Ukadaulo wa dicing wa Wafer, monga gawo lofunikira pakupanga ma semiconductor, umalumikizidwa mwachindunji ndi magwiridwe antchito a chip, zokolola, ndi mtengo wopanga.

#01 Mbiri ndi Kufunika kwa Dicing Wafer

1.1 Tanthauzo la Wafer Dicing

Dicing wafer (yomwe imadziwikanso kuti scribing) ndi gawo lofunikira popanga semiconductor, yomwe cholinga chake ndi kugawa zowotcha zophikidwa kuti zikhale anthu angapo akamwalira. Izi zimafa zimakhala ndi magwiridwe antchito athunthu ndipo ndizomwe zimagwiritsidwa ntchito popanga zida zamagetsi. Pamene mapangidwe a chip akukhala ovuta kwambiri komanso kukula kwake kukucheperachepera, zofunikira zolondola komanso zogwira mtima paukadaulo wa ukadaulo wawafer dicing zikuchulukirachulukira.

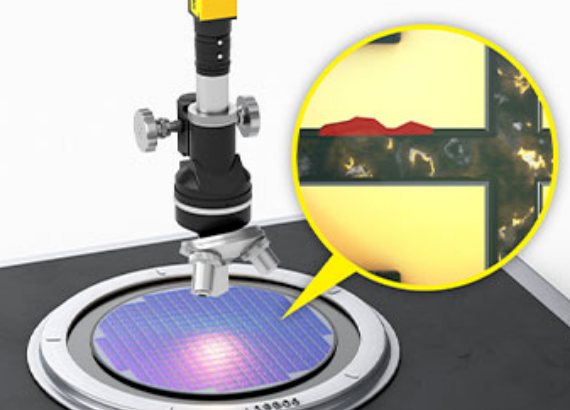

Pochita zinthu zowoneka bwino, ma dicing a wafer nthawi zambiri amagwiritsa ntchito zida zolondola kwambiri monga masamba a diamondi kuwonetsetsa kuti kufa kulikonse kumakhalabe kosasunthika komanso kugwira ntchito mokwanira. Njira zazikuluzikulu zimaphatikizapo kukonzekera musanadulidwe, kuwongolera molondola panthawi yodula, komanso kuyang'anitsitsa khalidwe mutatha kudula.

Musanadulidwe, chophikacho chiyenera kulembedwa ndi kuikidwa kuti muwonetsetse njira zodulira zolondola. Pakudula, magawo monga kuthamanga kwa chida ndi liwiro liyenera kuyendetsedwa mosamalitsa kuti mupewe kuwonongeka kwa mkate. Pambuyo podula, kuwunika kokwanira bwino kumachitidwa kuti kuwonetsetsa kuti chip chilichonse chikukwaniritsa magwiridwe antchito.

Mfundo zazikuluzikulu zaukadaulo wophatikizika wamakina amaphatikizanso kusankha kwa zida zodulira komanso kuyika magawo azinthu komanso chikoka cha makina ndi mawonekedwe a zida zodula. Mwachitsanzo, ma silicon otsika a k dielectric silicon, chifukwa cha zinthu zotsika zamakina, amatha kuvutitsidwa kwambiri panthawi yodula, zomwe zimapangitsa kulephera monga kupukuta ndi kusweka. Kulimba kocheperako komanso kuwonongeka kwa zinthu zotsika-k kumapangitsa kuti ziwonongeke kwambiri pamakina ndi mphamvu yamakina kapena kupsinjika kwamafuta, makamaka panthawi yodula. Kulumikizana pakati pa chidacho ndi pamwamba pake, komanso kutentha kwambiri, kumatha kukulitsa kupsinjika.

Ndi kupita patsogolo kwa sayansi ya zinthu, ukadaulo wawafer dicing wakula kupitilira ma semiconductors achikhalidwe a silicon kuti aphatikizenso zida zatsopano monga gallium nitride (GaN). Zida zatsopanozi, chifukwa cha kuuma kwawo ndi kapangidwe kake, zimabweretsa zovuta zatsopano pakupanga dicing, zomwe zimafuna kuwongolera kwina kwa zida zodulira ndi njira.

Monga njira yofunika kwambiri pamakampani opanga ma semiconductor, kuyika kwawafer kukupitilizabe kukonzedwa potsatira zomwe zikufunika komanso kupita patsogolo kwaukadaulo, kuyala maziko aukadaulo wamtsogolo wamagetsi amagetsi ndi ukadaulo wophatikizika.

Kupititsa patsogolo ukadaulo wa makina ophatikizika amapitilira kukula kwa zida ndi zida zothandizira. Amaphatikizanso kukhathamiritsa kwazinthu, kuwongolera magwiridwe antchito a zida, komanso kuwongolera moyenera magawo a dicing. Kupita patsogolo kumeneku kumafuna kuwonetsetsa kulondola kwambiri, kuchita bwino, komanso kukhazikika pamakina ophatikizika, kukwaniritsa kufunikira kwamakampani a semiconductor pamiyeso yaying'ono, kuphatikiza kwakukulu, komanso ma chip ovuta kwambiri.

| Malo opititsa patsogolo | Miyezo Enieni | Zotsatira zake |

| Kukhathamiritsa kwa Njira | - Limbikitsani zokonzekera zoyambira, monga kuyika bwino kwa mawafa ndi kukonza njira. | - Chepetsani zolakwika zodula ndikuwongolera bata. |

| - Chepetsani zolakwika zodula ndikukulitsa bata. | - Gwiritsani ntchito njira zowunikira nthawi yeniyeni ndi mayankho kuti musinthe kuthamanga kwa zida, kuthamanga, ndi kutentha. | |

| - Kutsika kwapang'onopang'ono kwapang'onopang'ono ndikuwongolera mtundu wa chip. | ||

| Kupititsa patsogolo Kachitidwe ka Zida | - Gwiritsani ntchito makina olondola kwambiri komanso ukadaulo wapamwamba wowongolera makina. | - Limbikitsani kulondola kwa kudula ndikuchepetsa kuwonongeka kwa zinthu. |

| - Yambitsani ukadaulo wodulira wa laser woyenerera zowotcha zakuthupi zolimba kwambiri. | - Kupititsa patsogolo luso la kupanga ndikuchepetsa zolakwika zamanja. | |

| - Onjezani makina opangira makina kuti aziwunikira komanso kusintha. | ||

| Precise Parameter Control | - Sinthani bwino magawo monga kudula kuya, kuthamanga, mtundu wa zida, ndi njira zoziziritsira. | - Onetsetsani kufa kukhulupirika ndi ntchito magetsi. |

| - Sinthani magawo potengera zinthu zophika, makulidwe, ndi kapangidwe kake. | - Limbikitsani mitengo yokolola, chepetsa kuwononga zinthu, ndikuchepetsa mtengo wopangira. | |

| Kufunika kwa Strategic | - Fufuzani mosalekeza njira zatsopano zaukadaulo, konzani njira, ndikuwonjezera luso la zida kuti zikwaniritse zomwe msika ukufunikira. | - Kupititsa patsogolo zokolola ndi magwiridwe antchito a chip, kuthandizira kupanga zida zatsopano ndi mapangidwe apamwamba a chip. |

1.2 Kufunika kwa Dicing Wafer

Dicing wa Wafer imakhala ndi gawo lofunikira kwambiri popanga semiconductor, kukhudza mwachindunji masitepe otsatirawa komanso mtundu ndi magwiridwe antchito a chinthu chomaliza. Kufunika kwake kutha kufotokozedwa motere:

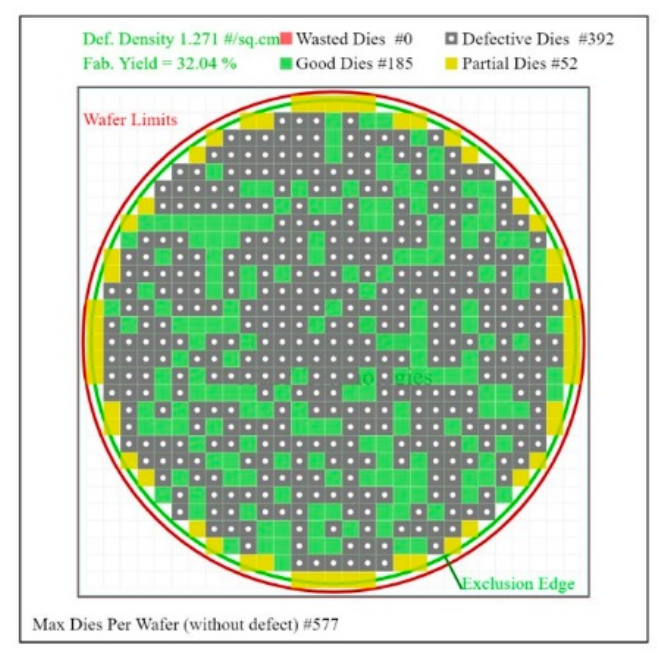

Choyamba, kulondola ndi kusasinthasintha kwa dicing ndizofunikira pakuwonetsetsa kukolola kwa chip ndi kudalirika. Pakupanga, zowotcha zimadutsa masitepe angapo kuti apange magawo angapo ozungulira, omwe amayenera kugawidwa ndendende kukhala tchipisi tating'ono (kufa). Ngati pali zolakwika zazikulu pakuwongolera kapena kudula panthawi yopanga dicing, mabwalo amatha kuwonongeka, zomwe zimakhudza magwiridwe antchito ndi kudalirika kwa chip. Chifukwa chake, ukadaulo wowongolera kwambiri umangotsimikizira kukhulupirika kwa chip chilichonse komanso kumalepheretsa kuwonongeka kwa mabwalo amkati, kuwongolera kuchuluka kwa zokolola.

