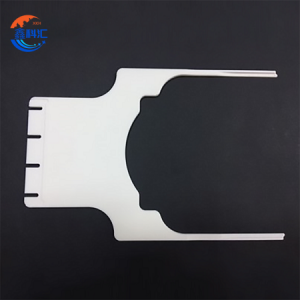

Alumina Ceramic End Effector / Fork Arm for Wafer and Substrate Handling

Chithunzi chatsatanetsatane

Chidule cha Alumina Ceramic End Effector

Alumina Ceramic End Effector, yomwe nthawi zambiri imatchedwa kuti ceramic fork arm kapena ceramic gripper, ndi chida chofunikira kwambiri chomwe chimagwiritsidwa ntchito popanga ma robotic ndi mizere yopanga zipinda zoyeretsa. Alumina Ceramic End Effector imayikidwa pa mkono wa robotic ngati mawonekedwe omaliza ndi chinthucho, chomwe chili ndi udindo wotolera, kugwira, kugwirizanitsa, ndi kusamutsa ziwalo zokhudzidwa kwambiri monga zowotcha za silicon, mapanelo agalasi, kapena zida za microelectronic.

Wopangidwa kuchokera ku ultra-pure alumina ceramic (Al2O3), mkono wa folokowu umapereka yankho laukhondo komanso lokhazikika m'malo omwe kuipitsidwa kwachitsulo, kupunduka kwa pulasitiki, kapena kupanga tinthu sikungaloledwe.

Zinthu Zakuthupi - Chifukwa Chake Alumina

About Alumina Ceramic End Effector,Alumina (Al2O3) ndi imodzi mwazokhazikika komanso zodalirika.ukadaulo wapamwamba wa ceramics. Kalasi yomwe timagwiritsa ntchito (≥99.5% kuyera) imapereka kuphatikiza kwapadera kwakuthupi ndi mankhwala komwe kumapangitsa kukhala chinthu chosankha pa semiconductor ndi vacuum application:

-

Kuuma kwambiri- Ndi kuuma kwa Mohs 9, kumapereka kulimba kwanthawi yayitali komanso kukana kukanda.

-

Kupirira kutentha- Imasunga umphumphu wapangidwe kupitirira 1600 ° C, zitsulo zopambana ndi ma polima.

-

Kutsekereza magetsi- Imachotsa static buildup ndipo imapereka chitetezo chokwanira cha dielectric.

-

Chemical chitetezo chokwanira- Osakhudzidwa ndi ma acid, alkalis, mpweya wa plasma, ndi njira zoyeretsera mwamphamvu.

-

Chiwopsezo cha kuipitsidwa kwambiri- Malo osatulutsa mpweya, osasunthika pang'ono omwe amachepetsa kutulutsidwa kwa tinthu m'zipinda zoyera.

Makhalidwe awa amalola kuti ma alumina ceramic end effectors azigwira ntchito mosalakwitsa m'malo ovuta, olondola kwambiri.

Kugwiritsa Ntchito Kwambiri kwa Alumina Ceramic End Effector

Kusinthasintha kwa zida za alumina ceramic end effectorfork zimawapangitsa kukhala ofunikira m'mafakitale angapo apamwamba kwambiri:

-

Njira zoyendetsera semiconductor wafer- Kusuntha zowotcha za silicon mosatekeseka kuchokera pakupanga kupita ku ntchito popanda zokopa zazing'ono.

-

Kupanga mawonekedwe a flat panel- Kugwira magalasi osalimba a OLED, LCD, kapena microLED.

-

Kupanga kwa Photovoltaic (PV).- Kuthandizira kutsitsa kwapang'onopang'ono kwa dzuwa ndikutsitsa mozungulira mothamanga kwambiri.

-

Optical ndi electronic chigawo msonkhano- Kugwira magawo osalimba ngati masensa, zopinga, ndi tchipisi tating'ono.

-

Vacuum ndi makina oyeretsa mchipindacho- Kuchita ntchito zolondola m'malo osayera kwambiri, oyendetsedwa ndi tinthu.

Muzochitika zilizonse, Alumina Ceramic End Effector imapereka ulalo wofunikira pakati pa makina opangira ma robotic ndi zomwe zikusunthidwa.

Kupanga ndi Kusintha Mwamakonda Alumina Ceramic End Effector

Mzere uliwonse wopanga uli ndi zofunikira zapadera. Chifukwa chake, timapereka mayankho opangidwa mwaluso a Alumina Ceramic End Effector amitundu yosiyanasiyana yophika, makina a robotic, ndi njira zogwirira ntchito:

Kugwirizana kwa Wafer: Imagwira zopindika kuchokera ku 2 "mpaka 12" ndipo zitha kusinthidwa pazigawo zachikhalidwe.

Zosankha za geometry: Foloko imodzi, foloko iwiri, mipata yambiri, kapena mawonekedwe amtundu wokhala ndi zotsalira zophatikizika.

Kugwira vacuum: Njira zoyamwitsa za vacuum kuti zithandizire popanda kulumikizana.

