Chidule cha SiC wafer

Silicon carbide (SiC).zakhala gawo losankhidwa lamagetsi apamwamba kwambiri, ma frequency apamwamba, komanso kutentha kwambiri pamagalimoto, mphamvu zongowonjezwdwa, ndi zamlengalenga. Mbiri yathu imakhudza ma polytypes ndi ma doping schemes - nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), ndi p-type 4H/6H (4H/6H-P) -yoperekedwa m'makalasi atatu: PRIME (yopukutidwa bwino, yopukutidwa bwino, makina opukutidwa, opukutidwa) FUFUZANI (zosanjikiza za epi ndi mbiri ya doping ya R&D). Wafer diameters utalikirana 2 ″, 4 ″, 6 ″, 8 ″, ndi 12 ″ kuti igwirizane ndi zida zonse zakale ndi nsalu zapamwamba. Timaperekanso ma boules a monocrystalline ndi makristasi ambewu omwe amawongolera ndendende kuti athandizire kukula kwa kristalo mnyumba.

Zophika zathu za 4H-N zimakhala ndi kachulukidwe konyamula kuchokera ku 1 × 10¹⁶ mpaka 1 × 10¹⁹ cm⁻³ ndi zopinga za 0.01–10 Ω·cm, zoperekera ma elekitironi abwino kwambiri ndi magawo osweka pamwamba pa 2 MV/cm—oyenera ma diodi a Schottky, ndi ma JMOSsFET. Magawo a HPSI amapitilira 1×10¹² Ω·cm resistivity yokhala ndi kachulukidwe ka ma micropipe pansi pa 0.1 cm⁻², kuwonetsetsa kutayikira kochepa kwa zida za RF ndi microwave. Cubic 3C-N, yomwe imapezeka mumitundu ya 2 ″ ndi 4 ″, imathandizira heteroepitaxy pa silicon ndipo imathandizira mapulogalamu amtundu wa Photonic ndi MEMS. P-mtundu wa 4H/6H-P zowotcha, zopangidwa ndi aluminiyamu mpaka 1×10¹⁶–5×10¹⁸ cm⁻³, zimathandizira kamangidwe ka zida.

SiC wafer, PRIME wafers amapangidwa ndi mankhwala-makina kupukuta mpaka <0.2 nm RMS pamwamba roughness, okwana makulidwe kusiyana pansi 3 µm, ndi uta <10 µm. Magawo a DUMMY amafulumizitsa kuyesa kusonkhanitsa ndi kuyika, pomwe zowotcha za RESEARCH zimakhala ndi makulidwe a epi-layer a 2-30 µm ndi doping yodziwika bwino. Zogulitsa zonse zimatsimikiziridwa ndi X-ray diffraction (rocking curve <30 arcsec) ndi Raman spectroscopy, ndi mayesero amagetsi-Mayeso a Hall, C-V profiling, ndi micropipe scanning-kuonetsetsa kuti JEDEC ndi SEMI zitsatiridwa.

Ma boules mpaka 150 mm m'mimba mwake amakula kudzera pa PVT ndi CVD ndi kusasunthika kosasunthika pansi pa 1 × 10³ cm⁻² komanso kuchuluka kwa ma micropipe. Makhiristo a mbeu amadulidwa mkati mwa 0.1° wa c-axis kuti atsimikizire kukula bwino komanso zokolola zambiri.

Pophatikiza ma polytypes angapo, mitundu yosiyanasiyana ya doping, magiredi apamwamba, kukula kwa SiC wafer, ndi kupanga m'nyumba ndi makristalo ambewu, nsanja yathu ya SiC substrate imawongolera maunyolo ndikufulumizitsa chitukuko cha zida zamagalimoto amagetsi, ma gridi anzeru, komanso kugwiritsa ntchito malo ovutitsa.

