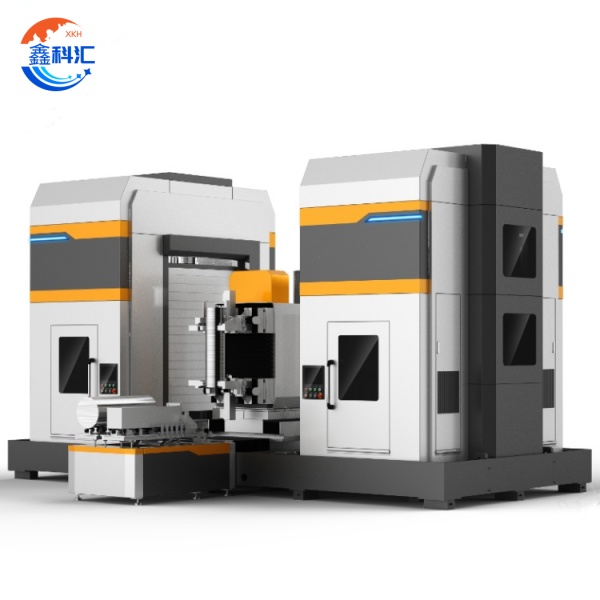

Pawiri station lalikulu makina monocrystalline pakachitsulo ndodo processing 6/8/12 inchi pamwamba flatness Ra≤0.5μm

Zida Makhalidwe:

(1) Double station synchronous processing

· Kuchita bwino kawiri: Kukonza nthawi imodzi yazitsulo ziwiri za silicon (Ø6 "-12") kumawonjezera zokolola ndi 40% -60% motsutsana ndi zida za Simplex.

· Kudzilamulira paokha: siteshoni iliyonse imatha kusintha paokha magawo odulira (kuvuta, kuthamanga kwa chakudya) kuti agwirizane ndi mitundu yosiyanasiyana ya ndodo ya silicon.

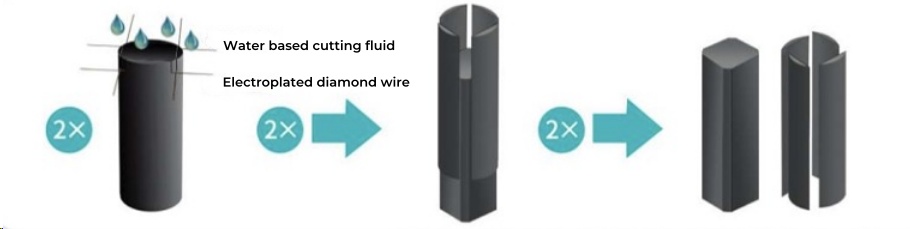

(2) Kudula kwambiri

· Dimensional kulondola: lalikulu bala mbali mtunda kulolerana ± 0.15mm, osiyanasiyana ≤0.20mm.

· Ubwino wapamtunda: kusweka m'mphepete <0.5mm, kuchepetsa kuchuluka kwakupera kotsatira.

(3) Kulamulira mwanzeru

Kudula kosinthika: kuwunika kwenikweni kwa silicon ndodo morphology, kusintha kwamphamvu kwa njira yodulira (monga kukonza ndodo yopindika ya silicon).

· Kutsatiridwa kwa data: lembani magawo osinthira a ndodo iliyonse ya silicon kuti muthandizire kuyika dongosolo la MES.

(4) Mtengo wotsika mtengo

· Kugwiritsa ntchito waya wa diamondi: ≤0.06m/mm (utali wa ndodo ya silicon), m'mimba mwake waya ≤0.30mm.

· Kuzungulira koziziritsa: Makina osefera amatalikitsa moyo wautumiki ndikuchepetsa kutaya zinyalala.