Malo olowera: Mabowo opangidwa mwamakonda, ma flange, kapena mapangidwe opindika kuti agwirizane ndi mkono uliwonse wa robotic.

Zomaliza zapamtunda: Malo opukutidwa kapena omalizidwa kwambiri (mpaka Ra <0.15 μm).

Mbiri zam'mphepete: M'mphepete mwachamfered kapena zozungulira kuti mutetezeke kwambiri.

Gulu lathu la uinjiniya la Alumina Ceramic End Effector litha kugwira ntchito kuchokera pazojambula zamakasitomala za CAD kapena zigawo zachitsanzo, kuwonetsetsa kuti ziphatikizidwe mosagwirizana ndi makina omwe alipo.

Ubwino Waikulu wa Alumina Ceramic End Effects

| Mbali | Chifukwa Chake Kuli Kofunika? |

|---|---|

| Kulondola kwenikweni | Imasunga mulingo wangwiro ngakhale mumayendedwe othamanga kwambiri, obwerezabwereza. |

| Zosayipitsa | Sipanga tinthu ting'onoting'ono, timakwaniritsa zofunikira zaukhondo. |

| Umboni wa kutentha ndi dzimbiri | Imapirira masitepe opangira mwamphamvu komanso kugwedezeka kwamafuta. |

| Palibe static charge | Kuteteza zowotcherera tcheru ndi zigawo zikuluzikulu ku chiwopsezo cha electrostatic. |

| Wopepuka koma wosasunthika | Amapereka kuuma kwakukulu popanda kusokoneza mkono wa robotic. |

| Moyo wowonjezera wautumiki | Imaposa mikono yachitsulo ndi polima mu moyo ndi kudalirika. |

Kuyerekeza Zinthu za Alumina Ceramic End Effector

| Malingaliro | Pulasitiki Fork Arm | Aluminium / Metal Fork Arm | Alumina Ceramic Fork Arm |

|---|---|---|---|

| Kuuma | Zochepa | Wapakati | Wapamwamba kwambiri |

| Thermal Range | ≤ 150°C | ≤500°C | Kufikira 1600 ° C |

| Chemical Kukhazikika | Osauka | Wapakati | Zabwino kwambiri |

| Chiyero cha Malo Oyera | Zochepa | Avereji | Zabwino kwa Class 100 kapena kuposa |

| Valani Kukaniza | Zochepa | Zabwino | Zabwino kwambiri |

| Mwamakonda Mulingo | Wapakati | Zochepa | Zambiri |

Mafunso Ofunsidwa Kawirikawiri (FAQ) a Alumina Ceramic End Effector

Q1: Nchiyani chimapangitsa kuti alumina ceramic end effector ikhale yosiyana ndi chitsulo?

A1:Mosiyana ndi mikono ya aluminiyamu kapena yachitsulo, alumina ceramic siiwononga, kusokoneza, kapena kuyambitsa ma ion azitsulo mumayendedwe a semiconductor. Imakhalabe yokhazikika pansi pazovuta kwambiri ndipo imatulutsa pafupifupi tinthu tating'ono.

Q2: Kodi Alumina Ceramic End Effector angagwiritsidwe ntchito m'zipinda zokhala ndi vacuum ndi plasma?

A2:Inde. Alumina ceramic ndiosatulutsa mpweyandi kugonjetsedwa ndi plasma, zomwe zimapangitsa kukhala chinthu chokondedwa chopangira vacuum ndi etching zipangizo.

Q3: Kodi mikono ya foloko ya Alumina Ceramic End Effector ndi yotheka bwanji?

A3:Chigawo chilichonse chikhoza kukhalakwathunthu makonda-kuphatikiza mawonekedwe, mipata, mabowo oyamwa, masitayilo okwera, ndi kumaliza - kuti zigwirizane ndi zomwe makina anu amaloboti amafuna.

Q4: Kodi ndi zofooka?

A4:Ngakhale ceramic ili ndi kuwonongeka kwachilengedwe, uinjiniya wathu wamapangidwe amagawa katundu mofanana ndikuchepetsa kupsinjika. Akagwiridwa bwino, moyo wautumiki nthawi zambiri umaposa wazitsulo kapena ma polima.

Zambiri zaife

XKH imagwira ntchito mwaukadaulo wapamwamba kwambiri, kupanga, ndi kugulitsa magalasi apadera owoneka bwino ndi zida zatsopano za kristalo. Zogulitsa zathu zimagwiritsa ntchito zamagetsi zamagetsi, zamagetsi zamagetsi, komanso zankhondo. Timapereka zida zowoneka bwino za Sapphire, zovundikira ma lens amafoni, Ceramics, LT, Silicon Carbide SIC, Quartz, ndi zowotcha za semiconductor crystal. Ndi ukadaulo waluso komanso zida zotsogola, timachita bwino kwambiri pakukonza zinthu zomwe sizili muyeso, tikufuna kukhala bizinesi yotsogola yaukadaulo wa optoelectronic.