Chidule cha SiC wafer

Silicon carbide (SiC).zakhala gawo laling'ono la SiC losankhira mphamvu zamphamvu, zothamanga kwambiri, komanso zamagetsi zotentha kwambiri pamagalimoto, mphamvu zongowonjezwdwa, ndi zamlengalenga. Mbiri yathu imakhudza ma polytypes ndi ma doping schemes-nitrogen-doped 4H (4H-N), high-purity semi-insulating (HPSI), nitrogen-doped 3C (3C-N), ndi p-type 4H/6H (4H/6H-P)-yoperekedwa m'makalasi atatu: SiC waferPRIME (yopukutidwa bwino, magawo amtundu wa chipangizo), DUMMY (yopukutidwa kapena yosapukutidwa kuti iyesedwe), ndi RESEARCH (zosanjikiza za epi ndi mbiri yaukadaulo ya R&D). SiC Wafer diameters span 2 ″, 4 ″, 6 ″, 8 ″, ndi 12 ″ kuti igwirizane ndi zida zonse zakale komanso nsalu zapamwamba. Timaperekanso ma boules a monocrystalline ndi makristasi ambewu omwe amawongolera ndendende kuti athandizire kukula kwa kristalo mnyumba.

Zophika zathu za 4H-N SiC zimakhala ndi kachulukidwe konyamula kuchokera ku 1 × 10¹⁶ mpaka 1 × 10¹⁹ cm⁻³ ndi zopinga za 0.01–10 Ω·cm, zoperekera ma elekitironi oyenda bwino komanso magawo osweka pamwamba pa 2 MV/cm—oyenera ma Schottky diode, MOSFETS, ndi ma JFET. Magawo a HPSI amapitilira 1×10¹² Ω·cm resistivity yokhala ndi kachulukidwe ka ma micropipe pansi pa 0.1 cm⁻², kuwonetsetsa kutayikira kochepa kwa zida za RF ndi microwave. Cubic 3C-N, yomwe imapezeka mumitundu ya 2 ″ ndi 4 ″, imathandizira heteroepitaxy pa silicon ndipo imathandizira mapulogalamu amtundu wa Photonic ndi MEMS. SiC wafer P-mtundu wa 4H/6H-P, wopangidwa ndi aluminiyamu mpaka 1×10¹⁶–5×10¹⁸ cm⁻³, amathandizira kamangidwe ka zida.

SiC wafer PRIME wafer amapangidwa ndi mankhwala-makina kupukuta mpaka <0.2 nm RMS pamwamba roughness, kusiyanasiyana makulidwe pansi pa 3 µm, ndi uta <10 µm. Magawo a DUMMY amafulumizitsa kuyesa kusonkhanitsa ndi kuyika, pomwe zowotcha za RESEARCH zimakhala ndi makulidwe a epi-layer a 2-30 µm ndi doping yodziwika bwino. Zogulitsa zonse zimatsimikiziridwa ndi X-ray diffraction (rocking curve <30 arcsec) ndi Raman spectroscopy, ndi mayesero amagetsi-Mayeso a Hall, C-V profiling, ndi micropipe scanning-kuonetsetsa kuti JEDEC ndi SEMI zitsatiridwa.

Ma boules mpaka 150 mm m'mimba mwake amakula kudzera pa PVT ndi CVD ndi kusasunthika kosasunthika pansi pa 1 × 10³ cm⁻² komanso kuchuluka kwa ma micropipe. Makhiristo a mbeu amadulidwa mkati mwa 0.1° wa c-axis kuti atsimikizire kukula bwino komanso zokolola zambiri.

Pophatikiza ma polytypes angapo, mitundu yosiyanasiyana ya doping, magiredi apamwamba, kukula kwa SiC wafer, ndi kupanga m'nyumba ndi makristalo ambewu, nsanja yathu ya SiC substrate imawongolera maunyolo ndikufulumizitsa chitukuko cha zida zamagalimoto amagetsi, ma gridi anzeru, komanso kugwiritsa ntchito malo ovutitsa.

