High Purity SiC Optical Lens Kiyubiki 4H-semi 6SP Kukula Mwamakonda

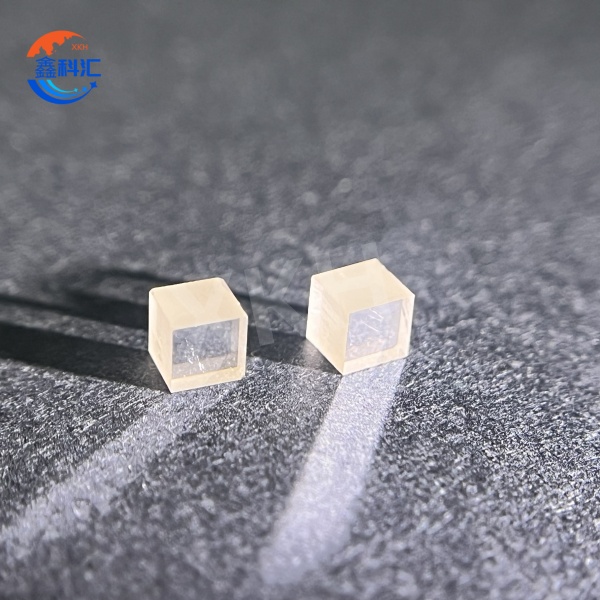

Makhalidwe a SiC Optical Lens

1. Zinthu Zapamwamba Zapamwamba

Kusinthasintha Kwambiri kwa Chilengedwe: Imapirira kutentha > 1500 ° C, dzimbiri la asidi / alkali wamphamvu, ndi cheza champhamvu champhamvu, chomwe chili choyenera popanga zida zamlengalenga ndi zida za nyukiliya.

Mphamvu Zapadera Zamakina: Kulimba kwa diamondi pafupi (Mohs 9.5), mphamvu yosunthika> 400 MPa, komanso kukana kwamphamvu kuposa magalasi owala wamba.

Kukhazikika kwa Matenthedwe: Kutentha kwamafuta 100 × apamwamba kuposa silika wosakanikirana, ndi CTE 1/10 chabe ya galasi wamba, kuonetsetsa bata pansi pa njinga yamoto yothamanga.

2. Kuwala Magwiridwe Ubwino

Kutumiza kowoneka bwino (0.2-6 μm); zokutira zapaderazi zimatha kukhathamiritsa kufalikira kwa> 95% m'magulu apadera (mwachitsanzo, 3-5 μm pakati pa IR).

Kutaya kobalalika kochepa (<0.5%/cm), kutha kwa pamwamba mpaka 10/5 kukanda-kumba muyezo, ndi kusalala kwapansi λ/10@633 nm.

High laser-induced damage threshold (LIDT)> 15 J/cm² (1064 nm, 10 ns pulses), yoyenera makina amphamvu kwambiri a laser.

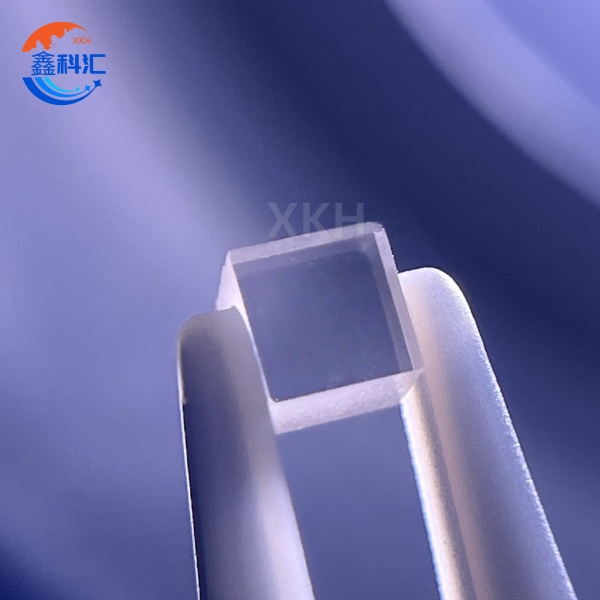

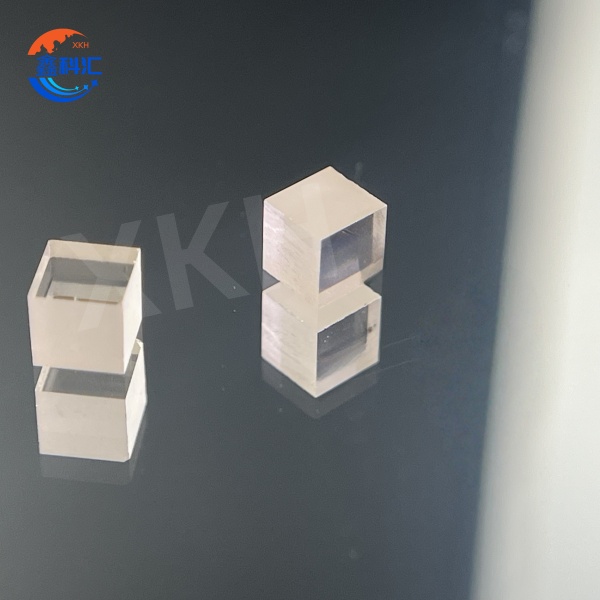

3. Mwatsatanetsatane Machining Kukhoza

Imathandizira malo ovuta (aspheric, freeform) ndi mawonekedwe olondola <100 nm PV ndi centration <1 arcmin.

Wotha kupanga magalasi akulu a SiC (m'mimba mwake> 500 mm) a telescope yakuthambo ndi ma optics amlengalenga.

