M'ndandanda wazopezekamo

1. Zolinga Zazikulu ndi Kufunika Koyeretsa Wafer

2. Kuwunika kwa Kuipitsidwa ndi Njira Zapamwamba Zowunikira

3.Njira Zoyeretsera Zapamwamba ndi Mfundo Zaumisiri

4.Technical Implementation and Process Control Essentials

5. Mayendedwe Amtsogolo ndi Njira Zatsopano

6. XKH End-to-End Solutions and Service Ecosystem

Kuyeretsa kwawafa ndi njira yofunika kwambiri popanga semiconductor, chifukwa ngakhale zoyipitsidwa pamlingo wa atomiki zimatha kusokoneza magwiridwe antchito kapena kukolola kwa chipangizocho. Kuyeretsa kumaphatikizapo njira zingapo zochotsera zowononga zosiyanasiyana, monga zotsalira za organic, zonyansa zachitsulo, tinthu tating'onoting'ono, ndi ma oxide achilengedwe.

1. Zolinga za Wafer Cleaning

- Chotsani zowononga zachilengedwe (monga zotsalira za photoresist, zisindikizo za zala).

- Chotsani zonyansa zachitsulo (mwachitsanzo, Fe, Cu, Ni).

- Chotsani kuipitsidwa kwa tinthu ting'onoting'ono (mwachitsanzo, fumbi, zidutswa za silicon).

- Chotsani ma oxides achilengedwe (mwachitsanzo, zigawo za SiO₂ zomwe zimapangidwira panthawi ya mpweya).

2. Kufunika Koyeretsa Molimba Wafer

- Imatsimikizira zokolola zambiri komanso magwiridwe antchito a chipangizocho.

- Amachepetsa zolakwika ndi mitengo yawafer scrap.

- Imawongolera mawonekedwe apamwamba komanso kusasinthika.

Musanayambe kuyeretsa kwambiri, m'pofunika kuunikanso kuipitsidwa komwe kulipo. Kumvetsetsa mtundu, kagawidwe kake, ndi kulinganiza kwa malo a zonyansa pamtunda wowotcha kumakulitsa chemistry yoyeretsera ndi kuyika kwamagetsi pamakina.

3. Advanced Analytical Techniques for Contamination Assessment

3.1 Surface Particle Analysis

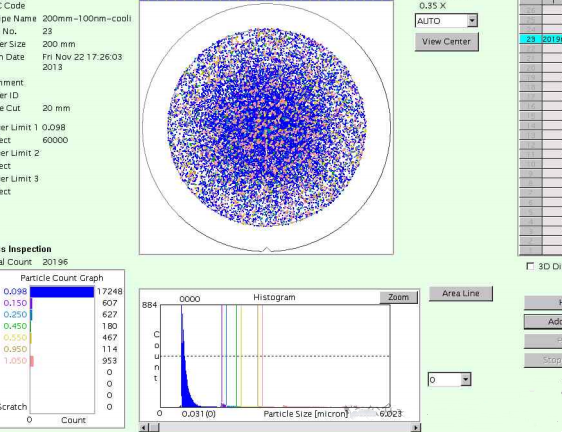

- Zowerengera zapadera za tinthu tating'onoting'ono zimagwiritsa ntchito kufalikira kwa laser, kapena masomphenya apakompyuta kuwerengera, kukula, ndi zinyalala zamapu.

- Kuchuluka kwa kubalalitsa kopepuka kumalumikizana ndi kukula kwa tinthu kakang'ono ngati makumi a nanometers, komanso kachulukidwe otsika mpaka 0.1 particles/cm².

- Kuwongolera ndi miyezo kumatsimikizira kudalirika kwa hardware. Kusanthula kusanachitike komanso pambuyo poyeretsa kumatsimikizira kuchotsedwa kwachangu, kuwongolera njira yoyendetsera.

3.2 Elemental Surface Analysis

- Njira zoganizira zapamtunda zimazindikira zomwe zidapangidwa.

- X-ray Photoelectron Spectroscopy (XPS/ESCA): Imasanthula zinthu zakuthambo poyatsa chophatikizikacho ndi ma X-ray ndi kuyeza ma elekitironi otuluka.