Tsamba la data la 6inch 4H-N mtundu wa SiC wafer

| 6inch SiC wafers data sheet | ||||

| Parameter | Sub-Parameter | Z kalasi | P kalasi | D kalasi |

| Diameter | 149.5-150.0 mm | 149.5-150.0 mm | 149.5-150.0 mm | |

| Makulidwe | 4H-N | 350µm ± 15µm | 350µm ± 25µm | 350µm ± 25µm |

| Makulidwe | 4H‑SI | 500µm ± 15µm | 500µm ± 25µm | 500µm ± 25µm |

| Wafer Orientation | Kuchokera kumbali: 4.0 ° kulowera <11-20> ± 0.5 ° (4H-N); Pa axis: <0001> ±0.5° (4H-SI) | Kuchokera kumbali: 4.0 ° kulowera <11-20> ± 0.5 ° (4H-N); Pa axis: <0001> ±0.5° (4H-SI) | Kuchokera kumbali: 4.0 ° kulowera <11-20> ± 0.5 ° (4H-N); Pa axis: <0001> ±0.5° (4H-SI) | |

| Kuchuluka kwa Micropipe | 4H-N | ≤ 0.2cm⁻² | ≤ 2cm⁻² | ≤ 15 cm⁻² |

| Kuchuluka kwa Micropipe | 4H‑SI | ≤ 1 cm⁻² | ≤ 5cm⁻² | ≤ 15 cm⁻² |

| Kukaniza | 4H-N | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | 0.015–0.028 Ω·cm |

| Kukaniza | 4H‑SI | ≥ 1×10¹⁰ Ω·cm | ≥ 1×10⁵ Ω·cm | |

| Chiyambi cha Flat Orientation | [10-10] ± 5.0° | [10-10] ± 5.0° | [10-10] ± 5.0° | |

| Utali Woyambira Wathyathyathya | 4H-N | 47.5 mm ± 2.0 mm | ||

| Utali Woyambira Wathyathyathya | 4H‑SI | Notch | ||

| Kupatula M'mphepete | 3 mm | |||

| Warp/LTV/TTV/Bow | ≤2.5 µm / ≤6 µm / ≤25 µm / ≤35 µm | ≤5 µm / ≤15 µm / ≤40 µm / ≤60 µm | ||

| Ukali | Chipolishi | Ra ≤ 1 nm | ||

| Ukali | CMP | Ra ≤ 0.2 nm | Ra ≤ 0.5 nm | |

| Ming'alu Zam'mphepete | Palibe | Kutalika kokwanira ≤ 20 mm, limodzi ≤ 2 mm | ||

| Zithunzi za Hex | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 0.1% | Malo owonjezera ≤ 1% | |

| Madera a Polytype | Palibe | Malo owonjezera ≤ 3% | Malo owonjezera ≤ 3% | |

| Carbon Inclusions | Malo owonjezera ≤ 0.05% | Malo owonjezera ≤ 3% | ||

| Zolemba Pamwamba | Palibe | Utali wokwanira ≤ 1 × wafer awiri | ||

| Chips za Edge | Palibe chololedwa ≥ 0.2 mm m'lifupi & kuya | Mpaka tchipisi 7, ≤ 1 mm iliyonse | ||

| TSD (Threading screw Dislocation) | ≤500cm⁻² | N / A | ||

| BPD (Base Plane Dislocation) | ≤1000cm⁻² | N / A | ||

| Kuipitsidwa Pamwamba | Palibe | |||

| Kupaka | Multi-wafer cassette kapena single wafer container | Multi-wafer cassette kapena single wafer container | Multi-wafer cassette kapena single wafer container | |