Ubwino waukadaulo ndi chitukuko:

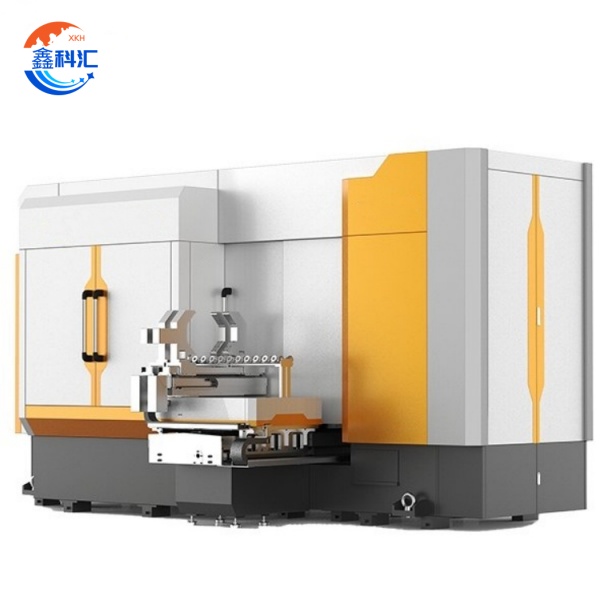

(1) Kudula kukhathamiritsa kwaukadaulo

- Kudula mizere yambiri: mizere ya diamondi 100-200 imagwiritsidwa ntchito mofanana, ndipo liwiro lodula ndi ≥40mm / min.

- Kuwongolera kwamphamvu: Dongosolo lotsekeka la loop (± 1N) kuti muchepetse chiopsezo cha kusweka kwa waya.

