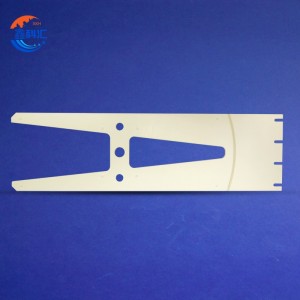

Alumina Ceramic End Effector Yapamwamba (Fork Arm) ya Semiconductor ndi Cleanroom Automation

Chithunzi chatsatanetsatane

Chiyambi cha Zamalonda

The Alumina Ceramic End Effector, yomwe imatchedwanso kuti mkono wa fork wa ceramic kapena mkono wa robotic ceramic, ndi gawo lapamwamba kwambiri lopangira makina opangira makina a semiconductor, photovoltaic, panel display, and high- purity laboratory environments. Imapangidwa kuti ipereke kukhazikika kwapadera kwamafuta, kusasunthika kwamakina, komanso kukana kwamankhwala, kupereka zoyendera zoyera, zodalirika, komanso zotetezeka zazinthu zodziwikiratu monga zowotcha za silicon, magawo agalasi, ndi zida zazing'ono zamagetsi.

Monga mtundu wa ma robotic end effector, gawo la ceramic iyi ndi mawonekedwe omaliza pakati pa makina opangira makina ndi chogwirira ntchito. Imakhala ndi gawo lofunikira pakusamutsa molondola, kuyanjanitsa, kutsitsa / kutsitsa, ndikuyika ntchito m'zipinda zoyera ndi malo opanda vacuum.

Zowoneka Mwachidule - Alumina Ceramic (Al₂O₃)

Alumina ceramic ndi chinthu chokhazikika komanso chosasunthika chaukadaulo cha ceramic chomwe chimadziwika chifukwa cha makina ake abwino kwambiri komanso magetsi. Kuyera kwambiri (≥ 99.5%) alumina yomwe imagwiritsidwa ntchito pazotsatira izi imatsimikizira:

-

Kuuma kwakukulu (Mohs 9): Chachiwiri kwa diamondi, aluminiyamu imapereka kukana kwambiri kuvala.

-

Kutentha kwakukulu: Imasunga umphumphu wapangidwe pamwamba pa 1600 ° C.

-

Chemical inertness: Kusamva ma acid, alkalis, solvents, ndi plasma etching environments.

-

Kutsekereza magetsi: Ndi mphamvu yapamwamba ya dielectric komanso kuchepa kwa dielectric.

-

Kuwonjezeka kochepa kwa kutentha: Imawonetsetsa kukhazikika kwapang'onopang'ono kwapang'onopang'ono.

-

Low tinthu kupanga: Zofunikira kuti zigwirizane ndi zipinda zoyera (Mkalasi 10 mpaka Mkalasi 1000).

Izi zimapangitsa kuti alumina ceramic ikhale yabwino pamachitidwe ofunikira kwambiri m'mafakitale omwe amakhudzidwa ndi kuipitsidwa.

Ntchito Mapulogalamu

Mphamvu yomaliza ya alumina ceramic imatengedwa kwambiri m'mafakitale apamwamba kwambiri, makamaka pomwe zida zachitsulo kapena pulasitiki zimasowa chifukwa chakukula kwamafuta, kuipitsidwa, kapena dzimbiri. Minda yayikulu yogwiritsira ntchito ndi:

- Semiconductor wafer transfer

- Photolithography kutsitsa ndi kutsitsa machitidwe

- Kugwira gawo lapansi lagalasi mumizere ya OLED ndi LCD

- Kusintha kwa Crystalline silicon wafer mukupanga ma cell a solar

- Automated Optical or microelectronic inspection

- Zitsanzo zoyendera mu ma analytical kapena biomedical labs

- Vacuum environment automation systems

Kutha kwake kuchita popanda kubweretsa tinthu tating'onoting'ono kapena static charger kumapangitsa kuti ikhale yofunikira kwambiri pakuchita bwino kwa robotic mu cleanroom automation.

Mawonekedwe Apangidwe & Kusintha Mwamakonda Anu

Chilichonse chomaliza cha ceramic chimapangidwa kuti chigwirizane ndi mkono wina wa robotic kapena makina opangira nsalu. Timathandizira makonda onse kutengera:

-

Kugwirizana kwa kukula kwa Wafer: 2 ", 4", 6", 8", 12" ndi zina

-

Slot geometry ndi masitayilo: Imakhazikika m'mphepete, chithandizo chakumbuyo chakumbuyo, kapena mapangidwe ang'onoang'ono opindika

-

Madoko a Suction: Mabowo ophatikizika a vacuum kapena njira zogwirira ntchito osalumikizana

-

Kuyika kasinthidwe: Mabowo, ulusi, mipata yogwirizana ndi flange ya chida cha loboti yanu

-

Chithandizo chapamwamba: Wopukutidwa, wokutidwa, kapena kumaliza bwino (Ra <0.2 µm ilipo)

-

Chitetezo cha m'mphepete: Zozungulira ngodya kapena chamfering kupewa kuwonongeka kwa mkate

Pogwiritsa ntchito zojambula za CAD kapena mitundu ya 3D yoperekedwa ndi makasitomala, mainjiniya athu amatha kukulitsa mkono uliwonse wa foloko kulemera kwake, mphamvu, ndi ukhondo.