Tsamba la data la 4inch 4H-N mtundu wa SiC wafer

| Tsamba la data la 4inch SiC wafer | |||

| Parameter | Zero MPD Production | Gulu Lokhazikika Lopanga (P Grade) | Dummy Grade (D Grade) |

| Diameter | 99.5 mm-100.0 mm | ||

| Kukula (4H-N) | 350µm±15µm | 350µm±25µm | |

| Makulidwe (4H-Si) | 500µm±15µm | 500µm±25µm | |

| Wafer Orientation | Kuchokera kumbali: 4.0 ° kulowera <1120> ± 0.5 ° kwa 4H-N; Pa axis: <0001> ± 0.5 ° kwa 4H-Si | ||

| Kachulukidwe ka Micropipe (4H-N) | ≤0.2cm⁻² | ≤2 cm⁻² | ≤15cm⁻² |

| Kachulukidwe ka Micropipe (4H-Si) | ≤1cm⁻² | ≤5cm⁻² | ≤15cm⁻² |

| Kukaniza (4H-N) | 0.015–0.024 Ω·cm | 0.015–0.028 Ω·cm | |

| Kukaniza (4H-Si) | ≥1E10 Ω·cm | ≥1E5 Ω·cm | |

| Chiyambi cha Flat Orientation | [10-10] ±5.0° | ||

| Utali Woyambira Wathyathyathya | 32.5 mm ± 2.0 mm | ||

| Kutalika kwa Sekondale | 18.0 mm ± 2.0 mm | ||

| Sekondale Flat Orientation | Silicon yayang'ana m'mwamba: 90 ° CW kuchokera kumtunda wapamwamba ± 5.0 ° | ||

| Kupatula M'mphepete | 3 mm | ||

| LTV/TTV/Bow Warp | ≤2.5 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ukali | Chipolishi Ra ≤1 nm; CMP Ra ≤0.2 nm | Ra ≤0.5 nm | |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Palibe | Palibe | Kutalika kokwanira ≤10 mm; Utali umodzi ≤2 mm |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤0.05% | Malo owonjezera ≤0.05% | Malo owonjezera ≤0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Palibe | Malo owonjezera ≤3% | |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤0.05% | Malo owonjezera ≤3% | |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Palibe | Kutalika kochulukira ≤1 m'mimba mwake | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥0.2 mm m'lifupi ndi kuya | 5 zololedwa, ≤1 mm iliyonse | |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | Palibe | ||

| Kusintha kwa screw screw | ≤500cm⁻² | N / A | |

| Kupaka | Multi-wafer cassette kapena single wafer container | Multi-wafer cassette kapena single wafer container | Multi-wafer cassette kapena single wafer container |

Tsamba la data la 4inch HPSI mtundu wa SiC wafer

| Tsamba la data la 4inch HPSI mtundu wa SiC wafer | |||

| Parameter | Zero MPD Kalasi Yopanga (Z Giredi) | Gulu Lokhazikika Lopanga (P Grade) | Dummy Grade (D Grade) |

| Diameter | 99.5-100.0 mm | ||

| Makulidwe (4H-Si) | 500µm ±20µm | 500µm ±25µm | |

| Wafer Orientation | Kuchokera pamtunda: 4.0 ° kulowera <11-20> ± 0.5 ° kwa 4H-N; Pa axis: <0001> ± 0.5 ° kwa 4H-Si | ||

| Kachulukidwe ka Micropipe (4H-Si) | ≤1cm⁻² | ≤5cm⁻² | ≤15cm⁻² |

| Kukaniza (4H-Si) | ≥1E9 Ω·cm | ≥1E5 Ω·cm | |

| Chiyambi cha Flat Orientation | (10-10) ± 5.0° | ||

| Utali Woyambira Wathyathyathya | 32.5 mm ± 2.0 mm | ||

| Kutalika kwa Sekondale | 18.0 mm ± 2.0 mm | ||

| Sekondale Flat Orientation | Silicon yayang'ana m'mwamba: 90 ° CW kuchokera kumtunda wapamwamba ± 5.0 ° | ||