Kugwiritsa Ntchito Kwambiri kwa SiC Optical Lens

1. Space Optics & Defense

Magalasi owonera kutali a satellite ndi ma telescope optics amlengalenga, kugwiritsa ntchito mphamvu zopepuka za SiC (kachulukidwe 3.21 g/cm³) komanso kukana ma radiation.

Mawindo owunikira oponya mizinga, opirira kutentha kwa mpweya (> 1000 ° C) panthawi yowuluka.

2. High-Power Laser Systems

Magalasi a mafakitale a laser kudula / kuwotcherera, kuwonetsa nthawi yayitali kwa ma lasers opitilira kalasi ya kW.

Mapangidwe a Beam mu machitidwe a inertial confinement fusion (ICF), kuwonetsetsa kufalikira kwamphamvu kwamphamvu kwa laser.

3. Semiconductor & Precision Manufacturing

Magalasi a SiC amtundu wa EUV lithography optics, okhala ndi matenthedwe ocheperako <1 nm pansi pa 10 kW/m² kutentha kotuluka.

Magalasi amagetsi a zida zowunikira ma e-beam, pogwiritsa ntchito mawonekedwe a SiC pakuwongolera kutentha.

4. Kuyendera kwa Industrial & Energy

Magalasi a Endoscope a ng'anjo zotentha kwambiri (1500°C ntchito mosalekeza).

Zida zopangira ma infrared pazida zodulira mitengo yamafuta, kukana kutsika kwapansi (> 100 MPa) ndi media zowononga.

Ubwino Wampikisano Wapakati

1. Utsogoleri Wamachitidwe Okwanira

Ma lens a SiC amaposa zida zamawonekedwe achikhalidwe (silika wosakanikirana, ZnSe) mu kukhazikika kwamafuta/makina/mankhwala, okhala ndi "high conductivity + low expansion" zomwe zimathetsa zovuta zakusintha kwamafuta muzowoneka zazikulu.

2. Kugwiritsa Ntchito Mtengo Wamoyo

Ngakhale kuti ndalama zoyamba ndizokwera, magalasi a SiC 'otalikirapo moyo wautumiki (5-10× magalasi wamba) ndi ntchito yopanda kukonza zimachepetsa mtengo wa umwini (TCO).

3. Ufulu Wopanga

Njira zolumikizirana kapena CVD zimathandizira mawonekedwe opepuka a SiC (chisa cha uchi), kukwaniritsa kuuma kosagwirizana ndi kulemera kwake.

Maluso a Utumiki wa XKH

1. Custom Manufacturing Services

Mayankho omalizira mpaka kumapeto kuchokera ku kapangidwe ka kuwala (Zemax/Code V kuyerekezera) mpaka kufikitsa komaliza, kuthandizira malo a aspheric/off-axis parabolic freeform.

Zovala zapadera: anti-reflection (AR), carbon ngati diamondi (LIDT> 50 J/cm²), conductive ITO, etc.

2. Njira Zotsimikizira Ubwino

Zida za Metrology kuphatikiza ma interferometers a 4D ndi ma profilers owunikira oyera omwe amatsimikizira kulondola kwa λ/20 pamwamba.

QC-level QC: Kusanthula kwa XRD crystallographic orientation kwa SiC iliyonse yopanda kanthu.

3. Ntchito Zowonjezera Phindu

Thermo-structural coupling analysis (ANSYS simulation) pakulosera kwa magwiridwe antchito.

Mapangidwe okhathamiritsa a SiC lens mounting structure kukhathamiritsa.

Mapeto

Ma lens a SiC akufotokozeranso malire a magwiridwe antchito a makina owoneka bwino kwambiri kudzera muzinthu zawo zosayerekezeka. Kuthekera kwathu kophatikizika kophatikizika mu kaphatikizidwe kazinthu za SiC, makina olondola, ndi kuyesa kumapereka mayankho osinthika azamlengalenga ndi mafakitale apamwamba. Ndi kupita patsogolo kwa kukula kwa kristalo wa SiC, zomwe zidzachitike m'tsogolo zidzayang'ana ma apertures akulu (> 1m) ndi ma geometries ovuta kwambiri (mitundu yaulere).

Monga otsogola opanga zida zapamwamba zowunikira, XKH imagwiritsa ntchito zida zowoneka bwino kwambiri kuphatikiza safiro, silicon carbide (SiC), ndi zowotcha za silicon, zomwe zimapereka mayankho omaliza kuchokera pakukonza zinthu mpaka kumaliza bwino. Ukadaulo wathu umayambira:

1. Kupanga Mwambo: Kukonzekera mwatsatanetsatane kwa ma geometries ovuta (aspheric, freeform) ndi kulolerana mpaka ± 0.001mm

2. Kusinthasintha Kwazinthu: Kukonza safiro (mawindo a UV-IR), SiC (mawotchi apamwamba kwambiri), ndi silikoni (IR/micro-optics)

3. Ntchito Zowonjezera Mtengo:

Zotchingira zotchingira / zokhazikika (UV-FIR)

Metrology-backed quality assurance (λ/20 flatness)

Kusonkhana m'chipinda choyera kwa ntchito zomwe zingakhudzidwe ndi kuipitsidwa

Kutumikira mafakitale amlengalenga, semiconductor, ndi laser, timaphatikiza ukatswiri wa sayansi ya zinthu ndi zopanga zapamwamba kuti tipereke ma optics omwe amapirira malo ovuta kwambiri kwinaku akukhathamiritsa magwiridwe antchito.