- Glow Discharge Optical Emission Spectroscopy (GD-OES): Imadumphira zigawo zowonda kwambiri motsatizana ndikusanthula mawonekedwe otuluka kuti adziwe zomwe zimadalira mozama.

- Malire ozindikira amafika magawo miliyoni (ppm), ndikuwongolera kusankha koyenera kwa chemistry.

3.3 Kusanthula kwa Kuwonongeka kwa morphological

- Scanning Electron Microscopy (SEM)—Imajambula zithunzi zowoneka bwino kwambiri kuti iwulule zodetsedwa ndi mawonekedwe a zoipitsitsa, kusonyeza njira zomatira (chemical vs. mechanical).

- Atomic Force Microscopy (AFM): Maps nanoscale topography kuti adziwe kutalika kwa tinthu ndi makina amakina.

- Focused Ion Beam (FIB) Milling + Transmission Electron Microscopy (TEM): Imapereka malingaliro amkati a zonyansa zokwiriridwa.

4. Njira Zapamwamba Zoyeretsera

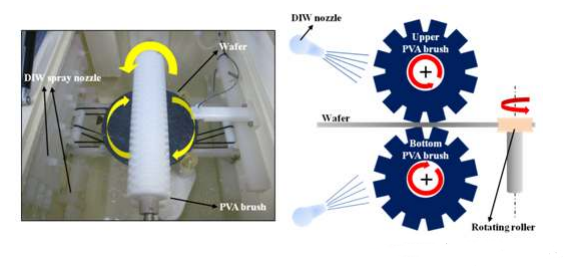

Ngakhale kuyeretsa zosungunulira kumachotsa bwino zoyipitsidwa ndi organic, njira zowonjezera zowonjezera zimafunikira kuti tinthu tating'onoting'ono, zotsalira zazitsulo, ndi zonyansa za ionic:

pa

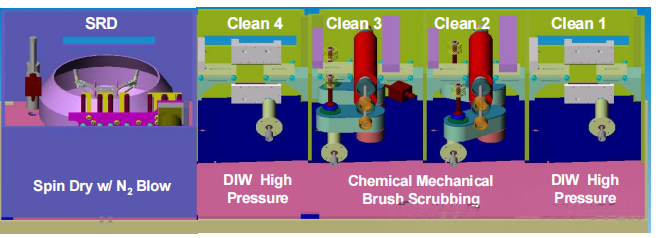

4.1 Kuyeretsa kwa RCA

- Yopangidwa ndi RCA Laboratories, njira iyi imagwiritsa ntchito njira yosambira iwiri kuti ichotse zonyansa za polar.

- SC-1 (Standard Clean-1): Imachotsa zonyansa ndi tinthu tating’ono ting’ono pogwiritsa ntchito NH₄OH, H₂O₂, ndi H₂O (mwachitsanzo, 1:1:5 chiŵerengero pa ~20°C). Amapanga wosanjikiza woonda wa silicon dioxide.

- SC-2 (Standard Clean-2): Imachotsa zonyansa zachitsulo pogwiritsa ntchito HCl, H₂O₂, ndi H₂O (mwachitsanzo, chiŵerengero cha 1:1:6 pa ~80°C). Amasiya passivated pamwamba.

- Kulinganiza ukhondo ndi chitetezo pamwamba.

pa

4.2 Kuyeretsedwa kwa Ozone

- Imamiza zophika m'madzi odzaza ndi ozoni (O₃/H₂O).

- Mogwira ma okosijeni ndi kuchotsa organics popanda kuwononga yopyapyala, kusiya mankhwala passivated pamwamba.