Kachiwiri, kudulira kwawafer kumakhudza kwambiri kupanga bwino komanso kuwongolera mtengo. Monga gawo lofunikira pakupanga, kuchita bwino kwake kumakhudza mwachindunji kupita patsogolo kwa masitepe otsatirawa. Mwa kukhathamiritsa njira yodulira, kukulitsa milingo yodzipangira okha, ndikuwongolera liwiro lodulira, kuchita bwino kwambiri kumatha kupitilizidwa kwambiri.

Kumbali inayi, kuwononga zinthu panthawi ya dicing ndi chinthu chofunikira kwambiri pakuwongolera mtengo. Kugwiritsa ntchito matekinoloje apamwamba a dicing sikungochepetsa kutayika kwa zinthu zosafunikira panthawi yodula komanso kumawonjezera kagwiritsidwe kake ka mkate, potero kumachepetsa ndalama zopangira.

Ndi kupita patsogolo kwaukadaulo wa semiconductor, ma diameter a wafer akupitilira kukula, ndipo kachulukidwe kadera kumakwera moyenerera, kuyika zofunikira kwambiri paukadaulo wa dicing. Zophika zazikuluzikulu zimafunikira kuwongolera moyenera njira zodulira, makamaka m'malo ozungulira omwe ali ndi kachulukidwe kwambiri, komwe ngakhale zopatuka zing'onozing'ono zimatha kupangitsa tchipisi tambiri kukhala ndi vuto. Kuphatikiza apo, zowotcha zazikulu zimaphatikizanso mizere yodulira komanso njira zovuta kwambiri, zomwe zimafunikira kuwongolera kolondola, kusasinthika, komanso luso laukadaulo wodulira kuti athane ndi zovuta izi.

1.3 Njira ya Wafer Dicing

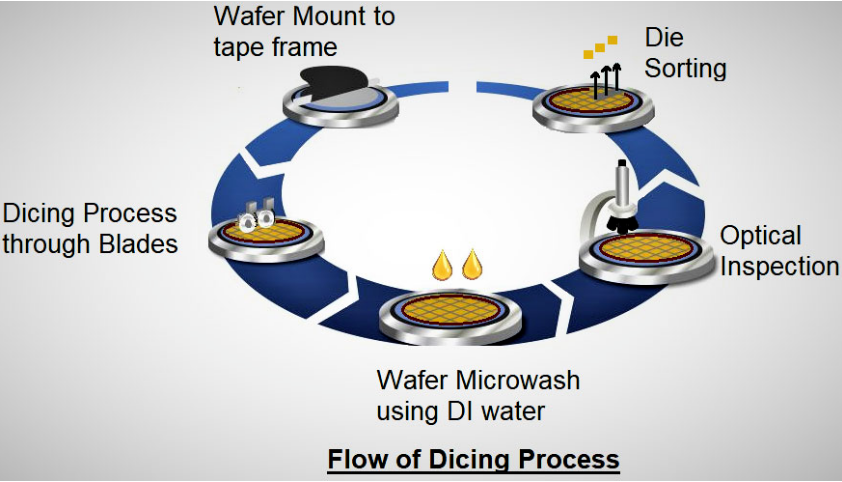

Dongosolo la dicing wa wafer limaphatikizapo masitepe onse kuyambira gawo lokonzekera mpaka pakuwunika komaliza, ndipo gawo lililonse limakhala lofunikira kwambiri pakuwonetsetsa kuti tchipisi tating'onoting'ono tikuyenda bwino. Pansipa pali kufotokozera mwatsatanetsatane gawo lililonse.

| Gawo | Kufotokozera Mwatsatanetsatane |

| Gawo Lokonzekera | -Kuyeretsa Wafer: Gwiritsani ntchito madzi oyera kwambiri ndi oyeretsa apadera, kuphatikizapo akupanga kapena makina opukuta, kuchotsa zonyansa, tinthu tating'onoting'ono, ndi zowonongeka, kuonetsetsa kuti pakhale paukhondo. -Maonekedwe Olondola: Gwiritsani ntchito zida zolondola kwambiri kuti muwonetsetse kuti chophikacho chimagawika bwino m'njira zodulira. -Kukonzekera kwa Wafer: Tetezani chowotchacho pa tepi chimango kuti chikhale chokhazikika panthawi yodula, kuteteza kuwonongeka kwa kugwedezeka kapena kuyenda. |

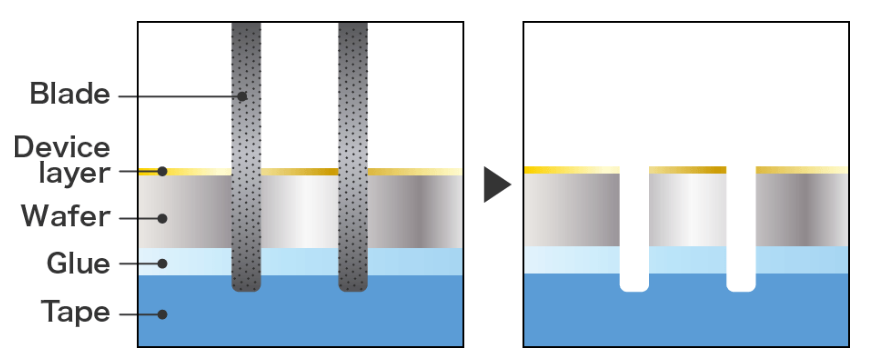

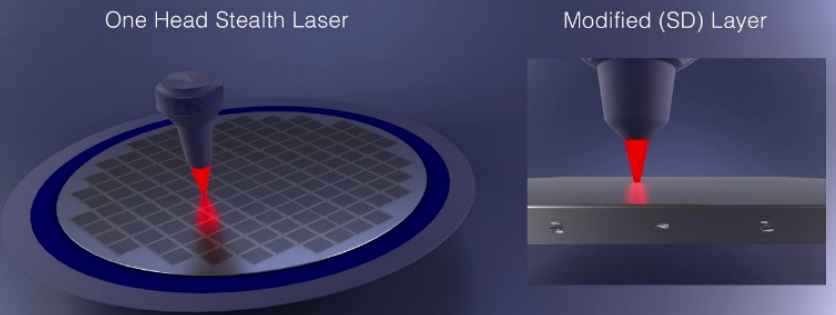

| Kudula Gawo | -Blade Dicing: Gwiritsani ntchito zida zomata za diamondi zothamanga kwambiri podula thupi, zoyenera kupangira zida za silicon komanso zotsika mtengo. -Laser Dicing: Gwiritsani ntchito matabwa amphamvu kwambiri a laser podula osalumikizana, abwino kwa zida zolimba kapena zolimba kwambiri monga gallium nitride, zomwe zimapereka kulondola kwambiri komanso kutaya zinthu zochepa. -New Technologies: Yambitsani matekinoloje odulira laser ndi plasma kuti mupititse patsogolo kuchita bwino komanso kulondola kwinaku mukuchepetsa madera omwe akukhudzidwa ndi kutentha. |

| Kuyeretsa Gawo | - Gwiritsani ntchito madzi a deionized (DI madzi) ndi oyeretsa apadera, ophatikizidwa ndi akupanga kapena kupopera mankhwala, kuchotsa zinyalala ndi fumbi zomwe zimapangidwira panthawi yodula, kuteteza zotsalira kuti zisakhudze njira zotsatila kapena chip magetsi. - Madzi oyeretsedwa kwambiri a DI amapewa kubweretsa zowononga zatsopano, kuonetsetsa kuti pamakhala malo oyera. |

| Gawo Loyendera | -Kuwunika kwa Optical: Gwiritsani ntchito makina ozindikira ophatikizika ndi ma algorithms a AI kuti muzindikire zolakwika mwachangu, kuwonetsetsa kuti palibe ming'alu kapena ming'alu ya tchipisi tating'onoting'ono, kukonza magwiridwe antchito, ndikuchepetsa zolakwika za anthu. -Kuyeza kwa Dimension: Tsimikizirani kuti kukula kwa chip kumagwirizana ndi kapangidwe kake. -Kuyesa kwa Magetsi: Onetsetsani kuti magetsi a tchipisi ofunikira akugwirizana ndi miyezo, kutsimikizira kudalirika pamagwiritsidwe otsatirawa. |

| Gawo Losankha | - Gwiritsani ntchito zida zamaloboti kapena makapu oyamwa vacuum kuti mulekanitse tchipisi toyenerera ndi chimango cha tepi ndikuzisintha zokha malinga ndi momwe zimagwirira ntchito, kuwonetsetsa kuti kupanga bwino komanso kusinthasintha kwinaku mukuwongolera molondola. |

