Zida za ceramic za High-purity silicon carbide (SiC) zakhala zikugwiritsidwa ntchito ngati zida zofunika kwambiri pamagulu opangira ma semiconductor, mlengalenga, ndi mafakitale amafuta chifukwa cha kutenthetsa kwawo kwapadera, kukhazikika kwamankhwala, komanso mphamvu zamakina. Pakuchulukirachulukira kwa zida za ceramic zogwira ntchito kwambiri, zosaipitsa pang'ono, kupanga matekinoloje okonzekera bwino komanso owopsa a zida zadothi za SiC zoyera kwambiri zakhala gawo lofufuza padziko lonse lapansi. Pepalali likuwunikiranso njira zazikulu zokonzekera zoumba za SiC zoyera kwambiri, kuphatikiza recrystallization sintering, pressureless sintering (PS), hot pressing (HP), spark plasma sintering (SPS), and additive production (AM), ndikugogomezera kukambirana za sintering, magawo ofunikira, katundu wakuthupi, ndi zovuta zomwe zilipo panjira iliyonse.

Kugwiritsa ntchito zida za ceramic za SiC m'magawo ankhondo ndi mainjiniya

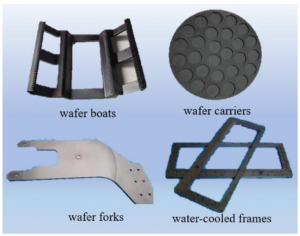

Pakadali pano, zida za ceramic zoyeretsedwa kwambiri za SiC zimagwiritsidwa ntchito kwambiri pazida zopangira silicon wafer, zomwe zimagwira ntchito zazikulu monga makutidwe ndi okosijeni, lithography, etching, ndi ion implantation. Ndi kupita patsogolo kwa ukadaulo wawafer, kukula kwa zowotcha zakhala chinthu chofunikira kwambiri. Kukula kwake komweko komweko ndi 300 mm, kukwaniritsa bwino pakati pa mtengo ndi mphamvu yopangira. Komabe, motsogozedwa ndi Lamulo la Moore, kupanga kwakukulu kwa zowotcha 450 mm kuli kale pandandanda. Zophika zazikuluzikulu nthawi zambiri zimafunikira mphamvu zapamwamba kuti zithe kumenyedwa ndi kupindika, kupititsa patsogolo kufunikira kwa zinthu zazikuluzikulu, zamphamvu kwambiri, zoyera kwambiri za SiC ceramic. M'zaka zaposachedwa, kupanga zowonjezera (kusindikiza kwa 3D), monga teknoloji yofulumira ya prototyping yomwe imasowa nkhungu, yawonetsa kuthekera kwakukulu pakupanga zigawo za ceramic za SiC za ceramic chifukwa cha mapangidwe ake-ndi-wosanjikiza ndi luso lotha kusintha, kukopa chidwi cha anthu ambiri.

Pepalali lisanthula mwadongosolo njira zisanu zokonzekerera zoyimilira za ceramics za SiC zoyera kwambiri - recrystallization sintering, sinteringless sintering, hot pressing, spark plasma sintering, and additive production - molunjika pamakina awo a sintering, njira zokhathamiritsa, magwiridwe antchito azinthu, komanso momwe angagwiritsire ntchito mafakitale.

Zofunika kwambiri za silicon carbide zopangira

I. Recrystallization Sintering

Recrystallized silicon carbide (RSiC) ndi chinthu choyera kwambiri cha SiC chomwe chimakonzedwa popanda zithandizo za sintering pa kutentha kwakukulu kwa 2100-2500 ° C. Chiyambireni Fredriksson kupeza chodabwitsa cha recrystallization kumapeto kwa zaka za zana la 19, RSiC yatenga chidwi kwambiri chifukwa cha malire ake oyera komanso kusowa kwa magawo agalasi ndi zonyansa. Pakutentha kwambiri, SiC imawonetsa kupanikizika kwa nthunzi wochuluka, ndipo njira yake yosungiramo madzi imagwiritsa ntchito njira yochepetsera mpweya: njere zabwino zimasanduka nthunzi ndikuyikanso pamalo anjere zazikulu, kulimbikitsa kukula kwa khosi ndi kugwirizana kwachindunji pakati pa njere, potero kumawonjezera mphamvu zakuthupi.

