Pakukula kwamakampani opanga ma semiconductor, kristalo wopukutidwamapepala a silicongwirani ntchito yofunika kwambiri. Amakhala ngati zinthu zofunika kwambiri popanga zida zosiyanasiyana za ma microelectronic. Kuyambira mabwalo ovuta komanso olondola ophatikizika mpaka ma microprocessors othamanga kwambiri ndi masensa amitundu yambiri, kristalo wopukutidwamapepala a siliconndi zofunika. Kusiyanasiyana kwa machitidwe awo ndi machitidwe amakhudza mwachindunji ubwino ndi machitidwe a zinthu zomaliza. M'munsimu muli mafotokozedwe wamba ndi magawo a opukutidwa single crystal silikoni wophikira:

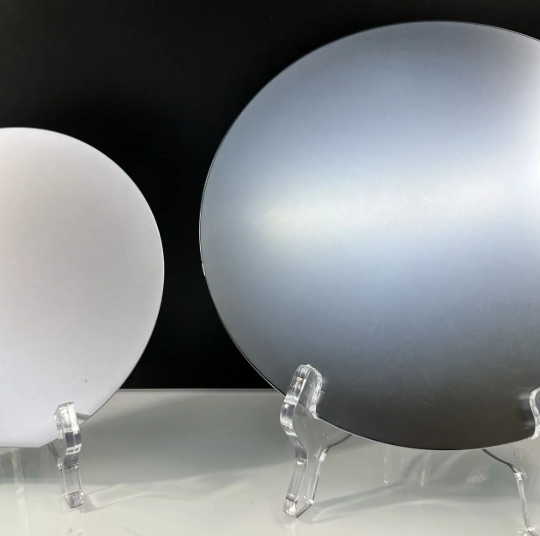

Diameter: Kukula kwa zowotcha za semiconductor single crystal silicon zimayesedwa ndi mainchesi ake, ndipo zimabwera mosiyanasiyana. Ma diameter wamba ndi mainchesi awiri (50.8mm), 3 mainchesi (76.2mm), 4 mainchesi (100mm), 5 mainchesi (125mm), 6 mainchesi (150mm), 8 mainchesi (200mm), 12 mainchesi (300mm), ndi 18 mainchesi (450mm). Ma diameter osiyanasiyana ndi oyenerera pazosowa zosiyanasiyana zopanga komanso zofunikira pakukonza. Mwachitsanzo, zowotcha zazing'ono zazing'ono zimagwiritsidwa ntchito pazida zapadera, zazing'ono zazing'ono zazing'ono zamagetsi, pomwe zowotcha zokulirapo zimawonetsa kugwirira ntchito bwino komanso kupindula kwamitengo pakupanga madera akuluakulu ophatikizika. Zofunikira zapamtunda zimagawidwa ngati zopukutidwa mbali imodzi (SSP) ndi zopukutidwa mbali ziwiri (DSP). Zophatikizika zopukutidwa za mbali imodzi zimagwiritsidwa ntchito pazida zomwe zimafuna kutsika kwambiri mbali imodzi, monga masensa ena. Zowotcherera mbali ziwiri zopukutidwa zimagwiritsidwa ntchito kwambiri popanga mabwalo ophatikizika ndi zinthu zina zomwe zimafunikira kulondola kwambiri pamawonekedwe onse awiri. Zofunika Pamwamba (Kumaliza): SSP yopukutidwa ya mbali imodzi / DSP yopukutidwa ya mbali ziwiri.