Njira yodulira yopingasa imaphatikizapo kuyeretsa, kuyika, kudula, kuyeretsa, kuyang'ana, ndi kusanja, ndipo gawo lililonse limakhala lofunikira. Ndi kupita patsogolo kwa ma automation, kudula kwa laser, ndi matekinoloje owunikira a AI, makina amakono odulira mawafa amatha kukwaniritsa kulondola kwambiri, kuthamanga, komanso kutayika kwa zinthu zochepa. M'tsogolomu, matekinoloje atsopano odula monga laser ndi plasma pang'onopang'ono adzalowa m'malo mwa kudula masamba achikhalidwe kuti akwaniritse zosowa za mapangidwe ovuta kwambiri a chip, ndikupititsa patsogolo chitukuko cha njira zopangira semiconductor.

Wafer Cutting Technology ndi Mfundo Zake

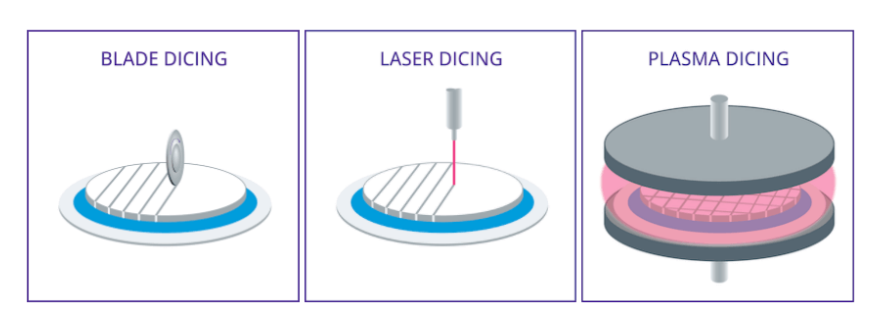

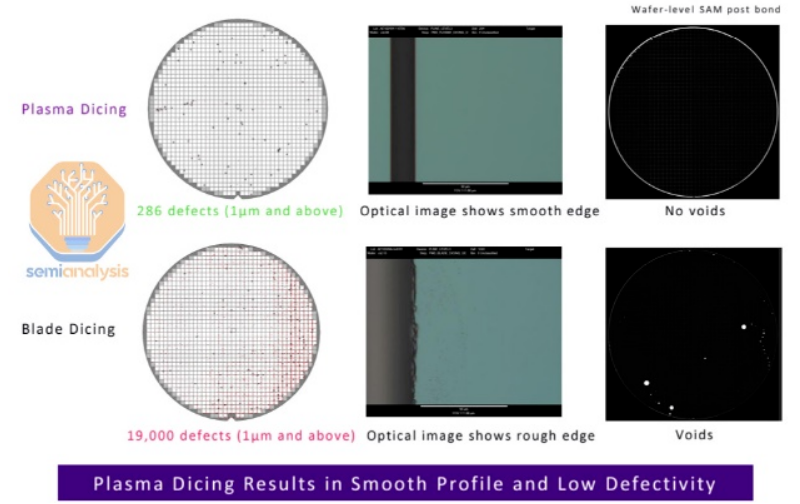

Chithunzichi chikuwonetsa matekinoloje atatu odziwika bwino ocheka mkate:Blade Dicing,Laser Dicing,ndiKuthamanga kwa Plasma. Pansipa pali kusanthula kwatsatanetsatane ndi kulongosola kowonjezera kwa njira zitatu izi:

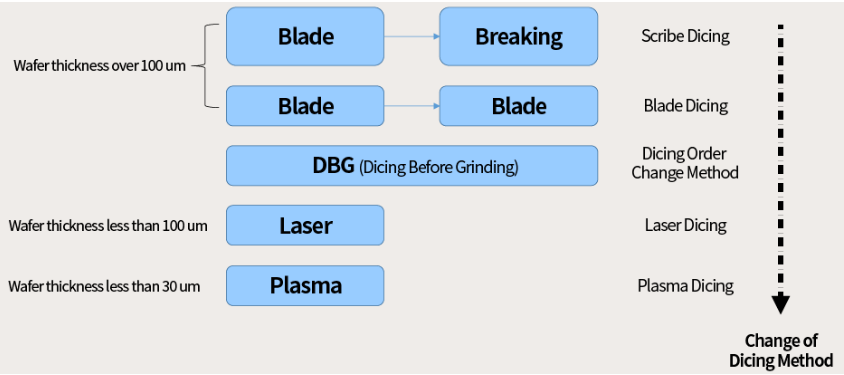

Popanga ma semiconductor, kudula kwa wafer ndi gawo lofunikira lomwe limafunikira kusankha njira yoyenera yodulira potengera makulidwe a chowotcha. Chinthu choyamba ndicho kudziwa makulidwe a mtandawo. Ngati makulidwe a wafer akupitilira ma microns 100, kudula masamba kumatha kusankhidwa ngati njira yodulira. Ngati kudulira masamba sikuli koyenera, mutha kugwiritsa ntchito njira yodumphadumpha, yomwe imaphatikizapo kudula ndi kudula masamba.

Pamene makulidwe a mkate ali pakati pa 30 ndi 100 microns, njira ya DBG (Dice Before Grinding) ndiyomwe ikulimbikitsidwa. Pamenepa, kudula alembi, kudula masamba, kapena kusintha ndondomeko yodulira ngati pakufunika kusankhidwa kuti apeze zotsatira zabwino.

Pa zowonda zowonda kwambiri zokhala ndi makulidwe osakwana ma microns 30, kudula kwa laser kumakhala njira yabwino kwambiri chifukwa chakutha kwake kudula zowonda zopyapyala bwino popanda kuwononga kwambiri. Ngati kudula kwa laser sikungakwaniritse zofunikira zenizeni, kudula kwa plasma kungagwiritsidwe ntchito ngati njira ina. Flowchart iyi imapereka njira yopangira zisankho zomveka bwino kuti zitsimikizire kuti ukadaulo wodula bwino kwambiri wawafa umasankhidwa pansi pazikhalidwe zosiyanasiyana.

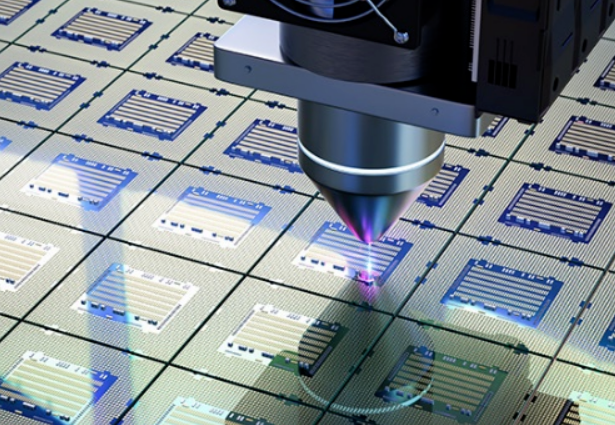

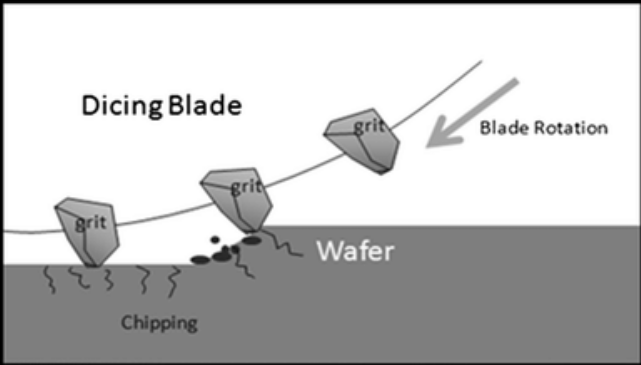

2.1 Mechanical Cutting Technology

Ukadaulo wamakina wamakina ndi njira yachikhalidwe pakudulira ma wafer. Mfundo yaikulu ndikugwiritsa ntchito gudumu lopera la diamondi lothamanga kwambiri ngati chida chodulira chodula chophatikizika. Zipangizo zazikuluzikulu zimaphatikizapo spindle yonyamula mpweya, yomwe imayendetsa chida cha magudumu a diamondi pa liwiro lalikulu kuti idulire bwino kapena kuponda panjira yodulira. Tekinolojeyi imagwiritsidwa ntchito kwambiri m'makampani chifukwa chotsika mtengo, kuchita bwino kwambiri, komanso kugwiritsa ntchito kwambiri.