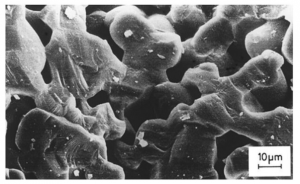

Mu 1990, Kriegesmann anakonza RSiC ndi kachulukidwe wachibale wa 79.1% pogwiritsa ntchito slip casting pa 2200 ° C, ndi gawo laling'ono lomwe likuwonetsa mawonekedwe ang'onoang'ono opangidwa ndi njere zolimba ndi pores. Pambuyo pake, Yi et al. adagwiritsa ntchito kuponyera kwa gel osakaniza kupanga matupi obiriwira ndikuwayika pa 2450 ° C, kupeza zoumba za RSiC zokhala ndi mphamvu zambiri za 2.53 g/cm³ ndi mphamvu yopindika ya 55.4 MPa.

Kuphulika kwa SEM pamwamba pa RSiC

Poyerekeza ndi SiC wandiweyani, RSiC ili ndi kachulukidwe kakang'ono (pafupifupi 2.5 g/cm³) komanso pafupifupi 20% kutseguka kotseguka, kumachepetsa magwiridwe ake pamapulogalamu amphamvu kwambiri. Chifukwa chake, kukonza kachulukidwe ndi makina a RSiC kwakhala chinthu chofunikira kwambiri pakufufuza. Sung et al. akufuna kulowa mkati mwa silicon yosungunuka mu carbon / β-SiC yosakaniza compacts ndi recrystallizing pa 2200 ° C, bwinobwino kumanga dongosolo network wopangidwa α-SiC mbewu coarse. Zotsatira zake za RSiC zidafikira kuchulukira kwa 2.7 g/cm³ ndi mphamvu yosunthika ya 134 MPa, kukhalabe okhazikika pamakina kutentha kwambiri.

Kuti muwonjezere kachulukidwe, Guo et al. ukadaulo wolowetsa polima ndi pyrolysis (PIP) pazochizira zingapo za RSiC. Pogwiritsa ntchito ma PCS/xylene solutions ndi SiC/PCS/xylene slurries monga olowera, pambuyo pa 3-6 PIP cycles, kachulukidwe ka RSiC adakula kwambiri (mpaka 2.90 g/cm³), pamodzi ndi mphamvu yake yosinthika. Kuphatikiza apo, adakonza njira yophatikizira PIP ndi recrystallization: pyrolysis pa 1400 ° C ndikutsatiridwa ndi recrystallization pa 2400 ° C, kuchotsa bwino zotsekeka ndi kuchepetsa porosity. Zinthu zomaliza za RSiC zidafikira 2.99 g/cm³ komanso mphamvu yosunthika ya 162.3 MPa, kuwonetsa magwiridwe antchito apamwamba kwambiri.

SEM zithunzi za chisinthiko microstructure wa opukutidwa RSiC pambuyo polima impregnation ndi pyrolysis (PIP) -recrystallization mkombero: Koyamba RSiC (A), pambuyo woyamba PIP-recrystallization mkombero (B), ndipo pambuyo mkombero wachitatu (C)

II. Pressureless Sintering

Zoumba za silicon carbide (SiC) zokhala ndi Pressureless-sintered silicon carbide (SiC) nthawi zambiri zimakonzedwa pogwiritsa ntchito chiyero chapamwamba, ultrafine SiC ufa ngati zopangira, zokhala ndi zida zocheperako zowonjezedwa, ndikuyikidwa mumlengalenga kapena vacuum pa 1800-2150 ° C. Njirayi ndi yoyenera kupanga zigawo zazikuluzikulu ndi zovuta zowonongeka za ceramic. Komabe, popeza SiC imakhala yomangika kwambiri, chigawo chake chodziyimira pawokha ndichotsika kwambiri, zomwe zimapangitsa kuti kukanika kukhale kovuta popanda zothandizira.