| Kupatula M'mphepete | 3 mm | ||

| LTV/TTV/Bow Warp | ≤3 µm/≤5 µm/≤15 µm/≤30 µm | ≤10 µm/≤15 µm/≤25 µm/≤40 µm | |

| Ukali (C nkhope) | Chipolishi | Ra ≤1 nm | |

| Ukali (Nkhope) | CMP | Ra ≤0.2 nm | Ra ≤0.5 nm |

| Mphepete Mng'alu Mwa Kuwala Kwakukulu Kwambiri | Palibe | Kutalika kokwanira ≤10 mm; Utali umodzi ≤2 mm | |

| Hex Plates Mwa Kuwala Kwakukulu Kwambiri | Malo owonjezera ≤0.05% | Malo owonjezera ≤0.05% | Malo owonjezera ≤0.1% |

| Madera a Polytype Mwa Kuwala Kwakukulu Kwambiri | Palibe | Malo owonjezera ≤3% | |

| Mawonekedwe a Carbon Inclusions | Malo owonjezera ≤0.05% | Malo owonjezera ≤3% | |

| Silicon Surface Scratches Ndi Kuwala Kwakukulu Kwambiri | Palibe | Kutalika kochulukira ≤1 m'mimba mwake | |

| Mphepete Chips Mwa High Intensity Kuwala | Palibe chololedwa ≥0.2 mm m'lifupi ndi kuya | 5 zololedwa, ≤1 mm iliyonse | |

| Silicon Surface Kuipitsidwa Ndi Kuwala Kwakukulu Kwambiri | Palibe | Palibe | |

| Kusintha kwa Screw Dislocation | ≤500cm⁻² | N / A | |

| Kupaka | Multi-wafer cassette kapena single wafer container | ||

Ntchito ya SiC wafer

-

Ma module a SiC Wafer Power a EV Inverters

Ma MOSFET opangidwa ndi SiC wafer-based MOSFET ndi ma diode omangidwa pamagawo apamwamba a SiC wafer amataya zotayika kwambiri. Pogwiritsa ntchito ukadaulo wa SiC wafer, ma module amagetsiwa amagwira ntchito pama voltages apamwamba komanso kutentha, zomwe zimapangitsa kuti ma inverters agwire bwino ntchito. Kuphatikizira SiC wafer kufa mu magawo amagetsi kumachepetsa zofunikira zoziziritsa komanso kupondaponda, kuwonetsa kuthekera konse kwaukadaulo wa SiC wafer. -

High-Frequency RF & 5G Devices pa SiC Wafer

Ma amplifiers a RF ndi ma switch opangidwa pamapulatifomu otchingira a SiC wafer amawonetsa kukhathamiritsa kwapamwamba kwamafuta ndi ma voltages owonongeka. SiC wafer substrate imachepetsa kutayika kwa dielectric pama frequency a GHz, pomwe mphamvu ya SiC wafer imalola kugwira ntchito kosasunthika pansi pa mphamvu zamphamvu, kutentha kwambiri - kupanga SiC wafer kukhala gawo laling'ono la masiteshoni amtundu wa 5G ndi makina a radar. -

Ma Optoelectronic & LED Substrates kuchokera ku SiC Wafer

Ma LED a buluu ndi a UV omwe amakula pazigawo zowotcha za SiC amapindula ndi kufananiza kwabwino kwa lattice ndi kutulutsa kutentha. Kugwiritsa ntchito chowotcherera cha C-face SiC chopukutidwa chimatsimikizira zigawo za epitaxial, pomwe kulimba kwa SiC wafer kumathandizira kuwonda bwino komanso kuyika zida zodalirika. Izi zimapangitsa SiC wafer kukhala nsanja yopititsira patsogolo mphamvu zapamwamba, zogwiritsa ntchito nthawi yayitali za LED.