pa

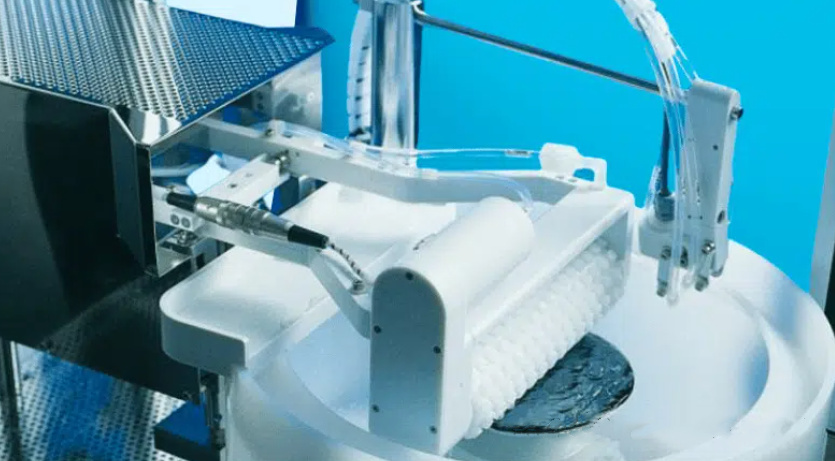

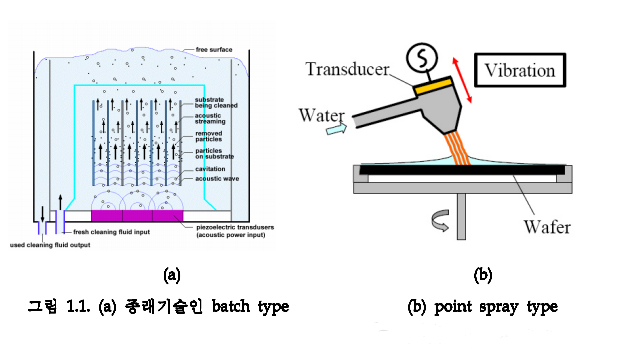

4.3 Kuyeretsa kwa Megasonicpa

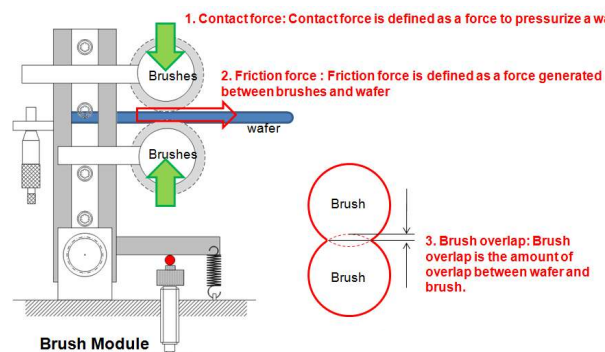

- Imagwiritsa ntchito mphamvu zamagetsi zamagetsi (nthawi zambiri 750-900 kHz) kuphatikiza njira zoyeretsera.

- Amapanga ma cavitation thovu omwe amachotsa zonyansa. Imalowa m'ma geometri ovuta kwinaku ndikuchepetsa kuwonongeka kwa zinthu zosalimba.

4.4 Kuyeretsa kwa Cryogenic

- Imazizira mwachangu zowotchera ku kutentha kwa cryogenic, zowononga zowononga.

- Kutsuka motsatira kapena kutsuka pang'onopang'ono kumachotsa tinthu tating'onoting'ono. Imalepheretsa kuipitsidwanso ndi kufalikira kumtunda.

- Njira yofulumira, yowuma yokhala ndi kugwiritsa ntchito mankhwala ochepa.

Pomaliza:

Monga wotsogola wotsogola wamitundu yonse, XKH imayendetsedwa ndi luso laukadaulo ndipo kasitomala amayenera kuperekera chilengedwe chakumapeto-kumapeto, kuphatikiza zida zapamwamba kwambiri, kupanga mawafa, komanso kuyeretsa mwatsatanetsatane. Sitimangopereka zida za semiconductor zodziwika padziko lonse lapansi (mwachitsanzo, makina a lithography, etching systems) zokhala ndi mayankho oyenerera komanso umisiri woyambilira—kuphatikiza kuyeretsa kwa RCA, kuyeretsa kwa ozoni, ndi kuyeretsa kwakukulu—kuonetsetsa ukhondo wa atomiki, popanga wafer, kupititsa patsogolo zokolola za makasitomala. Pogwiritsa ntchito magulu omwe akuyankha mwachangu, komanso maukonde anzeru, timapereka chithandizo chokwanira kuyambira kuyika zida ndi kukhathamiritsa njira mpaka kukonza zolosera zam'tsogolo, kupatsa mphamvu makasitomala kuthana ndi zovuta zaukadaulo ndikupita patsogolo kuukadaulo wapamwamba komanso chitukuko chokhazikika cha semiconductor. Tisankhireni kuti tipambane pawiri-katswiri waukadaulo komanso phindu lazamalonda.

Nthawi yotumiza: Sep-02-2025