Mtundu/Dopant: (1) Semiconductor yamtundu wa N: Pamene maatomu ena osadetsedwa alowetsedwa mu semiconductor yamkati, amasintha momwe amakhalira. Mwachitsanzo, pamene zinthu za pentavalent monga nayitrogeni (N), phosphorous (P), arsenic (As), kapena antimoni (Sb) ziwonjezedwa, ma elekitironi awo a valence amapanga ma electron ogwirizana ndi ma elekitironi a valence a maatomu a silicon ozungulira, kusiya ma elekitironi owonjezera osamangidwa ndi covalent chomangira. Izi zimapangitsa kuti ma elekitironi achuluke kwambiri kuposa momwe zimakhalira, kupanga semiconductor yamtundu wa N, yomwe imadziwikanso kuti electron-type semiconductor. Ma semiconductors amtundu wa N ndiofunikira kwambiri popanga zida zomwe zimafunikira ma elekitironi ngati zonyamulira zazikulu, monga zida zina zamagetsi. (2) P-mtundu Semiconductor: Pamene trivalent zinthu zonyansa monga boron (B), gallium (Ga), kapena indium (In) anadzetsa mu silicon semiconductor, ndi ma elekitironi valence wa maatomu chonyansa kupanga covalent nsinga ndi ozungulira pakachitsulo maatomu, koma alibe osachepera limodzi valence elekitironi ndipo sangathe kupanga covalent wathunthu. Izi zimatsogolera ku ndende ya dzenje kuposa kuchuluka kwa ma elekitironi, kupanga semiconductor yamtundu wa P, yomwe imadziwikanso kuti semiconductor yamtundu wa dzenje. Ma semiconductors amtundu wa P amagwira ntchito yofunika kwambiri popanga zida zomwe mabowo amakhala ngati zonyamulira zazikulu, monga ma diode ndi ma transistors ena.

Resistivity: Resistivity ndi gawo lofunikira kwambiri lomwe limayesa mphamvu yamagetsi yazitsulo zopukutidwa za crystal silicon. Mtengo wake umawonetsa momwe zinthu zimagwirira ntchito. Kutsika kwa resistivity, kumapangitsanso kukhala bwino kwa silicon wafer; Kumbali ina, ndipamwamba kwambiri resistivity, ndi osauka madutsidwe. Resistivity wa ma silicon wafers amatsimikiziridwa ndi zinthu zawo zakuthupi, ndipo kutentha kumakhalanso ndi mphamvu. Nthawi zambiri, resistivity wa silicon wafers kumawonjezeka ndi kutentha. Pakugwiritsa ntchito, zida zosiyanasiyana za ma microelectronic zimakhala ndi zofunikira zosiyana za resistivity za silicon wafers. Mwachitsanzo, zowonda zomwe zimagwiritsidwa ntchito popanga makina ophatikizika amafunikira kuwongolera koyenera kwa resistivity kuti zitsimikizire kukhazikika komanso kodalirika kwa chipangizocho.

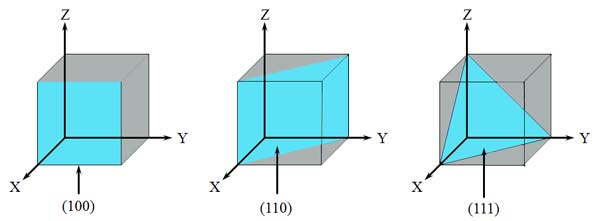

Kuwongolera: Kuwongolera kwa kristalo kwa chophatikizira kumayimira njira ya crystallographic ya silicon lattice, yomwe imatchulidwa ndi Miller indices monga (100), (110), (111), ndi zina zotero. Zosiyana za kristalo zimakhala ndi maonekedwe osiyanasiyana a thupi, monga kachulukidwe ka mzere, zomwe zimasiyana malinga ndi momwe zimayendera. Kusiyanaku kumatha kukhudza momwe chowotcha chimagwirira ntchito pamasitepe otsatirawa ndikugwirira ntchito komaliza kwa zida za microelectronic. Popanga, kusankha chophatikizika cha silicon chokhala ndi mawonekedwe oyenerera pazofunikira zosiyanasiyana za chipangizocho kumatha kukulitsa magwiridwe antchito a chipangizocho, kuwongolera magwiridwe antchito, komanso kukulitsa mtundu wazinthu.

