Silicon carbide (SiC) sikuti ndi ukadaulo wofunikira pachitetezo cha dziko komanso chinthu chofunikira kwambiri m'mafakitale oyendetsa magalimoto padziko lonse lapansi ndi mphamvu. Monga gawo loyamba lofunika kwambiri mu SiC single-crystal processing, kuwotcha wafer kumatsimikizira mwachindunji mtundu wa kupatulira kotsatira ndi kupukuta. Njira zachikale zodula nthawi zambiri zimabweretsa ming'alu ya pamwamba ndi pansi, kuchulukitsa mitengo yosweka komanso ndalama zopangira. Chifukwa chake, kuwongolera kuwonongeka kwa ming'alu ndikofunikira pakupititsa patsogolo kupanga zida za SiC.

Pakadali pano, kudula kwa SiC ingot kumakumana ndi zovuta zazikulu ziwiri:

- Kutayika kwakukulu kwazinthu muzocheka zamawaya ambiri:Kuuma koopsa kwa SiC komanso kulimba mtima kumapangitsa kuti ikhale yokhazikika komanso yosweka panthawi yodula, kugaya, ndi kupukuta. Malinga ndi deta ya Infineon, macheka amtundu wa diamondi-resin-bonded multi-waya amapindula ndi 50% yokha yogwiritsidwa ntchito podula, ndi kutaya kwathunthu kwa wafer imodzi kufika ~ 250 μm pambuyo popukuta, kusiya zinthu zochepa zomwe zingagwiritsidwe ntchito.

- Kuchepa kwa magwiridwe antchito komanso nthawi yayitali yopanga:Ziwerengero zopanga zapadziko lonse lapansi zikuwonetsa kuti kupanga zowotcha 10,000 pogwiritsa ntchito mawola 24 mosalekeza pamawaya ambiri kumatenga ~ masiku 273. Njirayi imafuna zida zambiri ndi zogwiritsira ntchito pamene imapanga pamwamba pa roughness ndi kuipitsa (fumbi, madzi onyansa).

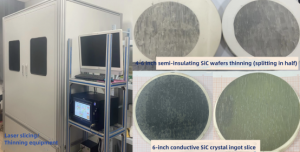

Pofuna kuthana ndi mavutowa, gulu la Professor Xiu Xiangqian ku yunivesite ya Nanjing lapanga zida zodula kwambiri za laser za SiC, zomwe zimagwiritsa ntchito ukadaulo wa laser wachangu kwambiri kuti uchepetse kuwonongeka komanso kukulitsa zokolola. Kwa ingot ya SiC ya 20-mm, ukadaulo uwu umachulukitsa zokolola zawafesi kuyerekeza ndi macheka achikale. Kuphatikiza apo, zowotcherera zokhala ndi laser zimawonetsa kufananiza kwa geometric, zomwe zimathandiza kuchepetsa makulidwe mpaka 200 μm pa wafer ndikuwonjezera kutulutsa.

Ubwino waukulu:

- Kumalizidwa kwa R&D pazida zazikulu zofananira, zovomerezeka podula ma SiC ma wafer a 4-6-inch semi-insulating ndi ma 6-inch conductive SiC ingots.

- 8-inch ingot slicing ikutsimikiziridwa.

- Nthawi yayifupi yodula, kutulutsa kwakukulu kwapachaka, ndi> 50% kuwongolera zokolola.

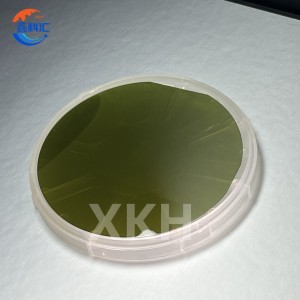

Gawo la XKH la SiC la mtundu wa 4H-N

Kuthekera kwa Msika:

Zipangizozi zatsala pang'ono kukhala njira yothetsera 8-inch SiC ingot slicing, yomwe pano ikulamulidwa ndi katundu wa ku Japan omwe ali ndi ndalama zambiri komanso zoletsa kutumiza kunja. Kufunika kwapakhomo kwa zida zowotchera / kuwonda ndi laser kumaposa mayunitsi 1,000, komabe palibe njira zina zopangira zopangidwa ndi China zomwe zilipo. Ukadaulo waku yunivesite ya Nanjing uli ndi phindu lalikulu pamsika komanso kuthekera kwachuma.

Kugwirizana kwazinthu zambiri:

Kupitilira SiC, zidazi zimathandizira kukonza kwa laser gallium nitride (GaN), aluminium oxide (Al₂O₃), ndi diamondi, kukulitsa ntchito zake zamafakitale.

Posintha masinthidwe ophatikizika a SiC, lusoli lithana ndi zovuta zopanga ma semiconductor pomwe zikugwirizana ndi zomwe zikuchitika padziko lonse lapansi pakuchita bwino kwambiri, zogwiritsa ntchito mphamvu.

Mapeto

Monga mtsogoleri wamakampani opanga silicon carbide (SiC) gawo lapansi, XKH imagwira ntchito popereka magawo a SiC 2-12-inch (kuphatikizapo 4H-N / SEMI-mtundu, 4H / 6H / 3C-mtundu) ogwirizana ndi kukula kwakukulu monga magalimoto atsopano amphamvu (NEVs, 5G) kusungirako mphamvu, 5G) Pogwiritsa ntchito umisiri wodula kwambiri wochepa kwambiri, komanso umisiri wolondola kwambiri, takwanitsa kupanga magawo 8-inchi komanso kuchita bwino paukadaulo wakukula kwa SiC crystal wa 12-inch, kuchepetsa kwambiri mtengo wa chipangizo chilichonse. Kupita patsogolo, tipitiliza kukhathamiritsa ma laser a ingot-level, ndi njira zanzeru zowongolera kupsinjika, kuti tikweze zokolola za mainchesi 12 mpaka pamipikisano yapadziko lonse lapansi, kupatsa mphamvu makampani apakhomo a SiC kuti athetse maulamuliro apadziko lonse lapansi ndikufulumizitsa ntchito zomwe zingachitike m'magawo apamwamba monga zida zamagetsi zamagetsi za AI.

Gawo la XKH la SiC la mtundu wa 4H-N

Nthawi yotumiza: Aug-15-2025