Kuyambira m'ma 1980, kachulukidwe kaphatikizidwe ka mabwalo apakompyuta akuwonjezeka pachaka cha 1.5 × kapena mwachangu. Kuphatikizana kwapamwamba kumabweretsa kuchulukirachulukira kwapano komanso kutulutsa kutentha pakugwira ntchito.Ngati sichitayidwa bwino, kutentha kumeneku kungayambitse kulephera kwa kutentha ndi kuchepetsa moyo wa zipangizo zamagetsi.

Kuti akwaniritse zofuna zomwe zikuchulukirachulukira za kasamalidwe ka matenthedwe, zida zapamwamba zamagetsi zamagetsi zokhala ndi matenthedwe apamwamba akufufuzidwa mozama ndikuwongoleredwa.

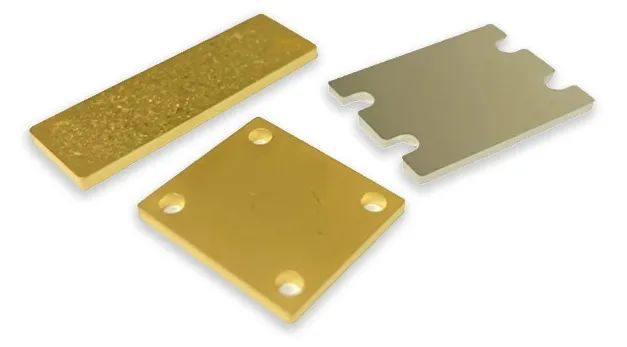

Zida za diamondi / mkuwa

01 Diamondi ndi Copper

Zida zopangira zachikhalidwe zimaphatikizapo zitsulo, mapulasitiki, zitsulo, ndi ma alloys awo. Ma Ceramics ngati BeO ndi AlN amawonetsa ma CTE ofananira ndi ma semiconductors, kukhazikika kwamankhwala abwino, komanso kuwongolera kwamafuta pang'ono. Komabe, ma processing awo ovuta, kukwera mtengo (makamaka poizoni BeO), ndi brittleness kuchepetsa ntchito. Kupaka kwa pulasitiki kumapereka mtengo wotsika, kulemera kopepuka, ndi kutsekereza koma kumakhala ndi kusakhazikika kwamafuta komanso kutentha kwambiri. Zitsulo zoyera (Cu, Ag, Al) zimakhala ndi matenthedwe apamwamba kwambiri koma CTE yochulukirapo, pomwe ma alloys (Cu-W, Cu-Mo) amasokoneza magwiridwe antchito amafuta. Chifukwa chake, zida zonyamula zatsopano zosinthira matenthedwe apamwamba komanso CTE yabwino kwambiri ndizofunikira mwachangu.

| Kulimbikitsa | Thermal Conductivity (W/(m·K)) | CTE (×10⁻⁶/℃) | Kachulukidwe (g/cm³) |

| Diamondi | 700-2000 | 0.9–1.7 | 3.52 |

| Zithunzi za BeO | 300 | 4.1 | 3.01 |

| Zithunzi za AlN | 150-250 | 2.69 | 3.26 |

| Zithunzi za SiC | 80-200 | 4.0 | 3.21 |

| B₄C particles | 29–67 | 4.4 | 2.52 |

| Boron fiber | 40 | ~5.0 | 2.6 |

| Zithunzi za TiC | 40 | 7.4 | 4.92 |

| Al₂O₃ particles | 20–40 | 4.4 | 3.98 |

| Ndevu za SiC | 32 | 3.4 | - |

| Si₃N₄ particles | 28 | 1.44 | 3.18 |

| TiB₂ particles | 25 | 4.6 | 4.5 |

| SiO₂ particles | 1.4 | <1.0 | 2.65 |

Diamondi, zinthu zachilengedwe zolimba kwambiri (Mohs 10), zilinso ndi zapaderakutentha kwapakati (200–2200 W/(m·K)).

Diamondi micro-ufa

Mkuwa, ndi mkulu matenthedwe/magetsi conductivity (401 W/(m·K)), ductility, ndi kuwononga ndalama, amagwiritsidwa ntchito kwambiri mu ICs.

Kuphatikiza zinthu izi,diamondi/mkuwa (Dia/Cu) zophatikiza-ndi Cu monga matrix ndi diamondi monga chilimbikitso-zikutuluka ngati zipangizo zoyendetsera kutentha za m'badwo wotsatira.

02 Njira Zazikulu Zopangira

Njira zodziwika bwino zopangira diamondi / mkuwa ndi monga: zitsulo za ufa, kutentha kwambiri komanso kupanikizika kwambiri, kusungunula kumizidwa, kutulutsa madzi a plasma, kupopera mbewu mankhwalawa mozizira, ndi zina zambiri.

