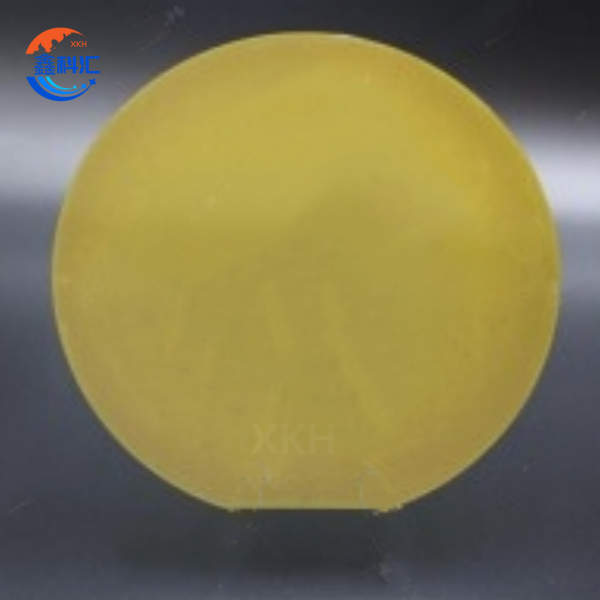

6 inchi Conductive single galasi SiC pa polycrystalline SiC gulu gawo gawo lapansi Diameter 150mm P mtundu N mtundu

Zosintha zaukadaulo

| Kukula: | 6 inchi |

| Diameter: | 150 mm |

| Makulidwe: | 400-500 μm |

| Monocrystalline SiC Film Parameters | |

| Polytype: | 4H-SiC kapena 6H-SiC |

| Kukhazikika kwa Doping: | 1×10¹⁴ - 1×10¹⁸cm⁻³ |

| Makulidwe: | 5-20 mm |

| Kukaniza Mapepala: | 10-1000 Ω/sq |

| Electron Mobility: | 800-1200 cm² / Vs |

| Hole Mobility: | 100-300 cm² / Vs |

| Polycrystalline SiC Buffer Layer Parameters | |

| Makulidwe: | 50-300 mamilimita |

| Thermal Conductivity: | 150-300 W/m·K |

| Magawo a Monocrystalline SiC Substrate | |

| Polytype: | 4H-SiC kapena 6H-SiC |

| Kukhazikika kwa Doping: | 1×10¹⁴ - 1×10¹⁸cm⁻³ |

| Makulidwe: | 300-500 μm |

| Kukula Kwambewu: | > 1 mm |

| Kukalipa Pamwamba: | <0.3 mm RMS |

| Mechanical & Electrical Properties | |

| Kulimba: | 9-10 mphindi |

| Compressive Mphamvu: | 3-4 GPA |

| Kulimba kwamakokedwe: | 0.3-0.5 GPA |

| Mphamvu Zagawo Zowonongeka: | > 2 MV/cm |

| Kupirira Kwa Mlingo Wonse: | > 10 Mayi |

| Kukaniza kwa Zochitika Pamodzi: | > 100 MeV·cm²/mg |

| Thermal Conductivity: | 150-380 W/m·K |

| Kutentha kwa Ntchito: | -55 mpaka 600 ° C |

Makhalidwe Ofunikira

6-inch conductive monocrystalline SiC pa polycrystalline SiC composite gawo lapansi imapereka kusanja kwapadera kwa kapangidwe kazinthu ndi magwiridwe antchito, ndikupangitsa kuti ikhale yoyenera malo ofunikira mafakitale:

1.Cost-Effectiveness: Maziko a polycrystalline SiC amachepetsa kwambiri ndalama poyerekeza ndi SiC yodzaza monocrystalline, pamene SiC ya monocrystalline yogwira ntchito imatsimikizira kuti chipangizochi chimagwira ntchito, chomwe chili choyenera pa ntchito zotsika mtengo.

2.Zapadera Zamagetsi Zamagetsi: Wosanjikiza wa monocrystalline SiC amawonetsa kuyenda kwakukulu kwa chonyamulira (> 500 cm²/V·s) ndi kuchepa kwapang'onopang'ono, kumathandizira kuwongolera pafupipafupi komanso kugwiritsa ntchito zida zamphamvu kwambiri.

Kukhazikika kwa 3.Kutentha Kwambiri: Kutentha kwa SiC kwachilengedwe (> 600 ° C) kumatsimikizira kuti gawo lapansi lophatikizana limakhalabe lokhazikika pansi pa zovuta kwambiri, zomwe zimapangitsa kuti zikhale zoyenera kwa magalimoto amagetsi ndi magalimoto opangira mafakitale.