Ubwino wake

Kulimba kwamphamvu komanso kukana kwa zida zamagudumu a diamondi kumathandizira ukadaulo wodulira makina kuti ugwirizane ndi zosowa zodulira zamitundu yopyapyala, kaya zida zachikhalidwe za silicon kapena ma semiconductors atsopano. Ntchito yake ndi yosavuta, yokhala ndi zofunikira zochepa zaukadaulo, zomwe zimalimbikitsanso kutchuka kwake pakupanga kwakukulu. Kuphatikiza apo, poyerekeza ndi njira zina zodulira monga kudula kwa laser, kudula kwamakina kumakhala ndi ndalama zowongolera, ndikupangitsa kuti ikhale yoyenera pazosowa zopanga zambiri.

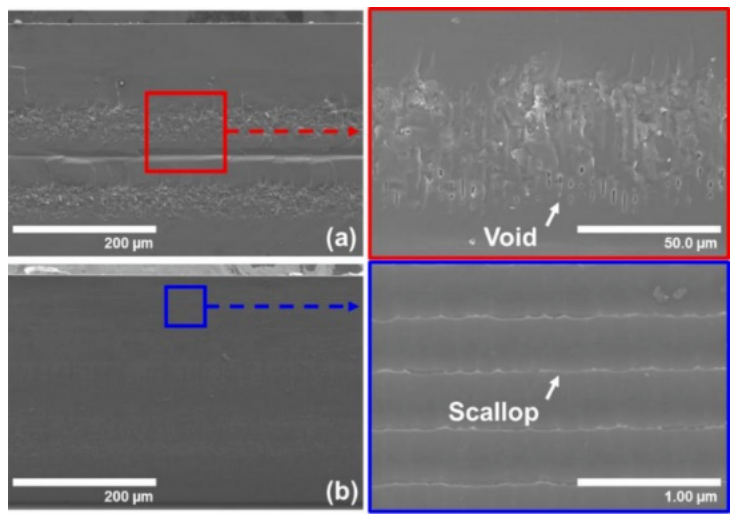

Zolepheretsa

Ngakhale zabwino zambiri, ukadaulo wodula makina ulinso ndi malire. Choyamba, chifukwa cha kukhudzana kwa thupi pakati pa chida ndi chophatikizira, kudula molondola kumakhala kochepa, nthawi zambiri kumayambitsa kupatuka komwe kungakhudze kulondola kwa kulongedza kwa chip ndikuyesa. Kachiwiri, zolakwika monga kupukuta ndi ming'alu zimatha kuchitika mosavuta panthawi yodulira makina, zomwe sizimangokhudza kuchuluka kwa zokolola komanso zimatha kusokoneza kudalirika komanso moyo wa tchipisi. Kuwonongeka kwa makina opangidwa ndi kupsinjika kumawononga makamaka kupanga chip chapamwamba kwambiri, makamaka podula zida zosalimba, pomwe nkhanizi zimawonekera kwambiri.

Kupititsa patsogolo Zamakono

Kuti athane ndi zofooka izi, ofufuza akupitiliza kukonza njira yodulira makina. Kusintha kwakukulu kumaphatikizapo kupititsa patsogolo mapangidwe ndi kusankha kwa zinthu za mawilo opera kuti apititse patsogolo kudula ndi kulimba. Komanso, kukhathamiritsa kamangidwe kamangidwe ndi kulamulira kachitidwe kudula zida zathandizanso bata ndi zochita zokha za kudula ndondomeko. Kupititsa patsogolo uku kumachepetsa zolakwika zomwe zimachitika chifukwa cha zochita za anthu ndikuwongolera kusasinthika kwa mabala. Kukhazikitsidwa kwaukadaulo wapamwamba wowunikira komanso kuwongolera kwaubwino pakuwunika kwakanthawi kwakanthawi kwakanthawi kwakanthawi kodula kwathandiziranso kwambiri kudalirika komanso zokolola.

Future Development ndi New Technologies

Ngakhale ukadaulo wodulira wamakina umagwirabe ntchito kwambiri pakudulira zopindika, matekinoloje atsopano odulira akupita patsogolo pomwe njira za semiconductor zikusintha. Mwachitsanzo, ntchito matenthedwe laser kudula luso amapereka njira zatsopano zolondola ndi chilema nkhani kudula makina. Njira yodulira yosalumikizana iyi imachepetsa kupsinjika kwa thupi pa chophatikizira, ndikuchepetsa kwambiri kuphulika ndi kusweka, makamaka podula zida zolimba kwambiri. M'tsogolomu, kuphatikiza kwaukadaulo wamakina odulira ndi njira zodulira zomwe zikutuluka zidzapereka kupanga semiconductor ndi zosankha zambiri komanso kusinthasintha, kupititsa patsogolo kupanga bwino komanso mtundu wa chip.

Pomaliza, ngakhale makina kudula luso ali ndi zovuta zina, mosalekeza luso luso ndi kusakanikirana ndi njira zatsopano kudula kulola kuti akadali mbali yofunika kwambiri mu semiconductor kupanga ndi kukhalabe mpikisano mu njira tsogolo.

2.2 Laser Cutting Technology

Ukadaulo wodula wa laser, monga njira yatsopano yodulira, pang'onopang'ono wapeza chidwi chofala mumakampani a semiconductor chifukwa cha kulondola kwake, kusowa kwa kuwonongeka kwamakina, komanso kuthekera kodula mwachangu. Tekinoloje iyi imagwiritsa ntchito kachulukidwe kamphamvu komanso kuthekera koyang'ana kwa mtengo wa laser kuti ipange malo ang'onoang'ono omwe amakhudzidwa ndi kutentha pamwamba pa zinthu zopyapyala. Mtengo wa laser ukagwiritsidwa ntchito pa chophatikizira, kupsinjika kwamafuta komwe kumapangidwa kumapangitsa kuti zinthuzo ziphwanyike pamalo omwe adasankhidwa, ndikudula bwino.

Ubwino wa Laser Cutting Technology

• Kulondola Kwambiri: Kuthekera kokhazikika kwa mtengo wa laser kumapangitsa kuti ma micron kapena ngakhale mulingo wa nanometer adulidwe molondola, kukwaniritsa zofunikira zamakono apamwamba kwambiri, ophatikizika kwambiri.

• Palibe Kulumikizana ndi Makina: Kudula kwa laser kumapewa kukhudzana ndi chophatikizira, kupewa zovuta zodziwika bwino pakudula kwamakina, monga kupukuta ndi kusweka, kuwongolera kwambiri kuchuluka kwa zokolola komanso kudalirika kwa tchipisi.

• Kuthamanga Kwambiri Kudula: Kuthamanga kwambiri kwa laser kudula kumathandizira kuti pakhale ntchito yowonjezereka, ndikupangitsa kuti ikhale yoyenera pazochitika zazikulu, zothamanga kwambiri.

Mavuto Amene Akukumana Nawo

• Mtengo Wokwera wa Zida: Ndalama zoyamba za zida zodulira laser ndizokwera, zomwe zimapereka kupsinjika kwachuma, makamaka kwamakampani ang'onoang'ono mpaka apakatikati.

• Complex Process Control: Kudula kwa laser kumafuna kuwongolera moyenera magawo angapo, kuphatikiza kachulukidwe kamphamvu, malo olunjika, ndi liwiro lodulira, zomwe zimapangitsa kuti ntchitoyi ikhale yovuta.

• Nkhani Zokhudzidwa ndi Kutentha: Ngakhale kusalumikizana kwa laser kudula kumachepetsa kuwonongeka kwamakina, kupsinjika kwamatenthedwe komwe kumachitika chifukwa cha kutentha komwe kumakhudzidwa ndi kutentha (HAZ) kumatha kusokoneza zinthu zawafer. Kukhathamiritsa kwina kwa njirayi ndikofunikira kuti muchepetse izi.

Njira Zowongolera Zamakono

Kuti athane ndi zovuta izi, ofufuza akuyang'ana kwambiri kutsitsa mtengo wa zida, kukonza njira zodulira, komanso kukhathamiritsa kayendedwe kake.

• Ma laser Ogwira Ntchito ndi Optical Systems: Popanga ma lasers owoneka bwino komanso makina apamwamba owoneka bwino, ndizotheka kutsitsa mtengo wa zida ndikuwonjezera kulondola komanso kuthamanga.

• Kukonzekeletsa Magawo a Njira: Kafukufuku wozama pa kugwirizana pakati pa ma lasers ndi zinthu zowonda akuchitika kuti apititse patsogolo njira zomwe zimachepetsa madera omwe amakhudzidwa ndi kutentha, potero kupititsa patsogolo kudula.