Kuyerekeza njira zosiyanasiyana zokonzekera, njira ndi katundu wamagulu amodzi a diamondi / mkuwa

| Parameter | Powder Metallurgy | Vacuum Hot-Pressing | Spark Plasma Sintering (SPS) | High-Pressure High-Temperature (HPHT) | Cold Spray Deposition | Sungunulani Infiltration |

| Mtundu wa Diamondi | MBD8 | HFD-D | MBD8 | MBD4 | PDA | MBD8/HHD |

| Matrix | 99.8% Cu ufa | 99.9% electrolytic Cu ufa | 99.9% Cu ufa | Aloyi/pure Cu ufa | Pure Cu powder | Pure Cu kuchuluka / ndodo |

| Kusintha kwa Mawonekedwe | - | - | - | B, Ti, Si, Cr, Zr, W, Mo | - | - |

| Kukula kwa Tinthu (μm) | 100 | 106–125 | 100-400 | 20-200 | 35-200 | 50-400 |

| Gawo la Voliyumu (%) | 20-60 | 40-60 | 35–60 | 60-90 | 20–40 | 60-65 |

| Kutentha (°C) | 900 | 800-1050 | 880-950 | 1100-1300 | 350 | 1100-1300 |

| Pressure (MPa) | 110 | 70 | 40-50 | 8000 | 3 | 1–4 |

| Nthawi (mphindi) | 60 | 60-180 | 20 | 6–10 | - | 5–30 |

| Kuchulukana Kwambiri (%) | 98.5 | 99.2–99.7 | - | - | - | 99.4–99.7 |

| Kachitidwe | ||||||

| Mulingo Wokwanira Wotenthetsera (W/(m·K)) | 305 | 536 | 687 | 907 | - | 943 |

Njira zodziwika bwino za Dia/Cu zimaphatikizapo:

(1)Powder Metallurgy

Mafuta osakanikirana a diamondi/Cu amaphatikizidwa ndikuwotchedwa. Ngakhale kuti ndi yotsika mtengo komanso yosavuta, njira iyi imapereka kachulukidwe kochepa, ma microstructures osakanikirana, ndi miyeso yocheperako.

Sunit unit

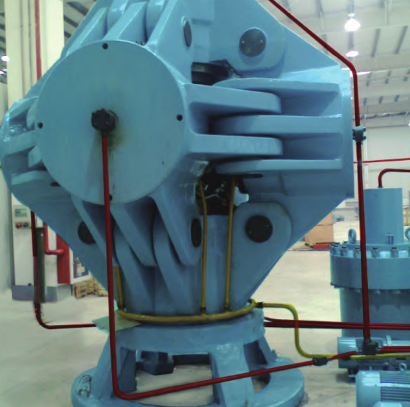

(1)High-Pressure High-Temperature (HPHT)

Pogwiritsa ntchito makina osindikizira amitundu yambiri, Cu yosungunuka imalowa m'mabwalo a diamondi pansi pamikhalidwe yovuta kwambiri, ndikupanga zophatikiza zowirira. Komabe, HPHT imafuna nkhungu zodula ndipo ndiyosayenera kupanga zazikulu.

Cubic press

(1)Sungunulani Infiltration

Molten Cu imalowa mu ma preforms a diamondi kudzera mothandizidwa ndi kukakamiza kapena kulowetsedwa koyendetsedwa ndi capillary. Zotsatira zake zimakwaniritsa>446 W/(m·K) matenthedwe matenthedwe.

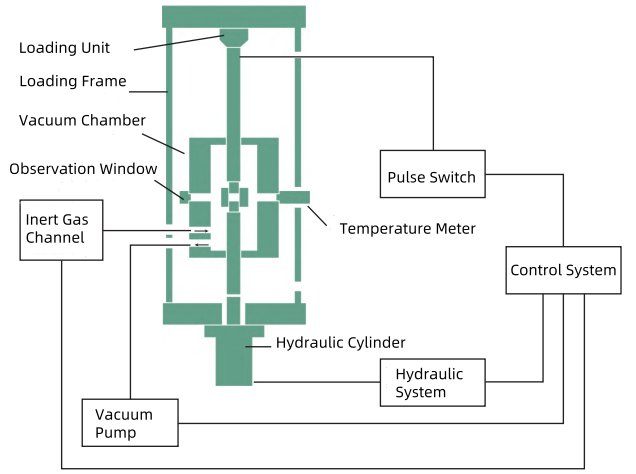

(2)Spark Plasma Sintering (SPS)

Pulsed panopa mofulumira siters osakaniza ufa pansi pampanipani. Ngakhale imagwira ntchito bwino, magwiridwe antchito a SPS amatsitsa magawo a diamondi> 65 vol%.

Chithunzi chojambula cha discharge plasma sintering system

(5) Kuyika kwa Cold Spray

Ufa umafulumizitsidwa ndikuyikidwa pagawo. Njira yoyambira iyi imakumana ndi zovuta pakuwongolera komaliza komanso kutsimikizira magwiridwe antchito.

