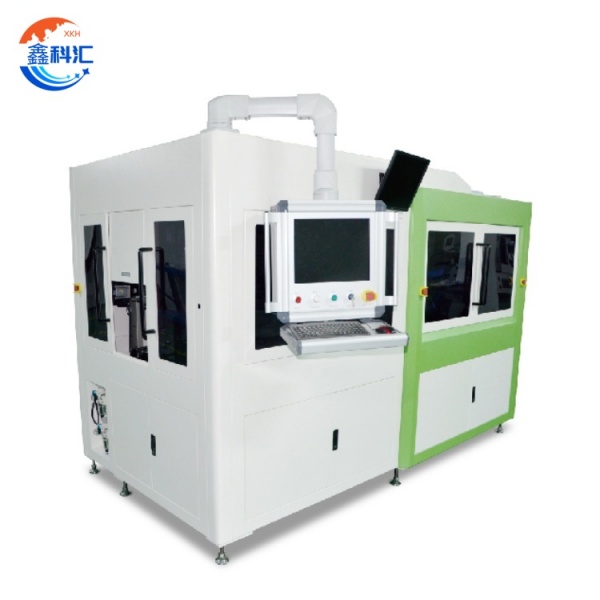

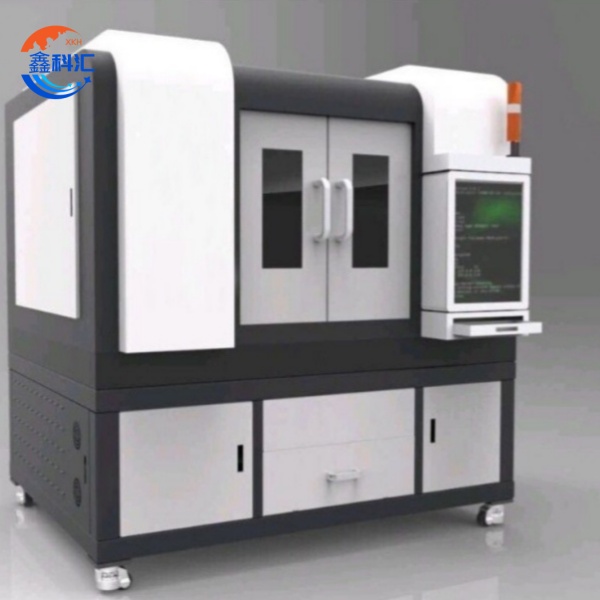

Makina otsogola apamwamba kwambiri a laser a safiro ceramic zinthu zamtengo wapatali zokhala ndi pobowola nozzle

Chiyambi cha Zamalonda

Zida zogwirira ntchito: Zoyenera zitsulo zachilengedwe, zitsulo za polycrystalline, ruby, safiro, mkuwa, zoumba, rhenium, chitsulo chosapanga dzimbiri, chitsulo cha carbon, alloy zitsulo ndi zina zapamwamba kwambiri, zipangizo zotentha kwambiri zosagwirizana ndi maonekedwe osiyanasiyana, diameter, kuya ndi kubowola taper.

Mikhalidwe yogwirira ntchito

1. Ndi oyenera kugwira ntchito pansi pa kutentha yozungulira 18 ℃-28 ℃ ndi chinyezi wachibale 30% -60%.

2. Oyenera magawo awiri magetsi /220V/50HZ/10A.

3. Konzani mapulagi omwe amakwaniritsa zofunikira za miyezo yoyenera yaku China. Ngati palibe pulagi yotereyi, adapter yoyenera iyenera kuperekedwa.

4. Amagwiritsidwa ntchito kwambiri pojambula mawaya a diamondi, kufa kwa waya pang'onopang'ono, dzenje la muffler, dzenje la singano, kunyamula miyala yamtengo wapatali, mphuno ndi mafakitale ena oboola.

Zosintha zaukadaulo

| Dzina | Deta | Ntchito |

| Kutalika kwa maser wavelength | 354.7nm kapena 355nm | Imatsimikizira kugawa mphamvu ndi mphamvu kulowa kwa mtengo laser, ndipo zimakhudza mlingo mayamwidwe zinthu ndi processing zotsatira. |

| Avereji yotulutsa mphamvu | 10.0 / 12.0/15.0 w@40khz | Kumakhudza processing dzuwa ndi liwiro kukhomerera, ndi apamwamba mphamvu, mofulumira processing liwiro. |

| Kugunda m'lifupi | Pansi pa 20ns@40KHz | Kuthamanga kwafupipafupi kumachepetsa madera omwe akhudzidwa ndi kutentha, kumapangitsa kuti makinawo azikhala olondola, komanso amapewa kuwonongeka kwa zinthuzo. |

| Kubwereza kwa kugunda | 10 ~ 200KHz | Dziwani kuchuluka kwa kufalikira ndi kugunda kwamphamvu kwa mtengo wa laser, kukweza ma frequency, kuthamangitsa liwiro la kukhomerera. |

| kuwala mtengo khalidwe | M²<1.2 | Miyendo yapamwamba kwambiri imatsimikizira kubowola molondola komanso mtundu wamphepete, kuchepetsa kutaya mphamvu. |

| Spot diameter | 0.8±0.1mm | Dziwani kabowo kakang'ono ndi makina olondola, malo ang'onoang'ono, kabowo kakang'ono, ndipamwamba kwambiri. |

| mbali ya mtengo-kusiyana | Kuposa 90% | Kuthekera koyang'ana komanso kugunda kwakuya kwa mtengo wa laser kumakhudzidwa. Pang'ono pang'ono kusiyana kwa ngodya, kumapangitsanso luso loyang'ana kwambiri. |

| Mtundu wa elliptical | Pansi pa 3% RMS | Zing'onozing'ono za elliptical, kuyandikira mawonekedwe a dzenje ndi bwalo, kumtunda kwa makina olondola. |