•Nzeru Control Systems: Kukula kwaukadaulo wanzeru kuwongolera cholinga chake ndikuwongolera ndikuwongolera njira yodulira laser, kuwongolera kukhazikika kwake komanso kusasinthika.

Ukadaulo wodulira wa laser ndiwothandiza kwambiri pazowonda zowonda kwambiri komanso zochitika zodula kwambiri. Miyezo yopingasa ikachulukirachulukira ndikuchulukirachulukira kwa dera, njira zodulira zamakina zimavutikira kuti zikwaniritse zofunikira kwambiri komanso zogwira mtima kwambiri pakupanga ma semiconductor amakono. Chifukwa cha ubwino wake wapadera, laser kudula akukhala njira yabwino m'madera awa.

Ngakhale luso laser kudula akadali akukumana ndi mavuto monga mtengo zida mkulu ndi zovuta ndondomeko, ubwino wake wapadera mu mwatsatanetsatane mkulu ndi kuwonongeka sanali kukhudzana kupanga izo malangizo ofunika kwa chitukuko kupanga semiconductor. Monga luso la laser ndi machitidwe owongolera anzeru akupitilira patsogolo, kudula kwa laser kukuyembekezeka kupititsa patsogolo kuwongolera bwino kwawafa ndi mtundu, ndikuyendetsa kukula kosalekeza kwamakampani opanga ma semiconductor.

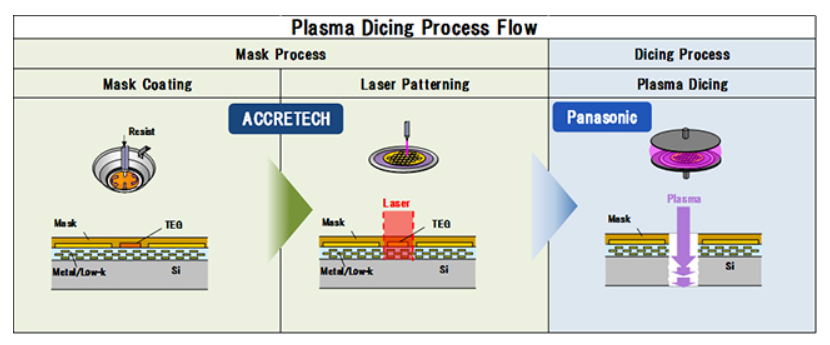

2.3 Ukadaulo Wodula Plasma

Ukadaulo wodulira plasma, ngati njira yomwe ikubwera yodulira, yatenga chidwi kwambiri m'zaka zaposachedwa. Tekinoloje iyi imagwiritsa ntchito matabwa a plasma amphamvu kwambiri kuti adule bwino zowotchera poyang'anira mphamvu, liwiro, ndi njira yodulira ya mtengo wa plasma, ndikupeza zotsatira zodula bwino.

Mfundo Yogwirira Ntchito ndi Ubwino wake

Njira yodulira plasma imadalira pamtengo wotentha kwambiri, wopatsa mphamvu kwambiri wa plasma wopangidwa ndi zida. Dongosololi limatha kutenthetsa chinthu chophwanyika kuti chisungunuke kapena kusungunuka mu nthawi yochepa kwambiri, ndikupangitsa kudula mwachangu. Poyerekeza ndi kudula kwachikale kwa makina kapena laser, kudula kwa plasma kumathamanga ndipo kumapanga malo ocheperako omwe amakhudzidwa ndi kutentha, kuchepetsa bwino ming'alu ndi kuwonongeka panthawi yodula.

Pakugwiritsa ntchito, ukadaulo wodulira plasma umakhala waluso kwambiri pakugwira zophika ndi mawonekedwe ovuta. Mtengo wake wamphamvu kwambiri, wosinthika wa plasma utha kudula zowombera zowoneka bwino mosakhazikika mwatsatanetsatane. Chifukwa chake, popanga ma microelectronics, makamaka pakupanga makonda komanso kachulukidwe kakang'ono ka tchipisi tapamwamba, ukadaulo uwu ukuwonetsa lonjezo lalikulu logwiritsidwa ntchito kwambiri.

Zovuta ndi Zolepheretsa

Ngakhale zabwino zambiri zaukadaulo wodula plasma, zimakumananso ndi zovuta zina.

• Njira Yovuta: Njira yodulira plasma ndi yovuta ndipo imafuna zida zolondola kwambiri komanso odziwa ntchito kuti atsimikizirekulondola ndi kukhazikika pakudula.

• Kuwongolera ndi Chitetezo pazachilengedwe: Kutentha kwakukulu, mphamvu yamtengo wapatali ya mtengo wa plasma imafuna kulamulira kolimba kwa chilengedwe ndi chitetezo, zomwe zimawonjezera zovuta ndi mtengo wa kukhazikitsa.

Njira Zachitukuko Zamtsogolo

Ndi kupita patsogolo kwaukadaulo, zovuta zokhudzana ndi kudula kwa plasma zikuyembekezeka kuthetsedwa pang'onopang'ono. Popanga zida zodulira zanzeru komanso zokhazikika, kudalira ntchito zamanja kumatha kuchepetsedwa, potero kumathandizira kupanga bwino. Panthawi imodzimodziyo, kukhathamiritsa magawo a ndondomeko ndi malo odulidwa kungathandize kuchepetsa chiopsezo cha chitetezo ndi ndalama zogwirira ntchito.

M'makampani opangira ma semiconductor, luso laukadaulo wodula mitengo yophatikizika ndi dicing ndizofunikira kwambiri pakupititsa patsogolo chitukuko chamakampani. Ukadaulo wodulira plasma, wokhala ndi zolondola kwambiri, zogwira ntchito bwino, komanso luso lotha kuthana ndi mawonekedwe ophatikizika, watulukira ngati wosewera watsopano m'munda uno. Ngakhale zovuta zina zidakalipo, izi zidzayankhidwa pang'onopang'ono ndikupitilira luso laukadaulo, kubweretsa mwayi wambiri komanso mwayi wopanga ma semiconductor.

Chiyembekezo chogwiritsa ntchito ukadaulo wodula plasma ndi waukulu, ndipo akuyembekezeka kutenga gawo lofunika kwambiri pakupanga semiconductor mtsogolomo. Kudzera mwaukadaulo wopitilira muyeso komanso kukhathamiritsa, kudula kwa plasma sikungothetsa zovuta zomwe zilipo komanso kudzakhala dalaivala wamphamvu pakukula kwamakampani a semiconductor.

2.4 Kudula Ubwino ndi Zomwe Zimayambitsa

Kudula kwawafer ndikofunikira kwambiri pakuyika kwa chip, kuyesa, komanso magwiridwe antchito onse ndi kudalirika kwa chinthu chomaliza. Mavuto omwe amakumana nawo panthawi yodula ndi monga ming'alu, kung'ambika, ndi kudulidwa. Mavutowa amakhudzidwa ndi zinthu zingapo zomwe zimagwirira ntchito limodzi.

| Gulu | Zamkatimu | Zotsatira |

| Process Parameters | Kudula liwiro, kuchuluka kwa chakudya, ndi kudula kuya kumakhudza mwachindunji kukhazikika ndi kulondola kwa kudula. Kukonzekera kosayenera kungayambitse kupsinjika maganizo ndi malo omwe amakhudzidwa ndi kutentha kwambiri, zomwe zimapangitsa kuti ming'alu iwonongeke. Kusintha magawo moyenerera kutengera zinthu zophatikizika, makulidwe, ndi zofunika kudula ndikofunikira kuti mukwaniritse zotsatira zomwe mukufuna. | Njira zoyenera zimatsimikizira kudula bwino komanso kuchepetsa chiopsezo cha zolakwika monga ming'alu ndi kupukuta. |

| Zida ndi Zinthu Zakuthupi | -Ubwino wa Blade: Zinthu, kuuma, ndi kuvala kukana kwa tsamba kumakhudza kusalala kwa njira yodulira komanso kusalala kwa malo odulidwa. Masamba osawoneka bwino amawonjezera kukangana ndi kupsinjika kwa kutentha, zomwe zimatha kupangitsa ming'alu kapena kung'ambika. Kusankha zinthu zoyenera zamasamba ndikofunikira. -Magwiridwe Oziziritsa: Zozizira zimathandiza kuchepetsa kutentha, kuchepetsa mikangano, ndi zinyalala zoyera. Kuziziritsa kosagwira ntchito kumatha kubweretsa kutentha kwambiri komanso kuchuluka kwa zinyalala, zomwe zimakhudza kudulidwa bwino komanso kuchita bwino. Kusankha zoziziritsa kukhosi zogwira ntchito bwino komanso zosawononga chilengedwe ndikofunikira. | Ubwino wa tsamba umakhudza kulondola komanso kusalala kwa odulidwa. Kuzizirira kosagwira ntchito kumatha kubweretsa kusadula bwino komanso kusagwira ntchito bwino, kuwunikira kufunikira kogwiritsa ntchito bwino zoziziritsa kukhosi. |

| Kuwongolera Njira ndi Kuyang'anira Ubwino | -Kuwongolera Njira: Kuwunika kwanthawi yeniyeni ndikusintha magawo ofunikira odula kuti atsimikizire kukhazikika komanso kusasinthika pakudula. -Kuyang'anira Ubwino: Macheke akuwonekera pambuyo podulidwa, miyeso yowoneka bwino, komanso kuyesa magwiridwe antchito amagetsi amathandizira kuzindikira ndi kuthana ndi zovuta mwachangu, kuwongolera kulondola komanso kusasinthika. | Kuwongolera njira moyenera komanso kuyang'anitsitsa kwabwino kumathandiza kuwonetsetsa kuti zotsatira zake zimakhala zokhazikika, zapamwamba komanso kuzindikira msanga zomwe zingachitike. |