4.6-inch Wafer Standardized Wafer: Poyerekeza ndi magawo achikhalidwe a 4-inch SiC, mawonekedwe a 6-inch amawonjezera zokolola za chip ndi 30%, kuchepetsa mtengo wa chipangizo chilichonse.

5.Conductive Design: Pre-doped N-type kapena P-type zigawo zimachepetsa masitepe a ion implantation pakupanga zipangizo, kupititsa patsogolo kupanga bwino ndi zokolola.

6.Superior Thermal Management: Polycrystalline SiC base's thermal conductivity (~ 120 W / m·K) ikufika ku monocrystalline SiC, kuthana bwino ndi zovuta zowonongeka kwa kutentha mu zipangizo zamphamvu kwambiri.

Makhalidwewa amayika 6-inch conductive monocrystalline SiC pa polycrystalline SiC composite gawo lapansi ngati njira yopikisana pamafakitale monga mphamvu zongowonjezwdwanso, zoyendera njanji, ndi zakuthambo.

Mapulogalamu Oyambirira

6-inch conductive monocrystalline SiC pa polycrystalline SiC composite substrate yayikidwa bwino m'magawo angapo ofunikira kwambiri:

1.Electric Vehicle Powertrains: Amagwiritsidwa ntchito mu ma SiC MOSFET apamwamba kwambiri ndi ma diode kuti apititse patsogolo kuyendetsa bwino kwa inverter ndikuwonjezera kuchuluka kwa batri (mwachitsanzo, Tesla, BYD zitsanzo).

2.Industrial Motor Drives: Imapangitsa ma modules amphamvu kwambiri, osinthasintha-othamanga kwambiri, kuchepetsa mphamvu zamagetsi mu makina olemera ndi makina opangira mphepo.

3.Photovoltaic Inverters: Zida za SiC zimathandizira kusintha kwa dzuwa (> 99%), pamene gawo lapansi lophatikizana limachepetsanso ndalama za dongosolo.

4.Mayendedwe a Sitima yapamtunda: Amagwiritsidwa ntchito m'makina osinthira njanji yothamanga kwambiri ndi masitima apamtunda, omwe amapereka kukana kwamagetsi apamwamba (> 1700V) ndi mawonekedwe ophatikizika.

5.Azamlengalenga: Ndibwino kwa machitidwe a mphamvu ya satana ndi maulendo oyendetsa injini za ndege, zomwe zimatha kupirira kutentha kwakukulu ndi ma radiation.

Pakupanga kothandiza, 6-inch conductive monocrystalline SiC pa polycrystalline SiC composite substrate imagwirizana kwathunthu ndi njira zokhazikika za chipangizo cha SiC (mwachitsanzo, lithography, etching), osafuna ndalama zowonjezera.

Ntchito za XKH

XKH imapereka chithandizo chokwanira cha 6-inch conductive monocrystalline SiC pa polycrystalline SiC composite substrate, yophimba R&D pakupanga zinthu zambiri:

1.Kusintha mwamakonda: makulidwe osinthika a monocrystalline wosanjikiza (5-100 μm), kukhazikika kwa doping (1e15-1e19 cm⁻³), ndi kuwongolera kwa kristalo (4H/6H-SiC) kuti zikwaniritse zofunikira pazida zosiyanasiyana.