Kutengera sintering limagwirira, pressureless sintering akhoza kugawidwa m'magulu awiri: pressureless liquid-phase sintering (PLS-SiC) ndi pressureless solid-state sintering (PSS-SiC).

1.1 PLS-SiC (Liquid-Phase Sintering)

PLS-SiC nthawi zambiri imayikidwa pansi pa 2000 ° C powonjezera pafupifupi 10 wt.% ya eutectic sintering aids (monga Al₂O₃, CaO, MgO, TiO₂, ndi osowa-earth oxides RE₂O₃) kuti apange gawo lamadzimadzi, kulimbikitsa kufalikira kwa tinthu tating'onoting'ono tomwe timatulutsa timadzi tambirimbiri. Njirayi ndi yoyenera pazitsulo za SiC zamafakitale, koma sipanakhalepo malipoti a SiC yoyera kwambiri yomwe imapezeka kudzera mu sintering yamadzimadzi.

1.2 PSS-SiC (Solid-State Sintering)

PSS-SiC imakhudza kulimba kwa dziko pa kutentha pamwamba pa 2000 ° C ndi pafupifupi 1 wt.% ya zowonjezera. Njirayi imadalira makamaka kufalikira kwa atomiki ndi kukonzanso kwambewu komwe kumayendetsedwa ndi kutentha kwambiri kuti kuchepetsa mphamvu zapamtunda ndikukwaniritsa kachulukidwe. Dongosolo la BC (boron-carbon) ndilophatikizira wamba, lomwe limatha kuchepetsa mphamvu zamalire ambewu ndikuchotsa SiO₂ kumtunda wa SiC. Komabe, zowonjezera zachikhalidwe za BC nthawi zambiri zimabweretsa zonyansa zotsalira, kuchepetsa chiyero cha SiC.

Mwa kulamulira zowonjezera zowonjezera (B 0.4 wt.%, C 1.8 wt.%) ndi sintering pa 2150 ° C kwa maola 0.5, zoyera za SiC ceramics zoyera za 99.6 wt.% ndi kuchuluka kwa 98.4% kunapezedwa. Mipangidwe yaying'ono idawonetsa njere zam'mbali (zina zopitilira 450 µm m'litali), zokhala ndi timabowo tating'ono pamalire a tirigu ndi tinthu tating'ono ta graphite mkati mwa njere. Zida za ceramic zimasonyeza mphamvu yosinthika ya 443 ± 27 MPa, modulus yotanuka ya 420 ± 1 GPa, ndi coefficient yowonjezera kutentha kwa 3.84 × 10⁻⁶ K⁻¹ mu kutentha kwa chipinda mpaka 600 ° C, kusonyeza ntchito yabwino kwambiri.

Microstructure ya PSS-SiC: (A) SEM chithunzi pambuyo kupukuta ndi NaOH etching; (BD) Zithunzi za BSD pambuyo popukutidwa ndi kukokera

III. Hot Pressing Sintering

Hot pressing (HP) sintering ndi njira ya densification yomwe nthawi imodzi imagwiritsa ntchito kutentha ndi kupanikizika kwa uniaxial ku zipangizo za ufa pansi pa kutentha kwambiri komanso kupanikizika kwambiri. Kuthamanga kwakukulu kumalepheretsa mapangidwe a pore ndi kuchepetsa kukula kwa tirigu, pamene kutentha kwakukulu kumalimbikitsa kuphatikizika kwa tirigu ndi kupanga mapangidwe olimba, potsirizira pake kumapanga zoumba zapamwamba, zoyera kwambiri za SiC. Chifukwa cha kukakamiza komwe kumayendera, njirayi imakonda kuyambitsa anisotropy yambewu, yomwe imakhudza makina ndi mavalidwe.