Q&A ya SiC wafer

1. Q: Kodi zowotcha za SiC zimapangidwa bwanji?

A:

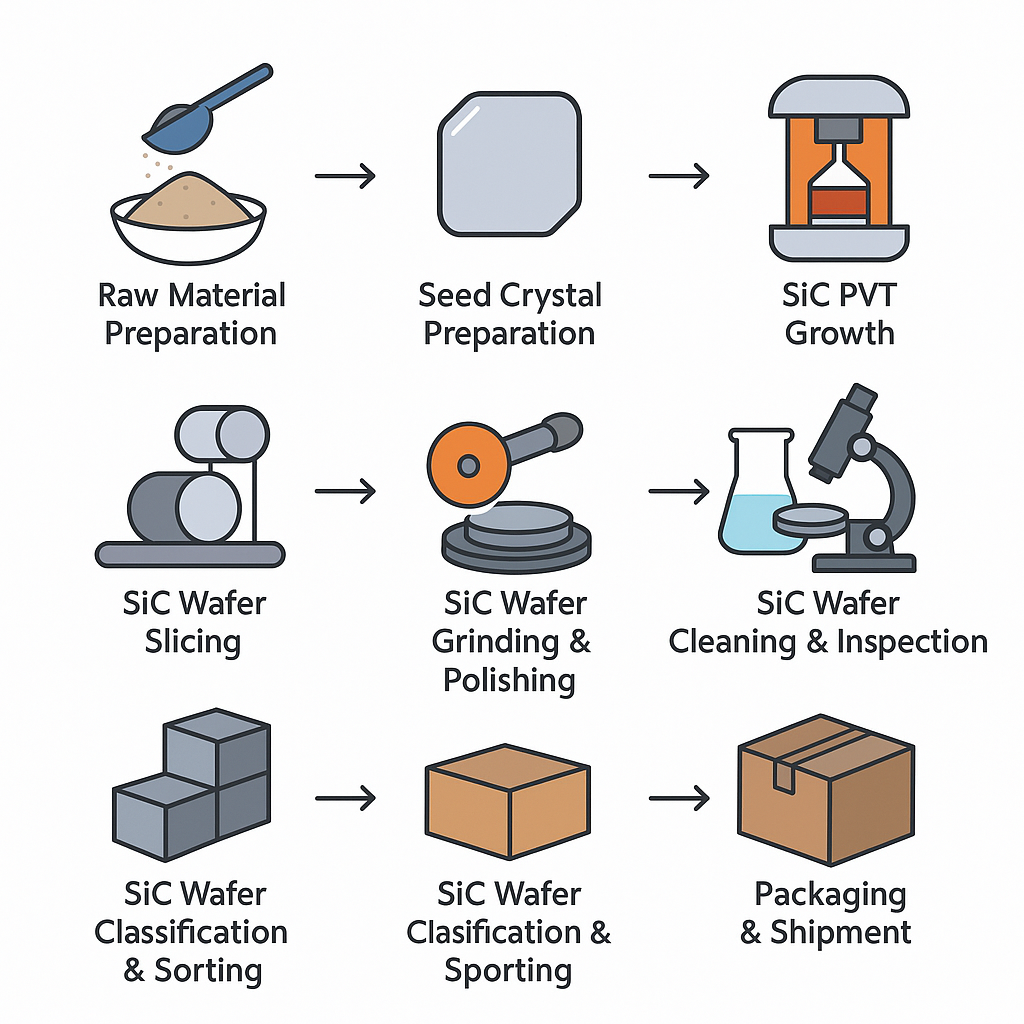

Zophika za SiC zopangidwaMwatsatanetsatane Masitepe

-

Zophika za SiCKukonzekera Zakuthupi

- Gwiritsani ntchito ≥5N-grade SiC powder (zonyansa ≤1 ppm).

- Sefa ndi kuphika kale kuti muchotse zotsalira za kaboni kapena nayitrogeni.

-

SiCKukonzekera kwa Crystal Mbewu

-

Tengani chidutswa cha kristalo wa 4H-SiC, kagawo motsatira 〈0001〉 ku ~ 10 × 10 mm².

-

Pulitchi yolondola mpaka ku Ra ≤0.1 nm ndikuyika chizindikiro cha kristalo.

-

-

SiCKukula kwa PVT (Physical Vapor Transport)

-

Kwezani graphite crucible: pansi ndi ufa wa SiC, pamwamba ndi kristalo wambewu.

