Kuyeretsa Konyowa (Kuyeretsa Konyowa) ndi imodzi mwamasitepe ofunikira pakupanga ma semiconductor, omwe cholinga chake ndi kuchotsa zonyansa zosiyanasiyana pamwamba pa chofufumitsa kuti zitsimikizire kuti njira zotsatila zitha kuchitika pamalo oyera.

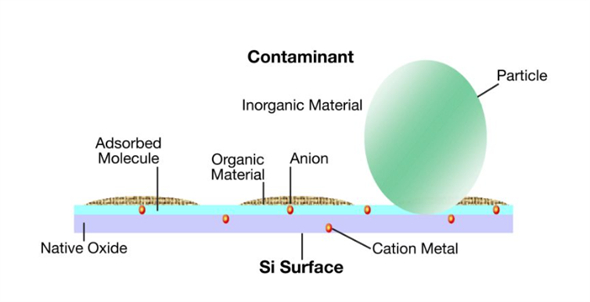

Pamene kukula kwa zida za semiconductor kukucheperachepera komanso zofunikira zakulondola zikuchulukirachulukira, kufunikira kwaukadaulo pakutsuka kwa mawafa kukukulirakulira. Ngakhale tinthu tating'ono kwambiri, zinthu zakuthupi, ayoni zitsulo, kapena zotsalira za oxide pamtunda wowotcha zimatha kukhudza kwambiri magwiridwe antchito a chipangizocho, zomwe zimasokoneza zokolola komanso kudalirika kwa zida za semiconductor.

Mfundo Zazikulu Zakutsuka Wafer

Pakatikati pa kuyeretsa kwa wafer ndikuchotsa bwino zowononga zosiyanasiyana kuchokera pamwamba pake kudzera m'thupi, mankhwala, ndi njira zina kuwonetsetsa kuti chovalacho chili ndi malo oyera oyenera kukonzedwanso.

Mtundu wa Kuyipitsidwa

Kukokera Kwakukulu pa Zida Zazida

| nkhani Kuipitsidwa | Zowonongeka zapatani

Kuwonongeka kwa ion implantation

Kuwonongeka kwa kuwonongeka kwa filimuyi

| |

| Kuwonongeka kwa Metallic | Zitsulo za Alkali | Kusakhazikika kwa MOS transistor

Kuwonongeka kwa filimu ya Gate oxide / kuwonongeka

|

| Zitsulo Zolemera | Kuchulukitsa kwa PN junction reverse leakage pano

Kuwonongeka kwa filimu ya Gate oxide

Ochepa chonyamulira moyo kuwonongeka

Oxide excitation layer defect generation

| |

| Kuwonongeka kwa Chemical | Zinthu Zachilengedwe | Kuwonongeka kwa filimu ya Gate oxide

Kusiyanasiyana kwa filimu ya CVD (nthawi zoyambitsa)

Kusiyana kwa makulidwe a filimu ya Thermal oxide (kuchuluka kwa okosijeni)

Kuwoneka kwa haze (wafer, lens, galasi, mask, reticle)

|

| Ma Dopants a Inorganic (B, P) | Kusintha kwa MOS transistor Vth

Si gawo lapansi komanso kukana kwakukulu kwa ma poly-silicon sheet resistance

| |

| Maziko a Inorganic (amines, ammonia) & Acids (SOx) | Kuwonongeka kwa chigamulo cha mankhwala amplified kukaniza

Kuwonongeka kwa tinthu tating'ono ndi chifunga chifukwa cha kupanga mchere

| |

| Mafilimu Achibadwidwe ndi Chemical Oxide Chifukwa cha Chinyezi, Mpweya | Kuwonjezeka kukana kukhudzana

Kuwonongeka kwa filimu ya Gate oxide / kuwonongeka

| |

Mwachindunji, zolinga za ndondomeko yoyeretsera wafer ndi monga:

Kuchotsa Tinthu ting'onoting'ono: Kugwiritsa ntchito njira zakuthupi kapena zamankhwala kuti muchotse tinthu tating'onoting'ono tating'onoting'ono. Tinthu tating'onoting'ono ndizovuta kwambiri kuchotsa chifukwa champhamvu yamagetsi yamagetsi pakati pawo ndi pamwamba pake, zomwe zimafunikira chithandizo chapadera.

