· Kuphatikizika kwakukulu kogwiritsa ntchito mphamvu zochepa komanso ntchito yosavuta;

· Non-kukhudzana processing zimathandiza wopanda malire chitsanzo geometries kuposa njira ochiritsira;

· Kugwiritsa ntchito kwaulere kumachepetsa ndalama zogwirira ntchito komanso kumapangitsa kuti chilengedwe chiziyenda bwino;

· Kulondola kwapamwamba kwambiri ndikupukuta pang'ono ndikuchotsa kuwonongeka kwachiwiri;

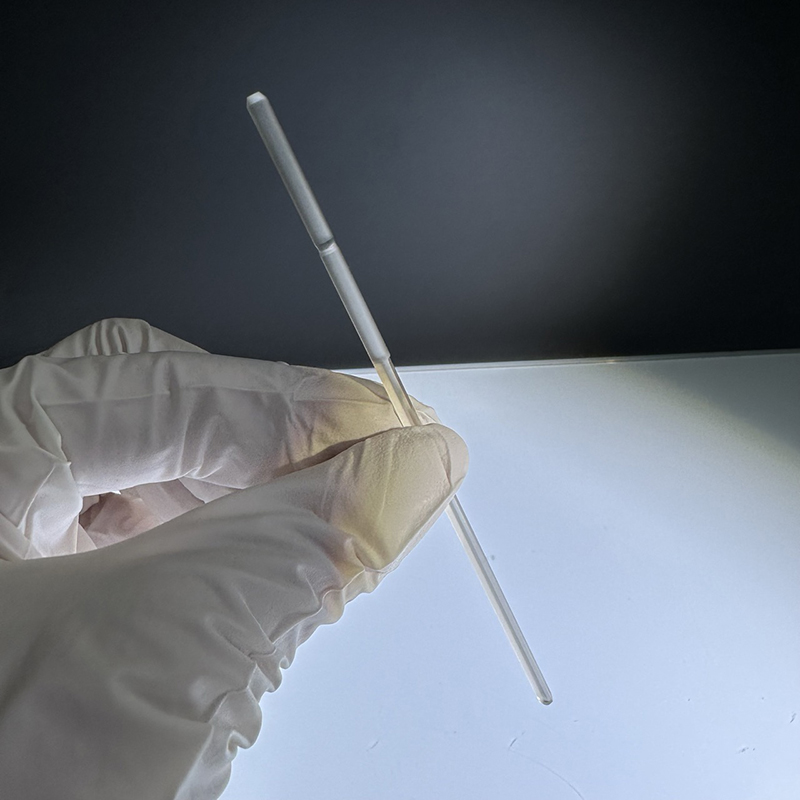

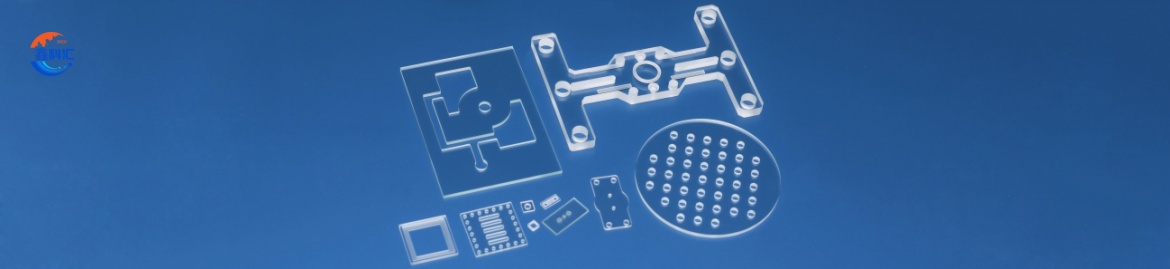

Chiwonetsero chachitsanzo

Sinthani Mapulogalamu

Dongosololi limapangidwa kuti lizitha kukonza bwino zinthu zosalimba/zolimba kuphatikiza kubowola, grooving, kuchotsa filimu, ndi kulemba pamwamba. Zomwe zimagwiritsidwa ntchito ndizo:

