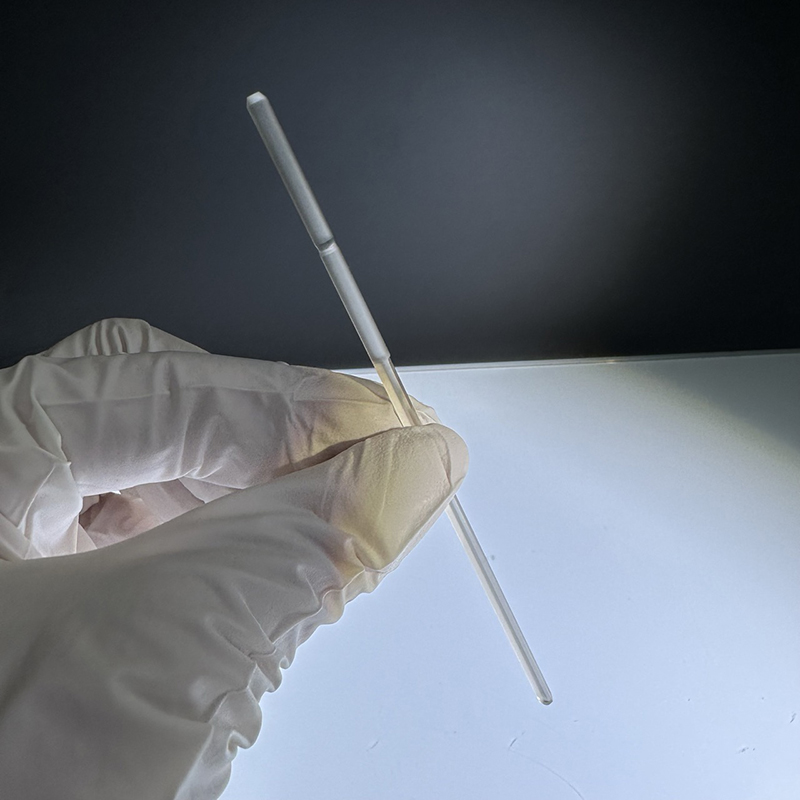

Bionic non-slip pad wafer yokhala ndi vacuum sucker friction pad sucker

Zofunikira za Bionic anti-slip pad:

• Kugwiritsa ntchito uinjiniya wapadera elastomer kompositi zakuthupi, kukwaniritsa palibe zotsalira, kuipitsidwa-free aukhondo odana skid kwenikweni, wangwiro kwa semiconductor kupanga chilengedwe amafuna.

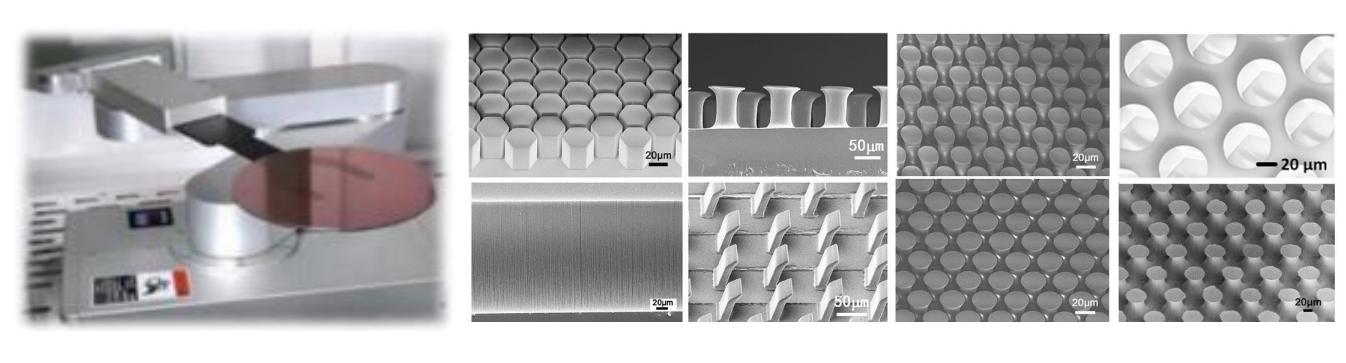

• Kupyolera mu ndondomeko yolondola ya micro-nano kapangidwe kake, kuwongolera mwanzeru kwa mawonekedwe a kukangana kwapamtunda, ndikusunga ma coefficient apamwamba akukangana ndikukwaniritsa zomatira zotsika kwambiri.

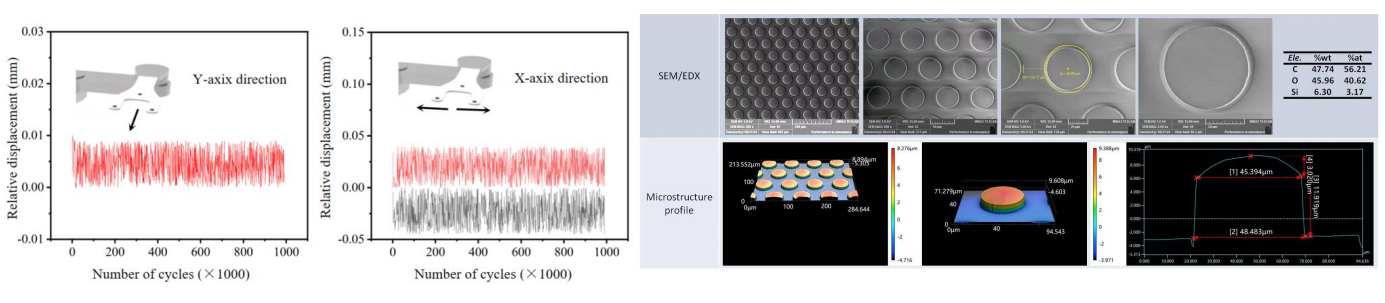

• Kapangidwe kakapangidwe kakapangidwe kake kamathandizira kugwira ntchito kwabwino kwa kukangana kwapamwamba kwambiri (μ>2.5) komanso kumamatira kocheperako (<0.1N/cm²).