Zoumba zoyera za SiC zimakhala zovuta kuchulukira popanda zowonjezera, zomwe zimafuna kuti sintering ultrahigh-pressure. Nadeau et al. anakonzekera bwino SiC wandiweyani popanda zowonjezera pa 2500 ° C ndi 5000 MPa; Sun et al. adapeza zida zochulukirapo za β-SiC zolimba za Vickers mpaka 41.5 GPa pa 25 GPa ndi 1400 ° C. Pogwiritsa ntchito mphamvu ya 4 GPa, zoumba za SiC zokhala ndi kachulukidwe pafupifupi 98% ndi 99%, kuuma kwa 35 GPa, ndi modulus zotanuka za 450 GPa zinakonzedwa pa 1500 ° C ndi 1900 ° C, motsatira. Sintering micron-size SiC powder pa 5 GPa ndi 1500 ° C inapereka zoumba ndi kuuma kwa 31.3 GPa ndi kachulukidwe wachibale wa 98.4%.

Ngakhale zotsatirazi zikuwonetsa kuti kuthamanga kwapamwamba kumatha kukwaniritsa kuchulukira kopanda zowonjezera, zovuta komanso kukwera mtengo kwa zida zofunikira zimachepetsa ntchito zamafakitale. Chifukwa chake, pokonzekera kothandiza, kufufuza zowonjezera kapena granulation ya ufa nthawi zambiri amagwiritsidwa ntchito kupititsa patsogolo mphamvu yoyendetsa sintering.

Powonjezera 4 wt.% phenolic resin monga chowonjezera ndi sintering pa 2350 ° C ndi 50 MPa, SiC ceramics yokhala ndi chiwerengero cha 92% ndi chiyero cha 99.998% chinapezedwa. Pogwiritsa ntchito zowonjezera zowonjezera (boric acid ndi D-fructose) ndi sintering pa 2050 ° C ndi 40 MPa, chiyero chapamwamba cha SiC chokhala ndi kachulukidwe kakang'ono> 99.5% ndi zotsalira za B zokha za 556 ppm zinakonzedwa. Zithunzi za SEM zikuwonetsa kuti, poyerekeza ndi zitsanzo zopanda kupanikizika, zitsanzo zotenthedwa zotentha zinali ndi timbewu tating'ono, ma pores ochepa, komanso kachulukidwe kakang'ono. Mphamvu yosinthika inali 453.7 ± 44.9 MPa, ndipo zotanuka modulus zinafika 444.3 ± 1.1 GPa.

Powonjezera nthawi yogwira pa 1900 ° C, kukula kwa tirigu kunakula kuchokera ku 1.5 μm kufika ku 1.8 μm, ndipo kutentha kwa kutentha kunakula kuchokera ku 155 mpaka 167 W · m⁻¹·K⁻¹, komanso kumathandizira kukana kwa plasma.

Pansi pa 1850 ° C ndi 30 MPa, kukanikiza kotentha ndi kutentha kofulumira kwa SiC powder granulated ndi annealed anatulutsa zitsulo zolimba kwambiri za β-SiC popanda zowonjezera, ndi kachulukidwe ka 3.2 g/cm³ ndi kutentha kwa sintering 150-200 ° C kutsika kuposa njira zachikhalidwe. Zojambula za ceramic zimasonyeza kuuma kwa 2729 GPa, kulimba kwa fracture kwa 5.25-5.30 MPa·m^1/2, ndi kukana kwabwino kwambiri kwa kukwawa (kutsika kwa 9.9 × 10⁻¹⁰ s⁻¹ ndi 3.8 × 10⁻⁻⁹⁻⁻⁹⁻⁻⁹0 ° C1 ° C / 10 ° C1 ° 10 ° C / 10 ° 10 ° C / 10 ° 0 s / 10 ° na 10 ° 10 ° s / 10 ° 0 s / 1 ° 0 s 100 MPa).