Kuchotsa Zinthu Zachilengedwe: Zowonongeka za organic monga mafuta ndi zotsalira za photoresist zitha kumamatira pamwamba pake. Zowononga izi nthawi zambiri zimachotsedwa pogwiritsa ntchito ma oxidizing amphamvu kapena zosungunulira.

Kuchotsa kwa Metal Ion: Zotsalira za zitsulo zachitsulo pamtunda zimatha kusokoneza magwiridwe antchito amagetsi komanso kukhudza njira zotsatirira. Choncho, njira zothetsera mankhwala zimagwiritsidwa ntchito kuchotsa ma ions awa.

Kuchotsa Oxide: Njira zina zimafuna kuti pamwamba pake pasakhale ndi oxides, monga silicon oxide. Zikatero, zigawo za oxide zachilengedwe ziyenera kuchotsedwa panthawi yoyeretsa.

Vuto laukadaulo waukadaulo wotsuka zowotchera zagona pakuchotsa bwino zonyansa popanda kuwononga pamwamba pake, monga kupewa kukhwinyata pamwamba, dzimbiri, kapena kuwonongeka kwina.

2. Wafer Kuyeretsa Njira Flow

Njira yoyeretsera mawafa nthawi zambiri imakhala ndi masitepe angapo kuti zitsimikizire kuchotsedwa kwathunthu kwa zowononga ndikukwaniritsa malo oyera.

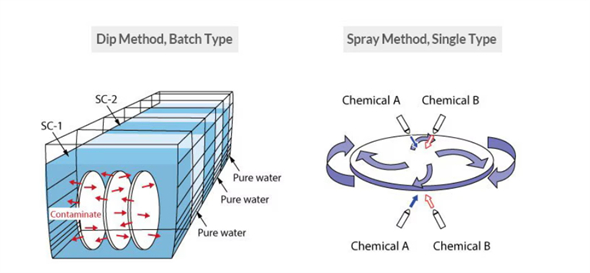

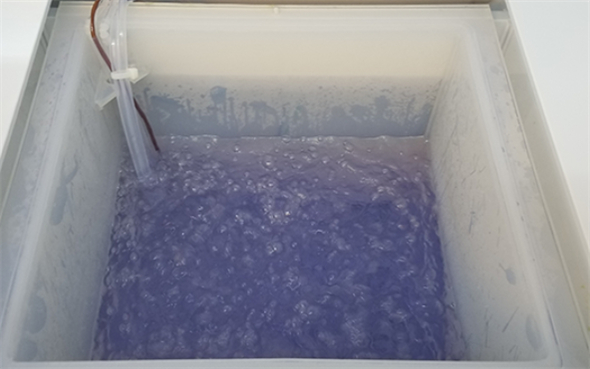

Chithunzi: Kufananiza Pakati pa Batch-Type ndi Single-Wafer Cleaning

Njira yoyeretsera wafer imakhala ndi izi:

1. Kuyeretsa (Pre-Clean)

Cholinga cha kuyeretsa chisanadze ndikuchotsa zonyansa zotayirira ndi tinthu tating'onoting'ono tating'onoting'ono, zomwe zimatheka kudzera m'madzi a deionized (DI Water) rinsing ndi akupanga kuyeretsa. Deionized madzi poyamba kuchotsa particles ndi kusungunuka zonyansa ku chophwanyika pamwamba, pamene akupanga kuyeretsa amagwiritsa cavitation zotsatira kuswa mgwirizano pakati pa particles ndi yopyapyala pamwamba, kuwapangitsa mosavuta dislodge.

2. Chemical Cleaning

Kuyeretsa Chemical ndi imodzi mwamasitepe ofunikira pakutsuka kwa wafer, pogwiritsa ntchito njira zamankhwala kuchotsa zinthu zakuthupi, ma ion achitsulo, ndi ma oxides pamtunda.