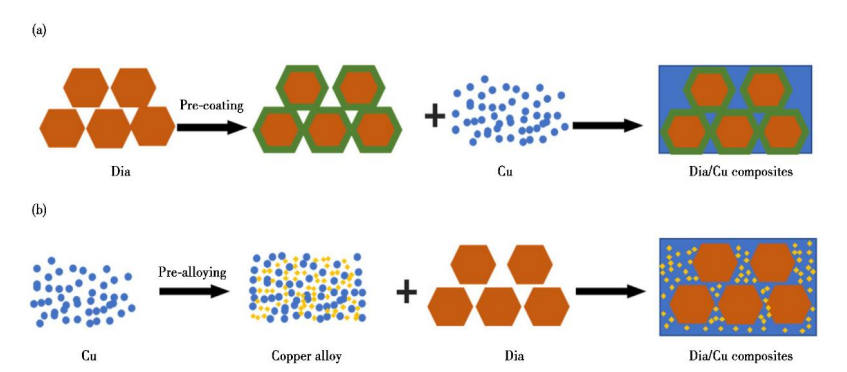

03 Kusintha kwa Chiyankhulo

Pokonzekera zida zophatikizika, kunyowetsa kwapakati pakati pa zigawo ndizofunikira kwambiri pakupanga kophatikizana ndi chinthu chofunikira chomwe chimakhudza mawonekedwe a mawonekedwe ndi mawonekedwe olumikizirana. The sanali kunyowetsa chikhalidwe pa mawonekedwe pakati diamondi ndi Cu kumabweretsa kwambiri mawonekedwe matenthedwe kukana. Chifukwa chake, ndikofunikira kwambiri kuchita kafukufuku wosintha pamawonekedwe apakati paziwirizi kudzera munjira zosiyanasiyana zamaukadaulo. Pakalipano, pali njira ziwiri zowonjezeretsa vuto la mawonekedwe pakati pa diamondi ndi Cu masanjidwewo: (1) Kuwongolera pamwamba pa diamondi; (2) Alloying mankhwala a masanjidwewo mkuwa.

Chithunzi chosinthira: (a) Kuyika pachindunji pamwamba pa diamondi; (b) Matrix alloying

(1) Kusintha pamwamba pa diamondi

Kuyika zinthu zogwira ntchito monga Mo, Ti, W ndi Cr pamwamba pa gawo lolimbikitsa kumatha kusintha mawonekedwe a diamondi, potero kumapangitsa kuti matenthedwe ake azitentha. Sintering imatha kupangitsa kuti zinthu zomwe zili pamwambapa zigwirizane ndi kaboni pamwamba pa ufa wa diamondi kuti apange gawo la kusintha kwa carbide. Izi zimakulitsa kunyowa pakati pa diamondi ndi maziko achitsulo, ndipo zokutira zimatha kulepheretsa mapangidwe a diamondi kuti asasinthe pa kutentha kwakukulu.

(2) Kuphatikizika kwa matrix a mkuwa

Pamaso pa gulu processing wa zipangizo, chisanadze alloying mankhwala ikuchitika pa zitsulo mkuwa, amene angapange zipangizo gulu ndi ambiri mkulu matenthedwe madutsidwe. Doping yogwira zinthu mu masanjidwewo amkuwa sangangochepetsa bwino kunyowa Kongolera pakati pa diamondi ndi mkuwa, komanso kupanga wosanjikiza wa carbide womwe umakhala wosungunuka m'masanjidwe amkuwa pamawonekedwe a diamondi / Cu pambuyo pa zomwe zimachitika. Mwanjira imeneyi, mipata yambiri yomwe ilipo pamawonekedwe azinthu amasinthidwa ndikudzazidwa, potero kuwongolera matenthedwe.

04 Mapeto

Zida zopakira wamba zimasowa pakuwongolera kutentha kuchokera ku tchipisi tapamwamba. Zophatikizira za Dia/Cu, zokhala ndi CTE yosinthika komanso matenthedwe apamwamba kwambiri, zimayimira njira yosinthira yamagetsi am'badwo wotsatira.

Monga mabizinesi apamwamba kwambiri ophatikiza malonda ndi malonda, XKH imayang'ana kwambiri kafukufuku ndi chitukuko ndi kupanga zida za diamondi / zamkuwa komanso zida zachitsulo zogwira ntchito kwambiri monga SiC/Al ndi Gr/Cu, zomwe zimapereka njira zatsopano zoyendetsera matenthedwe ndi matenthedwe opitilira 900W/(m·K) pagawo lamagetsi, gawo lamagetsi apamlengalenga.

XKH's Diamondi copper clad laminate composite zakuthupi:

Nthawi yotumiza: May-12-2025