• Zida za polima zopangidwira makamaka makampani a semiconductor, zomwe zimakwaniritsa ntchito yokhazikika popanda kuchepetsedwa kwa 100,000 zogwiritsidwanso ntchito pogwiritsa ntchito teknoloji ya micro ndi nano.

Ntchito ya Bionic anti-slip pad:

(1) Makampani a semiconductor

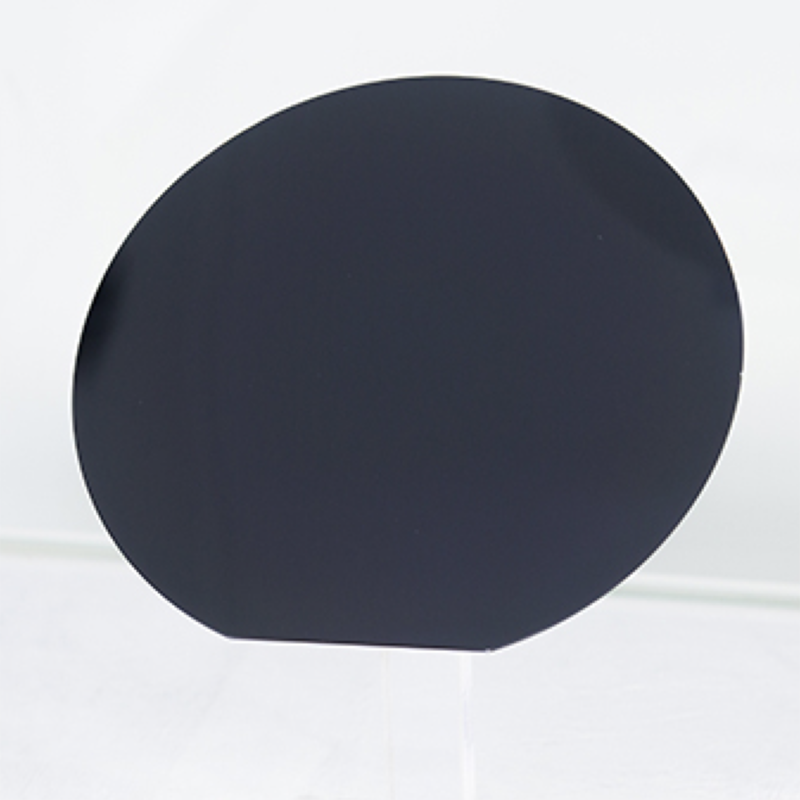

1. Kupanga Wafer:

Malo osatsetsereka pakutumiza zowonda kwambiri mpaka mainchesi 12 (50-300μm)

· Kukonzekera kolondola kwa chonyamulira chonyamulira cha makina a lithography

· Wafer non-slip liner yoyesera zida

2. Mayeso a phukusi:

· Kukonzekera kosawonongeka kwa zida zamagetsi za silicon carbide/gallium nitride

· Anti-slip buffer panthawi yokweza chip

· Yesani kugwedezeka ndi kutsetsereka kwa tebulo lofufuzira

(2) Makampani a Photovoltaic

1. Silicon wafer processing:

· Kukonzekera kosasunthika panthawi yodula ndodo ya monocrystalline

· Wopyapyala wowonda kwambiri wa silicon (<150μm) wotumiza mosatsetsereka

· Kuyika kwa silicon wafer pamakina osindikizira pazenera

2. Kuphatikiza kwazinthu:

· Galasi backplane laminated sanali kuzembera

· Kuyika kwa chimango

· Bokosi lomangiriza lokhazikika

(3) makampani opanga zithunzi

1. Gulu lowonetsera:

· Njira yosasunthika ya OLED/LCD yagalasi

· Kuyika bwino kwa polarizer kokwanira

· Zipangizo zoyezera zinthu zomwe sizingagwedezeke komanso kutsetsereka

2. Zowonera:

· Kuphatikiza ma module a lens osasunthika

· Kukonzekera kwa prism / galasi

· Shock-proof laser Optical system

(4) Zida zolondola

1. Pulatifomu yolondola ya makina a lithography ndi anti-slip

2. Gome loyezera la zida zodziwikiratu ndi umboni wodabwitsa

3. Zida zodziwikiratu zamawotchi mkono osalowerera

Zambiri zaukadaulo:

| Zolemba: | C, O, Si |

| Kulimba kwa nyanja (A) : | 50-55 |

| Elastic recovery coefficient: | 1.28 |

| Kutentha kwapamwamba kwambiri: | 260 ℃ |

| Friction coefficient: | 1.8 |

| Kukana kwa PLASMA: | Kulekerera |

Ntchito za XKH:

XKH imapereka bionic anti-slip mat ntchito zonse zosinthira makonda, kuphatikiza kusanthula kwazomwe akufuna, kapangidwe kake, kutsimikizira mwachangu komanso chithandizo chopanga misa. Kudalira luso lazopangapanga laling'ono ndi la nano, XKH imapereka njira zothana ndi zotchingira zamaluso zama mafakitale a semiconductor, photovoltaic ndi photoelectric, ndipo yathandiza bwino makasitomala kukwaniritsa zotsatira zazikulu monga kuchepetsa zinyalala mpaka 0.005% ndikuwonjezera zokolola ndi 15%.

Chithunzi chatsatanetsatane