Kuchotsa Zinthu Zamoyo: Nthawi zambiri, acetone kapena ammonia/peroxide osakaniza (SC-1) amagwiritsidwa ntchito kusungunula ndi kutulutsa zowononga zamoyo. Chiyerekezo chodziwika bwino cha yankho la SC-1 ndi NH₄OH

₂O₂

₂O = 1:1:5, ndi kutentha kwa ntchito pafupifupi 20°C.

Kuchotsa Zitsulo za Ion: Nitric acid kapena hydrochloric acid/peroxide zosakaniza (SC-2) zimagwiritsidwa ntchito pochotsa ayoni achitsulo pamtunda. Chiyerekezo chodziwika bwino cha yankho la SC-2 ndi HCl

₂O₂

₂O = 1:1:6, kutentha kumasungidwa pafupifupi 80°C.

Kuchotsa Oxide: Munjira zina, kuchotsedwa kwa wosanjikiza wa oxide kumtunda kumafunika, komwe njira ya hydrofluoric acid (HF) imagwiritsidwa ntchito. Chiŵerengero chofanana cha HF yankho ndi HF

₂O = 1:50, ndipo itha kugwiritsidwa ntchito kutentha.

3. Final Clean

Pambuyo poyeretsa mankhwala, ma wafers nthawi zambiri amatha kuyeretsedwa komaliza kuti atsimikizire kuti palibe zotsalira za mankhwala zomwe zimatsalira pamwamba. Kuyeretsa komaliza makamaka kumagwiritsa ntchito madzi oyeretsedwa kuti azitsuka bwino. Kuphatikiza apo, kuyeretsa madzi a ozone (O₃/H₂O) kumagwiritsidwa ntchito kupititsa patsogolo zowononga zilizonse zomwe zatsala pamtunda.

4. Kuyanika

Zophika zotsukidwazo ziyenera kuumitsidwa mwachangu kuti tipewe ma watermark kapena kulumikizanso zowononga. Njira zowumitsa zodziwika bwino zimaphatikizapo kuyanika kwa spin ndi nitrogen purging. Yoyamba imachotsa chinyontho kuchokera pamwamba pake pozungulira mothamanga kwambiri, pamene yotsirizirayo imaonetsetsa kuti kuyanika kotheratu pouzira mpweya wouma wa nayitrogeni pamwamba pake.

Zoipitsa

Dzina la Njira Yoyeretsera

Kufotokozera kwa Chemical Mix

Mankhwala

| Tinthu ting'onoting'ono | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI madzi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI madzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| Zitsulo (osati mkuwa) | SC-2 (HPM) | Hydrochloric acid/hydrogen peroxide/DI madzi | HCl/H2O2/H2O1:1:6; 85°C |

| Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI madzi | H2SO4/H2O2/H2O3-4:1; 90°C | |

| DHF | Dilute hydrofluoric acid/DI madzi (sachotsa mkuwa) | HF/H2O1:50 | |

| Zachilengedwe | Piranha (SPM) | Sulfuric acid/hydrogen peroxide/DI madzi | H2SO4/H2O2/H2O 3-4:1; 90°C |

| SC-1 (APM) | Ammonium hydroxide / hydrogen peroxide / DI madzi | NH4OH/H2O2/H2O 1:4:20; 80°C | |

| DIO3 | Ozone m'madzi a de-ionized | O3/H2O Zosakaniza Zokometsera | |

| Native oxide | DHF | Chepetsani hydrofluoric acid/DI madzi | HF/H2O 1:100 |

| BHF | Kuphatikizika kwa hydrofluoric acid | NH4F/HF/H2O |

3. Common Wafer Kuyeretsa Njira

1. Njira Yoyeretsera RCA

Njira yoyeretsera ya RCA ndi imodzi mwazinthu zapamwamba kwambiri zotsuka zowotchera m'mafakitale a semiconductor, opangidwa ndi RCA Corporation zaka 40 zapitazo. Njirayi imagwiritsidwa ntchito pochotsa zonyansa za organic ndi zitsulo za ion zachitsulo ndipo zimatha kumalizidwa munjira ziwiri: SC-1 (Standard Clean 1) ndi SC-2 (Standard Clean 2).