Kupititsa patsogolo Ubwino Wodula

Kupititsa patsogolo kudula khalidwe kumafuna njira yokwanira yomwe imaganizira magawo a ndondomeko, zida ndi zosankha zakuthupi, kulamulira ndondomeko, ndi kuyendera. Mwa kupitiriza kuyenga umisiri kudula ndi kukhathamiritsa njira ndondomeko, mwatsatanetsatane ndi kukhazikika kwa yopyapyala kudula akhoza zina patsogolo, kupereka odalirika thandizo luso kwa makampani semiconductor kupanga.

#03 Kugwira Pambuyo Kudula ndi Kuyesa

3.1 Kutsuka ndi Kuyanika

Masitepe oyeretsera ndi kuyanika pambuyo podula chopinga ndi chofunikira kwambiri pakuwonetsetsa kuti chip chili chabwino komanso kupita patsogolo kwabwino kwa njira zotsatila. Panthawi imeneyi, ndikofunikira kuchotsa bwino zinyalala za silicon, zotsalira zoziziritsa kukhosi, ndi zonyansa zina zomwe zimapangidwa podula. Ndikofunikiranso kuwonetsetsa kuti tchipisi zisawonongeke panthawi yoyeretsa, ndipo mutatha kuyanika, onetsetsani kuti palibe chinyezi chomwe chimatsalira pa chip kuti muteteze zinthu monga dzimbiri kapena kutulutsa ma electrostatic.

Kugwira Pambuyo Podula: Kuyeretsa ndi Kuyanika

| Njira Njira | Zamkatimu | Zotsatira |

| Kuyeretsa Njira | -Njira: Gwiritsani ntchito zida zapadera zoyeretsera ndi madzi oyera, kuphatikiza ndi akupanga kapena makina otsuka maburashi poyeretsa. | Imawonetsetsa kuchotsedwa bwino kwa zowononga ndikuletsa kuwonongeka kwa tchipisi pakutsuka. |

| -Kusankha Wothandizira Kuyeretsa: Sankhani kutengera zinthu zopyapyala ndi mtundu woyipitsidwa kuti mutsimikizire kuyeretsa bwino popanda kuwononga chip. | Kusankhidwa koyenera kwa wothandizira ndikofunikira pakuyeretsa bwino komanso kuteteza chip. | |

| -Parameter Control: Yang'anirani bwino kutentha kwa kutentha, nthawi, ndi kuyeretsa yankho kuti mupewe zovuta zomwe zimachitika chifukwa choyeretsa molakwika. | Kuwongolera kumathandizira kupewa kuwononga chophatikizika kapena kusiya zoyipitsidwa, ndikuwonetsetsa kuti zikhala bwino. | |

| Kuyanika Njira | -Njira Zachikhalidwe: Kuyanika kwachilengedwe ndi kuyanika kwa mpweya wotentha, zomwe zimakhala ndi mphamvu zochepa ndipo zimatha kupangitsa kuti magetsi azikhala osasunthika. | Zitha kupangitsa kuti nthawi yowuma pang'onopang'ono komanso zovuta zomwe zitha kukhala zokhazikika. |

| -Modern Technologies: Gwiritsani ntchito matekinoloje apamwamba monga kuyanika vacuum ndi kuyanika kwa infrared kuti tchipisi ziume mwachangu ndikupewa zoyipa. | Kuyanika kofulumira komanso kothandiza, kuchepetsa chiopsezo cha kutulutsa kosasunthika kapena zovuta zokhudzana ndi chinyezi. | |

| Kusankha Zida & Kukonza | -Kusankha Zida: Makina otsuka kwambiri ndi kuyanika amathandizira kukonza magwiridwe antchito ndikuwongolera bwino zomwe zingachitike mukamagwira. | Makina apamwamba kwambiri amatsimikizira kukonza bwino ndikuchepetsa kuthekera kwa zolakwika pakuyeretsa ndi kuyanika. |

| -Kukonza Zida: Kuyang'anira ndi kukonza zida nthawi zonse zimatsimikizira kuti zikugwirabe ntchito bwino, ndikutsimikizira chip quality. | Kukonzekera koyenera kumalepheretsa kulephera kwa zida, kuonetsetsa kuti ntchito yodalirika komanso yapamwamba. |

Pambuyo Kudula Kuyeretsa ndi Kuyanika

Njira zoyeretsera ndi zowumitsa pambuyo podula zopingasa ndizovuta komanso zosavuta zomwe zimafunikira kulingalira mozama pazinthu zingapo kuti zitsimikizidwe zomaliza. Pogwiritsa ntchito njira zasayansi ndi njira zokhwima, ndizotheka kuwonetsetsa kuti chip chilichonse chikulowa m'magawo otsatirawa ndikuyesa mulingo woyenera.

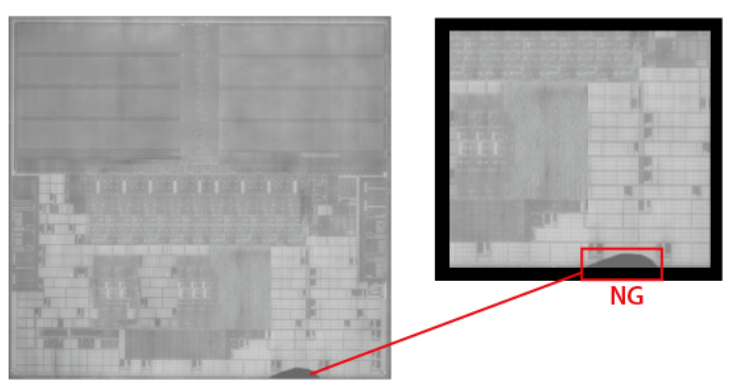

Kuyang'anira ndi Kuyesa Pambuyo Podula

| Khwerero | Zamkatimu | Zotsatira |

| Kuyang'ana Gawo | 1.Kuyang'anira Zowoneka: Gwiritsani ntchito zida zowunikira zowonera kapena zokha kuti muwone zolakwika zowoneka ngati ming'alu, kupukuta, kapena kuipitsidwa ndi chip pamwamba. Dziwani mwachangu tchipisi towonongeka kuti mupewe zinyalala. | Zimathandizira kuzindikira ndikuchotsa tchipisi tambiri poyambira, kuchepetsa kutayika kwa zinthu. |

| 2.Kuyeza Kukula: Gwiritsani ntchito zida zoyezera mwatsatanetsatane kuti muyeze molondola kukula kwa chip, kuwonetsetsa kuti kukula kwake kukugwirizana ndi kapangidwe kake ndikupewa zovuta zogwirira ntchito kapena zovuta pakuyika. | Imawonetsetsa kuti tchipisi zili mkati mwa malire ofunikira, kuteteza kuwonongeka kwa magwiridwe antchito kapena zovuta zapagulu. | |

| 3.Kuyesa kwa Magetsi: Yang'anirani magawo ofunikira amagetsi monga kukana, mphamvu, ndi inductance, kuti muzindikire tchipisi tosagwirizana ndikuwonetsetsa kuti tchipisi tomwe timagwira ntchito timapitilira gawo lotsatira. | Imawonetsetsa kuti tchipisi tating'onoting'ono tomwe timagwira ntchito komanso toyezedwa bwino timapita patsogolo, ndikuchepetsa chiwopsezo chakulephera pambuyo pake. | |

| Kuyesa Gawo | 1.Kuyesa kwantchito: Tsimikizirani kuti magwiridwe antchito a chip amagwira ntchito monga momwe amafunira, kuzindikira ndikuchotsa tchipisi zomwe zili ndi zolakwika. | Imawonetsetsa kuti tchipisi chikukwaniritsa zofunikira zogwirira ntchito musanapitirire mtsogolo. |

| 2.Mayeso odalirika: Unikani kukhazikika kwa magwiridwe antchito a chip mukamagwiritsa ntchito nthawi yayitali kapena malo ovuta, omwe nthawi zambiri amakhala okalamba kwambiri, kuyezetsa kutentha pang'ono, ndi kuyezetsa chinyezi kuti ayesere zochitika zenizeni zapadziko lapansi. | Imawonetsetsa kuti tchipisi zitha kugwira ntchito modalirika pansi pazikhalidwe zosiyanasiyana, kupititsa patsogolo moyo wautali wazinthu komanso kukhazikika. | |

| 3.Kuyesa Kugwirizana: Onetsetsani kuti chip chimagwira ntchito bwino ndi zigawo zina kapena machitidwe, kuonetsetsa kuti palibe zolakwika kapena kuwonongeka kwa ntchito chifukwa chosagwirizana. | Imawonetsetsa kuti ikugwira ntchito bwino pamapulogalamu apadziko lonse lapansi popewa zovuta zofananira. |