(A) Chithunzi cha SEM chapamwamba chopukutidwa; (B) Chithunzi cha SEM cha fracture pamwamba; (C, D) BSD chithunzi cha pamwamba opukutidwa

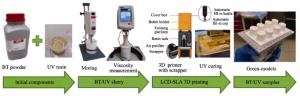

Mu kafukufuku wosindikiza wa 3D wa zoumba za piezoelectric, ceramic slurry, monga chinthu chachikulu chomwe chimathandizira kupanga ndi magwiridwe antchito, chakhala chofunikira kwambiri mdziko muno komanso padziko lonse lapansi. Kafukufuku wamakono nthawi zambiri akuwonetsa kuti magawo monga kukula kwa tinthu tating'ono, kukhuthala kwa slurry, ndi zinthu zolimba zimakhudza kwambiri kapangidwe kake komanso mawonekedwe a piezoelectric a chinthu chomaliza.

Kafukufuku wapeza kuti matope a ceramic omwe amakonzedwa pogwiritsa ntchito ufa wa micron-, submicron-, ndi nano-size barium titanate amawonetsa kusiyana kwakukulu pamachitidwe a sterolithography (mwachitsanzo, LCD-SLA). Pamene kukula kwa tinthu kumachepa, kukhuthala kwa slurry kumawonjezeka kwambiri, ndi ufa wa nano-kakulidwe umatulutsa slurries ndi viscosities kufika mabiliyoni a mPa·s. Malure okhala ndi ma ufa ang'onoang'ono ang'onoang'ono amatha kusungunuka komanso kusenda panthawi yosindikiza, pomwe ufa wa submicron ndi nano-size amawonetsa mawonekedwe okhazikika. Pambuyo pa kutentha kwambiri, zitsanzo za ceramic zomwe zinatsatira zinafikira 5.44 g/cm³, piezoelectric coefficient (d₃₃) ya pafupifupi 200 pC/N, ndi zinthu zotayika zochepa, zosonyeza mphamvu zabwino kwambiri za electromechanical.

Kuonjezera apo, mu njira za micro-stereolithography, kusintha zolimba za PZT-type slurries (mwachitsanzo, 75 wt.%) zinapereka matupi a sintered okhala ndi 7.35 g / cm³, kukwaniritsa piezoelectric constant mpaka 600 pC / N pansi pa minda yamagetsi ya poling. Kafukufuku wokhudzana ndi kubwezeredwa kwa ma micro-scale deformation adasintha kwambiri kupanga kulondola, kupititsa patsogolo kulondola kwa geometric mpaka 80%.

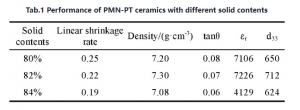

Kafukufuku wina pa PMN-PT piezoelectric ceramics adawonetsa kuti zolimba zimakhudza kwambiri kapangidwe ka ceramic ndi mphamvu zamagetsi. Pa 80 wt.% zolimba, zopangira zidawonekera mosavuta muzoumba; pomwe zolimba zidachulukira mpaka 82 wt.% ndi kupitilira apo, zopangira zidazimiririka pang'onopang'ono, ndipo kapangidwe ka ceramic kadakhala koyera, ndikuchita bwino kwambiri. Pa 82 wt.%, ziwiya zadothi zidawonetsa mphamvu zamagetsi zabwino kwambiri: piezoelectric constant ya 730 pC/N, chilolezo chachibale cha 7226, ndi kutayika kwa dielectric kokha 0.07.

Mwachidule, tinthu kukula, okhutira olimba, ndi rheological katundu wa ceramic slurries osati kukhudza bata ndi kulondola kwa ndondomeko yosindikiza komanso mwachindunji kudziwa kachulukidwe ndi piezoelectric kuyankha kwa sintered matupi, kuwapanga magawo ofunika kwambiri kuti akwaniritse ntchito zapamwamba za 3D-zosindikizidwa piezoelectric ceramics.