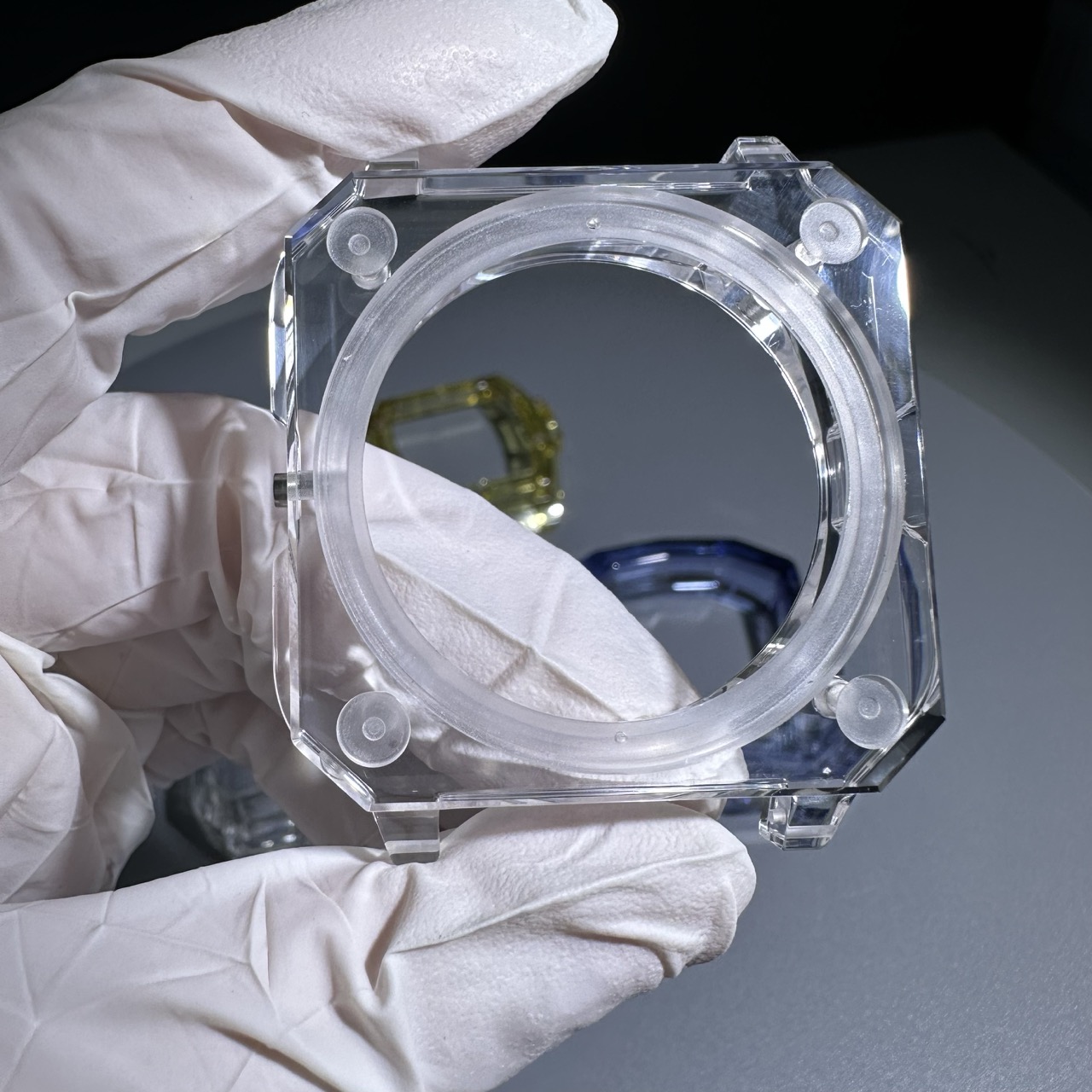

2.Wafer Processing: Kuchuluka kwa magawo 6-inch okhala ndi kupatulira kumbuyo ndi ntchito zazitsulo zophatikizira pulagi-ndi-sewero.

3.Technical Validation: Zimaphatikizapo kusanthula kwa crystallinity kwa XRD, kuyesa kwa Hall effect, ndi kuyeza kukana kwa kutentha kuti kufulumizitse kuyenerera kwa zinthu.

4.Rapid Prototyping: 2- ku 4-inch zitsanzo (njira yofanana) kwa mabungwe ofufuza kuti apititse patsogolo chitukuko.

5.Kusanthula Kulephera & Kukhathamiritsa: Njira zothetsera mavuto pokonza zovuta (mwachitsanzo, epitaxial layer defects).

Cholinga chathu ndikukhazikitsa 6-inch conductive monocrystalline SiC pa polycrystalline SiC composite substrate ngati njira yabwino yosinthira mtengo wamagetsi amagetsi a SiC, yopereka chithandizo chakumapeto kuchokera ku prototyping mpaka kupanga voliyumu.

Mapeto

SiC ya 6-inch conductive monocrystalline SiC pa polycrystalline SiC composite substrate imakwaniritsa bwino pakati pa magwiridwe antchito ndi mtengo kudzera mu mawonekedwe ake osakanizidwa a mono/polycrystalline. Pamene magalimoto amagetsi akuchulukirachulukira komanso kupita patsogolo kwa Viwanda 4.0, gawo ili limapereka maziko odalirika amagetsi am'badwo wotsatira. XKH landirani mgwirizano kuti mupitirize kufufuza luso laukadaulo wa SiC.