1. Kubowola ndi notch kwa zigawo shawa chitseko

2. Kubowola mwatsatanetsatane kwa mapanelo agalasi

3. Solar panel kudzera pobowola

4. Kusintha / zitsulo chophimba mbale perforation

5. Galasi ❖ kuyanika kuchotsa ndi kubowola

6. Kujambula kwamtundu wapamwamba ndi grooving kwa mankhwala apadera

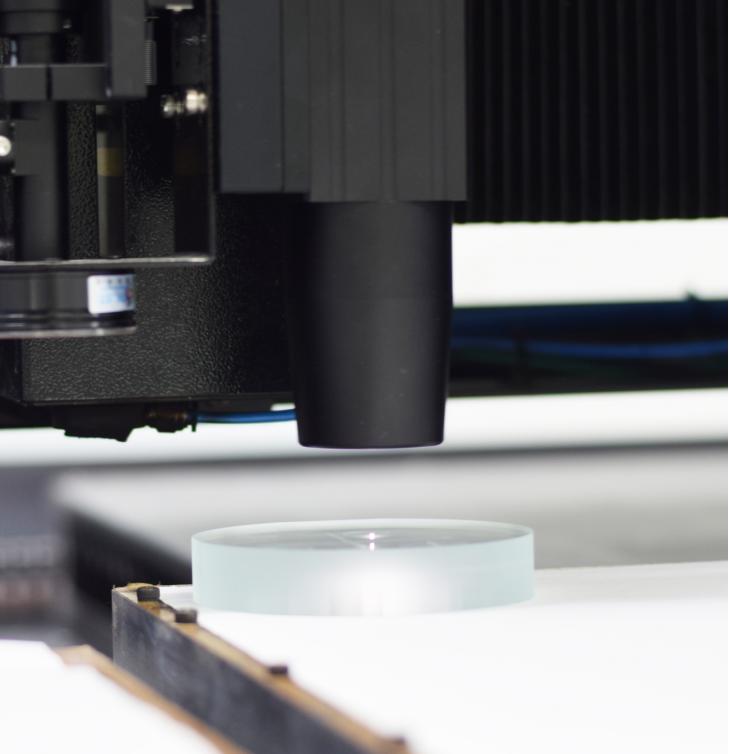

Processing Ubwino

1. Mapulatifomu amitundu yayikulu amakhala ndi mitundu yosiyanasiyana yazinthu zamafakitale

2. Kubowola kovutirapo komwe kumatheka pakadutsa chiphaso chimodzi

3. M'mphepete pang'ono kutsetsereka ndi kutsirizitsa kwapamwamba (Ra <0.8μm)

4. Kusintha kosasunthika pakati pazomwe zimapangidwira ndi ntchito mwachilengedwe

5. Kuchita bwino kokhala ndi:

Zokolola zambiri (> 99.2%)

· Consumable-free processing

· Kutulutsa koyipitsa kulibe

6.Kusamalidwa kosagwirizana kumatsimikizira kusungidwa kwa umphumphu pamwamba

Zofunika Kwambiri

1. Precision Thermal Management Technology:

Amagwiritsa ntchito kubowola kopitilira muyeso kopitilira muyeso ndi mphamvu imodzi yosinthika (0.1–50 mJ)

· Njira yodzitchinjiriza yoteteza katani yamphepo imatsekereza malo omwe amakhudzidwa ndi kutentha mkati mwa 10% ya dzenje lalikulu.

