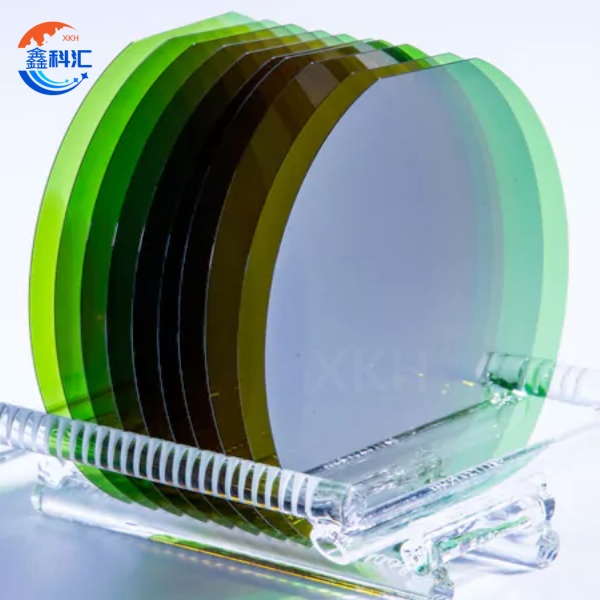

12 inch SiC Substrate N Mtundu Waukulu Wakukulu Wapamwamba Wogwiritsa Ntchito RF

Zosintha zaukadaulo

| 12 inch Silicon Carbide (SiC) Matchulidwe a gawo lapansi | |||||

| Gulu | ZeroMPD Production Giredi (Z Giredi) | Standard Production Giredi (P) | Dummy Grade (D kalasi) | ||

| Diameter | 3 00mm ~ 1305mm | ||||

| Makulidwe | 4H-N | 750μm ± 15 μm | 750μm±25μm | ||

| 4H-SI | 750μm ± 15 μm | 750μm±25μm | |||

| Wafer Orientation | Kutalikirana: 4.0 ° kulowera <1120 > ± 0.5 ° kwa 4H-N, Pa axis: <0001> ± 0.5 ° kwa 4H-SI | ||||

| Kuchuluka kwa Micropipe | 4H-N | ≤0.4cm-2 | ≤4cm-2 | ≤25cm-2 | |

| 4H-SI | ≤5cm-2 | ≤10cm-2 | ≤25cm-2 | ||

| Kukaniza | 4H-N | 0.015 ~ 0.024 Ω·cm | 0.015 ~ 0.028 Ω·cm | ||

| 4H-SI | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |||

| Chiyambi cha Flat Orientation | {10-10} ±5.0° | ||||

| Utali Woyambira Wathyathyathya | 4H-N | N / A | |||

| 4H-SI | Notch | ||||

| Kupatula M'mphepete | 3 mm | ||||

| LTV/TTV/Bow/Warp | ≤5μm/≤15μm/≤35 μm/≤55 μm | ≤5μm/≤15μm/≤35 □ μm/≤55 □ μm | |||

| Ukali | Chipolishi Ra≤1 nm | ||||

| CMP Ra≤0.2 nm | Ra≤0.5 nm | ||||

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri Hex Plates Mwa Kuwala Kwakukulu Kwambiri Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri Mawonekedwe a Carbon Inclusions Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Palibe Malo owonjezera ≤0.05% Palibe Malo owonjezera ≤0.05% Palibe | Utali wokwanira ≤ 20 mm, utali umodzi≤2 mm Malo owonjezera ≤0.1% Malo owonjezera≤3% Malo owonjezera ≤3% Kutalikirana ≤1 × awiri wafer | |||

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥0.2mm m'lifupi ndi kuya | 7 zololedwa, ≤1 mm iliyonse | |||