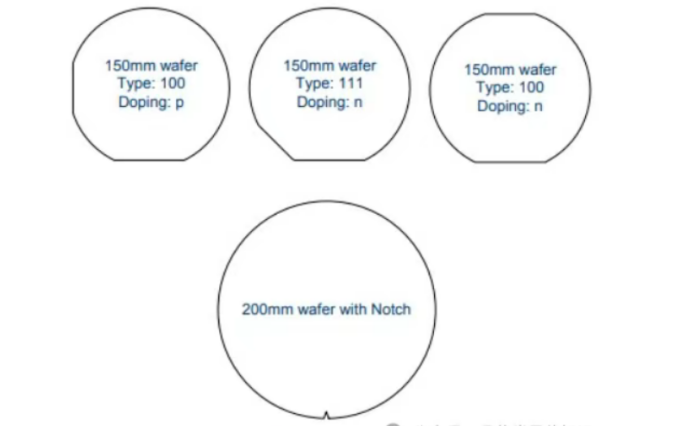

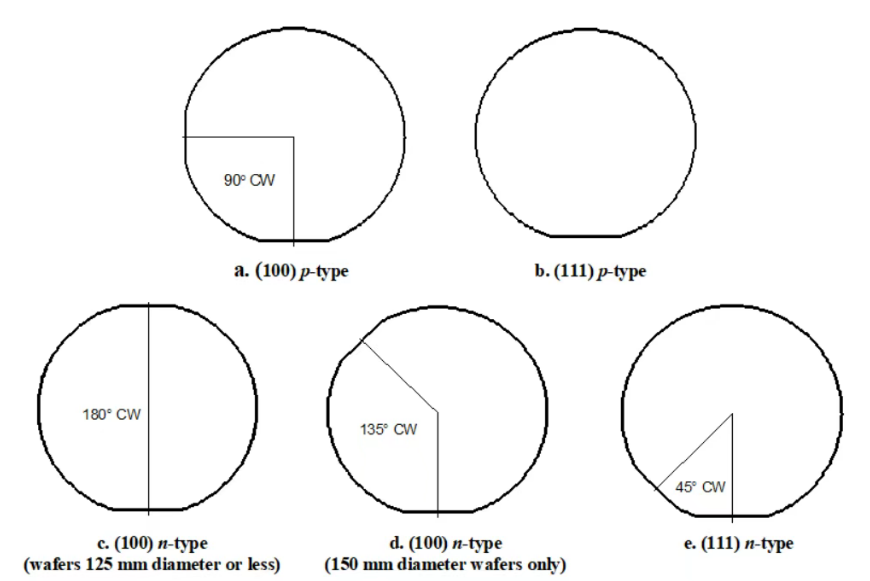

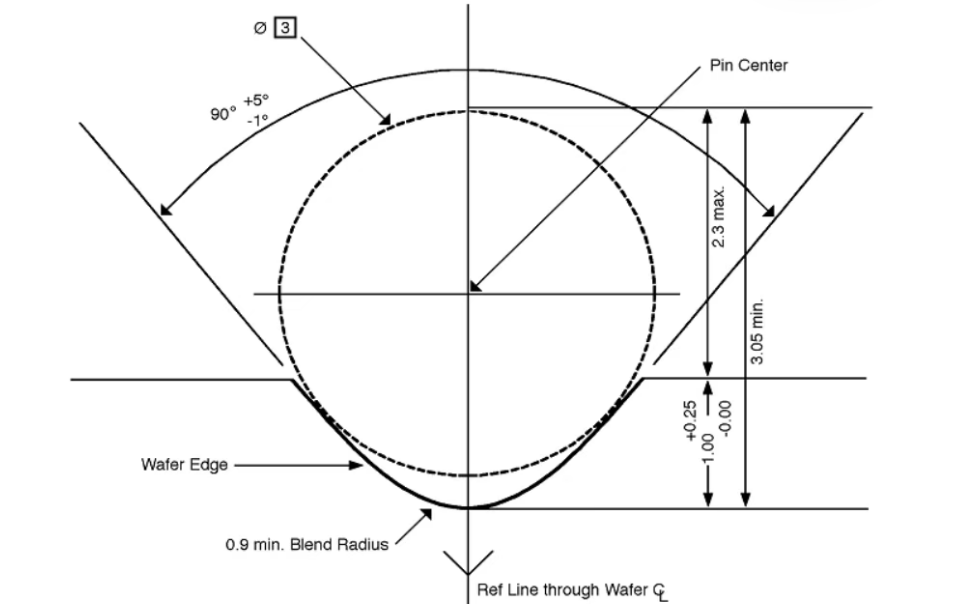

Lathyathyathya/Notch: Mphepete mwathyathyathya (Flat) kapena V-notch (Notch) pa circumference ya silicon wafer imakhala ndi gawo lofunikira pakuwongolera koyang'ana kwa kristalo ndipo ndi chizindikiritso chofunikira popanga ndi kukonza chophatikiziracho. Zophika zokhala ndi ma diameter osiyanasiyana zimayenderana ndi miyezo yosiyanasiyana ya kutalika kwa Flat kapena Notch. Mphepete zolumikizana zimagawika m'magawo oyambira komanso achiwiri. Gombe loyambira limagwiritsidwa ntchito makamaka kudziwa momwe kristalo imayambira ndikugwiritsidwira ntchito kwa chophatikizira, pomwe chipinda chachiwiri chimathandiziranso kuwongolera bwino ndikukonza, kuwonetsetsa kuti chiwombankhangacho chimagwira ntchito molondola komanso mosasinthasintha mumzere wonse wopanga.

Kukhuthala: Kukhuthala kwa kanyumba kakang'ono kamene kamatchulidwa mu ma micrometer (μm), okhala ndi makulidwe wamba pakati pa 100μm ndi 1000μm. Ma Wafers a makulidwe osiyanasiyana ndi oyenera mitundu yosiyanasiyana ya zida za microelectronic. Zowonda zowonda (mwachitsanzo, 100μm - 300μm) nthawi zambiri zimagwiritsidwa ntchito popanga chip zomwe zimafunikira kuwongolera kolimba, kuchepetsa kukula ndi kulemera kwa chip ndikuwonjezera kachulukidwe kaphatikizidwe. Zophika zowonda (mwachitsanzo, 500μm - 1000μm) zimagwiritsidwa ntchito kwambiri pazida zomwe zimafunikira mphamvu zamakina apamwamba, monga zida zamagetsi zamagetsi, kuti zitsimikizire kukhazikika pakugwira ntchito.