Processing mphamvu

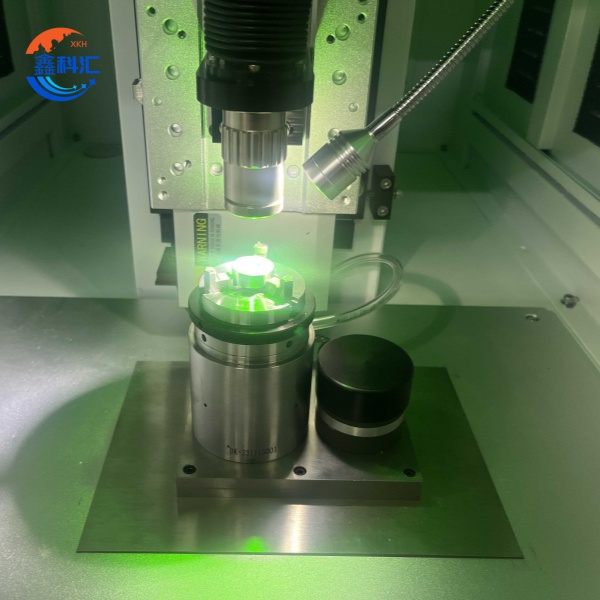

Makina obowola olondola kwambiri a laser ali ndi luso lamphamvu lowongolera ndipo amatha kubowola mabowo kuchokera ku ma microns angapo mpaka mamilimita angapo m'mimba mwake, ndipo mawonekedwe, kukula, malo ndi ngodya za mabowo zitha kuwongoleredwa bwino. Nthawi yomweyo, zidazo zimathandizira kubowola mozungulira mozungulira madigiri 360, zomwe zimatha kukwaniritsa zosowa zamitundu yosiyanasiyana ndi zomangira. Kuphatikiza apo, makina apamwamba kwambiri okhomerera a laser alinso ndi mtundu wabwino kwambiri wam'mphepete komanso kumalizidwa kwapamwamba, mabowo okonzedwa ndi opanda burr, osasungunuka m'mphepete, ndipo dzenjelo ndi losalala komanso lathyathyathya.

Kugwiritsa ntchito makina apamwamba kwambiri a laser kukhomerera:

1. Makampani opanga zamagetsi:

Printed circuit board (PCB) : amagwiritsidwa ntchito pokonza ma microhole kuti akwaniritse zosowa zamalumikizidwe apamwamba kwambiri.

Kupaka kwa Semiconductor: Khomani mabowo muzowotcha ndi zida zonyamula kuti muwongolere kachulukidwe ndi magwiridwe antchito.

2. Zamlengalenga:

Mabowo oziziritsa a injini: Mabowo oziziritsa ang'onoang'ono amapangidwa pamasamba a superalloy kuti injini igwire bwino ntchito.

Kukonza kompositi: Pobowola mwatsatanetsatane ma composites a carbon fiber kuti muwonetsetse mphamvu zamapangidwe.

3. Zida Zachipatala:

Zida zopangira maopaleshoni zocheperako pang'ono: Kukonza ma microholes mu zida zopangira opaleshoni kuti apititse patsogolo kulondola komanso chitetezo.

Dongosolo loperekera mankhwala: Khomerani mabowo mu chipangizo choperekera mankhwala kuti muchepetse kuchuluka kwa mankhwalawo.

4. Kupanga Magalimoto:

Dongosolo la jakisoni wamafuta: Kukonza mabowo ang'onoang'ono pamphuno ya jakisoni wamafuta kuti muwongolere mphamvu ya atomiki.

Kupanga masensa: Kubowola mabowo mu chinthu cha sensor kuti chiwongolere chidwi chake komanso kuthamanga kwake.

5. Zida zowonera:

Cholumikizira CHIKWANGWANI cha Optical: Machining ma microholes pa cholumikizira CHIKWANGWANI cha kuwala kuti muwonetsetse kufalikira kwa siginecha.

Zosefera za Optical: Khomerani mabowo mu fyuluta ya kuwala kuti mukwaniritse kusankha kwanthawi yayitali.

6. Makina olondola:

Precision nkhungu: Machining ma microholes pa nkhungu kukonza magwiridwe antchito ndi moyo wautumiki wa nkhungu.

Magawo ang'onoang'ono: Khomerani mabowo pazigawo zazing'ono kuti mukwaniritse zosowa za msonkhano wolondola kwambiri.

XKH imapereka ntchito zonse zamakina apamwamba kwambiri a laser pobowola makina, kuphatikiza kugulitsa zida, chithandizo chaukadaulo, zothetsera makonda, kukhazikitsa ndi kutumiza, maphunziro ogwirira ntchito ndi kukonza pambuyo pakugulitsa, ndi zina zambiri, kuwonetsetsa kuti makasitomala akugwiritsa ntchito akatswiri, ogwira ntchito komanso othandizira mokwanira.

Chithunzi chatsatanetsatane