| (TSD) Kusokoneza screw screw | ≤500 cm-2 | N / A | |||

| (BPD) Kusuntha kwapansi kwa ndege | ≤1000 cm-2 | N / A | |||

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | Palibe | ||||

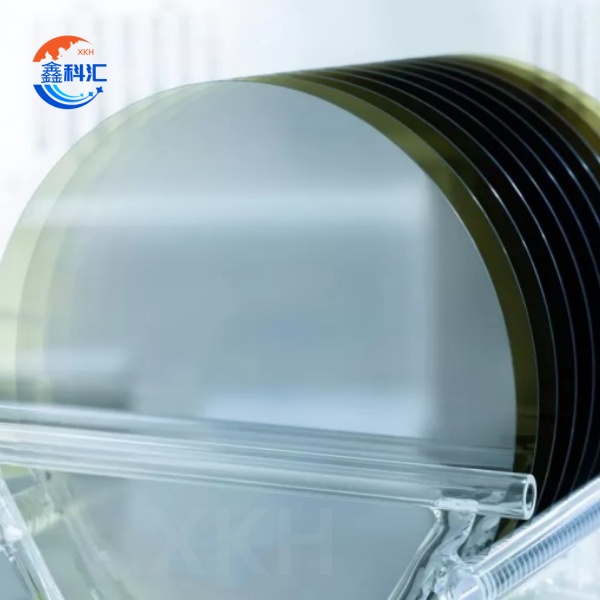

| Kupaka | Makaseti amitundu yopyapyala Kapena Chidebe Chowotcha Chimodzi | ||||

| Ndemanga: | |||||

| 1 Malire opunduka amagwira ntchito pamtunda wonse wophatikizika kupatula m'mphepete mwake. 2Zikandazi ziyenera kuyang'aniridwa pa Si nkhope yokha. 3 Zomwe zasunthidwa zimangochokera ku KOH etched wafers. | |||||

Zofunika Kwambiri

1. Ubwino Waukulu Wakukulu: Gawo la 12-inch SiC (12-inch silicon carbide substrate) limapereka malo akuluakulu amtundu umodzi wonyezimira, zomwe zimapangitsa kuti tchipisi tambiri timene tipangidwe pamapazi, potero kuchepetsa ndalama zopangira ndikuwonjezera zokolola.

2. Zida Zapamwamba: Kutentha kwa Silicon carbide ndi kuphulika kwakukulu kwa munda kumapangitsa kuti gawo lapansi la 12-inch likhale labwino kwambiri pamagetsi apamwamba komanso othamanga kwambiri, monga EV inverters ndi makina othamanga mofulumira.

3. Kugwirizana Kwamakonzedwe: Ngakhale kuuma kwakukulu ndi zovuta za SiC, gawo lapansi la 12-inch SiC limakwaniritsa zofooka zochepa zapamtunda pogwiritsa ntchito njira zodulira bwino ndi kupukuta, kukonza zokolola za chipangizocho.

4. Superior Thermal Management: Pokhala ndi kutentha kwabwino kwambiri kuposa zipangizo zopangira silicon, gawo lapansi la 12-inch limayendetsa bwino kutentha kwa kutentha mu zipangizo zamphamvu kwambiri, kukulitsa moyo wa zipangizo.

Main Applications

1. Magalimoto a Magetsi: Gawo la 12-inch SiC (12-inch silicon carbide substrate) ndilo gawo lalikulu la machitidwe oyendetsa magetsi a m'badwo wotsatira, zomwe zimathandiza ma inverters apamwamba kwambiri omwe amawonjezera nthawi ndi kuchepetsa nthawi yolipiritsa.

2. 5G Base Stations: Magawo akuluakulu a SiC amathandizira zipangizo zamakono za RF, zomwe zimakwaniritsa zofunikira za 5G maziko a mphamvu zamphamvu ndi kutayika kochepa.

3.Industrial Power Supplies: Mu ma inverters a dzuwa ndi ma grids anzeru, gawo lapansi la 12-inch limatha kupirira ma voltages apamwamba ndikuchepetsa kuchepa kwa mphamvu.

4.Consumer Electronics: Ma charger othamanga amtsogolo ndi zida zamagetsi zapakati pa data zitha kutengera magawo a 12-inch SiC kuti akwaniritse kukula kophatikizana komanso kuchita bwino kwambiri.

Ntchito za XKH

Timakhala ndi ntchito zosinthira makonda a 12-inch SiC substrates (12-inch silicon carbide substrates), kuphatikiza:

1. Dicing & polishing: Zowonongeka pang'ono, zowonongeka kwambiri zowonongeka zogwirizana ndi zofuna za makasitomala, kuonetsetsa kuti chipangizochi chikugwira ntchito mokhazikika.

2. Epitaxial Growth Support: Ntchito zapamwamba za epitaxial wafer kuti zifulumizitse kupanga chip.

3. Small-Batch Prototyping: Imathandizira kutsimikizika kwa R&D kwa mabungwe ofufuza ndi mabizinesi, kufupikitsa mizungulira yachitukuko.

4. Technical Consulting: Mayankho otsiriza-ku-mapeto kuchokera ku zosankha zakuthupi kuti akonze kukhathamiritsa, kuthandiza makasitomala kuthana ndi zovuta za SiC processing.

Kaya ndizopanga zambiri kapena mwamakonda mwapadera, ntchito zathu zapakati pa 12-inch SiC zimagwirizana ndi zosowa zanu, ndikupangitsa kupita patsogolo kwaukadaulo.