SC-1 Kuyeretsa: Njira imeneyi imagwiritsidwa ntchito makamaka kuchotsa zowononga ndi tinthu tating'onoting'ono. Njira yothetsera vutoli ndi kusakaniza kwa ammonia, hydrogen peroxide, ndi madzi, zomwe zimapanga wosanjikiza wopyapyala wa silicon oxide pamwamba pake.

SC-2 Kuyeretsa: Njira imeneyi imagwiritsidwa ntchito pochotsa zowononga ayoni zitsulo, pogwiritsa ntchito osakaniza a hydrochloric acid, hydrogen peroxide, ndi madzi. Zimasiya kagawo kakang'ono kakang'ono pamwamba pa kabati kuti tipewe kuipitsidwanso.

2. Njira Yoyeretsera Piranha (Piranha Etch Clean)

Njira yoyeretsera Piranha ndi njira yabwino kwambiri yochotsera zinthu zachilengedwe, pogwiritsa ntchito sulfuric acid ndi hydrogen peroxide, makamaka mu chiŵerengero cha 3:1 kapena 4:1. Chifukwa champhamvu kwambiri ya okosijeni ya yankho ili, imatha kuchotsa zinthu zambiri zachilengedwe komanso zowononga zowuma. Njirayi imafunika kuwongolera kwambiri zinthu, makamaka pankhani ya kutentha ndi ndende, kupewa kuwononga mtandawo.

Akupanga kuyeretsa amagwiritsa ntchito cavitation zotsatira kwaiye mkulu-pafupipafupi phokoso mafunde mu madzi kuchotsa zodetsa pa yopyapyala pamwamba. Poyerekeza ndi chikhalidwe akupanga kuyeretsa, megasonic kuyeretsa umagwira ntchito pafupipafupi kwambiri, kupangitsa kuti kuchotsedwa kothandiza kwambiri kwa tinthu tating'onoting'ono tating'onoting'ono popanda kuwononga pamwamba.

4. Kuyeretsa Ozoni

Ukadaulo wotsuka wa ozoni umagwiritsa ntchito mphamvu ya okosijeni ya ozoni kuti iwononge ndikuchotsa zowononga zamoyo kuchokera pamwamba pake, ndikuzisintha kukhala carbon dioxide ndi madzi opanda vuto. Njira imeneyi sikutanthauza ntchito mtengo reagents mankhwala ndi kuchititsa zochepa kuipitsa chilengedwe, kupanga izo akutulukira luso m'munda wa yopyapyala kuyeretsa.

4. Wafer Kuyeretsa Njira Zida

Kuwonetsetsa kuti njira zoyeretsera zowotchera zikuyenda bwino komanso zotetezeka, zida zosiyanasiyana zoyeretsera zapamwamba zimagwiritsidwa ntchito popanga semiconductor. Mitundu yayikulu ndi:

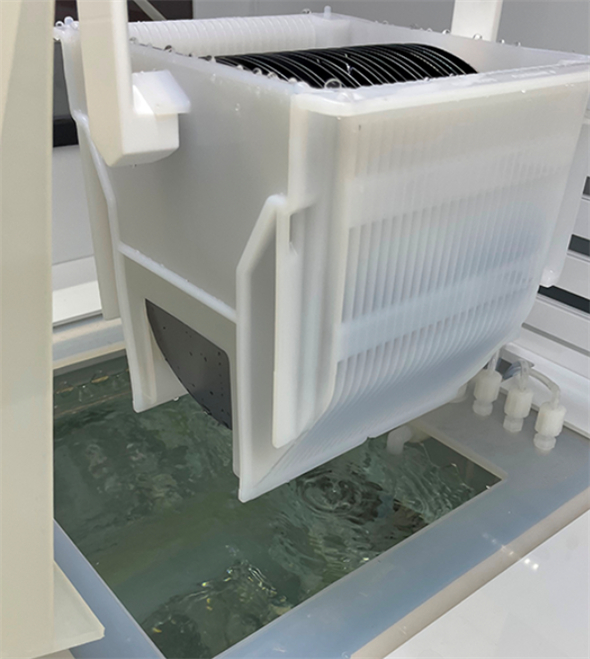

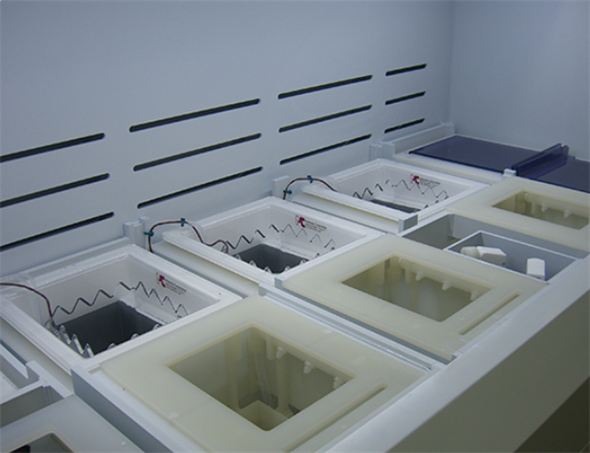

1. Zida Zonyowa Zoyeretsera

Zida zoyeretsera zonyowa zimaphatikizapo akasinja omiza osiyanasiyana, akasinja oyeretsera akupanga, ndi zowumitsira ma spin. Zipangizozi zimaphatikiza mphamvu zamakina ndi ma reagents amadzimadzi kuti achotse zodetsa pamtunda. Matanki omiza amakhala ndi zida zowongolera kutentha kuti zitsimikizire kukhazikika komanso kuchita bwino kwa mayankho amankhwala.

2. Dry Cleaning Zida

Zipangizo zoyeretsera zowuma zimaphatikizanso zotsukira plasma, zomwe zimagwiritsa ntchito tinthu tambiri ta plasma kuti tigwire ndikuchotsa zotsalira pamwamba pake. Kuyeretsa kwa plasma ndikoyenera makamaka pamachitidwe omwe amafunikira kusunga umphumphu pamwamba popanda kubweretsa zotsalira za mankhwala.

3. Makina Odzitchinjiriza Oyeretsa

Ndikukula kosalekeza kwa kupanga semiconductor, makina otsuka okha ndi omwe akhala chisankho chomwe amakonda pakuyeretsa kwakukulu. Makinawa nthawi zambiri amakhala ndi makina osinthira okha, makina oyeretsera akasinja ambiri, komanso makina owongolera olondola kuti awonetsetse kuti chophika chilichonse chizikhala choyeretsera.

5. Zochitika Zam'tsogolo

Pamene zida za semiconductor zikuchulukirachulukira, ukadaulo woyeretsa wawafa ukupita kunjira zothetsera bwino komanso zosamalira chilengedwe. Ukadaulo woyeretsa m'tsogolo udzayang'ana pa:

Sub-nanometer Particle Removal: Ukadaulo wotsuka womwe ulipo ungathe kuthana ndi tinthu tating'onoting'ono ta nanometer, koma ndikuchepetsanso kukula kwa chipangizocho, kuchotsa tinthu tating'onoting'ono kudzakhala vuto latsopano.

Kuyeretsa kobiriwira komanso kochezeka: Kuchepetsa kugwiritsa ntchito mankhwala owononga chilengedwe ndikukhazikitsa njira zoyeretsera zachilengedwe, monga kuyeretsa kwa ozoni ndi kuyeretsa kwa megasonic, zidzakhala zofunika kwambiri.

Miyezo Yapamwamba ya Automation ndi Intelligence: Makina anzeru amathandizira kuyang'anira nthawi yeniyeni ndikusintha magawo osiyanasiyana panthawi yoyeretsa, kupititsa patsogolo kuyeretsa bwino komanso kupanga bwino.

Ukadaulo woyeretsa wawafa, monga gawo lofunikira popanga ma semiconductor, umagwira ntchito yofunika kwambiri pakuwonetsetsa kuti malo ozungulira ayera panjira zotsatila. Kuphatikizika kwa njira zosiyanasiyana zoyeretsera kumachotsa bwino zonyansa, ndikupereka gawo lapansi loyera pamasitepe otsatirawa. Pomwe ukadaulo ukupita patsogolo, njira zoyeretsera zipitilizidwa kukonzedwa kuti zikwaniritse zofunikira pakulondola kwambiri komanso kutsika kwachilema pakupanga semiconductor.

Nthawi yotumiza: Oct-08-2024