Kukula Kwapamtunda: Kuvuta kwapamtunda ndi chimodzi mwazinthu zofunika kwambiri pakuwunika mtundu wawafer, chifukwa zimakhudza mwachindunji kumamatira pakati pa chophatikizika ndi zinthu zoonda zomwe zimayikidwa pambuyo pake, komanso magwiridwe antchito amagetsi a chipangizocho. Nthawi zambiri amawonetsedwa ngati muzu wotanthauza square (RMS) roughness (mu nm). Kutsika kwamphamvu kwapamtunda kumatanthauza kuti pamwamba pake ndi yosalala, zomwe zimathandiza kuchepetsa zochitika ngati kubalalika kwa ma elekitironi ndikuwongolera magwiridwe antchito ndi kudalirika kwa chipangizocho. M'njira zapamwamba zopangira zida za semiconductor, zofunikira za roughness zapamtunda zikuchulukirachulukira, makamaka popanga makina ophatikizika apamwamba, pomwe kuuma kwapamtunda kuyenera kuwongoleredwa mpaka ma nanometer ochepa kapena kutsika.

Kusiyanasiyana Kwa Makulidwe Onse (TTV): Kusiyanasiyana kwa makulidwe onse kumatanthawuza kusiyana pakati pa makulidwe apamwamba ndi ochepa omwe amayezedwa pamagawo angapo pamtunda, womwe umawonetsedwa mu μm. TTV yapamwamba imatha kupangitsa kuti pakhale zopatuka pamachitidwe monga kujambula zithunzi ndi etching, zomwe zingakhudze kusasinthika kwa chipangizocho komanso kuchuluka kwake. Chifukwa chake, kuwongolera TTV panthawi yopanga zophika ndi gawo lofunikira pakuwonetsetsa kuti zinthu zili bwino. Pakupanga zida zamakina owoneka bwino kwambiri, TTV nthawi zambiri imafunika kukhala mkati mwa ma micrometer ochepa.