3.3 Kuyika ndi Kusunga

Pambuyo podula chowotcha, tchipisi ndi chinthu chofunikira kwambiri popanga semiconductor, ndipo magawo awo oyika ndi osungira nawonso ndizofunikira. Kuyika ndi kusungirako koyenera ndikofunikira osati pakuwonetsetsa chitetezo ndi kukhazikika kwa tchipisi panthawi ya mayendedwe ndi kusungirako komanso popereka chithandizo champhamvu pazotsatira zopanga, kuyesa, ndi kuyika.

Chidule cha Magawo Oyendera ndi Kuyesa:

Masitepe owunikira ndi kuyesa tchipisi pambuyo podulira wafer amaphatikiza zinthu zingapo, kuphatikiza kuyang'ana kowoneka, kuyeza kukula, kuyezetsa magwiridwe antchito amagetsi, kuyesa magwiridwe antchito, kuyesa kudalirika, komanso kuyesa kufananiza. Masitepewa ndi olumikizana komanso ogwirizana, ndikupanga chotchinga cholimba kuti zitsimikizire mtundu wazinthu komanso kudalirika. Kupyolera mu ndondomeko zowunikira ndi kuyesa, zovuta zomwe zingathe kudziwika ndi kuthetsedwa mwamsanga, kuonetsetsa kuti chinthu chomaliza chikukwaniritsa zofuna za makasitomala ndi ziyembekezo.

| Mbali | Zamkatimu |

| Kuyika Njira | 1.Antistatic: Zida zoyikamo ziyenera kukhala ndi zinthu zabwino kwambiri zoletsa ma static kuti magetsi okhazikika asawononge zida kapena kusokoneza magwiridwe antchito. |

| 2.Zosakwanira chinyezi: Zida zoyikapo ziyenera kukhala ndi chinyezi chabwino kuti chiteteze dzimbiri komanso kuwonongeka kwa magetsi chifukwa cha chinyezi. | |

| 3.Zosagwedezeka: Zida zoyikamo ziyenera kupereka mayamwidwe odabwitsa kuti ateteze tchipisi kuti zisagwedezeke komanso kukhudzidwa panthawi yamayendedwe. | |

| Malo Osungirako | 1.Kuwongolera Chinyezi: Yang'anirani mosamalitsa chinyezi m'malo oyenera kuti musatenge chinyezi komanso dzimbiri zomwe zimadza chifukwa cha chinyezi chambiri kapena zovuta zosasunthika chifukwa cha chinyezi chochepa. |

| 2.Ukhondo: Sungani malo osungiramo oyera kuti musaipitsidwe ndi tchipisi ndi fumbi ndi zonyansa. | |

| 3.Kuwongolera Kutentha: Khazikitsani kutentha koyenera ndikusunga kutentha kuti mupewe kukalamba msanga chifukwa cha kutentha kwakukulu kapena zovuta za condensation chifukwa cha kutentha kochepa. | |

| Kuyendera Nthawi Zonse | Yang'anani nthawi zonse ndikuwunika tchipisi tosungidwa, pogwiritsa ntchito zowunika zowona, miyeso ya kukula, ndi kuyesa magwiridwe antchito amagetsi kuti muzindikire ndikuthana ndi zovuta zomwe zingachitike munthawi yake. Kutengera nthawi yosungirako komanso momwe zinthu ziliri, konzani kagwiritsidwe ntchito ka tchipisi kuti muwonetsetse kuti akugwiritsidwa ntchito moyenera. |

Nkhani ya ma microcracks ndi kuwonongeka panthawi yopanga dicing wafer ndizovuta kwambiri pakupanga semiconductor. Kupanikizika kodula ndiye chifukwa chachikulu cha izi, chifukwa zimapanga ming'alu yaying'ono ndikuwonongeka pamtunda, zomwe zimapangitsa kuti pakhale mtengo wopangira komanso kuchepa kwa zinthu.

Kuti tithane ndi vutoli, ndikofunikira kuchepetsa kupsinjika ndikugwiritsa ntchito njira zodulira bwino, zida, ndi mikhalidwe. Kusamalira mosamala zinthu monga zamasamba, kuthamanga, kuthamanga, ndi njira zoziziritsa kungathandize kuchepetsa mapangidwe a microcracks ndikuwongolera zokolola zonse. Kuphatikiza apo, kafukufuku wopitilira muukadaulo wapamwamba kwambiri wodula, monga dicing laser, akufufuza njira zochepetsera izi.

Monga zinthu zosalimba, zopyapyala zimatha kusintha mawonekedwe amkati akamakhudzidwa ndi makina, kutentha, kapena kupsinjika kwamankhwala, zomwe zimapangitsa kupanga ma microcracks. Ngakhale kuti ming'aluyi singawonekere nthawi yomweyo, imatha kufalikira ndikuwononga kwambiri pamene ntchito yopangira ikupita. Nkhaniyi imakhala yovuta kwambiri panthawi yolongedza ndikuyesa, pomwe kusinthasintha kwa kutentha ndi kupanikizika kowonjezera kwamakina kumatha kupangitsa kuti ma microcracks awa asinthe kukhala ma fractures owoneka, zomwe zingayambitse kulephera kwa chip.

Kuti muchepetse chiwopsezochi, ndikofunikira kuyang'anira njira yodulira mosamala ndikuwongolera magawo monga kudula liwiro, kuthamanga, ndi kutentha. Kugwiritsa ntchito njira zodulira zocheperako, monga ma laser dicing, kumatha kuchepetsa kupsinjika kwamakina pawafa ndikuchepetsa mapangidwe a microcracks. Kuphatikiza apo, kugwiritsa ntchito njira zowunikira zapamwamba monga kuwunika kwa infrared kapena kujambula kwa X-ray panthawi yopangira ma dicing amatha kuthandizira kuzindikira ming'alu yoyambilira isanawonongenso.

Kuwonongeka kwa chipwirikiti ndichodetsa nkhawa kwambiri pakupanga dicing, chifukwa kumatha kukhudza mwachindunji magwiridwe antchito ndi kudalirika kwa chip. Kuwonongeka kotereku kumatha kuchitika chifukwa chogwiritsa ntchito molakwika zida zodulira, zodulira molakwika, kapena zolakwika zomwe zimapezeka mumphika womwewo. Mosasamala chomwe chimayambitsa, zowonongekazi zingayambitse kusintha kwa mphamvu yamagetsi kapena capacitance ya dera, zomwe zimakhudza ntchito yonse.

Pofuna kuthana ndi mavutowa, njira ziwiri zazikulu zikufufuzidwa:

1.Optimizing kudula zida ndi magawo: Pogwiritsa ntchito masamba akuthwa, kusintha liwiro la kudula, ndi kusintha kuya kwa kudula, kupsinjika maganizo panthawi yodula kumatha kuchepetsedwa, motero kuchepetsa kuwonongeka.

2.Kufufuza matekinoloje atsopano odula: Njira zapamwamba monga kudula kwa laser ndi kudula kwa plasma kumapereka kulondola bwino pomwe kumachepetsa kuchuluka kwa kuwonongeka komwe kumachitika pawafa. Matekinoloje awa akuphunziridwa kuti apeze njira zopezera kulondola kwambiri ndikuchepetsa kupsinjika kwamafuta ndi makina pawafa.

Thermal Impact Area ndi Zotsatira Zake pa Ntchito

Munjira zodulira matenthedwe monga kudula kwa laser ndi plasma, kutentha kwambiri kumapangitsa kuti pakhale malo otenthetsera pamwamba pa chophikacho. Malowa, kumene kutentha kwa kutentha kumakhala kwakukulu, kungasinthe zinthu zakuthupi, zomwe zimakhudza ntchito yomaliza ya chip.