Njira yayikulu yosindikizira ya LCD-SLA 3D ya zitsanzo za BT/UV

Makhalidwe a ceramics a PMN-PT okhala ndi zinthu zosiyanasiyana zolimba

IV. Spark Plasma Sintering

Spark plasma sintering (SPS) ndiukadaulo wotsogola wa sintering womwe umagwiritsa ntchito kukakamiza kwaposachedwa komanso kumakina nthawi imodzi pa ufa kuti ufikire kuchulukira mwachangu. Pochita izi, pakali pano amatenthetsa nkhungu ndi ufa, kutulutsa kutentha kwa Joule ndi plasma, zomwe zimapangitsa kuti sintering ikhale yabwino pakanthawi kochepa (nthawi zambiri mkati mwa mphindi 10). Kutentha kofulumira kumalimbikitsa kufalikira kwa pamwamba, pomwe kutuluka kwa spark kumathandizira kuchotsa mipweya ya adsorbed ndi zigawo za oxide pamalo a ufa, ndikuwongolera magwiridwe antchito. Mphamvu ya electromigration yoyambitsidwa ndi minda yamagetsi imathandiziranso kufalikira kwa atomiki.

Poyerekeza ndi kukanikiza kotentha kwachikhalidwe, SPS imagwiritsa ntchito kutentha kwachindunji, kupangitsa kuti kachulukidwe pamatenthedwe otsika kwinaku akulepheretsa kukula kwa tirigu kuti apeze ma microstructures abwino komanso ofanana. Mwachitsanzo:

- Popanda zowonjezera, pogwiritsa ntchito nthaka ya SiC ufa monga zopangira, sintering pa 2100 ° C ndi 70 MPa kwa mphindi 30 zinapereka zitsanzo ndi 98% yachibale.

- Sintering pa 1700 ° C ndi 40 MPa kwa mphindi 10 opangidwa kiyubiki SiC ndi 98% kachulukidwe ndi makulidwe njere 30-50 nm okha.

- Kugwiritsa ntchito 80 µm granular SiC ufa ndi sintering pa 1860 ° C ndi 50 MPa kwa mphindi 5 zinapangitsa kuti ziwiya za ceramic za SiC zikhale zogwira ntchito kwambiri ndi 98.5% kuchulukira kwachibale, Vickers microhardness ya 28.5 GPa, flexural mphamvu ya 395 MPa, ndi fracture ^ 4 MPa · kulimba.

Kusanthula kwa Microstructural kunawonetsa kuti kutentha kwa sintering kumawonjezeka kuchokera ku 1600 ° C mpaka 1860 ° C, porosity yakuthupi inachepa kwambiri, ikuyandikira kachulukidwe chonse pa kutentha kwakukulu.

The microstructure ya SiC ceramics sintered pa kutentha kosiyana: (A) 1600°C, (B) 1700°C, (C) 1790°C ndi (D) 1860°C.

V. Zowonjezera Zopanga

Additive Production (AM) posachedwapa yawonetsa kuthekera kwakukulu pakupanga zida zovuta za ceramic chifukwa cha ntchito yake yomanga mosanjikiza-ndi-wosanjikiza. Kwa SiC ceramics, matekinoloje angapo a AM apangidwa, kuphatikiza binder jetting (BJ), 3DP, selective laser sintering (SLS), inki yolunjika (DIW), ndi stereolithography (SL, DLP). Komabe, 3DP ndi DIW zili ndi kulondola kochepa, pomwe SLS imakonda kuyambitsa kupsinjika kwamafuta ndi ming'alu. Mosiyana ndi izi, BJ ndi SL zimapereka maubwino ochulukirapo popanga zoumba zoyera kwambiri, zolondola kwambiri.

- Binder Jetting (BJ)

Ukadaulo wa BJ umaphatikizapo kupopera mbewu pagawo-ndi-wosanjikiza kwa binder kupita ku ufa wa bond, kutsatiridwa ndikuchotsa ndi kusisita kuti mupeze chomaliza cha ceramic. Kuphatikiza BJ ndi kulowetsedwa kwa nthunzi wamankhwala (CVI), chiyero chapamwamba, zitsulo zokhala ndi makristalo a SiC zidakonzedwa bwino. Njirayi ikuphatikizapo:

① Kupanga matupi obiriwira a SiC ceramic pogwiritsa ntchito BJ.