(2) Kugwirizana kowonjezera

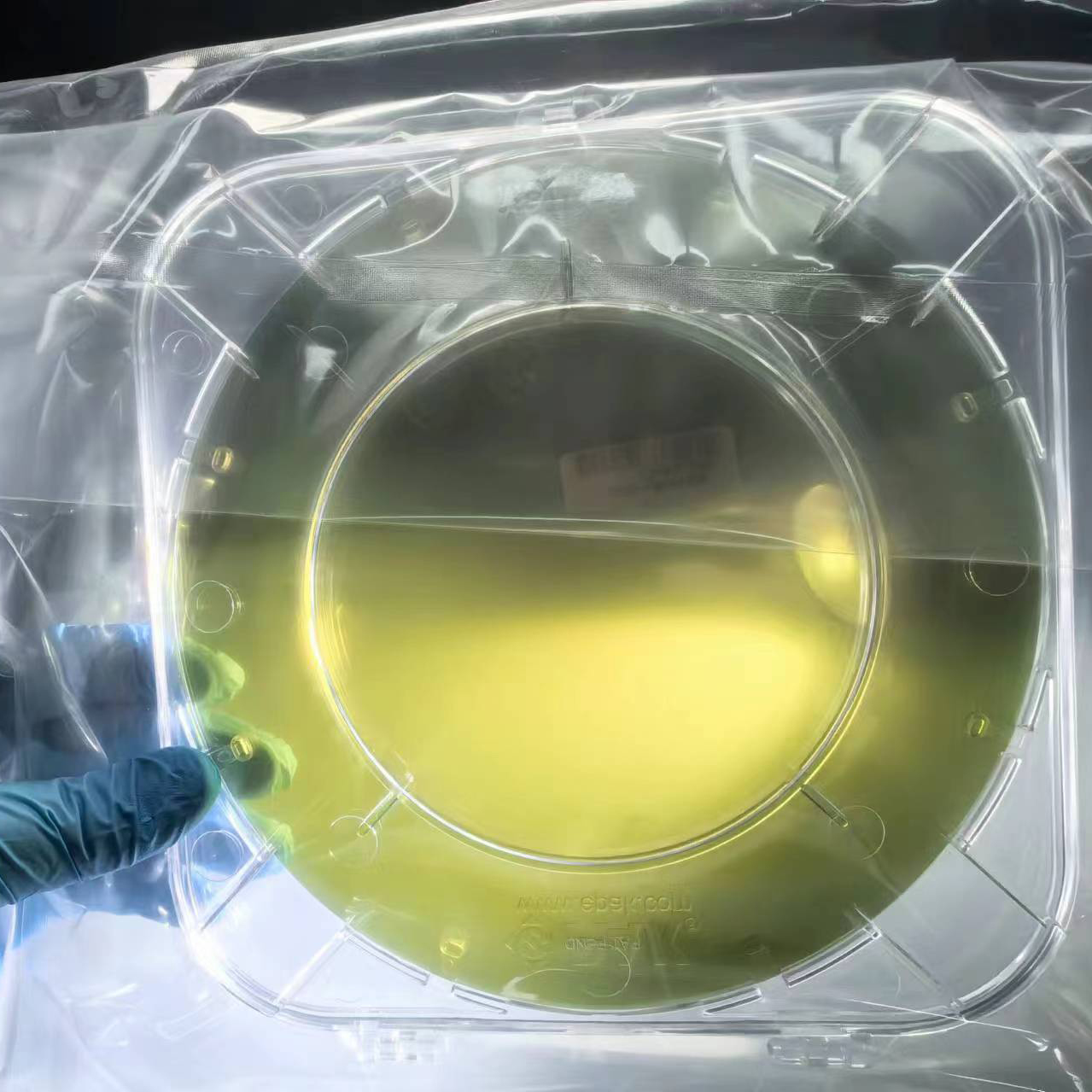

- Kusintha kwazinthu: Kuthandizira P-mtundu / N-mtundu wa silicon ya monocrystalline, yogwirizana ndi TOPCon, HJT ndi ndodo zina za silicon zamphamvu kwambiri.

- Kukula kosinthika: silicon ndodo kutalika 100-950mm, masikweya ndodo mbali mtunda 166-233mm chosinthika.

(3) Kusintha kwazinthu zokha

- Kutsegula ndi kutsitsa kwa roboti: kutsitsa / kutsitsa ndodo za silicon, kumenya ≤3 mphindi.

- Kuzindikira mwanzeru: Kukonzekera molosera kuti muchepetse nthawi yosakonzekera.

(4) Utsogoleri wamakampani

- Thandizo la Wafer: imatha kukonza ≥100μm silicon yowonda kwambiri yokhala ndi ndodo zazikulu, kugawanika <0.5%.

- Kukhathamiritsa kogwiritsa ntchito mphamvu: Kugwiritsa ntchito mphamvu pagawo lililonse la ndodo ya silicon kumachepetsedwa ndi 30% (kuyerekeza ndi zida zachikhalidwe).

Technical parameters:

| Dzina la parameter | Mtengo wa index |

| Chiwerengero cha mipiringidzo yokonzedwa | 2 zidutswa / seti |

| Kutalika kwa bar yokonza | 100-950 mm |

| Machining margin range | 166-233 mm |

| Kudula liwiro | ≥40mm/mphindi |

| Liwiro la waya wa diamondi | 0 ~ 35m/s |

| Diamondi m'mimba mwake | 0.30 mm kapena kuchepera |

| Kugwiritsa ntchito mzere | 0.06 m/mm kapena kuchepera |

| Yogwirizana mozungulira ndodo awiri | Kutsirizitsa sikweya ndodo m'mimba mwake + 2mm, Onetsetsani kuti kupukuta kumadutsa |

| Kuwongolera kwapang'onopang'ono kusweka | Mphepete mwaiwisi ≤0.5mm, Palibe kupukuta, mawonekedwe apamwamba kwambiri |

| Kutalika kwa Arc | Mawerengedwe osiyanasiyana <1.5mm, Kupatula kupotoza kwa ndodo ya silicon |

| Makulidwe a makina (makina amodzi) | 4800×3020×3660mm |

| Mphamvu zonse zovoteledwa | 56kw pa |

| Kulemera kwakufa kwa zida | 12t |

Table yolondola ya Machining:

| Chinthu cholondola | Kulekerera osiyanasiyana |

| Kulekerera kwapakati pa bar | ± 0.15mm |

| Mphepete mwa Square bar | ≤0.20 mm |

| Ngongole mbali zonse za square ndodo | 90°±0.05° |

| Kukhazikika kwa square ndodo | ≤0.15mm |

| Maloboti mobwerezabwereza malo olondola | ± 0.05mm |

Ntchito za XKH:

XKH amapereka ntchito zonse mkombero kwa mono-crystalline pakachitsulo wapawiri-station makina, kuphatikizapo zida mwamakonda (yogwirizana ndi ndodo zazikulu pakachitsulo), ndondomeko kutumidwa (kudula chizindikiro kukhathamiritsa), maphunziro ntchito ndi pambuyo-malonda thandizo (gawo zofunika, matenda akutali), kuonetsetsa kuti makasitomala kukwaniritsa zokolola zambiri (> 99%) ndi otsika consumable mtengo kupanga, ndi kupereka kukweza luso monga kukhathamiritsa AI (kudula). Nthawi yobereka ndi miyezi 2-4.

Chithunzi chatsatanetsatane