Uta: Bow amatanthauza kupatuka pakati pa chopingasa pamwamba ndi ndege yabwino yosalala, yomwe imayesedwa mu μm. Zophika zokhala ndi kugwada mopitilira muyeso zimatha kusweka kapena kukhala ndi nkhawa zosagwirizana pakukonza kotsatira, zomwe zimakhudza kupanga bwino komanso mtundu wazinthu. Makamaka muzochita zomwe zimafuna flatness yapamwamba, monga photolithography, kuwerama kuyenera kuyendetsedwa mkati mwamtundu wina kuti zitsimikizire kulondola ndi kusagwirizana kwa chithunzi cha photolithographic.

Warp: Warp imasonyeza kupatuka pakati pa chopingasa pamwamba ndi mawonekedwe abwino ozungulira, omwe amayesedwanso mu μm. Mofanana ndi uta, warp ndi chizindikiro chofunikira cha flatness ya wafer. Kuwotcha kwambiri sikumangokhudza kulondola kwa kuyika kwa chophatikizira mu zida zopangira, komanso kungayambitsenso zovuta pakuyika chip, monga kusalumikizana bwino pakati pa chip ndi zinthu zoyika, zomwe zimakhudzanso kudalirika kwa chipangizocho. Pakupanga ma semiconductor apamwamba kwambiri, zofunikira za warp zikukhala zovuta kwambiri kuti zikwaniritse zofunikira zaukadaulo wapamwamba wopanga ma chip ndikuyika.

Mbiri Yam'mphepete: Mbiri ya m'mphepete mwa chowotcha ndi yofunika kwambiri pakukonzedwa ndi kugwiridwa kwake. Nthawi zambiri imatchulidwa ndi Edge Exclusion Zone (EEZ), yomwe imatanthawuza mtunda kuchokera pamphepete mwachabechabe pomwe palibe kukonza komwe kumaloledwa. Mbiri yopangidwa bwino m'mphepete ndi kuwongolera kolondola kwa EEZ kumathandizira kupeŵa zolakwika za m'mphepete, kupsinjika maganizo, ndi zina pamene mukukonza, kupititsa patsogolo ubwino ndi zokolola. Munjira zina zopangira zapamwamba, kulondola kwa mbiri yam'mphepete kumafunika kukhala pamlingo wa sub-micron.

Kuwerengera kwa Particle: Chiwerengero ndi kukula kwa tinthu tating'onoting'ono tomwe timakhala pamtunda kumakhudza kwambiri magwiridwe antchito a zida zamagetsi. Kuchulukirachulukira kapena tinthu tating'onoting'ono kungayambitse kulephera kwa zida, monga mabwalo amfupi kapena kutayikira, kuchepetsa zokolola. Chifukwa chake, kuchuluka kwa tinthu kumayesedwa powerengera tinthu tating'ono pagawo lililonse, monga kuchuluka kwa tinthu tokulirapo kuposa 0.3μm. Kuwongolera mosamalitsa kuchuluka kwa tinthu panthawi yopanga mawafa ndi njira yofunikira pakuwonetsetsa kuti zinthu zili bwino. Ukadaulo waukadaulo woyeretsa komanso malo opangira ukhondo amagwiritsidwa ntchito kuti achepetse kuipitsidwa ndi tinthu tating'onoting'ono.

![]()

![]()

![]()

![]()

![]()

Zogwirizana kupanga

Single Crystal Silicon Wafer Si Substrate Type N/P Optional Silicon Carbide Wafer

FZ CZ Si chowotcha chomwe chili mu stock 12inch Silicon wafer Prime kapena Test

Nthawi yotumiza: Apr-18-2025