Zotsatira za Thermal Affected Zone (TAZ):

Kusintha kwa Kapangidwe ka Crystal: Pa kutentha kwakukulu, maatomu omwe ali mkati mwa zinthu zowotcha amatha kukonzanso, kuchititsa kusokonezeka kwapangidwe ka kristalo. Kusokoneza uku kumafooketsa zinthuzo, kumachepetsa mphamvu yake yamakina ndi kukhazikika, zomwe zimawonjezera chiopsezo cha kulephera kwa chip pakagwiritsidwe ntchito.

Kusintha kwa Katundu Wamagetsi: Kutentha kwapamwamba kumatha kusintha kuchuluka kwa chonyamulira ndi kuyenda kwa zida za semiconductor, zomwe zimakhudza mphamvu yamagetsi ya chip komanso kufalikira kwapano. Zosinthazi zitha kupangitsa kuti chip chichepe, zomwe zingapangitse kuti chisayenerere cholinga chake.

Kuti muchepetse zotsatirazi, kuwongolera kutentha panthawi yodula, kukhathamiritsa magawo odulira, ndikuwunika njira monga ma jets ozizira kapena machiritso a pambuyo pokonza ndi njira zofunika kwambiri zochepetsera kuchuluka kwa kutentha komanso kusunga kukhulupirika kwa zinthu.

Ponseponse, ma microcracks ndi madera okhudzidwa ndi matenthedwe ndizovuta kwambiri paukadaulo wawafer dicing. Kafukufuku wopitilira, limodzi ndi kupita patsogolo kwaukadaulo komanso njira zowongolera zabwino, zikhala zofunikira kuti zinthu za semiconductor zikhale bwino komanso kukulitsa mpikisano wawo wamsika.

Njira Zowongolera Thermal Impact Zone:

Kukhathamiritsa Magawo Odula Njira: Kuchepetsa liwiro lodulira ndi mphamvu kumatha kuchepetsa kukula kwa malo otenthetsera matenthedwe (TAZ). Izi zimathandiza kuwongolera kuchuluka kwa kutentha komwe kumapangidwa panthawi yodulira, zomwe zimakhudza mwachindunji zinthu zakuthupi za mkate.

Advanced Cooling Technologies: Kugwiritsa ntchito matekinoloje monga kuzirala kwa nayitrogeni wamadzimadzi ndi kuziziritsa kwa microfluidic kumatha kuchepetsa kuchuluka kwa malo omwe amakhudzidwa ndi kutentha. Njira zoziziritsirazi zimathandiza kuchotsa kutentha bwino, motero zimateteza zinthu zamtengo wapatali komanso kuchepetsa kuwonongeka kwa kutentha.

Kusankha Zinthu: Ofufuza akufufuza zipangizo zatsopano, monga carbon nanotubes ndi graphene, zomwe zimakhala ndi matenthedwe abwino kwambiri komanso mphamvu zamakina. Zida izi zimatha kuchepetsa gawo lomwe limakhudzidwa ndi matenthedwe ndikuwongolera magwiridwe antchito onse a tchipisi.

Mwachidule, ngakhale malo okhudzidwa ndi kutentha ndi zotsatira zosapeŵeka za matekinoloje ocheka kutentha, akhoza kuyendetsedwa bwino pogwiritsa ntchito njira zowonongeka komanso kusankha zinthu. Kafukufuku wamtsogolo adzayang'ana kwambiri pakukonza bwino ndikudzipangira okha njira zodulira matenthedwe kuti mukwaniritse bwino komanso kulondola kwa ma wafer dicing.

Njira Yoyenera:

Kupeza bwino pakati pa zokolola za wafer ndi kupanga bwino ndizovuta nthawi zonse muukadaulo waukadaulo wawafer dicing. Opanga akuyenera kuganizira zinthu zingapo, monga kufunikira kwa msika, mtengo wopangira, ndi mtundu wazinthu, kuti apange njira yoyenera yopangira ndi magawo ake. Nthawi yomweyo, kuyambitsa zida zodulira zapamwamba, kuwongolera luso la ogwiritsa ntchito, komanso kuwongolera kasamalidwe kazinthu zopangira ndizofunikira kuti pakhale zokolola kapena kukulitsa zokolola ndikukulitsa luso lopanga.

Mavuto ndi Mwayi Wamtsogolo:

Ndi kupita patsogolo kwa ukadaulo wa semiconductor, kudula kwa wafer kumakumana ndi zovuta komanso mwayi. Pamene kukula kwa chip kumacheperachepera ndikuphatikizana kukukulirakulira, zofunikira pakudulira molondola komanso mtundu zimakula kwambiri. Nthawi yomweyo, matekinoloje omwe akubwera amapereka malingaliro atsopano pakupanga njira zodulira zophatikizika. Opanga akuyenera kukhala ogwirizana ndi momwe msika ukuyendera komanso momwe ukadaulo ukuyendera, kusintha mosalekeza ndikuwongolera njira zopangira ndikusintha magawo kuti akwaniritse kusintha kwa msika ndi zofuna zaukadaulo.

Pomaliza, pophatikiza malingaliro a msika, mtengo wopangira, ndi mtundu wazinthu, ndikuyambitsa zida zapamwamba ndiukadaulo, kukulitsa luso la opareshoni, ndi kulimbikitsa kuwongolera kwazinthu zopangira, opanga amatha kukwaniritsa bwino kwambiri pakati pa zokolola zamphepo ndikuchita bwino pakupanga kwapang'onopang'ono, zomwe zimapangitsa kuti pakhale ntchito yabwino komanso yapamwamba kwambiri yopanga zida za semiconductor.

Tsogolo lamtsogolo:

Ndi kupita patsogolo kofulumira kwaukadaulo, ukadaulo wa semiconductor ukupita patsogolo kwambiri kuposa kale. Monga gawo lofunika kwambiri pakupanga semiconductor, ukadaulo wodulira wawafer wakonzeka kupanga zatsopano zosangalatsa. Kuyang'ana m'tsogolo, ukadaulo wodulira wawafer ukuyembekezeka kupititsa patsogolo kulondola, kuchita bwino, komanso mtengo wake, ndikulowetsa mphamvu zatsopano pakupitilira kukula kwamakampani opanga ma semiconductor.

Kuchulukitsa Kulondola:

Pofunafuna apamwamba mwatsatanetsatane, yopyapyala kudula luso mosalekeza kukankhira malire a njira alipo. Pophunzira mozama njira zakuthupi ndi zamankhwala za kudula ndikuwongolera moyenera magawo odulira, zotsatira zodula bwino zidzakwaniritsidwa kuti zikwaniritse zofunikira zomwe zimachulukirachulukira. Kuonjezera apo, kufufuza kwa zipangizo zatsopano ndi njira zodulira zidzakulitsa kwambiri zokolola ndi khalidwe.

Kupititsa patsogolo Mwachangu:

Zida zatsopano zodulira zopyapyala zidzayang'ana pakupanga kwanzeru komanso kodzipangira. Kukhazikitsidwa kwa machitidwe apamwamba owongolera ndi ma aligorivimu kumathandizira zida kuti zizitha kusintha magawo odulira kuti zigwirizane ndi zida zosiyanasiyana ndi kapangidwe kazinthu, motero kuwongolera bwino kwambiri kupanga. Zatsopano monga ukadaulo wodulira mawafa ambiri komanso makina osinthira ma blade mwachangu atenga gawo lofunikira pakupititsa patsogolo luso.

Kuchepetsa Mtengo:

Kuchepetsa ndalama ndi njira yofunika kwambiri pakukula kwaukadaulo wodula mtanda. Pamene zida zatsopano ndi njira zodulira zikupangidwa, ndalama zogulira zida ndi kukonzanso zikuyembekezeka kuyendetsedwa bwino. Kuphatikiza apo, kukhathamiritsa njira zopangira komanso kuchepetsa zinyalala kudzachepetsanso zinyalala panthawi yopanga, zomwe zimabweretsa kuchepa kwa ndalama zonse zopangira.

Smart Manufacturing ndi IoT:

Kuphatikizika kwaukadaulo waukadaulo wapaintaneti wa Zinthu (IoT) kubweretsa kusintha kwaukadaulo wodulira wafer. Kupyolera mu kugwirizanitsa ndi kugawana deta pakati pa zipangizo, sitepe iliyonse ya kupanga ikhoza kuyang'aniridwa ndi kukonzedwa mu nthawi yeniyeni. Izi sizimangowonjezera luso la kupanga komanso mtundu wazinthu komanso zimapatsa makampani kuneneratu kolondola kwa msika komanso thandizo lopanga zisankho.

M'tsogolomu, ukadaulo wodulira wawafer upanga kupita patsogolo kwambiri pakulondola, kuchita bwino komanso mtengo wake. Kupita patsogolo kumeneku kudzapititsa patsogolo chitukuko cha mafakitale a semiconductor ndikubweretsa zatsopano zamakono ndi zopindulitsa kwa anthu.

Nthawi yotumiza: Nov-19-2024