② Kuchulukitsa kudzera pa CVI pa 1000 ° C ndi 200 Torr.

③ Ceramic yomaliza ya SiC ceramic inali ndi kachulukidwe ka 2.95 g/cm³, kutentha kwa 37 W/m·K, ndi kusinthasintha kwamphamvu kwa 297 MPa.

Chithunzi chojambula cha zomatira ndege (BJ) yosindikiza. (A) Chitsanzo chothandizira makompyuta (CAD), (B) chojambula cha BJ mfundo, (C) kusindikizidwa kwa SiC ndi BJ, (D) kusakanikirana kwa SiC ndi kulowetsedwa kwa vapor (CVI)

- Stereolithography (SL)

SL ndi ukadaulo wopangira zida za UV-ochiritsa zokhala ndi zida zotsogola kwambiri komanso zovuta kupanga. Njira imeneyi amagwiritsa photosensitive ceramic slurries ndi okhutira mkulu olimba ndi otsika mamasukidwe akayendedwe kupanga 3D ceramic matupi wobiriwira kudzera photopolymerization, kenako debinding ndi mkulu-kutentha sintering kupeza chomaliza mankhwala.

Pogwiritsa ntchito 35 vol.% SiC slurry, matupi obiriwira apamwamba kwambiri a 3D adakonzedwa pansi pa 405 nm UV kuwala ndi kuwonjezereka kudzera mumoto wa polima pa 800 ° C ndi chithandizo cha PIP. Zotsatira zinawonetsa kuti zitsanzo zokonzedwa ndi 35 vol.% slurry zidapeza kachulukidwe wa 84,8%, wopambana 30% ndi 40% magulu owongolera.

Poyambitsa lipophilic SiO₂ ndi phenolic epoxy resin (PEA) kuti asinthe slurry, ntchito ya photopolymerization idakonzedwa bwino. Pambuyo pa sintering pa 1600 ° C kwa 4 h, pafupifupi kutembenuka kwathunthu ku SiC kunapezedwa, ndi mpweya womaliza wa 0.12% wokha, zomwe zimapangitsa kuti sitepe imodzi ikhale yoyera kwambiri, yopangidwa ndi zovuta za SiC ceramics popanda pre-oxidation kapena pre-infiltration masitepe.

Chithunzi cha mawonekedwe osindikizira ndi njira yake yopangira sintering. Maonekedwe a chitsanzo atayanika pa (A) 25°C, pyrolysis pa (B) 1000°C, ndi sintering pa (C) 1600°C.

Popanga zithunzi zowoneka bwino za Si₃N₄ ceramic slurries for stereolithography 3D printing ndi kugwiritsa ntchito debinding-presntering-presintering-presintering-presintering-presintering-presintering-presntering-presintering-presintering and high-temperature okalamba, Si₃N₄ ceramics 93.3% theoretical density, tensile strength of 279.8 MPa of 279.8 MPa5–303. Kafukufuku adapeza kuti pansi pazikhalidwe za 45 vol.% zolimba komanso nthawi ya 10 s kuwonetseredwa, matupi obiriwira osanjikiza omwe ali ndi machiritso a IT77-level atha kupezeka. Njira yochepetsera kutentha yotsika ndi kutentha kwa 0.1 °C/min idathandizira kupanga matupi obiriwira opanda ming'alu.