· Munthawi yeniyeni yowunikira kutentha kwa infrared imangobweza magawo amagetsi (± 2% kukhazikika)

2. Intelligent Processing Platform:

· Wokhala ndi siteji yamoto yolondola kwambiri (kubwereza kulondola kwa malo: ± 2 μm)

* Dongosolo lophatikizana la masomphenya (5-megapixel CCD, kulondola kwa kuzindikira: ± 5 μm)

+ Zosungidwa zakale zamapulogalamu zokhala ndi magawo okometsedwa amitundu 50+ ya zida zamagalasi

3. Kupanga Mwachangu Kwambiri:

· Njira zosinthira masiteshoni apawiri ndi nthawi yosinthira zinthu ≤3 masekondi

Kuzungulira kokhazikika kwa 1 hole/0.5 sec (Φ0.5 mm kudutsa-bowo)

· Mapangidwe a modular amathandizira kusinthana kwachangu kwa ma lens omwe akulunjika (kusiyana kwa makonzedwe: Φ0.1–10 mm)

Brittle Hard Material Processing Applications

| Mtundu Wazinthu | Ntchito Scenario | Kukonza Zinthu |

| Soda-laimu Galasi | Zitseko za shawa | Kuyika mabowo & ngalande zotayira |

| Zida zowongolera zida | Mabowo a ngalande | |

| Galasi Yotentha | Mawindo owonera uvuni | Mpweya wolowera dzenje arrays |

| Zophika za induction | Njira zoziziritsira zopindika | |

| Galasi la Borosilicate | Makanema adzuwa | Mabowo okwera |

| Laborator glassware | Mwambo ngalande ngalande | |

| Galasi-ceramic | Malo ophikira | Mabowo oyatsira moto |

| Ma induction cookers | Sensor mounting hole arrays | |

| Safira | Zida zanzeru zimakwirira | Mabowo olowera mpweya |

| Malo owonera mafakitale | Analimbitsa mabowo | |

| Galasi Wokutidwa | Magalasi aku bafa | Mabowo okwera (kuchotsa zokutira + kubowola) |

| Makoma a nsalu | Magalasi a Low-E amabisa mabowo a ngalande | |

| Galasi ya Ceramicized | Sinthani / zovundikira socket | Mipata yachitetezo + mabowo amawaya |

| Zolepheretsa moto | Mabowo opereka chithandizo chadzidzidzi |

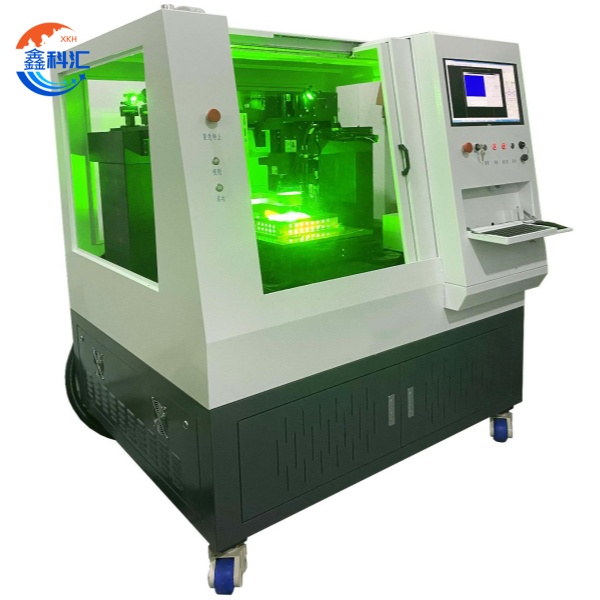

XKH imapereka chithandizo chokwanira chaukadaulo komanso ntchito zowonjezera pazida zobowolera magalasi a infrared nanosecond laser kuti zitsimikizire kuti zimagwira ntchito bwino pa nthawi yonse ya moyo wa zida. Timapereka ntchito zachitukuko zomwe gulu lathu la uinjiniya limagwirira ntchito limodzi ndi makasitomala kuti likhazikitse malaibulale okhudzana ndi zinthu, kuphatikiza mapulogalamu apadera obowola azinthu zovuta monga safiro ndi magalasi opumira okhala ndi makulidwe osiyanasiyana kuchokera ku 0.1mm mpaka 20mm. Pofuna kukhathamiritsa kupanga, timayesa kuyesa zida zapamalo ndikuyesa kutsimikizira magwiridwe antchito, kuwonetsetsa kuti ma metric ofunikira monga kulolerana kwa dzenje (± 5μm) ndi mtundu wam'mphepete (Ra<0.5μm) amakwaniritsa miyezo yamakampani.