-

Chokani ku 10⁻³–10⁻⁵ Torr kapena kudzaza mmbuyo ndi helium yoyera kwambiri pa 1 atm.

-

Malo oyambira kutentha mpaka 2100-2300 ℃, sungani zone yambewu 100-150 ℃ mozizira.

-

Yesetsani kukula kwa 1-5 mm / h kuti muyese bwino ndi kutulutsa.

-

-

SiCIngot Annealing

-

Anneal SiC ingot yomwe wakula pa 1600-1800 ℃ kwa maola 4-8.

-

Cholinga: Kuchepetsa kupsinjika kwamafuta ndikuchepetsa kusefukira kwa dislocation.

-

-

SiCWafer Slicing

-

Gwiritsani ntchito macheka wawaya wa diamondi kuti mudulire ingot kukhala zowonda za 0.5-1 mm zokhuthala.

-

Chepetsani kugwedezeka ndi mphamvu yakumbuyo kuti mupewe ming'alu yaying'ono.

-

-

SiCWaferKupera & Kupukuta

-

Coarse akuperakuchotsa kuwonongeka kwa macheka (kukala ~ 10-30 µm).

-

Akupera bwinokukwaniritsa flatness ≤5 µm.

-

Chemical-Mechanical polishing (CMP)kufika kumapeto ngati galasi (Ra ≤0.2 nm).

-

-

SiCWaferKuyeretsa & Kuyang'ana

-

Akupanga kuyeretsamu Piranha solution (H₂SO₄:H₂O₂), DI madzi, kenako IPA.

-

XRD/Raman spectroscopykutsimikizira polytype (4H, 6H, 3C).

-

Interferometrykuyeza kusalala (<5 µm) ndi kuzungulira (<20 µm).

-

Kufufuza kwa mfundo zinayikuyesa resistivity (mwachitsanzo HPSI ≥10⁹ Ω·cm).

-

Kuwona zolakwikapansi pa polarized light microscope ndi scratch tester.

-

-

SiCWaferGulu & Kusanja

-

Sanjani zowotcha potengera polytype ndi mtundu wamagetsi:

-

4H-SiC N-mtundu (4H-N): ndende yonyamula 10¹⁶–10¹⁸ cm⁻³

-

4H-SiC High Purity Semi-Insulating (4H-HPSI): resistivity ≥10⁹ Ω·cm

-

6H-SiC N-mtundu (6H-N)

-

Ena: 3C-SiC, P-mtundu, etc.

-

-

-

SiCWaferKupaka & Kutumiza

2. Q: Kodi maubwino otani a zowotcha za SiC pa zowotcha za silicon?

A: Poyerekeza ndi zowotcha za silicon, zopyapyala za SiC zimatha:

-

Kugwira ntchito kwamagetsi apamwamba(> 1,200 V) yokhala ndi kukana kutsika.

-

Kukhazikika kwa kutentha kwapamwamba(> 300 ° C) ndikuwongolera bwino kutentha.

-

Kuthamanga kwachangundi zotayika zotsika zosinthira, kuchepetsa kuziziritsa kwadongosolo komanso kukula kwa osinthira mphamvu.

4. Q: Ndi zolakwika ziti zomwe zimakhudza kukolola kwa SiC wafer ndi magwiridwe antchito?

A: Zowonongeka zazikulu mu zowotcha za SiC zimaphatikizapo ma micropipes, ma basal plane dislocation (BPDs), ndi zokanda pamwamba. Ma micropipes angayambitse kuwonongeka kwa chipangizo; BPDs kumawonjezera kukana pakapita nthawi; ndi kung'ung'udza pamwamba kumabweretsa kusweka kapena kusakula bwino kwa epitaxial. Kuwunika mozama komanso kuchepetsa zilema ndikofunikira kuti muwonjezere zokolola za SiC.

Nthawi yotumiza: Jun-30-2025