Sintering ndi gawo lofunikira lomwe likukhudza ntchito yomaliza mu stereolithography. Kafukufuku akuwonetsa kuti kuwonjezera zida zopangira sintering kumatha kupititsa patsogolo kachulukidwe ka ceramic ndi mawotchi. Pogwiritsa ntchito CeO₂ monga chithandizo cha sintering ndi teknoloji yopangira magetsi yopangira magetsi kuti akonze zitsulo zamtengo wapatali za Si₃N₄, CeO₂ inapezeka kuti imadzilekanitsa pamalire a tirigu, kulimbikitsa malire a tirigu ndi kuchulukitsa. Zoumba zomwe zidatuluka zidawonetsa kuuma kwa Vickers kwa HV10/10 (1347.9 ± 2.4) ndi kulimba kwa minyewa ya (6.57 ± 0.07) MPa·m¹/². Ndi MgO-Y₂O₃ monga zowonjezera, ceramic microstructure homogeneity idasinthidwa, kupititsa patsogolo magwiridwe antchito. Pa mlingo wokwanira wa doping wa 8 wt.%, kusinthasintha kwa mphamvu ndi kutentha kwa kutentha kunafika 915.54 MPa ndi 59.58 W·m⁻¹·K⁻¹, motsatira.

VI. Mapeto

Mwachidule, zida za ceramic za high-purity silicon carbide (SiC), monga zida zopangira uinjiniya, zawonetsa chiyembekezo chogwiritsa ntchito kwambiri mu semiconductors, mlengalenga, ndi zida zotengera zinthu monyanyira. Pepalali linasanthula mwadongosolo njira zisanu zokonzekera zopangira zida za SiC zoyera kwambiri - recrystallization sintering, sinteringless sintering, hot pressing, spark plasma sintering, and additive production - ndi zokambirana zatsatanetsatane pamakina awo akuchulukirachulukira, kukhathamiritsa kofunikira, magwiridwe antchito, komanso zabwino ndi zolephera.

Zikuwonekeratu kuti njira zosiyanasiyana zilizonse zimakhala ndi mawonekedwe apadera pokwaniritsa chiyero chapamwamba, kachulukidwe kakang'ono, kapangidwe kake, komanso kuthekera kwamakampani. Ukadaulo wowonjezera wopangira, makamaka, wawonetsa kuthekera kwamphamvu popanga zida zowoneka bwino komanso zosinthidwa makonda, ndikuyenda bwino m'magawo ang'onoang'ono monga stereolithography ndi binder jetting, zomwe zimapangitsa kukhala njira yofunikira yopangira zokonzekera za ceramic za SiC.

Kafukufuku wam'tsogolo wokonzekera bwino kwambiri wa SiC ceramic ayenera kufufuzidwa mozama, kulimbikitsa kusintha kuchokera ku labotale kupita kumagulu akuluakulu, odalirika kwambiri, potero akupereka chithandizo chofunikira kwambiri pakupanga zipangizo zamakono ndi zamakono zamakono zamakono.

XKH ndi bizinesi yapamwamba kwambiri yomwe imagwira ntchito pa kafukufuku ndi kupanga zida za ceramic zogwira ntchito kwambiri. Imaperekedwa kuti ipereke mayankho makonda kwa makasitomala mu mawonekedwe a zoumba zapamwamba za silicon carbide (SiC). Kampaniyo ili ndi matekinoloje apamwamba okonzekera zinthu komanso luso lokonzekera bwino. Bizinesi yake imaphatikizapo kufufuza, kupanga, kukonza molondola, ndi chithandizo chapamwamba chazitsulo zoyera za SiC, zomwe zimakwaniritsa zofunikira za semiconductor, mphamvu zatsopano, zamlengalenga ndi madera ena a zida za ceramic zogwira ntchito kwambiri. Pogwiritsa ntchito njira zopangira sintering okhwima ndi ukadaulo wopangira zowonjezera, titha kupatsa makasitomala ntchito imodzi yokha kuchokera ku kukhathamiritsa kwa zinthu, kapangidwe kake kovutira mpaka kukonza kolondola, kuwonetsetsa kuti zinthuzo zili ndi makina abwino kwambiri, kukhazikika kwamafuta komanso kukana dzimbiri.

Nthawi yotumiza: Jul-30-2025

-300x228.png)

1600°C、(B)1700°C、(C)1790°C-和(D)1860°C-300x223.png)

25°C-下干燥、(B)1000°C-下热解和(C)1600°C-下烧结后的外观-300x225.png)