Ubwino wa Ceramic End Effects

| Mbali | Pindulani |

|---|---|

| High Mechanical Kukhazikika | Imasunga kulondola kwenikweni pansi pa mphamvu zolozera za robotic |

| Kuchita bwino kwa Thermal Performance | Imagwira modalirika m'malo otentha kwambiri kapena a plasma |

| Zero Metal Kuipitsidwa | Palibe chiwopsezo cha kuipitsidwa kwa ion pakukonza kofunikira kwa semiconductor |

| Malo Otsika Otsika | Amachepetsa chiopsezo chokwapula pa wafer kapena magawo agalasi |

| Anti-Static ndi Non-Maginito | Sichikopa fumbi kapena kukhudza zinthu zomwe zimakhudzidwa ndi maginito |

| Moyo Wautumiki Wautali | Kukana kwapamwamba kwa mavalidwe mumayendedwe obwerezabwereza othamanga kwambiri |

| Kugwirizana Koyera Kwambiri | Yoyenera ISO 14644 zipinda zoyera (Class 100 ndi pansi) |

Poyerekeza ndi manja apulasitiki kapena aluminiyamu, alumina ceramic imapereka kukhazikika kwamankhwala komanso kukhazikika kwathupi komwe kumafunikira kukonza pang'ono.

| Katundu | Metal Arm | Pulasitiki Arm | Alumina Ceramic Arm |

|---|---|---|---|

| Kuuma | Wapakati | Zochepa | Pamwamba Kwambiri (Mohs 9) |

| Kutentha Kukhazikika | ≤500°C | ≤ 150°C | ≥1600°C |

| Kukaniza Chemical | Wapakati | Osauka | Zabwino kwambiri |

| Chipinda Chokwanira | Wapakati | Zochepa | Wapamwamba kwambiri |

| Valani Kukaniza | Wapakati | Zochepa | Zabwino kwambiri |

| Mphamvu ya Dielectric | Zochepa | Wapakati | Wapamwamba |

| Mwambo Machining Precision | Zochepa | Wapakati | Wapamwamba (± 0.01mm zotheka) |

Mfundo Zaukadaulo

| Parameter | Mtengo |

|---|---|

| Zakuthupi | Alumina woyenga kwambiri (≥ 99.5%) |

| Kutentha kwa Ntchito | Kufikira 1600 ° C |

| Kukalipa Pamwamba | Ra ≤ 0.2 µm (posankha) |

| Makulidwe a Wafer Ogwirizana | 2" mpaka 12" kapena mwambo |

| Kulekerera kwa Flatness | ± 0.01 mm (zotengera ntchito) |

| Chithandizo cha Vacuum Suction | Zosankha, njira zomwe mungasinthire |

| Zosankha Zokwera | Bolt-kupyola, flange, mabowo olowa |

Mafunso Ofunsidwa Kawirikawiri (FAQ)

Q1: Kodi mapeto amatha kuphatikizidwa ndi machitidwe a robotic omwe alipo?

A1:Inde. Timathandizira kusintha mwamakonda kutengera mawonekedwe anu a robotic. Mutha kutitumizira zojambula za CAD kapena miyeso ya flange kuti musinthe bwino.

Q2: Kodi zida za ceramic zitha kusweka mosavuta mukamagwiritsa ntchito?

A2:Ngakhale ceramic ndi yofooka mwachilengedwe, mapangidwe athu amagwiritsa ntchito geometry yokhazikika kuti achepetse kupsinjika. Pogwiritsa ntchito moyenera, amapereka moyo wautali wautali kuposa zitsulo kapena pulasitiki.

Q3: Kodi ndizotheka kugwiritsa ntchito izi mu vacuum yapamwamba kwambiri kapena zipinda zopangira plasma?

A3:Inde. Ceramic ya aluminiyamu ndiyosatulutsa mpweya, imakhala yosasunthika, komanso imalimbana ndi dzimbiri - ndiyoyenera malo okhala ndi vacuum, mpweya wotuluka, kapena plasma.

Q4: Kodi zigawozi zimatsuka kapena kusamalidwa bwanji?

A4:Atha kutsukidwa pogwiritsa ntchito madzi a DI, mowa, kapena zotsukira m'chipinda choyera. Palibe kukonzanso kwapadera komwe kumafunikira chifukwa cha kukhazikika kwawo kwamankhwala komanso pamwamba pa inert.

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.